These are specialized footwear designed for gliding across ice surfaces. Featuring a rigid boot attached to a metal blade, they provide support and control for various ice-related activities. A skater uses the edges of the blade to propel themselves and execute maneuvers.

The equipment offers enhanced performance capabilities in sports like figure skating and hockey. They provide superior ankle support and blade precision, allowing for complex movements and increased agility on the ice. Historically, this equipment has evolved from simple bone or wooden runners to sophisticated, technologically advanced designs that cater to specific skating disciplines.

The remainder of this discussion will delve into the specific attributes and considerations involved in selecting and maintaining such equipment, examining aspects such as boot construction, blade types, fitting guidelines, and maintenance procedures.

Equipment Usage and Maintenance Guidelines

The following guidelines are intended to optimize performance and longevity when utilizing this specialized equipment.

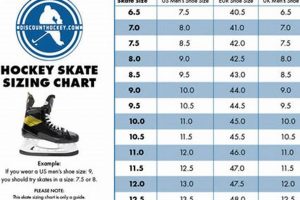

Tip 1: Ensure Proper Fit: Prioritize accurate sizing to guarantee adequate support and prevent discomfort. Consult with a qualified fitter to determine the appropriate size and width. Ill-fitting equipment can hinder performance and increase the risk of injury.

Tip 2: Regular Blade Sharpening: Maintain blade edges for optimal grip and control. Sharpening frequency depends on usage and ice conditions, but regular assessment by a professional is advised to determine when servicing is required.

Tip 3: Proper Lacing Technique: Utilize a consistent and secure lacing method. Begin with moderate tension at the toe and increase gradually toward the ankle, ensuring a snug but not overly tight fit that allows for adequate ankle flexion.

Tip 4: Careful Storage Practices: Store the equipment in a dry, well-ventilated environment to prevent rust and mildew. Use blade guards when off the ice and consider removing the insoles to promote drying after each use.

Tip 5: Routine Inspection: Regularly examine the boots for signs of wear and tear, such as cracks, loose stitching, or compromised support. Pay close attention to the blade attachment points and address any issues promptly to maintain structural integrity.

Tip 6: Gradual Break-In Period: New equipment requires a break-in period to conform to the user’s foot. Begin with shorter sessions and gradually increase the duration and intensity of use to minimize discomfort and potential blisters.

Tip 7: Avoid Abrasive Surfaces: Refrain from walking on abrasive surfaces without blade guards, as this can dull the edges and compromise performance. This practice also reduces the risk of damage to the blade structure.

Following these guidelines will contribute to enhanced performance, extended equipment lifespan, and a reduction in potential injuries.

The subsequent sections will explore advanced techniques for optimizing equipment performance and tailoring it to individual skating styles.

1. Blade Geometry

Blade geometry is a critical element in the performance of ice skates. It directly influences the skater’s ability to glide, turn, and perform intricate maneuvers. Understanding its various facets is essential for skaters seeking to optimize their equipment and enhance their on-ice capabilities.

- Rocker Profile

The rocker profile, or the curvature of the blade along its length, affects maneuverability. A more pronounced rocker facilitates tighter turns and increased agility, beneficial for figure skating. Conversely, a straighter rocker provides greater stability and glide efficiency, advantageous for hockey players seeking maximum speed. For instance, a figure skater executing a triple axel requires a specific rocker profile to initiate and control the rotation, while a hockey player skating down the ice aims for a profile that minimizes resistance and maximizes speed.

- Blade Radius

The blade radius refers to the curvature of the blade’s edges. A smaller radius results in sharper edges, offering enhanced grip and control. A larger radius yields smoother transitions and reduced resistance. The choice depends on the skater’s preference and the demands of their discipline. A skater practicing edge work will prefer a smaller radius to provide better control.

- Hollow Depth (Radius of Hollow – ROH)

The hollow depth, or ROH, describes the concave grind between the blade’s edges. This parameter greatly affects the bite of the blade into the ice. A deeper hollow creates sharper edges, enhancing grip for tight turns and intricate footwork. However, it also increases drag and requires more energy to maintain speed. A shallower hollow provides a smoother glide and reduced drag, suitable for long strides and sustained speed. A hockey player might opt for a shallower ROH to enable quicker acceleration, whereas a figure skater may require a deeper ROH for enhanced edge control during spins and jumps.

- Blade Pitch

Blade pitch refers to the angle of the blade relative to the boot. Adjusting the pitch can optimize the skater’s balance and posture, impacting power transfer and minimizing fatigue. Proper pitch alignment ensures the skater’s weight is distributed effectively over the blade, maximizing efficiency and control. A forward pitch may benefit skaters who prefer a more aggressive stance, while a neutral pitch provides a balanced feel for a wider range of skating styles.

