Personalized rolling footwear, crafted to individual specifications, represents a departure from mass-produced sporting equipment. These specialized skates are built with components selected and configured to match a skater’s unique foot shape, skating style, and performance goals. For instance, a speed skater might require a low-cut boot and lightweight frame for maximum efficiency, whereas an aggressive skater may prioritize a robust boot and grind-friendly frame.

The practice of tailoring skating equipment yields significant advantages. Enhanced comfort leads to reduced foot fatigue and blisters, allowing for longer and more enjoyable skating sessions. Improved performance is achieved through optimized power transfer and responsiveness. Historically, this level of customization was limited to elite athletes, but advancements in manufacturing and materials have made it increasingly accessible to a wider range of skaters seeking personalized performance and fit.

The subsequent sections will explore specific elements contributing to the personalization of rolling footwear, encompassing boot selection, frame options, wheel characteristics, and bearing considerations. Each element plays a crucial role in achieving a bespoke skating experience.

Guidance on Personalized Rolling Footwear Selection

The selection process for personalized rolling footwear demands careful consideration of individual needs and preferences. The following tips are designed to guide informed decisions, ensuring optimal performance and comfort.

Tip 1: Foot Measurement and Analysis: Prior to any component selection, a precise foot measurement is essential. Length, width, and arch height should be accurately recorded, and ideally, a professional foot analysis is recommended to identify specific biomechanical considerations.

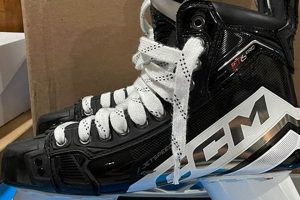

Tip 2: Boot Material and Construction: Boot materials directly influence performance and comfort. Carbon fiber boots offer superior stiffness and power transfer for experienced skaters, while heat-moldable materials allow for a customized fit, accommodating unique foot contours.

Tip 3: Frame Selection Based on Skating Style: The frame type should align with the intended skating discipline. Short frames enhance maneuverability for aggressive skating, while longer frames promote stability and speed for distance skating.

Tip 4: Wheel Durometer and Size Considerations: Wheel durometer (hardness) and size impact grip, speed, and roll. Softer wheels provide better grip on slick surfaces, while harder wheels offer greater speed and durability. Larger wheels generally roll faster but may be less agile.

Tip 5: Bearing Quality and Maintenance: Bearing quality significantly affects roll efficiency. High-precision bearings reduce friction and enhance speed. Regular cleaning and lubrication are essential for maintaining optimal bearing performance.

Tip 6: Liner Selection for Enhanced Comfort: The liner provides cushioning and support within the boot. Choosing a liner that conforms to the foot’s shape and offers adequate padding can minimize discomfort and improve control.

Tip 7: Professional Consultation and Fitting: Consulting with experienced skate technicians or retailers is highly recommended. A professional fitting ensures correct sizing and provides expert guidance on component selection.

By carefully considering these factors, individuals can create personalized rolling footwear that maximizes performance, comfort, and skating enjoyment. Selecting the appropriate components and ensuring a proper fit are crucial for achieving a truly bespoke skating experience.

The subsequent sections will delve into the maintenance and care of personalized rolling footwear, ensuring longevity and continued optimal performance.

1. Boot Fit Optimization

Boot fit optimization forms a cornerstone of personalized rolling footwear. Ill-fitting boots induce discomfort, blisters, and diminished control, directly impacting performance. When tailoring skates, the boot must conform precisely to the skater’s foot, addressing nuances like arch height, ankle width, and potential pressure points. An optimized fit enhances power transfer, allowing for more efficient skating and reduced fatigue. As an example, a skater with a high arch may require a heat-moldable boot with custom insoles to prevent plantar fasciitis and ensure proper alignment. Neglecting this aspect undermines the entire premise of customization.

The process of boot fit optimization frequently involves techniques such as heat molding, where the boot’s shell is heated and then molded to the skater’s foot shape. Custom orthotics provide further support and correct biomechanical imbalances. Furthermore, careful consideration is given to the lacing system, ensuring even pressure distribution across the foot. Skaters specializing in aggressive styles often demand a snugger fit for enhanced responsiveness, whereas those prioritizing long-distance skating may seek a more relaxed fit to maintain comfort over extended periods. Proper optimization is not merely about size; it’s about addressing the unique contours of each individual’s foot.

In summary, boot fit optimization is critical to the success of personalized rolling footwear. Failure to prioritize this element results in compromised performance and diminished skating enjoyment. This foundational understanding is essential for both skaters and technicians seeking to create truly bespoke equipment, addressing biomechanical needs and skating style requirements. It represents a necessary investment in comfort, efficiency, and overall skating experience.

