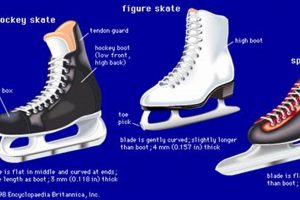

Maintaining a keen edge on the blades of ice skates is essential for optimal performance and safety on the ice. This process involves honing the steel to create a precise groove, or “hollow,” which provides the necessary grip for turns, stops, and overall control. Skates with dull blades can lead to instability, reduced maneuverability, and increased risk of falls. Consider the difference between gliding effortlessly with sharp blades versus struggling to maintain balance with dull ones as an illustration of the importance of this maintenance.

Properly maintained skates enhance the skating experience by providing greater confidence and responsiveness. Historically, this service was primarily offered by professional skate technicians, often located at ice rinks or specialty sports stores. However, advancements in sharpening tools and readily available information have made it increasingly feasible to perform this task at home. The benefit of performing this maintenance independently lies in cost savings, convenience, and the ability to customize the blade’s edge to suit individual skating styles and preferences.

The following sections will outline the necessary tools, techniques, and safety precautions for successfully achieving a sharp and well-maintained edge on ice skates. It will cover the evaluation of blade condition, the selection of appropriate sharpening equipment, the step-by-step process of blade honing, and methods for inspecting and maintaining the sharpened edge.

Essential Considerations for Blade Maintenance

Effective blade maintenance requires careful attention to detail and adherence to proper techniques. The following tips provide guidance for achieving optimal results and ensuring the longevity of skate blades.

Tip 1: Clean the Blades Thoroughly Before Sharpening. Remove any dirt, debris, or rust from the blades using a suitable cleaning agent and a soft cloth. A clean surface allows for a more consistent and effective sharpening process.

Tip 2: Invest in Quality Sharpening Tools. The effectiveness of blade maintenance is directly related to the quality of the sharpening equipment employed. Diamond stones or specialized skate sharpening jigs are recommended for consistent results.

Tip 3: Maintain a Consistent Angle and Pressure. When using a sharpening stone, maintain a consistent angle and apply even pressure along the entire length of the blade. Inconsistent pressure can lead to uneven sharpening and compromise blade performance.

Tip 4: Use a Honing Compound. Applying a honing compound to the sharpening stone or jig can help to refine the edge of the blade, resulting in a sharper and smoother finish. This step is particularly beneficial for achieving a professional-level edge.

Tip 5: Regularly Check the Blade’s Hollow. The hollow of the blade refers to the concave groove running along its length. Use a radius gauge to ensure that the hollow depth is consistent and appropriate for the skater’s skill level and skating style.

Tip 6: Deburr the Blades After Sharpening. Removing any burrs or imperfections from the edges of the blades is crucial for preventing cuts and ensuring smooth gliding. A deburring tool or fine-grit sandpaper can be used for this purpose.

Tip 7: Dry the Blades Thoroughly After Each Use. Moisture can lead to rust and corrosion, which can compromise the sharpness and integrity of the blades. Always dry the blades thoroughly with a clean cloth after each skating session.

These considerations are crucial for ensuring that ice skate blades are maintained to a high standard, providing the skater with optimal performance, control, and safety on the ice. Applying these methods will contribute to the longevity of the skates and elevate the overall skating experience.

The following conclusion will summarise all of the key points raised in this article.

1. Consistent Sharpening Angle

Maintaining a consistent sharpening angle is paramount when executing the task of blade maintenance at home. The angle at which the sharpening tool contacts the blade directly influences the shape and evenness of the resulting edge. An inconsistent angle leads to an uneven edge profile, where one side of the blade may be sharper than the other, or the edge may vary in sharpness along its length. This asymmetry compromises the skater’s ability to execute turns and maintain balance effectively. The connection can be defined in terms of cause and effect relationship, the impact of consistent sharpening angle is the ability to glide effortlessly.

