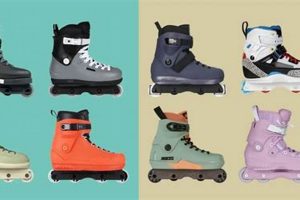

Specialised footwear designed for performing stunts and tricks within designated skate parks or urban environments. These adapted boots prioritize durability, support, and responsiveness, differing significantly from recreational models. An example is a boot with reinforced panels, a robust frame, and specialized wheels for grinding on rails and ledges.

The importance of equipment designed for the unique demands of this activity cannot be overstated. Such equipment provides enhanced protection against impact, enabling more ambitious maneuvers. Historically, these types of skates evolved from modified recreational models, eventually leading to purpose-built designs capable of withstanding intense stresses.

Subsequent sections will detail the component parts of these specialized skates, exploring customization options, the selection process, and maintenance requirements. These aspects are vital for optimizing performance and longevity.

Optimizing Performance and Longevity

The following recommendations are designed to maximize the utility and lifespan of the specialized equipment used in aggressive inline skating. Adherence to these guidelines will contribute to enhanced performance and reduce the risk of equipment failure.

Tip 1: Frame Selection. The frame, the component connecting the wheels to the boot, should be chosen based on skating style and preferred obstacle types. A longer frame provides stability for larger obstacles, while a shorter frame offers greater maneuverability for intricate tricks. Evaluate frame materials for impact resistance and weight.

Tip 2: Wheel Hardness. Wheel durometer, measured on the ‘A’ scale, influences grip and speed. Harder wheels (90A and above) are suitable for smooth surfaces and offer greater speed. Softer wheels (86A and below) provide enhanced grip on rougher terrains, but wear more rapidly.

Tip 3: Bearing Maintenance. Bearings facilitate wheel rotation. Regular cleaning and lubrication are essential. Remove bearings from wheels, clean with a solvent, and re-lubricate with bearing-specific oil. Contaminated bearings will degrade performance and potentially lead to premature failure.

Tip 4: Boot Support. The boot provides ankle support and impacts control. Ensure a snug fit without restricting circulation. Consider boots with adjustable straps or buckles for customized support. Inspect boots regularly for signs of wear or structural damage.

Tip 5: Hardware Inspection. Fasteners connecting the frame to the boot should be checked regularly for tightness. Loose hardware can compromise stability and lead to equipment failure. Replace worn or damaged fasteners immediately.

Tip 6: Grind Plate Integrity. Grind plates, designed for sliding on obstacles, are subject to considerable wear. Inspect for cracks or excessive abrasion. Replace grind plates when their integrity is compromised.

The implementation of these recommendations will contribute to a more efficient, safer, and prolonged skating experience. Regular maintenance and informed component selection are vital considerations.

The subsequent section will address the process of selecting a setup that meets individual requirements.

1. Boot Stiffness

Boot stiffness, a critical parameter, directly influences the performance characteristics of aggressive inline skates. Stiffer boots provide increased ankle support, enhancing stability during landings from aerial maneuvers and while navigating uneven surfaces. The rigidity minimizes ankle flexion, facilitating more efficient energy transfer during jumps and grinds. A stiffer boot can also offer greater protection against impact, reducing the risk of injury during falls or collisions. For example, skaters performing complex tricks involving high impacts often prefer boots constructed with rigid composite materials. The inverse is that a boot that is too stiff can reduce dexterity.

Conversely, excessively stiff boots can restrict ankle mobility, potentially hindering the execution of certain technical tricks requiring greater flexibility. Therefore, selecting boot stiffness must be balanced with individual skating style and preferred terrain. Skaters focusing on rail grinds may benefit from a slightly less rigid boot, providing improved feel and control. The boot’s upper design and lacing system also contribute to the overall stiffness profile, allowing for further customization to achieve optimal performance.

