Skateboard decks produced under the Expedition One brand are crafted from multiple plies of maple wood, pressed together to form a durable platform for skateboarding. These platforms serve as the foundation for a complete skateboard, facilitating tricks, transportation, and general riding. Different sizes and concave shapes cater to varying rider preferences and skateboarding styles.

The selection of a specific skateboard deck is influenced by factors such as board control, stability, and intended use. A quality constructed deck can enhance a rider’s performance, allowing for greater precision and confidence during maneuvers. Furthermore, the graphics and branding often reflect the rider’s personal style and connection to the skateboarding community. Historical context reveals the evolution of deck design, with brands pushing boundaries in material science and construction techniques to improve performance and durability.

This exploration serves as an introduction to a detailed discussion regarding the construction, characteristics, and selection considerations involved in choosing a suitable skateboard deck within the broader context of skateboarding equipment. Further analysis will delve into specific models, technologies, and factors that influence the overall riding experience.

Essential Guidance

The following guidance addresses critical considerations for selecting and maintaining skateboard decks to optimize performance and longevity.

Tip 1: Select Appropriate Dimensions: Deck width should correspond to foot size and preferred style. Wider decks enhance stability, while narrower options facilitate quicker rotations.

Tip 2: Evaluate Concave Depth: Deeper concave provides enhanced foot lock-in for technical tricks, whereas flatter concave offers a more relaxed riding experience.

Tip 3: Inspect Material Quality: High-grade maple wood contributes to deck durability and pop. Examine the plies for consistent layering and absence of defects.

Tip 4: Consider Deck Weight: Lighter decks can improve responsiveness and maneuverability. Heavier decks may offer increased stability at higher speeds.

Tip 5: Assess Graphic Integrity: While primarily aesthetic, a high-quality graphic indicates attention to detail, potentially reflecting overall manufacturing standards.

Tip 6: Maintain Deck Cleanliness: Regularly remove dirt and debris from the deck surface to maintain grip tape effectiveness and prevent potential damage.

Tip 7: Protect Against Moisture: Prolonged exposure to moisture can warp and weaken the deck. Store boards in dry environments and avoid riding in wet conditions whenever possible.

Tip 8: Replace Worn Components Promptly: Damaged or excessively worn decks compromise safety and performance. Replace the deck as soon as signs of significant wear are evident.

Adherence to these guidelines can contribute to an enhanced skateboarding experience through improved control, performance, and deck longevity.

These best practices provide a foundation for understanding deck selection and maintenance, ultimately leading to a more rewarding and safer skateboarding journey.

1. Wood Ply Composition

The composition of wood plies significantly influences the structural integrity and performance characteristics of skateboard decks. This aspect is paramount in determining the deck’s resilience, responsiveness, and overall lifespan, directly impacting the skateboarding experience.

- Type of Wood

Maple wood is predominantly used due to its density, strength, and flexibility. The specific species of maple, such as hard rock maple, can further impact the deck’s properties. Decks made from lower quality wood may exhibit premature wear or breakage, compromising safety and performance.

- Number of Plies

Skateboard decks typically consist of seven plies, offering a balance between strength and weight. Deviations from this standard, such as six or eight-ply constructions, can alter the deck’s stiffness and durability. Increased plies may enhance strength but can also increase weight, affecting maneuverability.

- Grain Orientation

The alignment of wood grain within each ply is crucial. Alternating grain direction between plies maximizes strength and resistance to warping or splitting. Improper grain orientation can lead to structural weaknesses, rendering the deck susceptible to failure under stress.

- Adhesive Type

The adhesive used to bond the plies together plays a critical role in the deck’s overall strength and water resistance. High-quality, water-resistant adhesives prevent ply separation and maintain structural integrity, particularly in humid or wet conditions. Inferior adhesives can degrade over time, leading to delamination and deck failure.

These elements of wood ply composition collectively dictate the performance and longevity of a skateboard deck. Understanding their individual contributions and interplay is essential for skateboarders seeking durable, reliable, and responsive equipment. The selection of appropriate materials and manufacturing processes directly correlates with the deck’s ability to withstand the stresses of skateboarding, ultimately impacting the rider’s experience and safety.