The practical significance of understanding and achieving a consistent angle becomes apparent in the skater’s performance. For example, a skater attempting a crossover turn on an inconsistently sharpened blade may find it difficult to maintain a clean edge, resulting in a loss of speed or a stumble. Similarly, during a stop, an uneven edge may cause the skater to veer to one side, impacting control. Professional skaters require precision in edge control for executing complex maneuvers. Their equipment is sharpened meticulously, emphasizing the consistent angle as a core component of the entire sharpening procedure.

Achieving a consistent sharpening angle can be challenging without specialized equipment. Jigs designed specifically for skate sharpening are available, providing a fixed angle guide for the sharpening tool. While freehand sharpening is possible, it requires considerable skill and practice to maintain the necessary consistency. Ultimately, a commitment to understanding and implementing consistent angle control contributes significantly to the quality and effectiveness of independent blade maintenance. This practice enhances skater safety, performance, and satisfaction.

2. Proper Tool Selection

The effectiveness of independent ice skate blade maintenance is inextricably linked to the selection of appropriate tools. This is not merely a matter of convenience; the chosen implements directly impact the quality of the resulting edge, the longevity of the blades, and the safety of the skater. A nuanced understanding of available tools and their specific functions is therefore essential for those seeking to perform blade sharpening at home.

- Sharpening Stones or Jigs

The core of any blade sharpening setup lies in the sharpening medium itself. Traditional oil stones, diamond stones, and specialized sharpening jigs each offer distinct advantages and disadvantages. Oil stones require careful maintenance and technique, while diamond stones provide faster material removal. Jigs, on the other hand, offer a controlled environment for consistent angle maintenance, but may limit the degree of customization. A novice might begin with a jig to master consistent sharpening angles before progressing to more advanced techniques. The use of incorrect or damaged sharpening tools can irreversibly damage the blade’s profile.

- Radius Gauges

The “hollow” of the blade, the concave curve running along its length, determines the skater’s grip on the ice. Radius gauges are essential for accurately measuring and maintaining this hollow. Without proper gauges, there is a risk of creating an inconsistent or inappropriate hollow depth, leading to reduced control and maneuverability. For example, a hockey player might prefer a deeper hollow for enhanced grip, while a figure skater might favor a shallower hollow for smoother gliding. Precise measurement is essential for replicating the desired hollow profile.

- Deburring Tools

Sharpening inevitably creates small burrs along the edges of the blade. These imperfections can negatively impact glide and potentially cause injury. Deburring tools, such as fine-grit stones or specialized deburring instruments, are used to remove these burrs and create a smooth, polished edge. Neglecting this step can result in a “scratchy” feel on the ice and reduced performance. A simple leather strop, as used in knife sharpening, can also serve as an effective deburring tool for skate blades.

- Blade Protectors and Cleaning Supplies

While not directly involved in the sharpening process, blade protectors and cleaning supplies are crucial for maintaining the condition of the blades between sharpening sessions. Moisture and debris can lead to rust and corrosion, shortening the lifespan of the blades and degrading their performance. Proper cleaning and storage with blade protectors are therefore essential components of a comprehensive blade maintenance strategy. Using a silicone-based lubricant can further prevent rust formation.

These tools, when selected and used correctly, empower skaters to maintain their equipment independently. However, it is crucial to acknowledge the potential for error and the possibility of causing irreversible damage to the blades. Therefore, beginners are advised to seek guidance from experienced skaters or professionals before attempting to sharpen ice skates at home. Proper tool selection is not merely a matter of convenience; it is a prerequisite for achieving optimal performance and ensuring safety on the ice.

3. Blade Cleanliness

The presence of contaminants on ice skate blades during the sharpening process compromises the integrity of the resulting edge and reduces the effectiveness of the sharpening procedure. Therefore, meticulous blade preparation is essential for achieving optimal sharpness and ensuring the longevity of the skates.

- Contaminant Interference

Dirt, rust, and ice residue introduce abrasive particles between the blade and the sharpening tool. These particles create inconsistent scratches, prevent uniform material removal, and generate an uneven edge profile. The presence of oil or grease interferes with the tool’s ability to grip the steel, leading to slippage and ineffective sharpening. For example, attempting to sharpen a blade covered in road salt residue will yield a significantly inferior edge compared to one that has been thoroughly cleaned.

