The term refers to skateboard platforms produced by Flip Skateboards, a company renowned within the skateboarding community. These platforms are essential components, connecting the rider to the wheels and enabling various maneuvers. The structural integrity and design of these platforms directly influence a skateboarder’s performance.

These products are significant because they represent a confluence of materials science, engineering, and artistic design tailored for a demanding activity. The company’s longevity in the industry demonstrates a consistent ability to provide skaters with reliable and responsive equipment. Historically, the brand has been associated with innovative designs and high-performance standards that have influenced skateboarding trends.

The following sections will delve into the specific construction techniques, material choices, and design features that contribute to the performance characteristics of these skateboarding platforms. An examination of the various models and their suitability for different skateboarding styles will also be presented.

Guidance for Selecting and Maintaining Skate Platforms

The following guidelines aim to provide objective advice for individuals seeking to purchase or maintain skateboard platforms manufactured by Flip Skateboards. Adherence to these principles can enhance both performance and longevity.

Tip 1: Assess Riding Style. Prior to purchase, determine the primary skateboarding discipline. Street skating, park skating, and vert skating each impose distinct demands on the platform. Select a model designed to withstand the specific stresses associated with the intended use.

Tip 2: Consider Platform Dimensions. Platform width and length influence stability and maneuverability. Wider platforms generally provide greater stability, while narrower platforms facilitate quicker turns. Experiment with different sizes to identify the optimal dimensions for individual preferences.

Tip 3: Evaluate Concavity. Concavity, the curvature of the platform’s surface, affects foot placement and board feel. Steeper concavity offers enhanced grip and control, while shallower concavity allows for greater freedom of movement. Evaluate the concavity based on comfort and control requirements.

Tip 4: Inspect Construction Quality. Examine the platform for consistent lamination and a smooth finish. Delamination or imperfections in the wood can compromise structural integrity. Ensure the platform is free from defects prior to purchase.

Tip 5: Employ Appropriate Hardware. Utilize high-quality mounting hardware designed for skateboarding applications. Properly tightened hardware is essential for maintaining platform stability and preventing premature wear.

Tip 6: Protect Against Environmental Factors. Minimize exposure to moisture and extreme temperatures. These conditions can warp the wood and weaken the adhesive bonds. Store the skateboard in a dry, climate-controlled environment when not in use.

Tip 7: Routinely Inspect and Clean. Regularly examine the platform for cracks, chips, or other signs of damage. Clean the surface with a damp cloth to remove dirt and debris, which can degrade grip tape performance.

By carefully considering these factors, individuals can maximize the performance and lifespan of their skateboarding platforms, ultimately enhancing the overall skateboarding experience.

The subsequent sections will explore more advanced topics related to skateboarding platform customization and repair.

1. Construction Materials

The performance and durability of skateboarding platforms manufactured by Flip Skateboards are inextricably linked to the materials employed in their construction. The selection of wood species, adhesive formulations, and reinforcement materials directly influences the structural integrity, flex characteristics, and overall lifespan of the product. A substandard material choice can lead to premature failure, compromised performance, and potential injury to the rider.

Canadian maple, a hardwood characterized by its dense grain and consistent mechanical properties, is frequently utilized in high-quality skateboarding platforms. The cross-grain lamination of multiple plies of this wood provides exceptional strength and resistance to warping. The type of adhesive used to bond these plies is also critical. High-strength epoxy resins or similar adhesives ensure a durable and water-resistant bond, preventing delamination under stress. Certain models incorporate reinforcement materials, such as fiberglass or carbon fiber, to enhance stiffness and impact resistance. These materials are strategically placed within the platform’s structure to optimize performance characteristics.

Understanding the construction materials used in skateboarding platforms is essential for making informed purchasing decisions. Selecting a model constructed from high-quality materials ensures both a satisfying riding experience and a prolonged product lifespan. Conversely, neglecting this aspect may result in frequent replacements and compromised safety. Therefore, consumers should prioritize platforms manufactured from durable materials appropriate for their intended skateboarding style and skill level.

2. Shape and Concave

The shaping and concave of a skateboarding platform significantly influence performance characteristics, including board feel, control, and maneuverability. Flip Skateboards offers platforms with varied shapes and concave depths, catering to diverse skating styles and preferences.

- Platform Outline

The platform outline dictates the overall distribution of surface area, influencing stability and foot placement. Symmetrical platforms are often favored for technical street skating, offering consistent performance in either direction. Asymmetrical shapes, with a wider nose or tail, can enhance pop and directional control. These variations directly impact a skater’s ability to execute tricks and maintain balance.

- Nose and Tail Dimensions

Nose and tail dimensions influence pop and responsiveness. Steeper angles and larger surface areas typically result in increased pop, allowing for higher ollies and more aggressive maneuvers. Shallower angles provide a more mellow feel, often preferred for cruising or technical flat ground tricks. Platform choice should reflect the skater’s need for either maximum vertical lift or controlled manipulation of the board.

