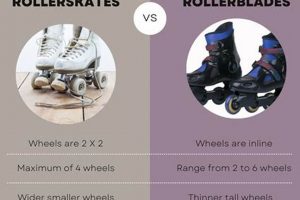

Constructing personalized motorized footwear involves adapting conventional roller skates or inline skates with electric motors, batteries, and control systems. This undertaking results in a self-propelled personal transportation device. An instance includes modifying a pair of inline skates with a small electric motor attached to one wheel, powered by a battery pack strapped to the user’s leg, and controlled by a handheld remote.

The appeal of such builds lies in their potential for cost-effectiveness and customization, providing an alternative to commercially available electric skateboards or scooters. Furthermore, crafting these devices offers a unique opportunity to learn about electric motors, battery technology, and basic engineering principles. Historically, the concept stems from early experimentation with motorized personal transport and a desire for increased mobility within urban environments.

The following sections will address the practical considerations for building such devices, including component selection, safety protocols, and legal implications.

Essential Guidance for Constructing Motorized Skates

Successful fabrication of these devices necessitates careful planning and execution. The following guidelines are crucial for ensuring both functionality and safety during the construction process.

Tip 1: Component Selection: Prioritize high-quality components, specifically motors and batteries. Opt for brushless DC motors for efficiency and longevity. Battery selection should consider voltage, capacity (Ah), and discharge rate (C-rating), matching the motor’s requirements and desired range. Always refer to manufacturer specifications.

Tip 2: Frame Reinforcement: The original skate frame may require reinforcement to withstand the added stress from the motor and battery. Consider adding metal brackets or plates to distribute the load and prevent structural failure. Welding or bolting techniques are applicable, depending on the frame material.

Tip 3: Secure Mounting: Implement a robust mounting system for the motor, battery, and control unit. Avoid relying solely on adhesives; mechanical fasteners such as screws, bolts, and brackets offer greater reliability and resistance to vibration. Ensure all connections are tightened and secured properly.

Tip 4: Electronic Connections: Implement proper wiring practices, including soldering and heat-shrinking connections. Use appropriate gauge wires to handle the current load and prevent overheating. Incorporate fuses or circuit breakers to protect the electrical system from overloads and short circuits.

Tip 5: Control System Design: The control system, typically a handheld remote, must provide precise throttle control and reliable communication with the motor controller. Consider incorporating features such as regenerative braking for increased efficiency and safety. Thoroughly test the responsiveness and reliability of the control system.

Tip 6: Safety Provisions: Integrate safety features, including an emergency cutoff switch readily accessible to the user. Consider adding protective enclosures for the battery and motor to prevent damage from impacts or debris. Prioritize personal protective equipment, such as a helmet, knee pads, and elbow pads during operation.

Tip 7: Weight Distribution: Strive for even weight distribution to maintain balance and maneuverability. Placing the battery pack close to the center of the skate can minimize the impact on handling. Conduct thorough testing to identify and address any balance issues.

The application of these tips will significantly enhance the likelihood of a safe and functional outcome, reducing the potential for mechanical or electrical failures. Careful attention to detail is essential throughout the entire fabrication process.

The following section will delve into the legal and regulatory considerations pertaining to the use of these devices in public spaces.

1. Component Compatibility

The functional success of self-assembled electric skates hinges critically on component compatibility. The electric motor, battery, and electronic speed controller (ESC) must operate in a coordinated fashion to deliver the desired performance characteristics. A mismatch in voltage requirements, current draw, or communication protocols can result in system malfunction, reduced efficiency, or even component failure. For example, using a motor with a higher voltage requirement than the battery’s output will result in insufficient power and impaired performance. Conversely, exceeding the ESC’s maximum current rating can lead to overheating and permanent damage.

A practical example illustrates this point: a builder might select a high-torque motor intended for steep inclines but pair it with a low-capacity battery. While the motor’s torque could be beneficial, the battery’s limited capacity would drastically reduce the skate’s usable range, negating the motor’s advantage. Furthermore, if the battery’s discharge rate (C-rating) is insufficient for the motor’s peak current draw, the battery’s voltage will sag under load, further hindering performance and potentially damaging the battery. Understanding the specific electrical characteristics of each component and ensuring they are properly matched is therefore crucial for a successful build. This involves careful review of manufacturer specifications and, ideally, preliminary testing before integrating the components into the skate assembly.

In conclusion, component compatibility is not merely a technical detail, but a fundamental principle underlying the operation and longevity of custom electric skates. Challenges arise in interpreting complex specifications and accurately predicting real-world performance. A thorough understanding of electrical principles and component characteristics is essential to overcome these challenges and create a safe and reliable personal transportation device. The integration of compatible components directly impacts the feasibility and overall effectiveness of these projects.