2. Concave Profile

Concave profile, the subtle curvature pressed into the surface of skateboard decks, represents a key design element influencing a rider’s control and board feel. The curvature, spanning the deck’s length and width, creates pockets for the feet, facilitating enhanced grip and responsiveness during tricks and maneuvers. Variations in concave depth and shape exist, each offering distinct advantages for specific skateboarding styles. As a component of Expedition One skate decks, the concave profile contributes directly to the deck’s overall performance characteristics.

The relationship between concave profile and riding style is significant. Deeper concave profiles, characterized by more pronounced curves, provide increased foot lock, allowing for more aggressive and technical tricks. Conversely, flatter concave profiles offer a more relaxed and stable platform, suitable for cruising and beginners. Expedition One decks often feature diverse concave options to accommodate varying rider preferences and skill levels. For instance, a deck designed for street skateboarding may incorporate a steeper concave to enhance flip tricks, while a park-oriented deck might utilize a mellower concave for greater stability on transitions.

Understanding the influence of concave profile is essential for skateboarders seeking to optimize their performance and comfort. The selection of an appropriate concave can improve board control, reduce foot fatigue, and enhance the overall riding experience. While aesthetic design and graphic appeal often factor into deck selection, the functional aspects, such as concave profile, ultimately dictate a deck’s suitability for a given riding style. Therefore, careful consideration of concave profile is a crucial step in choosing an Expedition One skateboard deck that aligns with individual needs and preferences.

3. Deck Width

Deck width, measured in inches, dictates a skateboard deck’s surface area and significantly influences rider stability, control, and maneuverability. As a fundamental characteristic of any skateboard deck, including those produced by Expedition One, deck width selection directly impacts a skater’s ability to execute tricks, navigate various terrains, and maintain overall balance. Wider decks, typically 8.25 inches or greater, provide increased foot placement area, resulting in enhanced stability, particularly at higher speeds or when landing challenging maneuvers. Narrower decks, conversely, generally fall below 8.0 inches and facilitate quicker rotations and more responsive board feel, often preferred for technical street skateboarding. For example, a skater focused on vert riding may select a wider Expedition One deck for enhanced stability on ramps and transitions, while a street skater might opt for a narrower option to aid in executing flip tricks.

The impact of deck width extends beyond simple stability and trick execution. It also influences the selection of other skateboard components, notably trucks. Appropriately sized trucks are essential for maintaining proper leverage and board control. Mismatched deck and truck widths can compromise stability and increase the risk of wheel bite, where the wheel makes contact with the deck during turning, causing sudden stops or loss of control. Expedition One offers decks in various widths to cater to diverse skateboarding styles and rider preferences, necessitating careful consideration of component compatibility. Real-world application demonstrates that selecting a deck width that aligns with a rider’s shoe size and intended skateboarding discipline is crucial for optimal performance.

In summary, deck width serves as a critical determinant of a skateboard deck’s functionality and suitability for specific skateboarding disciplines. Understanding the relationship between deck width, rider stability, maneuverability, and component compatibility is paramount for selecting an appropriate Expedition One skateboard deck. Failure to consider these factors can negatively impact performance, increase the risk of injury, and diminish the overall skateboarding experience. The interplay of deck width with other design features contributes to the overall performance profile of Expedition One’s products.

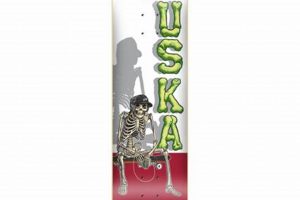

4. Graphic Application

Graphic application on Expedition One skate decks serves as more than mere aesthetic decoration; it represents a critical element of brand identity and product differentiation. The selection of imagery, color palettes, and printing techniques directly impacts consumer perception and can influence purchasing decisions. Furthermore, durable graphic application methods ensure the longevity of the design, resisting wear and tear from skateboarding activities. The choice of graphics may reflect team affiliations, artistic collaborations, or thematic representations, further solidifying the brand’s positioning within the skateboarding community. An example is the use of vibrant, street art-inspired designs to appeal to a younger demographic, while more minimalist or iconic graphics may target seasoned skaters. The practical significance of understanding graphic application lies in its contribution to brand recognition and market appeal.