- Tool Degradation

Contaminants accelerate the wear and tear of sharpening stones and jigs. Abrasive particles embedded in the stone’s surface reduce its cutting efficiency and shorten its lifespan. Rust particles can clog the pores of sharpening stones, rendering them ineffective. Regularly cleaning the sharpening tools in conjunction with the blades extends their usability and maintains their effectiveness. Consider the difference in the lifespan of a sharpening stone used to process clean blades versus one subjected to contaminated surfaces.

- Rust Prevention

Corrosion on ice skate blades degrades their structural integrity and reduces their sharpness. Moisture combined with salt or other corrosive agents accelerates the rusting process. Thorough cleaning and drying of the blades after each use, followed by the application of a rust inhibitor, prevents the formation of rust. Neglecting to clean the blades after exposure to wet ice significantly increases the risk of corrosion, leading to blade damage and premature replacement. The cost savings associated with preventing rust outweigh the effort required for proper cleaning.

- Inspection Clarity

A clean blade surface facilitates accurate inspection of the edge profile. Scratches, imperfections, and inconsistencies are more readily visible on a clean blade, enabling more precise sharpening. The presence of dirt or grime obscures the blade’s surface, hindering effective evaluation and leading to suboptimal sharpening. Using a magnifying glass on a cleaned blade allows for detailed assessment of the edge’s sharpness and uniformity.

These facets highlight the integral connection between blade cleanliness and achieving a successful sharpening outcome. The extra time spent ensuring a clean blade is more than compensated for in the enhanced quality of the sharpened edge, extended lifespan of the blades, and improved skating performance. Failure to address blade cleanliness undermines the entire sharpening process.

4. Edge Deburring

Edge deburring is an indispensable step in the process of blade maintenance performed independently. The act of sharpening inevitably creates microscopic burrsthin, raised edges of metalalong the newly formed edge. These burrs, if left untreated, negatively impact skating performance and compromise the blade’s intended function. Deburring removes these imperfections, resulting in a smooth, clean edge that interacts optimally with the ice. Without deburring, the sharpened edge may exhibit a ‘scratchy’ or uneven feel, reducing glide efficiency and control. The absence of deburring diminishes the benefits gained from the sharpening process itself.

The cause-and-effect relationship between sharpening and burr formation is fundamental to understanding the necessity of deburring. The sharpening process, whether achieved with a stone, jig, or machine, involves the removal of metal to create a defined edge. This removal inherently leaves behind fragmented metal along the blade’s edge. As an example, imagine a woodworker planing a piece of lumber; they inevitably leave behind splinters which must be removed for a smooth finish. Deburring is analogous to removing those splinters. Skaters attempting complex maneuvers on blades with untreated burrs will experience reduced edge hold and an increased risk of slipping. Conversely, a skater with properly deburred blades will experience improved glide, enhanced control, and greater confidence on the ice.

In conclusion, edge deburring is an inseparable component of the blade sharpening process, particularly for those undertaking this maintenance independently. Neglecting this step undermines the gains achieved through sharpening, diminishing skating performance and increasing the risk of instability. The seemingly minor act of removing burrs translates to a significant improvement in the skater’s experience, highlighting the practical importance of incorporating deburring into the blade maintenance routine. The process requires meticulous attention to detail and the use of appropriate tools, but the resulting enhancement in performance and safety validates the effort.

5. Hollow Depth

Hollow depth, the concave curvature ground into the blade of an ice skate, fundamentally determines the edge grip on the ice surface. It is not merely a setting, but a critical component of blade sharpening. The ability to control and adjust this parameter directly impacts a skater’s performance and control. The depth of the hollow is a direct result of the sharpening process; without proper technique and tools, the desired hollow cannot be achieved, therefore understanding its impact is a crucial element for those wanting to learn how to sharpen ice skates at home. A shallow hollow offers less resistance and facilitates gliding, whereas a deeper hollow provides greater bite and enhanced turning capabilities. The selection of an appropriate hollow depth depends on the skater’s skill level, skating style, and the specific discipline practiced.