2. Frame reinforcement

Frame reinforcement constitutes a critical element in the successful construction of self-assembled electric skates. The integration of electric motors, batteries, and control systems introduces significant additional weight and stress to the original skate frame. This added burden can exceed the frame’s designed capacity, leading to structural failure, compromised stability, and increased risk of accidents. Consequently, reinforcing the frame becomes essential to ensure the device’s structural integrity and operational safety. For instance, a standard inline skate frame, typically constructed from plastic or lightweight aluminum, may buckle or crack under the combined weight of a motor and battery pack, especially during high-impact maneuvers or rough terrain. Reinforcement strategies, such as adding metal plates, welding additional supports, or utilizing higher-grade materials, are therefore necessary to mitigate these risks and extend the lifespan of the motorized skate.

The specific reinforcement techniques employed vary depending on the original frame material, the size and weight of the added components, and the intended usage conditions. Skates designed for off-road use or higher speeds generally require more robust reinforcement than those intended for casual recreational use on smooth surfaces. Furthermore, the mounting methods used to attach the motor and battery to the frame directly impact the stress distribution. Secure and properly distributed mounting points minimize localized stress concentrations and reduce the likelihood of frame failure. Examples of reinforcement include welding steel brackets to an aluminum frame, bolting thick metal plates to distribute weight, or even replacing the original frame with a custom-fabricated, heavy-duty alternative. Finite element analysis (FEA) can be used to simulate stress distribution and optimize reinforcement designs, ensuring that the frame can withstand the expected loads without compromising its overall weight or maneuverability.

In summary, frame reinforcement is not merely an optional upgrade but a fundamental requirement for building safe and reliable electric skates. Neglecting this aspect can result in catastrophic failures and potential injuries. A thorough assessment of the frame’s original strength, the added weight and forces, and the intended operating conditions is essential for determining the appropriate reinforcement strategy. By implementing effective frame reinforcement, builders can ensure that their motorized skates are not only functional but also structurally sound and capable of withstanding the demands of regular use. Ultimately, prioritizing frame integrity contributes directly to the safety and longevity of these devices, mitigating the inherent risks associated with motorized personal transportation.

3. Electrical Safety

The integration of electrical systems in self-assembled motorized skates necessitates a thorough understanding and application of electrical safety principles. The potential consequences of neglecting these principles range from component failure to severe personal injury. Unprotected electrical components, exposed wiring, and inadequate insulation present significant hazards, particularly in the dynamic environment of skateboarding or skating. For instance, a short circuit in the battery pack, caused by chafing wires or improper connections, can result in a thermal runaway, potentially leading to fire or explosion. Similarly, direct contact with exposed high-voltage wiring poses a risk of electrocution. Therefore, meticulous attention to electrical safety is paramount throughout the design, construction, and operation of these devices.

Practical implementation of electrical safety measures includes several key elements. Proper insulation of all wiring, using heat-shrink tubing or electrical tape, prevents accidental shorts and protects against environmental factors. Fuses or circuit breakers must be incorporated into the electrical circuit to limit current flow and prevent overloads, which can damage components or ignite fires. The selection of appropriate gauge wiring is critical for handling the expected current load; undersized wiring can overheat and cause a fire hazard. Grounding the electrical system, where applicable, provides a path for stray currents to flow to ground, reducing the risk of electric shock. Regular inspection of wiring and connections is essential to identify and address potential problems before they escalate into hazardous situations. Furthermore, battery management systems (BMS) play a crucial role in protecting lithium-ion batteries from overcharging, over-discharging, and thermal runaway, thereby enhancing overall electrical safety. All these measures must be considered during construction of diy electric skates

In summary, electrical safety is not an ancillary consideration but an indispensable aspect of self-assembled electric skates. The inherent risks associated with high-voltage batteries and electric motors demand rigorous adherence to established safety protocols. Failure to prioritize electrical safety can result in catastrophic consequences. Diligent attention to wiring practices, component protection, and circuit protection is essential for ensuring the safety of both the user and the surrounding environment. Furthermore, regulatory compliance with local electrical codes and standards is advisable to minimize potential legal liabilities. Prioritizing safe construction also will ensure durability of the electric skates.