The methods employed in graphic application, such as heat transfer, screen printing, or direct digital printing, affect the graphic’s durability and visual fidelity. Heat-transferred graphics, while cost-effective, may exhibit lower resistance to abrasion compared to screen-printed designs, which involve applying ink directly onto the deck surface. Direct digital printing allows for greater detail and color accuracy but may also be more susceptible to scratching or fading over time. Expedition One’s selection of a specific graphic application method is a direct reflection of its commitment to quality, intended product lifespan, and target consumer base. The practical application of this understanding is the ability to assess the durability and value proposition of a given deck based on its graphic application method.

In summary, graphic application on Expedition One skate decks is a multifaceted aspect encompassing brand identity, aesthetic appeal, and durability considerations. The selection of appropriate imagery, printing techniques, and materials contributes to both the visual impact and the longevity of the deck. Recognizing the relationship between graphic application and product quality enables informed purchasing decisions and underscores the importance of this design element in the broader context of skateboarding equipment. The challenges inherent in graphic application, such as balancing cost-effectiveness with durability, necessitate careful planning and execution on the part of the manufacturer.

5. Truck Compatibility

Skateboard truck compatibility is a critical factor influencing the performance and safety of a complete skateboard assembly. When considering Expedition One skate decks, the selection of appropriate trucks is paramount. The width of the deck directly dictates the required axle width of the trucks. A mismatch between these dimensions can lead to instability, impaired turning ability, and an increased risk of wheel bite, compromising the overall riding experience. Expedition One decks, like most skateboard decks, are manufactured in varying widths, necessitating a careful matching process. For instance, an 8.25-inch deck typically requires trucks with an axle width between 8.25 and 8.5 inches.

Beyond axle width, truck height also plays a role in compatibility. Higher trucks necessitate the use of riser pads to prevent wheel bite, particularly when using larger wheels. Conversely, lower trucks may offer increased stability but can limit turning radius. The intended skateboarding discipline influences these choices; street skaters often prefer lower trucks for enhanced board feel, while transition skaters might opt for higher trucks to accommodate larger wheels. Expedition One decks, being versatile platforms, require careful consideration of these factors to ensure optimal performance across various skating styles. Truck brands often provide compatibility charts to assist in this selection process, facilitating informed decision-making.

In summary, skateboard truck compatibility with Expedition One skate decks hinges on accurate dimensional matching and consideration of intended use. Proper truck selection directly impacts stability, maneuverability, and overall safety. The availability of compatibility resources from truck manufacturers aids in mitigating potential issues. Achieving optimal truck compatibility is essential for realizing the full performance potential of an Expedition One skateboard deck.

6. Grip Tape Adhesion

Grip tape adhesion is a critical factor directly influencing the performance and safety of Expedition One skate decks. Adequate adhesion ensures a secure connection between the rider’s feet and the deck’s surface, enabling effective control during maneuvers. Insufficient adhesion can result in slippage, leading to missed tricks, loss of balance, and potential injuries. Expedition One decks, like all skateboards, rely on the integrity of this bond for optimal functionality. For example, during a high-impact landing, a firmly adhered grip tape allows the skater to maintain control and absorb the force effectively. Conversely, a poorly adhered grip tape might peel or shift, causing the rider to lose their footing.

The quality of grip tape adhesion is contingent on several factors, including the deck’s surface preparation, the adhesive properties of the grip tape itself, and the application technique. Expedition One decks are typically manufactured with a smooth, clean surface to promote optimal grip tape bonding. Premium grip tapes utilize high-strength adhesives designed to withstand the stresses of skateboarding. Proper application, involving even pressure and bubble removal, further enhances adhesion. A practical consideration involves cleaning the deck surface with isopropyl alcohol prior to grip tape application to remove any residual oils or contaminants that could impede bonding.

In summary, grip tape adhesion is an indispensable component of the overall functionality and safety of Expedition One skate decks. Its integrity directly impacts a rider’s ability to control the board and execute maneuvers effectively. Factors influencing adhesion include deck preparation, grip tape quality, and application technique. Maintaining adequate grip tape adhesion is essential for maximizing the performance and longevity of Expedition One skate decks while minimizing the risk of injury. The long-term stability of grip tape adhesion presents a persistent challenge requiring ongoing maintenance and periodic replacement.

