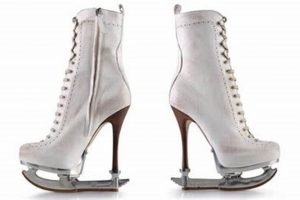

Specialized footwear designed for performing tricks and maneuvers in skate parks or urban environments. They feature a hard boot for ankle support, a durable frame to withstand impacts, and smaller, harder wheels for grinding on rails and ledges. These skates prioritize durability and control over speed and distance.

The equipment provides a platform for self-expression and skill development in a challenging sport. The design facilitates progression from beginner-level tricks to advanced maneuvers. Their development mirrors the evolution of the sport itself, with innovations constantly improving performance and durability.

The following sections will delve into the key features of high-quality models, essential considerations when selecting appropriate equipment, and tips for maintaining optimal performance.

Equipment Optimization Strategies

The following strategies provide guidance on maximizing the performance and longevity of specialized skate equipment.

Tip 1: Wheel Rotation: Consistent wheel rotation extends the lifespan and maintains consistent performance. Rotate wheels regularly to distribute wear evenly, preventing premature replacement.

Tip 2: Bearing Maintenance: Clean and lubricate bearings periodically to ensure smooth rolling. Dirt and debris impede performance; proper maintenance preserves bearing integrity.

Tip 3: Frame Inspection: Routinely inspect frames for cracks or damage, particularly after impact. A compromised frame jeopardizes stability and safety.

Tip 4: Liner Hygiene: Maintain liner hygiene to prevent odor and bacterial growth. Remove and air out liners after each use; consider using antimicrobial sprays.

Tip 5: Hardware Tightening: Regularly tighten all bolts and screws to prevent loosening during use. Loose hardware compromises control and increases the risk of equipment failure.

Tip 6: Grind Plate Condition: Assess the condition of grind plates for excessive wear. Replace grind plates as needed to maintain optimal grinding performance.

Adherence to these strategies enhances equipment performance, extends product lifespan, and contributes to a safer and more enjoyable skating experience.

The subsequent section provides insights into advanced techniques and competitive strategies within the sport.

1. Boot Support

Boot support is a critical element of specialized skate equipment, directly impacting performance and safety. The hard shell of the boot provides the necessary ankle stability to withstand the high-impact landings and abrupt movements characteristic of this activity. Inadequate boot support can lead to ankle sprains, fractures, or other lower extremity injuries. A well-designed boot offers a snug, secure fit that minimizes lateral movement within the boot, translating the skater’s movements directly to the frame and wheels. An example would be the difference between a recreational skate with a soft boot, which offers minimal support and would be unsuitable for aggressive skating, and a dedicated model with a rigid shell and reinforced cuff, which provides the necessary stability.

Furthermore, boot support influences the skater’s ability to execute complex tricks. A stable platform allows for greater control and precision during grinds, slides, and aerial maneuvers. The height and stiffness of the cuff the upper portion of the boot that wraps around the ankle are crucial design considerations. A higher, stiffer cuff provides greater support, while a lower, more flexible cuff offers increased range of motion, allowing for varied stylistic preferences. For instance, skaters who prioritize vert skating may prefer a stiffer boot for enhanced stability, while those focusing on street skating might opt for a more flexible boot for greater freedom of movement.

Effective boot support is achieved through a combination of shell design, liner materials, and closure systems. A properly fitted liner conforms to the skater’s foot, providing cushioning and preventing slippage. Secure buckles and straps further enhance stability, ensuring a snug fit throughout the skating session. The optimal design minimizes energy loss, maximizing the skaters efficiency and control. Consequently, boot support stands as a non-negotiable feature in equipment selection. The integrity and functionality of this feature has a direct impact on the longevity of the skaters career.

2. Frame Durability

Frame durability constitutes a critical attribute. The frame serves as the structural foundation, directly impacting the equipment’s capacity to withstand the forces generated during aggressive skating maneuvers. Frame failure can result in immediate loss of control, increasing the risk of injury. Materials selection and structural design govern frame longevity and resistance to deformation. High-density plastics or metal alloys are typically employed to ensure adequate strength-to-weight ratios. The frame must endure repeated impacts, grinds, and slides without compromising its integrity. An example would be a frame constructed from glass-reinforced nylon, which is resistant to impact but might not withstand prolonged grinding on rough surfaces compared to a frame made from aircraft-grade aluminum.