4. Control system reliability

Control system reliability is paramount in the domain of self-constructed motorized skates. The control system, typically consisting of a handheld remote, a receiver unit, and an electronic speed controller (ESC), governs the acceleration, deceleration, and braking functions. Any failure or malfunction within this system can lead to unpredictable behavior, loss of control, and potential accidents. The direct correlation between control system integrity and user safety necessitates meticulous design and implementation. The system’s ability to consistently and accurately translate user input into the desired motor response is fundamental to the safe operation of these devices. For instance, a malfunctioning throttle signal could result in unintended acceleration, exceeding the user’s control and leading to a collision. Similarly, unreliable braking could compromise the ability to stop in emergency situations. Thus, the reliability of the control system is not merely a desirable feature but a critical safety requirement.

The achievement of reliable control involves several key considerations. Redundancy in critical components, such as dual receivers or redundant signal pathways, can mitigate the risk of single-point failures. Thorough testing of the control system under various operating conditions, including different speeds, terrains, and battery levels, is essential to identify and address potential vulnerabilities. Implementing robust error-checking mechanisms can help detect and correct signal corruption, ensuring accurate command execution. Furthermore, the selection of high-quality components and adherence to established electronic design principles contribute significantly to the overall reliability of the system. Examples of unreliable systems include those using generic, untested ESCs, poorly shielded wiring prone to interference, or remotes with known connectivity issues. These frequently result in intermittent control, erratic motor behavior, and an increased risk of accidents.

In conclusion, control system reliability is a non-negotiable element in the construction of safe and functional electric skates. Its absence can compromise user safety and undermine the entire project. A robust, well-tested, and properly implemented control system is essential to minimize the risk of accidents and ensure a predictable and controllable riding experience. Prioritizing reliability in the control system reflects a commitment to user safety and responsible engineering practices within the realm of DIY motorized transportation. The reliable operation of a skate directly increases its feasibility of being used as a standard transportation method.

5. Regulatory compliance

Regulatory compliance constitutes a critical, often overlooked aspect of constructing and operating personalized motorized skates. The legal landscape governing such devices varies significantly across jurisdictions, impacting their legality, permissible usage locations, and operational requirements. Non-compliance can result in fines, impoundment of equipment, or even legal action. Therefore, builders and users must familiarize themselves with applicable regulations before engaging in any construction or operation of these devices.

- Speed Restrictions

Many jurisdictions impose speed limits on electric personal transportation devices, including motorized skates. These limits are often lower than the potential top speed of a custom-built skate. Exceeding these limits can result in fines or equipment confiscation. For instance, some cities may restrict electric skate speeds to 15 mph on sidewalks and bike paths, while others may prohibit their use entirely in pedestrian zones. Builders must consider these restrictions when selecting motor and battery configurations.

- Location Restrictions

The areas where motorized skates can legally operate are often restricted. Some jurisdictions prohibit their use on sidewalks, bike paths, or public roads, relegating them to private property or designated recreational areas. Other regions may allow their use on specific bike lanes or low-speed roads, subject to certain conditions. Ignoring these restrictions can lead to fines or impoundment. An example is a city ordinance banning electric skates from all public sidewalks due to pedestrian safety concerns.

- Licensing and Registration

In some locales, motorized skates may be classified as motor vehicles, requiring registration, licensing, and insurance. This classification subjects users to the same requirements as drivers of cars or motorcycles, including mandatory helmet use and adherence to traffic laws. Failure to comply with these requirements can result in significant penalties. For example, a state law requiring all electric vehicles exceeding a certain power output to be registered and insured would apply to sufficiently powerful motorized skates.

- Equipment Standards

Certain jurisdictions may mandate specific equipment standards for electric personal transportation devices. These standards can encompass requirements for braking systems, lighting, and audible warning devices. Failure to meet these standards can render the device illegal for use on public property. Examples include regulations requiring functioning brakes capable of stopping the device within a specified distance and the presence of front and rear lights for nighttime visibility.

The implications of these regulatory factors extend beyond mere legal compliance. They influence design choices, performance capabilities, and operational practices. By proactively addressing these considerations, builders and users can ensure the safe and legal operation of DIY electric skates, minimizing the risk of fines, equipment confiscation, or legal repercussions. Comprehensive understanding of local laws is vital.

6. Weight distribution

Weight distribution plays a pivotal role in the functionality and safety of personalized motorized skates. The placement and balance of components, including the motor, battery, and control system, directly influence the device’s stability, maneuverability, and overall riding experience. Improper weight distribution can lead to compromised handling, increased risk of falls, and reduced efficiency.

- Impact on Stability

Uneven weight distribution can create an unstable platform, making it difficult to maintain balance, especially at higher speeds. For example, if the battery pack is mounted solely on one side of the skate, it can cause the skate to lean in that direction, requiring constant effort to counteract and maintain a straight line. This instability increases the likelihood of losing balance and falling, particularly during sudden maneuvers or uneven terrain. Centrally located heavy components result in greater stability.