Each of these geometric properties interacts to define the overall performance characteristics of skates. Understanding and appropriately configuring these parameters is crucial for skaters seeking to maximize their potential on the ice. Adjustment and customization are often necessary to fine-tune equipment to individual preferences and skating style.

2. Boot Stiffness

Boot stiffness, a crucial characteristic of ice skates, profoundly affects performance and control. In the context of specialized skates, boot stiffness dictates the degree of support provided to the skater’s ankle and lower leg. This support directly influences the efficiency of power transfer from the skater to the blade, impacting speed, agility, and the execution of complex maneuvers. A stiffer boot offers greater resistance to ankle flexion, resulting in more direct energy transfer and enhanced control during demanding movements. A softer boot allows for increased ankle mobility but may compromise stability and power. For example, in figure skating, skaters executing multi-rotational jumps typically require extremely stiff boots to withstand the forces generated during take-off and landing, thereby minimizing the risk of ankle injury.

The appropriate level of boot stiffness is contingent on several factors, including the skater’s skill level, body weight, and skating discipline. Novice skaters often benefit from boots with moderate stiffness, which provide a balance of support and flexibility, facilitating the development of fundamental skating techniques. Advanced skaters, particularly those engaged in competitive disciplines such as figure skating or hockey, typically require stiffer boots to meet the demands of high-impact maneuvers. Furthermore, boot stiffness can be customized through heat molding and other adjustments to optimize the fit and performance characteristics for individual skaters. For instance, certain boot models incorporate adjustable lacing systems and customizable padding to fine-tune the level of support and comfort.

In summary, boot stiffness is an essential consideration when selecting ice skates. The optimal level of stiffness depends on the skater’s skill level, discipline, and personal preferences. Selecting equipment with appropriate boot stiffness enhances performance, reduces the risk of injury, and contributes to a more enjoyable skating experience. The interplay between boot stiffness and blade characteristics represents a critical aspect of equipment selection, demanding careful consideration to maximize on-ice potential.

3. Ankle Support

Adequate ankle support is a paramount factor influencing performance and safety. Within the context of these specialized ice skates, it dictates the stability and control a skater can achieve during various maneuvers.

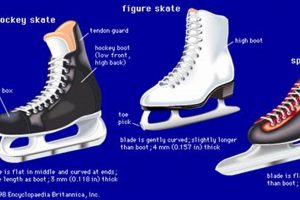

- Boot Height and Rigidity

The height and rigidity of the boot provide primary ankle stabilization. Higher boots offer more extensive support, limiting lateral movement and reducing the risk of sprains. Increased boot rigidity, achieved through advanced composite materials, further enhances support, enabling skaters to execute high-impact jumps and turns with greater confidence. For example, figure skaters performing complex aerial maneuvers rely on rigid, high-cut boots to maintain ankle stability during landing. Conversely, skaters seeking greater freedom of movement may opt for lower-cut boots with less rigidity.

- Lacing System and Tightening

The lacing system plays a critical role in customizing ankle support. A well-designed system allows for precise tightening adjustments, enabling skaters to fine-tune the level of support according to their individual needs and preferences. Lacing patterns can be tailored to provide targeted support to specific areas of the ankle. For instance, power lacing techniques can be employed to maximize support around the lower ankle region, enhancing stability during quick stops and starts. A well tightened skate will minimize potential injuries.

- Internal Padding and Contouring

The internal padding and contouring of the boot contribute significantly to ankle comfort and support. Strategically placed padding cushions the ankle against impacts and pressure points, while anatomical contouring ensures a snug and secure fit. Advanced padding materials, such as memory foam, mold to the individual skater’s ankle shape, providing customized support and minimizing slippage. Padding can be customized for each user by an authorized provider of these type of skates.

- Heel Counter Design

The heel counter, a structural component located at the rear of the boot, provides crucial support to the heel and ankle. A well-designed heel counter enhances stability by preventing excessive pronation or supination of the foot. The heel counter needs to prevent movements. Stiffer heel counters offer greater support, while more flexible counters allow for a greater range of motion. Skaters with a tendency towards ankle instability may benefit from a boot with a reinforced heel counter.

In conclusion, these distinct facets contribute significantly to ankle support within specialized ice skates. Optimizing these elements is essential for enhancing performance, minimizing injury risk, and ensuring a comfortable and secure skating experience. Different designs are available and need to be tested before an important competition.

4. Heat Molding

Heat molding, a crucial customization process, plays a significant role in optimizing the fit and performance of specialized ice skates. This process utilizes heat to soften the boot’s materials, allowing them to conform precisely to the individual skater’s foot. The resulting custom fit enhances comfort, improves energy transfer, and reduces the risk of pressure points and blisters.