The connection between frame durability and performance extends beyond mere safety. A rigid, durable frame provides a more responsive feel, allowing skaters to translate their movements efficiently. Frame flex can absorb energy, reducing control and precision. Frame design also influences grinding capabilities. Recessed or replaceable grind plates protect the frame from wear, extending its lifespan and preserving its functionality. Specific frame geometries optimize grinding performance on different surfaces. For instance, frames with a wider H-block area are better suited for flat grinds, while frames with smaller H-blocks are more maneuverable for aggressive edge work.

In summary, frame durability is not merely a desirable feature, but a fundamental requirement. Selection of equipment must prioritize frame construction to ensure safety, responsiveness, and longevity. Frame integrity directly affects control and trick execution. Understanding the interplay between material properties, design features, and skating style enables informed equipment choices. Failure to prioritize frame durability compromises safety, reduces performance, and limits the progression of skills within the sport.

3. Wheel Hardness

Wheel hardness represents a critical specification in aggressive skating, directly impacting performance characteristics and suitability for diverse skating environments. The durometer rating, typically measured on the A scale, quantifies the wheel’s resistance to indentation. Lower durometer values indicate softer wheels, while higher values denote harder wheels. The selection of appropriate wheel hardness depends significantly on the skater’s style, skill level, and preferred terrain.

- Grip and Control

Softer wheels (e.g., 88A-90A) offer enhanced grip on smooth surfaces, facilitating controlled turns and maneuvers. This increased grip is beneficial for beginners and skaters who prioritize stability. However, softer wheels wear down more quickly, especially on abrasive surfaces. A skater performing intricate slaloms or focusing on controlled slides may find softer wheels advantageous.

- Speed and Roll

Harder wheels (e.g., 95A-101A) provide lower rolling resistance, resulting in increased speed and glide. These wheels are more efficient for covering distances and maintaining momentum. However, the reduced grip can make them less forgiving on uneven surfaces or during sudden stops. A skater covering ground in an urban environment might prefer a harder wheel for its rolling efficiency.

- Grinding Characteristics

Wheel hardness influences grinding performance. Harder wheels slide more easily on rails and ledges, facilitating smooth grinds. Softer wheels tend to grip, making grinds more challenging. The choice depends on the skater’s grinding style and the type of obstacles encountered. Skaters focusing on technical grinds often opt for harder wheels with specialized anti-rocker setups to maximize grind surface.

- Durability and Wear

Harder wheels exhibit greater resistance to abrasion, extending their lifespan, particularly on rough surfaces. Softer wheels wear down more quickly, requiring more frequent replacement. Skaters who primarily skate in skateparks with smooth concrete surfaces can often use softer wheels without excessive wear. However, skaters who skate frequently on rough asphalt will require harder wheels.

Selecting the appropriate wheel hardness involves a careful consideration of these factors. Experienced skaters often experiment with different durometers to optimize their setup for specific conditions and styles. Furthermore, wheel hardness is not the sole determinant of performance; wheel profile, size, and core design also play significant roles. The optimal selection considers all these interconnected factors to achieve the desired balance of grip, speed, grinding ability, and durability.

4. Bearing Precision

Bearing precision significantly impacts the overall performance and rider experience. As an integral component within aggressive skates, bearings facilitate wheel rotation, influencing speed, smoothness, and energy transfer during maneuvers. Bearing quality directly correlates with the responsiveness and efficiency of the equipment.

- ABEC Rating and Its Limitations

The Annular Bearing Engineering Committee (ABEC) rating system (ABEC 1, 3, 5, 7, 9) quantifies bearing tolerances, with higher numbers indicating tighter tolerances and theoretically greater precision. While ABEC ratings provide a benchmark, they primarily address dimensional accuracy and do not fully encapsulate bearing quality. Material composition, lubrication, and internal design also contribute significantly to performance. For example, a high ABEC-rated bearing made with inferior materials may underperform compared to a lower-rated bearing constructed with superior materials and design. This illustrates the limitations of relying solely on ABEC ratings when evaluating bearing performance in aggressive skates.

- Material Composition and Durability

Bearing materials influence durability and resistance to wear. Chrome steel is a common material for bearing races and balls, offering a balance of hardness and corrosion resistance. Ceramic bearings, although more expensive, exhibit superior hardness, reduced friction, and increased lifespan. The material must withstand the stresses of impact and contamination. Consider a scenario where a skater frequently grinds on rough surfaces; bearings with robust seals and durable materials are essential to prevent premature failure. Selection of high-quality materials is paramount for maintaining bearing integrity.

