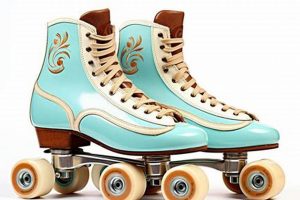

These specialized athletic shoes, designed for use on hard, flat surfaces, offer mobility similar to ice skates but without the need for ice. These products, manufactured by a well-known sporting goods company, incorporate wheels attached to the boot, allowing users to glide and maneuver on concrete, asphalt, or other smooth terrains. For example, individuals might use this type of equipment for recreational skating, roller hockey, or fitness training.

The appeal of this equipment lies in its ability to provide a low-impact workout, enhance agility, and offer a fun, engaging way to stay active. Historically, roller skating has served as both a popular pastime and a competitive sport. The introduction of high-performance designs and materials has further elevated their usability for serious athletes and recreational users alike, enabling improved speed, control, and durability.

Subsequent sections will delve into the specific features, technological advancements, and consumer considerations associated with this type of product, providing a detailed overview of their applications and impact within the broader context of roller sports and fitness.

Equipment Maintenance and Optimization

This section provides guidance on ensuring optimal performance and longevity of the equipment.

Tip 1: Wheel Rotation. Regularly rotate the wheels to ensure even wear and prolong their lifespan. Implement a consistent rotation pattern, such as swapping wheels from front to back and from inside to outside. This prevents uneven wear patterns that can affect performance and stability.

Tip 2: Bearing Maintenance. Clean and lubricate the bearings periodically. Remove the bearings from the wheels and use a specialized bearing cleaner to remove dirt and debris. Apply a small amount of lubricant designed for bearings to reduce friction and enhance speed.

Tip 3: Frame Alignment. Inspect the frame alignment regularly. Misalignment can cause uneven wear and reduce efficiency. Adjust the frame mounting bolts as needed to ensure proper alignment.

Tip 4: Boot Care. Keep the boot clean and dry. Wipe down the boot after each use to remove sweat and dirt. Allow the boot to air dry completely to prevent the growth of bacteria and mold.

Tip 5: Hardware Inspection. Routinely check all bolts and fasteners for tightness. Loose hardware can lead to instability and potential injury. Tighten any loose components to the manufacturer’s recommended torque specifications.

Tip 6: Brake Maintenance (if applicable). Replace the brake pad when it becomes worn. A worn brake pad reduces stopping power and can compromise safety. Use a replacement brake pad that is compatible with the model.

Adhering to these maintenance practices ensures the user maximizes the investment and maintains the equipment in peak operating condition. Consistent care promotes safety, performance, and longevity.

The following sections will explore advanced techniques and further considerations for optimizing performance and enhancing the overall experience.

1. Durability

The correlation between durability and athletic roller equipment significantly influences performance, safety, and overall cost-effectiveness. Equipment subjected to the stresses of frequent use, aggressive maneuvers, and varied environmental conditions requires robust construction. The materials selected, the manufacturing processes employed, and the overall design directly impact the equipment’s ability to withstand wear and tear, resist impacts, and maintain structural integrity over time. For example, a frame constructed from high-grade aluminum alloy is inherently more resistant to bending or cracking than a frame made from lower-quality materials. Similarly, wheels manufactured with high-rebound polyurethane are less prone to chunking or delamination compared to wheels made from less resilient polymers.

Practical significance extends beyond the initial purchase price. Equipment with greater durability typically requires less frequent replacement of components and fewer repairs, resulting in lower long-term operating expenses. Moreover, durable equipment enhances user safety by minimizing the risk of catastrophic failures during use. A wheel disintegrating at high speed, or a frame fracturing during a jump, can result in serious injury. Therefore, the quality and strength of materials used is of paramount importance.

In conclusion, durability is not merely a desirable attribute, but an essential characteristic that impacts performance, safety, and economic considerations. Investments in equipment crafted with high-quality materials and employing robust construction techniques translate into long-term value, enhanced safety, and a more consistent and reliable user experience. Considerations during purchase or upgrade should weigh these factors heavily to maximize benefits and avoid potential issues associated with inferior components.

2. Wheel Composition

Wheel composition is a critical determinant of performance characteristics for athletic equipment designed for hard surfaces. The materials used in the construction of these wheels directly influence speed, grip, durability, and overall user experience. Polyurethane (PU) is the most prevalent material, its properties allowing for tailored performance through variations in hardness and rebound. Harder compounds reduce rolling resistance and increase speed, while softer compounds offer enhanced grip and shock absorption. In the context of equipment from specific sporting goods company, the selection of wheel compound reflects the intended use case, whether recreational skating, aggressive maneuvers, or competitive roller hockey. An improper wheel choice will negatively affect performance.

The durometer, measured on the A scale, quantifies wheel hardness. Recreational wheels often fall within the 78A-85A range, providing a balance of grip and speed for various surfaces. Roller hockey wheels, conversely, typically range from 82A-88A or higher, prioritizing speed and responsiveness on smooth, indoor surfaces. Aggressive wheels, designed for skate parks and ramps, may feature specialized cores and formulations to withstand high impacts and grinding forces. For example, dedicated roller hockey models might implement dual-durometer designs, where a harder outer layer promotes speed and a softer inner layer enhances grip during quick turns. A practical result is a rider with more stability at faster speeds.