The practical implications of hollow depth are readily apparent in various skating disciplines. Hockey players, for example, often prefer a deeper hollow to enable quick stops and sharp turns, maximizing agility on the ice. Figure skaters, on the other hand, may opt for a shallower hollow to promote smoother gliding and facilitate intricate footwork. Speed skaters typically utilize the shallowest hollows possible to minimize friction and maximize speed. In each case, the hollow depth must be precisely adjusted to optimize performance for the specific demands of the discipline. Incorrectly sharpened skates, with an improper hollow depth, can lead to instability, reduced maneuverability, and an increased risk of falls. A figure skater with too deep a hollow, for instance, might find their blade catching excessively during spins, disrupting their performance.

In conclusion, the control and adjustment of hollow depth are integral to effective skate sharpening. This parameter profoundly influences a skater’s grip, glide, and overall control on the ice. A comprehensive understanding of hollow depth and its relationship to skating performance is therefore essential for anyone engaged in independent blade sharpening. However, achieving the desired hollow consistently requires specialized tools and a refined technique. The complexity of this element emphasizes the potential challenges of sharpening ice skates at home, and underscores the need for education and practice to master this critical skill.

Frequently Asked Questions

The following addresses common inquiries regarding the undertaking of ice skate blade maintenance in a home environment. The information provided is intended to clarify procedures and address concerns related to this task.

Question 1: Is independent blade sharpening advisable for novice skaters?

Independent sharpening carries inherent risks. Damage to the blades is possible if the correct techniques are not applied, and there is a probability of sustaining injury if the edges are not properly finished. Novice skaters are advised to seek professional sharpening services until a thorough understanding of blade geometry and sharpening techniques is achieved.

Question 2: What are the potential consequences of improper blade sharpening?

Improper sharpening can lead to several adverse outcomes, including uneven blade edges, incorrect hollow depth, and premature blade wear. These issues can compromise skating performance, increase the risk of falls, and reduce the lifespan of the blades.

Question 3: How frequently should ice skate blades be sharpened?

Sharpening frequency depends on usage and skating conditions. Blades subjected to frequent use or exposure to abrasive surfaces may require more frequent sharpening. A visual inspection of the blade edge for nicks or dullness is recommended to determine the need for sharpening.

Question 4: What specific tools are required for effective blade maintenance at home?

Essential tools include a sharpening stone or jig, a radius gauge for measuring hollow depth, a deburring tool for removing edge imperfections, and a cleaning cloth for maintaining blade hygiene. The specific type of sharpening stone or jig will depend on individual preferences and skill level.

Question 5: How can the risk of blade damage during sharpening be minimized?

The risk of damage can be reduced by using a sharpening jig to maintain a consistent angle, applying even pressure during sharpening, and carefully following established sharpening procedures. Novices are advised to practice on old or inexpensive blades before attempting to sharpen their primary skates.

Question 6: How is the correct hollow depth determined for individual skating needs?

The ideal hollow depth depends on the skater’s skill level, skating style, and the discipline practiced. Consultation with a qualified skate technician or coach is recommended to determine the appropriate hollow depth for individual needs.

In conclusion, independent blade maintenance can be a viable option for experienced skaters who possess the necessary skills, tools, and knowledge. However, it is crucial to approach this task with caution and to prioritize safety and blade integrity.

The next section will provide a step-by-step guide to begin to sharpen ice skates at home.

Conclusion

This exploration of performing ice skate blade maintenance independently has illuminated critical aspects of the process. Precise sharpening angle maintenance, proper tool selection, rigorous blade cleanliness, meticulous edge deburring, and accurate hollow depth adjustment are essential for optimal results. Proficiency in these areas is directly correlated with enhanced skating performance and reduced risk of injury. The decision to undertake this task should be predicated on a thorough understanding of these elements and a commitment to meticulous execution.

The pursuit of edge excellence demands dedication and precision. While independent blade maintenance offers potential cost savings and convenience, it also necessitates a responsibility for ensuring blade integrity and skater safety. Continued education, diligent practice, and a commitment to employing best practices will define the success of this endeavor. The quality of the sharpened edge is ultimately a reflection of the knowledge, skill, and attention to detail invested in the process.