- Lubrication and Maintenance

Proper lubrication minimizes friction and heat generation within the bearing, enhancing performance and extending lifespan. Grease and oil are common lubricants, each offering distinct advantages. Grease provides longer-lasting lubrication but can increase resistance, while oil offers lower resistance but requires more frequent application. Neglecting bearing maintenance leads to increased friction, reduced speed, and potential bearing failure. Regular cleaning and lubrication are essential for maintaining optimal performance. Contamination from dirt, debris, and moisture compromises bearing integrity. Therefore, conscientious maintenance significantly impacts the longevity and efficiency.

- Impact on Grind Performance and Speed

High-precision bearings enhance both grind performance and speed. Smooth, efficient rotation allows skaters to maintain momentum during grinds and slides. Reduced friction translates to faster acceleration and higher top speeds. Conversely, worn or poorly lubricated bearings can impede grind performance and reduce overall speed. The cumulative effect of small performance degradations across all eight bearings significantly impacts the equipment. High-quality, well-maintained bearings are crucial for maximizing the performance potential of aggressive skates, impacting both technical maneuvers and overall skating efficiency.

The interplay of ABEC rating, material composition, lubrication, and maintenance dictates bearing performance. While ABEC ratings offer a general guideline, comprehensive evaluation necessitates considering material quality, design, and maintenance practices. Selection and maintenance of high-precision bearings are essential investments for maximizing performance, safety, and equipment lifespan. Understanding the nuances of bearing technology empowers skaters to make informed decisions that improve their skating experience.

5. Grind Plate Material

The selection of material for grind plates directly impacts the performance and durability of specialized skate equipment. The material’s properties dictate its ability to withstand abrasion, absorb impact, and facilitate smooth grinding maneuvers, all of which contribute significantly to the overall quality and functionality.

- Coefficient of Friction

The coefficient of friction between the grind plate material and various surfaces (e.g., metal rails, concrete ledges) influences the ease and smoothness of grinding. Lower friction materials, such as certain types of high-density polyethylene (HDPE), allow for effortless sliding, while higher friction materials may create more resistance. A skater executing a long grind on a rough rail benefits from a material with a low coefficient of friction to maintain speed and control. The choice depends on the skater’s preference and the surfaces commonly encountered.

- Impact Resistance and Durability

The grind plate material must withstand repeated impacts and abrasion without fracturing or delaminating. Materials with high impact resistance, such as reinforced nylon or certain composite plastics, offer greater durability and longevity. A skater who frequently performs aggressive tricks with hard landings requires a material capable of absorbing significant impact forces without compromising its structural integrity. The longevity of the equipment is directly related to the material’s ability to resist damage under stress.

- Weight and Responsiveness

The density of the grind plate material affects the overall weight of the equipment. Lighter materials, such as certain polymers, reduce fatigue and improve responsiveness, allowing for quicker maneuvers. Heavier materials may provide increased stability but can also hinder agility. A skater who values quick transitions and aerial tricks benefits from a lighter grind plate material. The balance between weight and durability is a crucial design consideration.

- Replaceability and Customization

Many designs incorporate replaceable grind plates, allowing skaters to customize their equipment and extend its lifespan. Replaceable plates enable the substitution of worn-out or damaged components without requiring the replacement of the entire frame. A skater who frequently grinds on abrasive surfaces can easily replace worn grind plates to maintain optimal performance. The ability to customize the grind plate material allows skaters to tailor their equipment to their specific needs and preferences.

The material composition of grind plates is integral to evaluating specialized skate equipment. The optimal choice balances friction characteristics, impact resistance, weight considerations, and customization options to enhance performance and durability. Skaters should carefully assess the properties of different materials to select equipment aligned with their skating style and the environments they frequent.

6. Liner Comfort

Liner comfort within specialized skate equipment is not merely a superficial consideration, but a critical determinant of performance, endurance, and long-term foot health. The liner serves as the primary interface between the skater’s foot and the rigid boot shell, mediating pressure distribution, mitigating friction, and providing essential shock absorption. Inadequate liner comfort leads to discomfort, blisters, pressure points, and ultimately, a reduction in skating time and performance. A poorly designed or ill-fitting liner can negate the benefits of other high-quality components, rendering even the most advanced equipment ineffective.

The correlation between liner comfort and effective skating stems from the direct impact on proprioception and control. A comfortable, secure fit allows for a more precise transfer of energy from the skater’s foot to the frame and wheels. Conversely, discomfort or slippage within the boot compromises stability and reduces the skater’s ability to execute complex maneuvers. The skater, instead of focusing solely on trick execution, must expend energy compensating for the inadequate fit, leading to fatigue and diminished performance. Heat-moldable liners, for example, offer a customized fit, distributing pressure evenly across the foot and minimizing discomfort. Skates used extensively without consideration for liner comfort often result in long-term foot problems. Choosing a well-fitting and comfortable liner can prevent chronic injuries.

