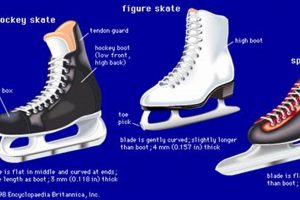

Equipment used for gliding across ice surfaces, typically featuring a boot attached to a blade, enables individuals to participate in activities such as recreational skating, ice hockey, and figure skating. These devices facilitate movement and balance on ice through a specialized design.

The use of such implements provides opportunities for physical exercise, social interaction, and skill development. Historically, their evolution has reflected advancements in materials science and manufacturing techniques, leading to improved performance and comfort. The design caters to various skill levels and purposes, from beginner-friendly recreational models to specialized equipment for competitive athletes.

The following sections will delve into the various aspects of selecting appropriate equipment, maintenance procedures crucial for longevity, and safety considerations for responsible use.

Essential Guidance for Selection and Upkeep

The selection and maintenance of ice skating equipment are critical for both performance and safety. Careful consideration of several factors can significantly enhance the skating experience and extend the lifespan of the equipment.

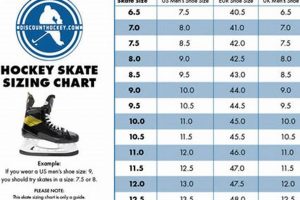

Tip 1: Size Assessment. Accurate foot measurement is essential. Ill-fitting equipment can lead to discomfort, blisters, and reduced control. Consult sizing charts and, ideally, seek professional fitting assistance.

Tip 2: Blade Material Evaluation. The composition of the blade directly influences performance. Higher-grade steel alloys generally offer superior edge retention and glide properties, although they may require more frequent sharpening.

Tip 3: Boot Stiffness Consideration. Boot stiffness should correspond to the skater’s skill level and skating discipline. Beginners typically benefit from softer, more flexible boots, while advanced skaters require stiffer boots for enhanced support and responsiveness.

Tip 4: Lacing Technique Proficiency. Proper lacing technique is crucial for achieving a secure and comfortable fit. Over-tightening can restrict circulation, while loose lacing can compromise ankle support.

Tip 5: Drying Procedure Implementation. Thoroughly drying the blades after each use prevents rust formation. A soft cloth should be used to remove moisture, and blade guards should be employed for storage.

Tip 6: Sharpening Frequency Determination. Regular blade sharpening is essential for maintaining optimal edge control. The frequency of sharpening depends on usage intensity and ice conditions.

Tip 7: Storage Environment Optimization. Storing equipment in a dry, well-ventilated environment minimizes the risk of moisture damage and extends the lifespan of the boots and blades.

Adhering to these guidelines will contribute to improved comfort, performance, and longevity of skating equipment, promoting a safer and more enjoyable skating experience.

The subsequent section will address safety protocols and best practices for responsible ice skating.

1. Blade Edge Quality

Blade edge quality is a critical determinant of performance in ice skating. Its characteristics directly influence maneuverability, control, and overall skating experience, particularly when evaluating equipment from various retailers. The following outlines essential facets of edge quality and their implications.

- Steel Hardness and Composition

The hardness and composition of the steel used in the blade directly impact its ability to maintain a sharp edge. Higher-quality steel alloys resist wear and require less frequent sharpening. For example, blades constructed from a high-carbon steel retain their edge longer than those made from softer, less durable materials. This becomes particularly important for skaters who use the equipment frequently.

- Edge Geometry and Profiling

The geometry and profiling of the blade edge, including the radius of hollow (ROH), influence the skater’s ability to grip the ice and execute turns. A properly profiled edge provides optimal bite without excessive drag. Deviations from the ideal geometry can lead to instability and reduced control, affecting the skater’s balance and agility.

- Sharpening Precision and Consistency

The precision and consistency of the sharpening process are crucial for achieving optimal edge quality. Inconsistent sharpening can result in uneven edges, making it difficult to maintain a straight line and execute precise movements. Professional sharpening services, utilizing specialized equipment, are essential for ensuring consistent and accurate edge profiling.

- Rust Resistance and Maintenance

The blade’s resistance to rust is a key factor in maintaining its edge quality over time. Rust can compromise the sharpness and integrity of the edge, leading to reduced performance and increased risk of injury. Regular cleaning and drying of the blades, along with the use of protective blade guards, are essential for preventing rust formation and preserving edge quality.

These interconnected facets of blade edge quality collectively define the performance characteristics. The interplay between these factors determines the skater’s ability to perform maneuvers effectively and safely. Consequently, careful assessment of these aspects is crucial when selecting and maintaining equipment for any level of skating proficiency.

2. Boot Ankle Support

Ankle support in ice skating boots is a paramount factor influencing stability, control, and injury prevention. The structural integrity of the boot in the ankle region determines the skater’s ability to maintain balance and execute maneuvers effectively.