- Concave Depth

Concave refers to the curvature of the platform’s surface between the nose and tail. Deeper concave provides enhanced foot lock-in, facilitating more precise control and responsiveness during flip tricks. Shallower concave offers a flatter, more forgiving feel, allowing for greater freedom of movement and a less restrictive riding experience. The optimal concave depth is a matter of personal preference and skating style, influencing board feel and control during technical maneuvers.

- Wheelbase Length

Wheelbase, the distance between the front and rear truck mounting holes, affects turning radius and stability. Shorter wheelbases promote tighter turns and quicker response, while longer wheelbases offer greater stability at higher speeds. Street skaters often prefer shorter wheelbases for enhanced maneuverability in confined spaces. Vert skaters typically opt for longer wheelbases to maintain stability on ramps and transitions.

Shape and concave choices on skateboarding platforms directly determine how the board interacts with the skater’s feet and the terrain. Selections should consider an individuals skating style. Flip Skateboards provides an array of options to match individual needs.

3. Size and weight.

The dimensions and mass of a skateboarding platform, particularly those manufactured by Flip Skateboards, are critical parameters influencing performance, handling, and suitability for specific skateboarding styles. Optimal size and weight contribute to a skater’s ability to execute tricks, maintain control, and comfortably navigate diverse terrains. These characteristics are not arbitrary but rather carefully considered design elements that affect the board’s responsiveness and the skater’s overall experience.

- Platform Width and its Influence on Stability

Wider platforms offer increased stability, particularly advantageous for beginners or skaters engaging in vert or transition skating. The increased surface area provides a more substantial platform for foot placement, reducing the likelihood of unintended shifts in balance. For example, a wider platform may be preferred when learning to drop in on a ramp, offering a more forgiving margin of error. Conversely, a narrower platform can enhance maneuverability, facilitating quicker turns and technical street skating. The trade-off is reduced stability, demanding greater precision and control from the skater.

- Platform Length and its Impact on Stance and Control

Platform length affects a skater’s stance and the board’s overall responsiveness. Longer platforms provide a more spacious stance, offering increased stability at higher speeds. However, the increased length can reduce the board’s agility, making it less responsive to quick turns and precise maneuvers. Shorter platforms are favored for technical street skating, allowing for rapid adjustments and facilitating complex tricks in confined spaces. The shorter length promotes a more compact stance, demanding greater control and precision from the skater.

- Weight and its Correlation to Pop and Momentum

The weight of a skateboarding platform directly affects its pop (the upward force generated when initiating an ollie or other aerial trick) and its momentum. Lighter platforms are generally easier to pop, requiring less effort to lift off the ground. This can be advantageous for technical street skating, where rapid and precise movements are essential. However, lighter platforms may also be more susceptible to instability at higher speeds. Heavier platforms provide increased momentum, maintaining speed and stability on ramps or during long runs. The increased mass requires greater effort to initiate tricks but can also provide a more stable and controlled ride.

- Material Density and its Contribution to Durability and Feel

The density of the materials used in the platform’s construction contributes to both its weight and its durability. Platforms constructed from denser materials, such as high-quality maple, are generally more durable and resistant to impact damage. These materials also provide a stiffer and more responsive feel, transmitting energy directly from the skater’s feet to the board. Platforms constructed from less dense materials may be lighter and more flexible but are also more susceptible to wear and tear. The selection of materials ultimately balances the desire for weight reduction with the need for durability and responsiveness.

The interplay between size and weight in Flip Skateboards’ platforms is not simply a matter of convenience but a carefully calibrated design consideration that directly influences performance. By understanding the nuances of these factors, skaters can make informed decisions that align with their individual skill levels, skating styles, and performance objectives.

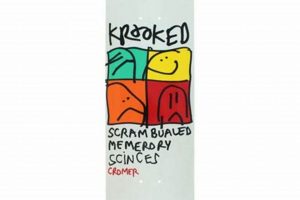

4. Graphic Design

Graphic design is an integral component of skateboarding platform branding and serves as a visual representation of the manufacturer’s identity. In the context of Flip Skateboards, graphic design extends beyond mere aesthetics; it communicates the brand’s history, values, and target demographic. The graphics on skateboarding platforms function as a canvas for artistic expression, incorporating elements that resonate with the skateboarding subculture. For example, a platform featuring bold, aggressive imagery might appeal to skaters who engage in high-impact street skating, while a platform with more subtle, artistic designs may attract skaters with a preference for creative expression. The success of a design hinges on its ability to effectively communicate the brand’s message and appeal to its intended audience.

The selection of colors, typography, and imagery is a deliberate process that can significantly impact a product’s appeal and perceived value. A well-executed graphic design can differentiate a product from its competitors, enhancing brand recognition and driving sales. Conversely, a poorly designed graphic can detract from the product’s perceived quality and negatively impact consumer perception. Flip Skateboards, like other established brands, invests resources in design professionals who understand the nuances of the skateboarding market and can create graphics that resonate with its target audience. These designs often incorporate elements of skateboarding culture, such as iconic tricks, locations, or personalities, further strengthening the brand’s connection to the skateboarding community.