Therefore, liner comfort should be a primary consideration when selecting specialized skate equipment. Manufacturers increasingly recognize the importance of liner design, incorporating features such as anatomical padding, moisture-wicking materials, and customizable fit options. While external features like frame durability and wheel hardness are vital, neglecting liner comfort undermines the skater’s ability to perform optimally. Liner comfort is a necessary foundation for efficient and effective skating. The combination improves performance and preserves foot health.

7. Buckle Security

Buckle security is paramount in specialized skate equipment, directly influencing safety and performance. The buckles, along with laces or power straps, form the closure system, ensuring a secure and snug fit of the boot to the skater’s foot. A compromised closure system compromises control, increasing the risk of injury. During aggressive maneuvers, significant forces are exerted on the foot and ankle. Without reliable buckle security, the foot can shift within the boot, leading to instability and potential loss of balance. A skater attempting a grind on a rail, for instance, relies on a secure boot fit to maintain precise control and prevent ankle roll. Buckles must withstand repetitive stress and impact, maintaining their integrity throughout the skating session. Failure of a buckle during a critical moment can lead to severe consequences.

The design and construction of buckles significantly affect their reliability. High-quality buckles often incorporate metal levers or ratchets for increased strength and durability. Plastic buckles, while lighter, must be constructed from robust materials to resist breakage. Adjustment mechanisms allow skaters to fine-tune the fit, accommodating varying foot shapes and sock thicknesses. Regular inspection and maintenance are crucial for ensuring buckle security. Loose or damaged buckles should be replaced promptly to prevent potential incidents. The choice of closure system, including the number and placement of buckles, influences the overall fit and stability of the equipment. Skates with multiple buckles and power straps offer a more secure and customizable fit compared to those with simpler closure systems. The integration of buckles with the liner and shell is essential for achieving a uniform distribution of pressure across the foot, maximizing comfort and control.

In summary, buckle security serves as a non-negotiable feature. Attention to the design, materials, and maintenance ensures a secure fit and reduces the risk of injury. Choosing high-quality buckles is critical. Skaters are more likely to focus on trick execution. Buckle security, and the equipment’s secure design and overall functionality are essential.

Frequently Asked Questions Regarding Specialized Skating Equipment

The following section addresses common inquiries concerning the selection, maintenance, and performance characteristics of specialized skating equipment.

Question 1: What distinguishes equipment designed for aggressive skating from recreational models?

Aggressive models feature a hard boot for enhanced ankle support, smaller and harder wheels optimized for grinding, and a robust frame engineered to withstand high-impact forces. Recreational models typically prioritize comfort and speed over durability and maneuverability.

Question 2: How does wheel hardness impact skating performance?

Wheel hardness, measured on the durometer scale, influences grip, speed, and grinding ability. Harder wheels offer lower rolling resistance and facilitate smooth grinds, while softer wheels provide greater grip on smooth surfaces.

Question 3: What role do bearings play, and how does the ABEC rating apply?

Bearings facilitate wheel rotation, influencing speed and smoothness. The ABEC rating quantifies bearing tolerances, but material composition and lubrication also significantly impact performance. Higher ABEC ratings do not guarantee superior performance in aggressive skating applications.

Question 4: How critical is frame durability for aggressive skating?

Frame durability is paramount. The frame must withstand repeated impacts and abrasion without compromising its integrity. High-density plastics or metal alloys are typically employed to ensure adequate strength-to-weight ratios.

Question 5: What factors should be considered when selecting a liner?

Liner comfort significantly impacts performance and long-term foot health. A well-fitting liner should provide cushioning, minimize friction, and distribute pressure evenly across the foot.

Question 6: How should specialized skate equipment be maintained?

Regular maintenance includes wheel rotation, bearing cleaning and lubrication, frame inspection, liner hygiene, and hardware tightening. Proper maintenance extends equipment lifespan and optimizes performance.

Careful consideration of these factors ensures optimal equipment selection and maintenance, enhancing both performance and safety.

The subsequent section delves into advanced skating techniques and competitive strategies.

Conclusion

A thorough understanding of equipment features is crucial for participant safety and skill development. As previously described, factors such as boot support, frame durability, wheel hardness, bearing precision, grind plate material, liner comfort and buckle security must be understood before any purchase. Good aggressive skates are an integral part of the equation and should be viewed as an investment in one’s experience.

Ultimately, selection should align with individual needs and preferences. Prioritizing equipment features will contribute to the skater’s progression. Ongoing research and a complete understanding of equipment will contribute to growth within the sport.