In summation, boot stiffness is a crucial element influencing both performance and safety. It’s an element that also affects the lifespan of the inline skate. Selecting the appropriate stiffness requires careful consideration of skating style and individual preferences, balancing the need for support with the need for maneuverability. Understanding the cause and effect on the skating mechanics allows one to customize a fit that works best. The trade-off is that there isn’t a “one size fits all” stiffness. The boot must allow the foot to function naturally.

2. Frame Material

The frame material fundamentally determines the structural integrity, weight, and responsiveness of aggressive inline skates. This component, responsible for connecting the wheels to the boot, experiences substantial stress during grinds, jumps, and landings. The choice of material directly impacts the skate’s ability to withstand these forces and maintain consistent performance. For example, aluminum frames, known for their high strength-to-weight ratio, are commonly used by experienced skaters who require maximum durability for demanding tricks. In contrast, composite frames offer a lighter alternative, potentially enhancing maneuverability, but may sacrifice some structural resilience. The frame also impacts alignment which would then impact overall skate experience.

Further impacting performance, different materials exhibit varying degrees of vibration dampening. Aluminum frames tend to transmit more vibrations from rough surfaces compared to composite frames, potentially affecting comfort and control. Material properties influence the skate’s responsiveness, defined as the speed and precision with which it translates the skater’s movements into action. Stiffer materials, like aluminum, generally provide a more direct and immediate response, while more flexible composites can offer a softer, more forgiving feel. Custom aggressive inline skates can be tailored to individual preferences by carefully selecting frame materials that align with desired performance characteristics and skating style. For example, someone who prefers more flexibility and dampening might go with a composite frame, while someone looking for power might prefer the stiffer aluminum.

Understanding frame material properties is crucial for selecting skates optimized for specific skating styles and terrain. The decision involves balancing durability, weight, vibration dampening, and responsiveness to achieve the desired performance profile. Neglecting material considerations can lead to equipment failure, reduced performance, and potentially increased risk of injury. Therefore, careful assessment of frame material is an integral part of the skate selection process, contributing to both performance optimization and the long-term reliability of the aggressive inline skates. The overall performance of aggressive inline skates is correlated with the quality of the frame material used.

3. Wheel durometer

Wheel durometer, a measure of a wheel’s hardness, is a critical factor in the performance and feel of custom aggressive inline skates. Measured on the ‘A’ scale, this property dictates the wheel’s grip, speed, and durability. The appropriate durometer selection depends heavily on the skater’s style, the surfaces skated on, and the desired performance characteristics.

- Grip vs. Speed

Softer wheels (lower durometer, e.g., 86A) provide increased grip, which is beneficial on slick or uneven surfaces. However, they also exhibit greater rolling resistance, reducing speed. Harder wheels (higher durometer, e.g., 90A or higher) offer lower rolling resistance, resulting in higher speeds on smooth surfaces, but sacrificing grip. For instance, a skater focused on park skating may prefer harder wheels for speed and controlled slides, while a skater navigating rougher street terrain might opt for softer wheels for better grip and shock absorption.

- Durability and Wear

Wheel durometer also affects durability. Softer wheels tend to wear down more quickly, especially on abrasive surfaces. Harder wheels, while more durable, may be more prone to chipping or cracking upon impact. The choice between durability and grip involves a trade-off dependent on skating frequency, terrain, and desired longevity. For example, a skater performing frequent grinds on rough concrete will likely experience faster wear on softer wheels compared to a skater primarily skating smooth skatepark ramps.

- Impact Absorption

Softer wheels offer superior impact absorption compared to harder wheels. This characteristic is advantageous for mitigating vibrations and reducing stress on joints, particularly when landing jumps or skating on uneven terrain. Skaters with joint sensitivities or those performing high-impact maneuvers may prioritize softer wheels for enhanced comfort and reduced risk of injury. The difference in impact absorption is significant when comparing an 86A wheel to a 92A wheel; the softer wheel provides a noticeably smoother ride.