Ultimately, graphic design on skateboarding platforms is a multifaceted aspect of branding that requires a careful balance of aesthetics, marketing, and cultural relevance. The effectiveness of a design can be measured by its ability to capture attention, communicate the brand’s message, and drive consumer engagement. The ongoing evolution of skateboarding culture necessitates that graphic designs remain fresh and relevant to maintain their impact. Brands that successfully adapt to these changes are better positioned to maintain their competitive edge and cultivate lasting relationships with their customers.

5. Durability Testing

Durability testing of skateboarding platforms manufactured by Flip Skateboards constitutes a critical phase in the product development cycle, aimed at ensuring the structural integrity and longevity of the product under simulated real-world conditions. The primary objective is to identify potential failure points and material weaknesses before the product reaches consumers, thereby minimizing the risk of injury and enhancing brand reputation. These tests often involve subjecting the platforms to a range of stresses, including impact loading, flexural stress, and environmental factors, simulating the wear and tear encountered during typical skateboarding activities. The data obtained from these tests informs design modifications and material selection, ultimately contributing to the production of more robust and reliable skateboarding platforms. For instance, a fatigue test might simulate repeated ollies to assess the platform’s resistance to cracking over time.

The specific tests employed can vary depending on the intended use of the platform, with models designed for street skating undergoing more rigorous impact testing than those intended for cruising. Standardized testing methodologies, such as those established by ASTM International, may be adapted or modified to suit the unique demands of skateboarding platforms. These methodologies often involve quantifiable metrics, such as the number of cycles to failure or the maximum load sustained before deformation, allowing for objective comparisons between different designs and materials. The results of these tests can be used to optimize the platform’s construction, identifying areas where reinforcement is needed or where alternative materials might offer improved performance. One practical application of durability testing is the identification of optimal wood grain orientation to maximize resistance to cracking along common failure lines.

In conclusion, durability testing serves as a vital feedback loop in the design and manufacturing process of Flip Skateboards’ platforms. It is not merely a perfunctory exercise but a rigorous process that directly contributes to product quality and skater safety. By systematically evaluating the platform’s performance under simulated real-world conditions, manufacturers can make informed decisions about material selection, design modifications, and production techniques, ensuring that the final product meets the demands of the skateboarding community. The challenges associated with accurately replicating the unpredictable nature of skateboarding are addressed through continuous refinement of testing protocols and the integration of real-world skater feedback into the design process.

Frequently Asked Questions

The following section addresses common inquiries regarding skateboarding platforms manufactured by Flip Skateboards, providing objective information to inform purchasing decisions and usage practices.

Question 1: What is the expected lifespan of a skateboarding platform?

The lifespan of a skateboarding platform varies significantly depending on usage frequency, intensity, and the skater’s skill level. Street skaters, who subject their platforms to higher impacts and stresses, may experience shorter lifespans compared to skaters who primarily cruise or skate transition. Proper maintenance, including avoiding exposure to moisture and impact damage, can extend the platform’s lifespan.

Question 2: How does platform width affect skateboarding performance?

Platform width influences stability and maneuverability. Wider platforms generally provide greater stability, particularly at higher speeds, while narrower platforms facilitate quicker turns and technical maneuvers. The optimal width is a matter of personal preference and skateboarding style.

Question 3: What factors contribute to platform delamination?

Platform delamination, the separation of wood plies, can be caused by moisture exposure, impact damage, or manufacturing defects. Proper storage and avoiding excessive stress on the platform can minimize the risk of delamination.

Question 4: Are all skateboarding platforms from Flip Skateboards made of maple?

While maple is a common material in skateboarding platforms, specific models may incorporate other materials, such as fiberglass or carbon fiber, to enhance stiffness or impact resistance. The material composition is typically indicated in the product specifications.

Question 5: How does concave depth influence board feel?

Concave depth affects the degree to which the skater’s feet are locked into the platform. Deeper concave provides enhanced grip and control, facilitating more precise execution of flip tricks. Shallower concave offers a flatter, less restrictive feel, allowing for greater freedom of movement.

Question 6: What maintenance procedures are recommended for platforms?

Recommended maintenance procedures include regularly inspecting the platform for cracks or chips, cleaning the surface with a damp cloth to remove dirt and debris, and storing the platform in a dry environment to prevent moisture damage. Replacing worn grip tape is also essential for maintaining traction.

Understanding these aspects allows for an informed approach to purchasing, utilizing, and maintaining skateboarding platforms.

The subsequent section will address platform customization options.

Concluding Remarks on Flip Skate Decks

The preceding analysis has explored various facets of platforms produced by Flip Skateboards, encompassing material composition, construction techniques, dimensional considerations, graphic design, and durability testing. These elements collectively determine the performance characteristics and longevity of these essential skateboarding components. A comprehensive understanding of these attributes is crucial for making informed purchasing decisions and optimizing the skateboarding experience.

Continued advancements in materials science and manufacturing processes are expected to further refine the performance and durability of skateboarding platforms. Skaters should remain informed about these developments to ensure they are utilizing equipment that meets the evolving demands of the sport. Rigorous adherence to recommended maintenance practices will maximize the lifespan of skateboarding platforms, contributing to both performance and safety.