- Boot Stiffness and Flex Rating

Boot stiffness is quantified by a flex rating, indicating the degree of resistance to forward bending. Higher flex ratings denote greater stiffness, providing enhanced support for advanced skaters performing complex jumps and spins. Conversely, lower flex ratings offer more flexibility, suitable for beginners who require a greater range of motion and comfort. Selecting the appropriate flex rating is crucial for optimizing performance and minimizing strain on the ankle joint.

- Lateral Support Construction

Lateral support construction involves the design and materials used to reinforce the sides of the boot around the ankle. Robust lateral support prevents excessive ankle roll during lateral movements, such as crossovers and turns. This is achieved through the strategic placement of rigid materials, such as reinforced polymers or carbon fiber, in the ankle region. Adequate lateral support contributes to improved stability and reduces the risk of ankle sprains.

- Heel Counter Design

The heel counter, a structural component at the rear of the boot, plays a critical role in stabilizing the heel and ankle. A well-designed heel counter securely cradles the heel, preventing slippage and maintaining proper alignment of the foot within the boot. This is particularly important during landings from jumps, where the heel counter absorbs impact and prevents excessive pronation or supination of the ankle.

- Lacing System Integration

The lacing system directly influences the degree of ankle support provided by the boot. A properly designed lacing system allows the skater to customize the fit around the ankle, providing varying levels of support as needed. Laces that extend high up the ankle provide additional support and stability, while strategically placed eyelets and hooks ensure even distribution of pressure and prevent lace bite. Proper lacing technique is essential for maximizing the benefits of the boot’s ankle support features.

The interplay between boot stiffness, lateral support, heel counter design, and lacing system integration collectively determines the effectiveness of ankle support. Optimal ankle support translates to enhanced control, reduced risk of injury, and improved overall skating performance. Therefore, careful consideration of these factors is essential when selecting ice skating equipment.

3. Size Fitting Accuracy

Size fitting accuracy is a critical determinant of comfort, performance, and safety when selecting ice skating equipment. Ill-fitting devices can lead to discomfort, blisters, and compromised control, increasing the risk of injury. The correlation between precise size fitting and the functionality of ice skates is therefore direct and significant. When the size is accurate, the skater’s foot is properly supported, allowing for efficient energy transfer and precise execution of maneuvers.

The importance of size fitting extends beyond mere comfort. An example includes a skater attempting complex jumps with incorrectly sized devices. If the devices are too large, the foot may shift within the boot, causing instability during takeoff and landing. Conversely, if the devices are too small, circulation may be restricted, leading to numbness and decreased sensitivity, hindering the skater’s ability to feel the ice. In both scenarios, performance is negatively impacted, and the risk of falls and injuries increases substantially.

In conclusion, prioritizing size fitting accuracy is not merely a matter of preference but a fundamental requirement for safe and effective skating. Addressing this aspect during selection is paramount to maximizing performance potential and minimizing the likelihood of discomfort or injury. This attention to detail contributes directly to a more positive and successful experience on the ice.

4. Material Durability Assessment

The evaluation of material durability is a fundamental aspect in the production and selection of ice skating equipment. It directly influences the longevity, performance, and safety of the product. The materials used in construction must withstand the rigors of ice skating, including exposure to moisture, cold temperatures, and repetitive stress.

- Boot Material Integrity

The boot, typically constructed from leather, synthetic materials, or a composite of both, must resist wear and tear from repeated flexing and abrasion. Inferior materials may exhibit premature cracking, delamination, or deformation, compromising ankle support and overall structural integrity. For instance, a synthetic boot material that lacks sufficient tensile strength may tear at stress points around the ankle, reducing support and increasing the risk of injury. The assessment involves evaluating the material’s resistance to tearing, stretching, and environmental degradation.

- Blade Steel Quality

The blade is subject to constant friction against the ice surface, necessitating the use of high-quality steel alloys. The steel must maintain its hardness and edge sharpness over prolonged use, resisting corrosion and chipping. A blade constructed from low-grade steel may dull quickly, requiring frequent sharpening and ultimately shortening the blade’s lifespan. Evaluation includes testing the steel’s hardness, tensile strength, and resistance to corrosion.

- Rivets and Fasteners Strength

Rivets and fasteners are crucial for securing the blade to the boot and maintaining the structural integrity of the entire assembly. These components must withstand significant stress and vibration without loosening or failing. Substandard rivets or fasteners may shear or corrode, leading to blade detachment or instability. Assessment involves testing the shear strength and corrosion resistance of these critical components.

- Liner and Padding Resilience

The liner and padding provide cushioning and support within the boot, contributing to comfort and fit. These materials must resist compression and retain their shape over time, maintaining consistent support and preventing pressure points. Low-quality padding may compress prematurely, resulting in discomfort and reduced ankle support. Evaluation includes assessing the compression resistance and durability of the liner and padding materials.

These facets of material durability assessment are interconnected and collectively determine the overall quality and longevity of the equipment. Rigorous testing and quality control measures are essential to ensure that materials meet the demands of ice skating, providing skaters with reliable and safe equipment. The performance and value of any equipment is ultimately tied to the quality and durability of its constituent materials.