- Grind Performance

While durometer primarily affects rolling performance, it also indirectly impacts grind performance. Harder wheels, due to their lower rolling resistance, facilitate faster and more controlled slides on coping or rails. However, softer wheels can provide a more forgiving feel, especially for beginner skaters learning to grind. The optimal durometer for grinding depends on individual skill level, preferred grind styles, and the surface characteristics of the obstacles. Some skaters prefer harder wheels that lock into grinds on coping, others prefer the buttery feel of softer wheels on various surfaces.

In conclusion, the selection of wheel durometer is a nuanced decision with significant implications for custom aggressive inline skate performance. The optimal choice depends on balancing grip, speed, durability, impact absorption, and grind performance according to individual skating style, terrain, and preferences. Thoughtful consideration of these factors ensures a more enjoyable and efficient skating experience while optimizing equipment lifespan.

4. Bearing Precision

Bearing precision, quantified using the Annular Bearing Engineers’ Committee (ABEC) scale (or equivalent ISO/DIN standards), critically affects the performance of aggressive inline skates. Higher ABEC ratings (e.g., ABEC-7 or ABEC-9) indicate tighter manufacturing tolerances, resulting in reduced friction and increased rotational efficiency. This translates to greater speed and smoother rolling characteristics, essential for executing complex tricks and maintaining momentum within skate parks or urban environments. For instance, skaters performing aerial maneuvers require bearings that maintain consistent speed throughout the trick, and higher precision bearings contribute to this stability.

However, the benefits of high-precision bearings must be considered in the context of the operating environment. Aggressive skating exposes bearings to significant impact loads, dirt, and debris. While high-precision bearings offer optimized performance under ideal conditions, their tighter tolerances can render them more susceptible to contamination and damage compared to lower-precision bearings (e.g., ABEC-3 or ABEC-5). A real-world example is a skater repeatedly landing hard on a ramp; the impact can deform high-precision bearing components, negating any initial performance advantage. The bearings lubrication also plays an important role. The ability of the bearing to be easily serviced and relubricated to remove contaminants is often overlooked.

Therefore, selecting bearing precision involves a trade-off between performance and durability. While high-precision bearings may offer a marginal increase in speed and smoothness under optimal circumstances, their vulnerability to damage in aggressive skating environments can limit their practical lifespan. A pragmatic approach balances precision with robustness, considering factors such as skating frequency, terrain, and maintenance practices. Moreover, proper bearing maintenance, including regular cleaning and lubrication, is paramount for maximizing the lifespan and performance of any bearing, regardless of its precision rating. Prioritizing ruggedness and ease of service, rather than solely focusing on the highest ABEC rating, can prove more beneficial for most aggressive inline skaters, contributing to both performance and cost-effectiveness.

5. Grind Plate Type

The grind plate is a component of aggressive inline skates that facilitates sliding on obstacles such as rails, ledges, and coping. Its design and material composition significantly influence a skater’s ability to execute grind tricks, impacting speed, control, and the longevity of the skate’s structure. Selection of a specific grind plate type directly contributes to the customisation of skates based on individual skating styles and preferred terrain. Grind plates also protect other components like the frame from damage.

- Material Composition and Grind Characteristics

Grind plates are typically constructed from durable plastics, composites, or, less commonly, metal alloys. The material dictates the plate’s sliding properties and resistance to wear. High-density polyethylene (HDPE) plates, for example, offer a balance between speed and durability, suitable for a variety of surfaces. Nylon-based plates may provide smoother grinds on rougher textures but might exhibit faster wear. The specific material dictates the texture of the grind.

- Shape and Profile Design

The shape of the grind plate influences the types of grinds that can be performed effectively. Flat plates provide stability for cess slides and similar tricks, while contoured plates with grooves or channels facilitate locking onto specific obstacles. Aggressive profiles allow for easier engagement with coping, whereas a flatter design may be advantageous for wider rails. The shape allows certain movements to occur more naturally and be easier to execute.