7. Overall Durability

Overall durability constitutes a fundamental characteristic of Expedition One skate decks, directly affecting their lifespan and the user’s skateboarding experience. The manufacturing processes, material selection, and design considerations employed by Expedition One exert a substantial influence on a deck’s ability to withstand the stresses inherent in skateboarding. Impact resistance, resistance to warping, and resistance to delamination are primary indicators of overall durability. Decks exhibiting high durability maintain their structural integrity over prolonged use, resulting in consistent performance and reduced replacement frequency. For example, a deck constructed from high-quality maple wood, properly laminated and sealed, will demonstrate greater resistance to cracking and chipping compared to a deck made from inferior materials. The practical significance of this understanding lies in the skater’s ability to make informed purchasing decisions, opting for decks that offer long-term value and reliable performance.

Furthermore, the environment in which the deck is used impacts overall durability. Exposure to moisture, extreme temperatures, and abrasive surfaces can accelerate wear and tear. Expedition One skate decks designed with enhanced weather resistance and reinforced construction elements exhibit increased resilience in diverse skating conditions. The application of protective coatings and the use of water-resistant adhesives contribute to minimizing moisture-induced damage. Consider, for instance, a street skater who frequently performs grinds and slides on concrete surfaces. A durable deck, equipped with reinforced edges and a resilient graphic layer, will withstand abrasion more effectively, extending its usable lifespan compared to a less durable alternative. This highlights the direct correlation between construction quality, environmental factors, and overall deck durability.

In summary, overall durability is a critical performance attribute of Expedition One skate decks, influenced by manufacturing processes, material selection, environmental factors, and skater usage. High durability translates to increased product lifespan, reduced replacement costs, and a more consistent skateboarding experience. While inherent limitations exist regarding the lifespan of any skateboard deck, informed material choices, responsible construction techniques, and conscientious usage habits can significantly enhance overall durability. The challenges associated with achieving optimal durability necessitate continuous innovation and refinement in deck manufacturing, ensuring skaters receive reliable and long-lasting equipment.

Frequently Asked Questions

The following questions address common inquiries regarding Expedition One skateboard decks, providing clear and concise information to assist in informed decision-making.

Question 1: What materials are typically used in the construction of Expedition One skate decks?

Expedition One skate decks primarily utilize maple wood, typically sourced from North America. The plies are laminated with a water-resistant adhesive to ensure structural integrity.

Question 2: How does deck width influence skateboarding performance?

Deck width affects stability and maneuverability. Wider decks generally enhance stability, while narrower decks facilitate quicker rotations. The optimal width depends on rider preference and skating style.

Question 3: What is the significance of concave in an Expedition One skate deck?

Concave refers to the curvature of the deck’s surface. Deeper concave provides greater foot lock, enhancing control during technical tricks. Flatter concave offers a more relaxed riding experience.

Question 4: How should one maintain Expedition One skate decks to prolong their lifespan?

Maintenance involves keeping the deck clean and dry. Avoid prolonged exposure to moisture, and promptly replace worn or damaged components. Inspect the deck regularly for signs of stress or delamination.

Question 5: What factors should be considered when selecting trucks for an Expedition One skate deck?

Truck width should correspond to the deck width. Ensure proper alignment to prevent instability and wheel bite. Truck height can also influence performance, with lower trucks offering increased board feel and higher trucks accommodating larger wheels.

Question 6: How does graphic application impact the overall quality of an Expedition One skate deck?

Graphic application can serve as an indicator of manufacturing standards. Durable graphics suggest attention to detail and a commitment to quality. However, the primary focus should remain on the deck’s structural integrity.

Understanding these elements contributes to informed selection and responsible ownership of Expedition One skateboard decks.

Consider these guidelines when evaluating the suitability of Expedition One skate decks for individual needs and skating styles.

Conclusion

This exploration of Expedition One skate decks has underscored the multifaceted considerations involved in their design, selection, and maintenance. Key elements, including wood ply composition, concave profile, deck width, graphic application, truck compatibility, grip tape adhesion, and overall durability, collectively determine the deck’s performance characteristics and longevity. Informed decision-making requires a thorough understanding of these factors and their interdependencies.

As advancements in materials science and manufacturing techniques continue to evolve, the pursuit of enhanced deck performance and durability remains paramount. Skateboarders are encouraged to critically evaluate product specifications and prioritize quality to ensure a safe and rewarding skateboarding experience. The longevity of the skateboarding industry hinges on the continued innovation and responsible manufacturing practices within the skateboard deck sector.