- Effect on Maneuverability

Weight distribution significantly affects the skate’s ability to turn and maneuver effectively. A skate with a rear-heavy distribution may be more difficult to turn sharply, while a front-heavy skate may feel unstable during quick stops. Achieving optimal maneuverability requires careful consideration of the placement of all components to ensure a balanced and responsive ride. A front-heavy skate can cause difficulty in lifting the front of the skate and create unbalance when trying to move the skate. The distribution should allow for predictable and controlled turning.

- Influence on Motor Performance

Weight distribution impacts the motor’s efficiency and overall performance. An unbalanced load can place undue stress on the motor, causing it to work harder to maintain speed and acceleration. This increased strain can reduce the motor’s lifespan and decrease the battery’s range. Optimal distribution enables the motor to operate more efficiently, maximizing performance and extending the skate’s usability. A lighter load allows for more efficiency, less strain and more control.

- Safety Implications

The safety implications of poor weight distribution are substantial. An unstable or difficult-to-control skate increases the risk of accidents and injuries. Uneven distribution can lead to unexpected wobbles, loss of balance, and difficulty in executing emergency maneuvers. Proper weight distribution is thus essential for minimizing the risk of accidents and ensuring a safe riding experience. Distribution also allows for smoother acceleration.

The multifaceted impact of weight distribution underscores its importance in the design and construction of motorized skates. Achieving optimal distribution requires careful planning, precise component placement, and thorough testing. A balanced, stable, and maneuverable skate not only enhances the riding experience but also significantly improves user safety, thereby promoting the viability and appeal of these personalized transportation devices. Moreover, regulatory compliance may impose further constraints on weight limits and distribution profiles, adding another layer of complexity to the design process.

Frequently Asked Questions Regarding Self-Assembled Motorized Skates

The following questions address common concerns and misconceptions surrounding the construction and operation of personalized electric skates. These answers provide factual information to promote safe and responsible practices.

Question 1: Are self-built electric skates legal for use on public roads?

The legality of operating such devices on public roads varies significantly by jurisdiction. It is imperative to consult local laws and ordinances to determine permissible usage areas and any applicable licensing or registration requirements. Failure to comply may result in fines or impoundment.

Question 2: What safety precautions are essential during the construction process?

Electrical safety is paramount. Proper insulation of all wiring, the inclusion of fuses or circuit breakers, and the use of appropriate gauge wiring are crucial. Frame reinforcement is also essential to withstand the added weight and stress from the motor and battery. Personal protective equipment, including a helmet, is highly recommended.

Question 3: How does component compatibility impact the performance of the skates?

The electric motor, battery, and electronic speed controller must operate in a coordinated fashion. A mismatch in voltage requirements, current draw, or communication protocols can result in system malfunction, reduced efficiency, or component failure. Consult manufacturer specifications to ensure compatibility.

Question 4: What are the primary considerations for ensuring control system reliability?

Redundancy in critical components, thorough testing under various operating conditions, and the implementation of robust error-checking mechanisms are vital. High-quality components and adherence to established electronic design principles are also recommended to promote safe operation.

Question 5: How does weight distribution affect the handling and stability of the skates?

Uneven weight distribution can create an unstable platform, making it difficult to maintain balance and maneuver effectively. Optimal weight distribution is achieved by strategically placing components to ensure a balanced and responsive ride. Centralize heavy components whenever possible.

Question 6: What is the expected lifespan of a custom-built electric skate’s battery pack?

Battery lifespan depends on usage patterns, battery chemistry, and maintenance practices. Lithium-ion batteries typically have a limited number of charge-discharge cycles before their capacity diminishes. Proper storage and avoiding extreme temperatures can extend battery life. Always refer to the manufacturer’s recommendations for optimal battery care.

In conclusion, constructing and operating these devices demands careful consideration of legal, safety, and technical factors. Adhering to these guidelines will enhance the probability of a safe and functional outcome.

The following section will provide a comparative analysis of commercially available electric skates versus self-assembled versions.

DIY Electric Skates

This exploration has illuminated the multifaceted aspects of DIY electric skates. From component selection and frame reinforcement to electrical safety, control system reliability, regulatory compliance, and weight distribution, each element demands meticulous attention. The construction of such devices presents both opportunities and inherent risks, requiring a commitment to safety and adherence to established engineering principles.

The decision to undertake a project involving DIY electric skates should not be taken lightly. A comprehensive understanding of the technical, legal, and safety implications is essential. Proceed with caution, prioritize safety, and respect all applicable regulations to ensure a responsible and rewarding experience. The future of personal electric transportation hinges on informed and conscientious innovation.