2. Frame Material Selection

Frame material selection exerts a significant influence on the performance characteristics of personalized rolling footwear. The frame, serving as the structural link between the boot and wheels, dictates responsiveness, stability, and weight distribution. The material composition directly affects these attributes, thereby impacting skating style suitability. For example, aluminum frames, known for their stiffness and efficient energy transfer, are often favored by speed skaters seeking maximum velocity. Conversely, composite frames, offering greater vibration dampening and a more forgiving ride, might be preferred by recreational skaters or those navigating uneven surfaces. Frame choice, therefore, is not arbitrary; it is a calculated decision influencing the skater’s experience.

Furthermore, the material selected influences the durability and longevity of the skates. Aggressive skaters, frequently subjecting their equipment to high-impact maneuvers and grinds, benefit from frames constructed of hardened aluminum alloys designed to withstand significant stress. Conversely, skaters focused on distance or recreational use may prioritize lighter materials, such as extruded aluminum, to reduce overall weight and minimize fatigue. The manufacturing process also contributes to the frame’s performance. CNC-machined frames, for instance, offer tighter tolerances and greater precision compared to cast frames, translating to improved alignment and smoother rolling. A comprehensive understanding of material properties, manufacturing techniques, and skating styles is, therefore, essential for optimal frame selection.

In conclusion, the choice of frame material is a critical component in the construction of individualized rolling footwear. Selecting the appropriate material necessitates a careful evaluation of skating style, performance goals, and environmental conditions. Aluminum alloys provide stiffness and energy transfer suitable for competitive environments, while composite materials offer dampening for recreational use. Frame selection is not merely a matter of preference; it is a fundamental element shaping the skate’s handling, durability, and overall performance. A deliberate selection process ensures the skates are tailored to the skater’s specific needs and expectations, optimizing the overall experience.

3. Wheel Durometer Variation

Wheel durometer variation represents a critical consideration in the realm of personalized rolling footwear. Durometer, measured on the A scale, indicates the wheel’s hardness, thereby influencing grip, speed, and durability. Precise durometer selection permits skaters to optimize performance based on skating style, surface conditions, and desired handling characteristics.

- Grip Optimization Through Softer Durometers

Softer wheels, typically ranging from 74A to 82A, offer enhanced grip, particularly on smooth or slick surfaces. This characteristic is beneficial for aggressive skaters executing intricate maneuvers in skate parks, or for skaters navigating indoor rinks where traction is paramount. The increased grip, however, comes at the cost of reduced speed and accelerated wear.

- Speed Enhancement with Harder Durometers

Harder wheels, generally ranging from 84A to 90A, prioritize speed and rolling efficiency. These wheels are favored by speed skaters and marathon skaters seeking to minimize rolling resistance and maximize velocity. The reduced grip, however, may necessitate careful technique and awareness of surface conditions, particularly when cornering at high speeds.

- Durability Considerations Across Durometer Ranges

Wheel durometer directly impacts longevity. Softer wheels, due to their increased grip, tend to wear down more quickly than harder wheels. Aggressive skaters, subjecting their wheels to frequent impacts and grinds, may prioritize durability over grip, opting for intermediate durometers in the 82A to 86A range. Conversely, skaters primarily focused on smooth surfaces can achieve extended wheel life with harder durometers.

- Adaptive Performance Through Mixed Durometer Configurations

Advanced skaters may employ mixed durometer configurations to optimize performance across varying conditions. For example, using harder wheels on the inner positions of the frame and softer wheels on the outer positions can enhance both speed and grip. This approach allows for nuanced control and adaptability to specific skating environments. Careful experimentation and analysis are required to determine the optimal configuration for individual skating styles and preferences.

The judicious selection of wheel durometer, tailored to individual needs and skating conditions, significantly enhances the performance and overall enjoyment of personalized rolling footwear. Durometer variation enables skaters to fine-tune their equipment, optimizing grip, speed, and durability to achieve specific performance goals. This aspect exemplifies the benefits of customization, allowing skaters to transcend the limitations of generic, mass-produced equipment and create a truly bespoke skating experience.

4. Bearing Precision Level

Bearing precision level, a critical but often overlooked aspect of rolling footwear, significantly impacts the performance of personalized inline skates. Bearings, nestled within the wheels, facilitate rotation and directly influence rolling efficiency. Higher precision bearings, manufactured to tighter tolerances, reduce friction and enhance speed. This, in turn, translates to a smoother, faster, and more efficient skating experience, particularly noticeable over extended distances or during competitive events. The bearing precision level is graded using the ABEC (Annular Bearing Engineers’ Committee) scale, or similar ISO standards, where higher numbers denote tighter tolerances and improved performance. For example, a skater using ABEC 7 or ABEC 9 bearings will experience a noticeably smoother and faster roll compared to using ABEC 3 bearings, assuming all other factors are equal.

The selection of bearing precision level should align with the skater’s skill level and intended use. While high-precision bearings offer performance advantages, they are often more expensive and may require more frequent maintenance. Recreational skaters may find that ABEC 5 or ABEC 7 bearings provide an adequate balance of performance and durability, while competitive skaters often demand the highest precision bearings available to gain every possible advantage. Furthermore, the type of bearing lubricant used also impacts performance. Low-viscosity lubricants reduce friction and enhance speed, while higher-viscosity lubricants provide greater protection against contamination and wear. Regular cleaning and lubrication are essential to maintain optimal bearing performance, regardless of precision level. For instance, aggressive skaters often use sealed bearings to protect against dirt and debris encountered during grinds and slides.