5. Lace Tightness Regulation

Lace tightness regulation is a critical factor governing comfort, support, and performance within ice skating footwear, directly impacting the functionality and safety profile of the user. This regulation involves adjusting the tension of the laces to achieve a secure and customized fit, which is essential for optimizing control and minimizing the risk of injury.

- Ankle Support Modulation

Lace tightness directly influences the degree of ankle support provided by the boot. Tighter lacing around the ankle joint restricts movement, enhancing stability and reducing the likelihood of sprains or strains, particularly during complex maneuvers or landings from jumps. Conversely, looser lacing allows for greater flexibility and range of motion, which may be preferred by skaters prioritizing agility over maximal support. The optimal lace tightness varies depending on the skater’s skill level, skating style, and individual preferences.

- Foot Confinement and Stability

Proper lace tightness ensures that the foot is securely confined within the boot, preventing slippage and maintaining consistent contact with the insole. Excessive foot movement within the boot can lead to blisters, friction burns, and reduced control over the blade. Achieving the appropriate level of foot confinement is particularly important during rapid changes in direction or abrupt stops, where the forces exerted on the foot are substantial. Inadequately tightened laces compromise stability and increase the risk of falls.

- Circulation Management

While adequate lace tightness is necessary for support and stability, excessive constriction can impede circulation, leading to numbness, tingling, or pain. Prolonged restriction of blood flow can also contribute to cold feet, reducing comfort and performance. Effective lace tightness regulation involves finding a balance between providing sufficient support and maintaining adequate circulation to the foot and ankle. Skaters should periodically assess their foot comfort and adjust lace tension as needed to prevent circulatory issues.

- Performance Customization

Lace tightness can be strategically adjusted to fine-tune performance characteristics, enabling skaters to tailor their boot fit to specific skating disciplines or maneuvers. For instance, figure skaters may tighten the laces around the ankle to maximize support during jumps and spins, while hockey players may prefer slightly looser lacing to enhance agility and responsiveness. The ability to customize lace tightness allows skaters to optimize their performance based on the demands of their chosen activity.

The ability to effectively regulate lace tightness within skating boots is paramount for achieving a secure, comfortable, and performance-enhancing fit. This critical adjustment enables skaters to tailor their equipment to their individual needs, maximizing control, minimizing injury risk, and optimizing overall skating experience. Attention to detail in lace tightness regulation is a hallmark of skilled and safety-conscious skaters.

Frequently Asked Questions about Ice Skating Equipment

This section addresses common inquiries and concerns regarding the selection, maintenance, and use of ice skating equipment.

Question 1: What criteria should guide equipment selection for beginners?

Beginners should prioritize comfort and stability. Lower boot stiffness facilitates ankle movement, aiding in balance development. Ensuring accurate sizing is essential to prevent discomfort and blisters. It is advisable to consult with a professional fitter to determine the appropriate equipment for individual needs.

Question 2: How frequently should blades be sharpened?

Sharpening frequency depends on usage intensity and ice conditions. Blades should be sharpened when the edge feels dull or when the skater experiences difficulty maintaining control. Regular inspection of the blade edge is recommended to identify signs of wear.

Question 3: What measures can be taken to prevent rust formation on the blades?

Thoroughly drying the blades after each use is crucial. A soft cloth should be used to remove all moisture. Blade guards should be employed during storage to protect the blades from environmental exposure.

Question 4: How does boot stiffness impact skating performance?

Boot stiffness directly affects ankle support and responsiveness. Stiffer boots provide greater support for advanced maneuvers, while more flexible boots offer increased range of motion for beginners. The appropriate stiffness level depends on the skater’s skill and the demands of their skating discipline.

Question 5: What is the recommended method for lacing equipment?

Lacing should be snug but not overly tight. The laces should be tightened progressively from the toes to the ankle, ensuring even pressure distribution. Over-tightening can restrict circulation and cause discomfort. It is important to relace the equipment periodically during extended skating sessions to maintain optimal fit.

Question 6: What are the signs that equipment needs replacement?

Equipment should be replaced when it exhibits significant wear and tear, such as cracking in the boot, excessive blade dulling, or loosening of rivets. Compromised equipment can jeopardize safety and hinder performance. Regular inspection and maintenance are crucial for identifying replacement needs.

The information provided in this FAQ section is intended to provide general guidance. It is recommended to consult with experienced professionals for personalized advice and recommendations.

The subsequent section will discuss advanced maintenance techniques to enhance the lifespan of the equipment.

Conclusion

This examination of equipment has addressed crucial aspects ranging from blade quality and boot support to size accuracy, material durability, and lace regulation. Each element contributes significantly to performance, safety, and longevity. Understanding these factors enables informed decision-making during selection and maintenance.

Proper equipment stewardship ensures a safer and more productive skating experience. Continuous attention to these critical areas will enhance the skater’s capabilities and contribute to a more enjoyable and secure participation in the sport.