- Customized Fit and Comfort

Heat molding enables a personalized fit that addresses the unique contours of each foot. By softening the boot’s internal materials, the process eliminates gaps and pressure points, enhancing overall comfort and minimizing friction. Skaters can experience reduced foot fatigue and improved control, particularly during extended training sessions or competitions. For example, skaters with bunions or other foot irregularities can benefit from heat molding, which allows the boot to accommodate these specific anatomical features.

- Enhanced Performance and Energy Transfer

A properly heat-molded boot provides a snug and secure fit, maximizing energy transfer from the skater’s foot to the blade. This efficient energy transfer enhances agility, power, and control, enabling skaters to execute complex maneuvers with greater precision. Heat molding eliminates slippage and movement within the boot, ensuring that every subtle movement translates directly to the ice. Competitive skaters often rely on heat molding to optimize their equipment for peak performance.

- Improved Ankle Support and Stability

Heat molding can enhance ankle support and stability by shaping the boot to conform precisely to the ankle’s contours. This improved fit minimizes ankle movement within the boot, reducing the risk of sprains and other injuries. Skaters can experience increased confidence and control, particularly when performing high-impact jumps and turns. Heat molding is frequently employed to address individual variations in ankle shape and size, ensuring optimal support for each skater.

- Long-Term Boot Durability

By providing a custom fit that minimizes stress on the boot’s materials, heat molding can contribute to increased durability. A properly fitted boot is less likely to experience excessive wear and tear, extending its lifespan and preserving its performance characteristics. Heat molding reduces the likelihood of creases, distortions, and other forms of damage, ensuring that the skates maintain their integrity over time. Skaters who invest in high-quality equipment often utilize heat molding to protect their investment and maximize its longevity.

These facets highlight the significance of heat molding in optimizing the fit, performance, and durability of specialized ice skates. By providing a customized fit that addresses individual anatomical variations, heat molding enables skaters to achieve peak performance, enhance comfort, and minimize the risk of injury. The process represents a crucial step in ensuring that skates perform to their full potential, allowing skaters to fully express their talent on the ice.

5. Lacing System

The lacing system on specialized ice skates is not merely a means of fastening the boot; it is an integral component that directly affects performance, comfort, and safety. The design and implementation of the lacing system have a profound impact on the skater’s ability to control the skate and execute maneuvers effectively. For example, a poorly designed system can lead to inconsistent pressure distribution, resulting in discomfort, blisters, and reduced ankle support. Conversely, a well-engineered system provides precise control over the boot’s fit, allowing the skater to customize the level of support and responsiveness according to their individual needs and skating style.

The materials used in the lacing system, such as the laces themselves and the eyelets through which they pass, are also critical considerations. High-quality laces maintain their integrity and tension throughout a skating session, preventing slippage and ensuring consistent support. Durable eyelets, often reinforced with metal, withstand repeated use and minimize the risk of lace breakage. The pattern of the lacing also plays a significant role. Certain lacing patterns can provide targeted support to specific areas of the foot and ankle, addressing individual anatomical variations and enhancing stability. Furthermore, advanced lacing systems may incorporate features such as power straps or speed hooks, which enable skaters to quickly and easily adjust the tightness of the boot. An appropriate lacing system leads to a better and safer experience.

In summary, the lacing system is a critical, often overlooked, element. It is not simply a closure mechanism, but a dynamic system that significantly influences the skater’s experience. Attention to the design, materials, and implementation of the lacing system is essential for optimizing performance, maximizing comfort, and minimizing the risk of injury. Its proper function is dependent on all other aspects discussed and the lacing system serves as the most important user interface available to customize fit and performance.

6. Blade Material

The material composition of the blade in specialized ice skates is a primary determinant of performance characteristics. The choice of material directly impacts the blade’s hardness, edge retention, resistance to corrosion, and overall durability. High-carbon steel, for instance, offers exceptional hardness and edge retention, enabling precise turns and control on the ice. Stainless steel, conversely, provides enhanced resistance to corrosion, prolonging the blade’s lifespan and reducing maintenance requirements. The selection process necessitates a careful evaluation of the trade-offs between these material properties, based on the intended use and performance priorities.

Specific examples illustrate the practical significance of this understanding. Elite figure skaters, who demand maximum edge control for executing complex jumps and spins, often prefer blades crafted from high-carbon steel. This material allows for exceptionally sharp edges that grip the ice with precision. In contrast, recreational skaters or hockey players, who prioritize durability and ease of maintenance, may opt for stainless steel blades. The differing demands of these skating disciplines underscore the importance of aligning blade material with the specific performance requirements. Furthermore, the blade material influences the frequency of sharpening. Softer steel requires more frequent sharpening to maintain optimal edge quality, while harder steel retains its edge for longer periods. This consideration impacts the ongoing maintenance costs associated with specialized ice skates.