In summary, bearing precision level is a fundamental element in personalized rolling footwear, influencing rolling efficiency, speed, and overall skating experience. Selecting the appropriate bearing precision level necessitates careful consideration of skill level, skating style, and maintenance capabilities. High-precision bearings offer performance benefits, particularly for competitive skaters, while recreational skaters may find that lower precision bearings provide an acceptable balance of performance and cost. Consistent maintenance, including cleaning and lubrication, is essential to maximize the lifespan and performance of all bearings. An informed selection process ensures that the bearings complement the overall configuration of the custom skates, contributing to an optimized and enjoyable skating experience.

5. Personalized Liner Choice

Personalized liner choice represents a critical aspect of custom inline skates, directly impacting comfort, performance, and overall fit. Liners, the inner layer within the skate boot, provide cushioning, support, and moisture management. A properly selected liner effectively eliminates pressure points, prevents blisters, and enhances control. For instance, a skater with narrow feet may benefit from a liner with a slimmer profile, while a skater with wider feet may require a liner with a more accommodating shape. Heat-moldable liners offer a customizable fit, conforming precisely to the contours of the skater’s foot. Improper liner selection negates the benefits of a custom boot, potentially leading to discomfort and reduced performance. The choice directly influences skating efficiency and comfort during prolonged use.

The materials used in liner construction further contribute to its performance characteristics. Liners constructed from memory foam provide superior cushioning and conform to the foot over time, enhancing comfort. Moisture-wicking materials, such as microfiber, help to keep the feet dry and prevent the buildup of odor-causing bacteria. Some liners incorporate shock-absorbing materials, such as gel padding, to mitigate impact forces and reduce foot fatigue, particularly beneficial for aggressive skaters or those performing high-impact maneuvers. The thickness of the liner also influences fit and performance. Thicker liners provide more cushioning but may reduce responsiveness, while thinner liners offer greater feel and control but may compromise comfort. Experienced skaters often experiment with different liner thicknesses and materials to find the optimal balance for their individual needs and skating style. Liners may be replaced independently of the boot, offering skaters an opportunity to fine-tune their fit and performance as their skills evolve.

In conclusion, personalized liner choice is an indispensable element of custom inline skates, significantly affecting comfort, performance, and fit. Appropriate liner selection involves careful consideration of foot shape, skating style, and material properties. The customized approach addresses individual needs and preferences, and ultimately enhances the skating experience. Neglecting this element compromises the benefits of the custom skate, resulting in reduced performance and compromised comfort. The investment in a properly fitted and high-quality liner ensures optimal performance and a prolonged skating experience.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions concerning personalized rolling footwear. The information is intended to provide clarity and assist informed decision-making.

Question 1: What distinguishes custom inline skates from standard models?

Custom inline skates are constructed to individual specifications, accommodating unique foot dimensions and skating styles. Standard models are mass-produced, potentially compromising fit and performance.

Question 2: How does the customization process impact performance?

Personalization enhances performance through optimized power transfer, improved comfort, and reduced foot fatigue. These factors contribute to increased efficiency and control.

Question 3: What are the key components involved in skate customization?

The customization process typically involves selecting or modifying the boot, frame, wheels, bearings, and liner to meet individual requirements.

Question 4: Is professional assistance necessary for customizing skates?

Consultation with experienced skate technicians is highly recommended, particularly for complex modifications. Professional guidance ensures proper fit and component selection.

Question 5: What is the approximate cost associated with custom inline skates?

The cost varies depending on the components selected and the extent of customization. Prices generally exceed those of standard models due to specialized labor and materials.

Question 6: How does maintenance differ for custom inline skates compared to standard models?

Maintenance procedures are generally similar, but custom skates may require more frequent adjustments to maintain optimal fit and performance. Inspection and care are crucial for extending the lifespan of specialized components.

In summary, opting for personalized rolling footwear provides skaters with considerable benefits. An informed understanding is a necessary element to ensure optimized output.

The subsequent section will offer an overview of the long-term performance and durability of custom inline skates.

Conclusion

This exploration has highlighted critical aspects of personalized rolling footwear, emphasizing the importance of tailoring equipment to individual needs and skating styles. From boot fit optimization to wheel durometer variation and bearing precision, the process of constructing custom inline skates demands meticulous attention to detail. The selection of appropriate materials and components directly impacts performance, comfort, and longevity, ultimately shaping the skating experience.

The decision to invest in custom inline skates represents a commitment to optimizing athletic performance and maximizing enjoyment. While the initial cost may exceed that of mass-produced alternatives, the benefits of enhanced fit, improved control, and reduced fatigue warrant serious consideration. Further research and professional consultation are encouraged to fully understand the potential advantages of custom-built equipment, allowing for a tailored approach that meets specific objectives.