- Mounting System and Compatibility

Grind plates attach to the skate frame using various mounting systems, including screws, rivets, or integrated designs. Compatibility between the grind plate and frame is paramount. Universal plates are designed to fit a wide range of skate models, while proprietary plates are specific to certain brands or frame types. Secure and flush mounting is essential to prevent interference with wheel rotation or instability during grinds.

- Impact on Skate Longevity

Grind plates serve as a sacrificial layer, protecting the underlying frame from abrasion and impact damage. By absorbing the brunt of wear during grinds, they extend the lifespan of the skate. Regularly replacing worn grind plates prevents damage to more expensive components, maintaining the overall performance and integrity of the custom aggressive inline skates.

In conclusion, the selection of grind plate type is a critical decision when assembling custom aggressive inline skates. Material, shape, mounting system, and the protective function of the plate directly influence grind performance, skate longevity, and overall skating experience. Skaters should carefully consider their preferred style and common grind surfaces when choosing a grind plate to optimize their equipment for maximum performance and durability.

Frequently Asked Questions About Custom Aggressive Inline Skates

This section addresses commonly asked questions regarding the selection, maintenance, and customization of aggressive inline skates. The information is intended to provide clarity and assist in making informed decisions.

Question 1: What distinguishes aggressive inline skates from recreational models?

Aggressive inline skates are specifically engineered for high-impact maneuvers, incorporating reinforced frames, durable wheels, and specialized grind plates. Recreational skates prioritize comfort and general mobility, lacking the robust construction required for aggressive skating.

Question 2: How often should bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage and environmental conditions. Generally, cleaning and lubrication are recommended every 2-4 weeks for regular skaters or immediately following exposure to water or debris. Neglecting maintenance can lead to premature bearing failure.

Question 3: What is the significance of wheel durometer?

Wheel durometer, measured on the ‘A’ scale, indicates wheel hardness. Lower durometer wheels offer greater grip and shock absorption, while higher durometer wheels provide increased speed and durability. The appropriate durometer depends on skating style and surface conditions.

Question 4: Can aggressive skate frames be replaced?

Yes, the frame is a replaceable component. Frame replacement allows for customization based on skating style and obstacle preferences. Frame selection should consider material, length, and mounting compatibility with the boot.

Question 5: How do grind plates contribute to skate longevity?

Grind plates protect the frame and boot from abrasion during grind tricks. They serve as a sacrificial layer, absorbing wear and extending the lifespan of the underlying skate components. Worn grind plates should be replaced promptly.

Question 6: What factors should be considered when selecting a skate boot?

Boot selection should prioritize fit, support, and durability. A snug fit without restricting circulation is essential. Ankle support is crucial for stability during landings. Material selection impacts durability and impact resistance.

In summary, proper maintenance, informed component selection, and understanding the intended skating environment are crucial for optimizing the performance and longevity of aggressive inline skates.

The subsequent section will focus on advanced customization techniques and emerging trends in the aggressive inline skating community.

Concluding Remarks on Aggressive Inline Skate Customization

This exploration has detailed the critical elements of optimizing specialized equipment, including frame selection, wheel durometer, bearing precision, boot support, hardware maintenance, and grind plate integrity. Informed decisions regarding these components are paramount for maximizing performance, enhancing safety, and extending the lifespan of equipment designed for aggressive maneuvers.

The continued evolution of specialized skating equipment necessitates ongoing evaluation of design and materials. Prioritizing safety, durability, and performance will ensure the continued growth and progression of the sport. A dedication to understanding and implementing best practices in equipment selection and maintenance is essential for all participants.

![True Inline Skates: Performance & Speed [Expert Guide] How to Skateboard: A Beginner's Guide to Your First Board & Tricks True Inline Skates: Performance & Speed [Expert Guide] | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-493-300x200.jpg)

![Best Chicago Skates Inline Skates: [Year] Guide & More! How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Chicago Skates Inline Skates: [Year] Guide & More! | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-470-300x200.jpg)