In summary, the selection of blade material is a critical decision in the acquisition and maintenance of specialized ice skates. The interplay between hardness, corrosion resistance, and durability dictates the blade’s performance characteristics and longevity. A comprehensive understanding of these factors allows skaters to make informed choices that align with their individual needs and optimize their on-ice experience. Challenges include balancing competing material properties and adapting maintenance practices to suit the specific material composition of the blade. The blade material also must work cohesively with the other components of the skate in order to provide the best performance possible.

7. Maintenance

Regular upkeep is indispensable for preserving the functionality, safety, and longevity of this specialized skating equipment. Inadequate maintenance can lead to diminished performance, increased risk of injury, and premature equipment failure. A comprehensive maintenance regimen encompasses various facets, each critical to sustaining optimal performance.

- Blade Sharpening and Edge Care

Consistent sharpening is imperative for maintaining blade edges, which directly affect grip, glide, and maneuverability on the ice. Frequency of sharpening depends on usage and ice conditions. Neglecting sharpening results in dull edges, compromising control and increasing the effort required for skating. The blade edges need to be kept in top condition for maximizing skating performance.

- Boot Cleaning and Drying

Moisture accumulation within the boot promotes bacterial growth, leading to odor and material degradation. Regular cleaning and thorough drying after each use prevent these issues. Removing insoles and allowing boots to air dry facilitates moisture evaporation, extending the boot’s lifespan. Preventing odor and material degradation is a key part of maintenance of this type of skate.

- Hardware Inspection and Tightening

Loose hardware, such as screws and rivets, compromises the structural integrity of the skate. Regular inspection and tightening of these components ensure stability and prevent potential failures. Neglecting this aspect can lead to instability and potential accidents. Ensuring stability and preventing failures will prevent accidents and future damages.

- Blade Protection and Storage

Protecting the blades from damage during off-ice transport and storage is crucial. Blade guards prevent nicks, scratches, and rust formation. Storing skates in a dry, well-ventilated area further minimizes corrosion. Proper blade protection preserves blade sharpness and extends equipment lifespan. Sharpness and life span is a main component of this type of skate.

These maintenance aspects are interconnected and collectively contribute to the sustained performance and reliability of specialized skating equipment. Adhering to a consistent maintenance schedule optimizes the user experience, minimizes the risk of injury, and safeguards the investment in high-quality skating equipment. The life span of a skate is dependent on the skates condition. A damaged skate will reduce the potential of the user.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding this specialized skating equipment.

Question 1: What factors determine the appropriate boot stiffness?

Boot stiffness is determined by the skater’s skill level, body weight, and skating discipline. Advanced skaters generally require stiffer boots to withstand the forces generated during complex maneuvers, while novice skaters benefit from more flexible boots that allow for greater range of motion.

Question 2: How often should ice skate blades be sharpened?

Sharpening frequency depends on the amount of usage, ice conditions, and the skater’s skill level. As a general guideline, blades should be sharpened when the edges feel dull or when the skater experiences a noticeable decrease in grip. Professional skaters might sharpen their blades daily, while recreational skaters might only require sharpening a few times per year.

Question 3: What are the key considerations when selecting blade material?

The primary factors to consider when selecting blade material are hardness, corrosion resistance, and durability. High-carbon steel offers exceptional hardness and edge retention, while stainless steel provides enhanced resistance to corrosion. The choice depends on the skater’s performance priorities and maintenance preferences.

Question 4: How does heat molding improve the fit of ice skates?

Heat molding utilizes heat to soften the boot’s materials, allowing them to conform precisely to the individual skater’s foot. This process eliminates gaps and pressure points, enhancing comfort, improving energy transfer, and reducing the risk of blisters.

Question 5: What role does the lacing system play in skate performance?

The lacing system enables skaters to customize the fit and support of the boot. A well-designed lacing system provides precise control over tightness, allowing skaters to adjust the level of ankle support and responsiveness according to their needs and preferences.

Question 6: How can corrosion on ice skate blades be prevented?

Corrosion can be prevented by thoroughly drying the blades after each use, applying a thin coat of rust inhibitor, and storing the skates in a dry, well-ventilated environment. Blade guards should be used during off-ice transport to protect the blades from damage and moisture.

Proper selection, maintenance, and customization are crucial for maximizing the performance and longevity of skating equipment. These efforts also ensure a safe and enjoyable skating experience.

The subsequent section will provide detailed guidance on selecting this equipment.

Conclusion

This exploration has comprehensively examined the critical attributes of graf ice skates, spanning from blade geometry and boot stiffness to ankle support, heat molding, lacing systems, blade materials, and essential maintenance practices. Each facet contributes uniquely to performance, safety, and longevity, demanding careful consideration from users.

Informed selection and diligent maintenance are paramount for optimizing the capabilities of such equipment. It is incumbent upon users to prioritize a holistic understanding of these components to maximize performance and safeguard against potential risks, ensuring continued advancement and innovation in skating disciplines.