In conclusion, the selection of appropriate wheel composition for inline skates is crucial for optimizing performance and ensuring safety. Considerations include the skating surface, intended use, and desired balance of speed, grip, and durability. Understanding the relationship between wheel durometer, material properties, and skating dynamics allows users to make informed decisions, enhancing their experience and achieving their desired outcomes. Improper selection can cause an unexpected fall, thus leading to injury. Wheel selection for a device is of paramount importance.

3. Bearing Precision

Bearing precision within equipment significantly affects performance characteristics. The dimensional accuracy, material quality, and assembly tolerances of bearings directly influence rolling resistance, speed, and the overall smoothness of operation. Bearings with higher precision ratings, typically denoted by ABEC (Annular Bearing Engineering Committee) or ISO (International Organization for Standardization) standards, exhibit tighter tolerances and reduced internal clearances. This results in lower friction, increased efficiency, and the capacity to sustain higher speeds with minimal vibration or heat generation. The consequences are clear, with more accuracy the skate will glide smoothly.

In the context of athletic equipment, such as roller skates, the selection of bearing precision plays a crucial role. Higher precision bearings are often preferred by competitive skaters or individuals seeking optimal performance. Lower friction translates into increased speed and reduced energy expenditure, allowing skaters to maintain higher velocities for longer periods. Conversely, lower precision bearings may be more suitable for recreational use or beginners, where cost considerations outweigh the need for maximum performance. Real-world scenarios often involve a trade-off between price, durability, and performance. For example, the selection of ABEC 7 or ABEC 9 bearings over ABEC 3 bearings can provide a noticeable performance boost, but may also require more frequent maintenance and replacement.

In summary, bearing precision is a key factor influencing equipment performance. It contributes to speed, efficiency, and overall user experience. The choice of bearing precision should align with the skater’s skill level, intended use, and budget considerations. Proper maintenance and timely replacement of bearings are essential to sustain performance and ensure safety. Precision bearings are essential in skating devices and make the ride smooth.

4. Frame Material

The frame, a critical component of any athletic skating device, directly influences performance characteristics, durability, and overall user experience. Material selection for the frame impacts weight, stiffness, vibration damping, and resistance to stress. The following details discuss key aspects of frame material in the context of these specialized athletic skates.

- Aluminum Alloys

Aluminum alloys are commonly used due to their high strength-to-weight ratio. Different aluminum alloys (e.g., 6061, 7005) offer varying degrees of stiffness and resistance to fatigue. Higher-grade alloys provide enhanced power transfer and responsiveness, particularly beneficial for competitive skating. In professional roller hockey, for instance, players often prefer frames made from high-strength aluminum to withstand the rigors of aggressive gameplay.

- Composite Materials

Composite materials, such as carbon fiber, offer exceptional stiffness and vibration damping properties. Carbon fiber frames are typically lighter than aluminum frames, enhancing agility and reducing fatigue. These frames are prevalent in high-end models, where weight reduction is a primary concern. However, composite materials can be more susceptible to impact damage compared to aluminum.

- Extrusion vs. Cast Frames

Frames can be manufactured using extrusion or casting processes. Extruded frames generally offer higher strength and dimensional accuracy due to the uniform grain structure of the material. Cast frames, while potentially more cost-effective to produce, may exhibit lower strength and increased porosity. Extruded frames are often favored in performance-oriented models.

- Frame Length and Configuration

Frame length and wheel configuration influence maneuverability and stability. Shorter frames enhance agility, while longer frames provide greater stability at higher speeds. Different wheel configurations (e.g., flat, hi-lo) cater to specific skating styles and performance requirements. For example, a hi-lo configuration, with larger wheels at the rear, is common in roller hockey to improve acceleration and cornering.

The selection of frame material is a critical decision that depends on the intended use, performance requirements, and budget considerations. Aluminum alloys offer a balance of strength, weight, and cost, while composite materials provide superior performance at a premium price. Extrusion and casting processes, along with frame length and wheel configuration, further contribute to the overall performance characteristics of athletic skating equipment.

5. Boot Comfort

Boot comfort is a paramount consideration in the design and functionality of athletic skating equipment. It directly impacts performance, endurance, and the overall user experience. Ill-fitting or uncomfortable boots can lead to blisters, chafing, and decreased performance, ultimately hindering the skater’s ability to perform optimally. The interaction between the boot and the foot significantly influences the efficiency of power transfer, stability, and control.

- Liner Material and Padding

The material composition and thickness of the boot liner play a vital role in providing cushioning and reducing friction. High-quality liners, often made from moisture-wicking fabrics and incorporating gel or foam padding, conform to the foot’s contours, minimizing pressure points and maximizing comfort. Inadequate padding can result in discomfort and potential injury, especially during prolonged use. The selection of appropriate liner material contributes significantly to thermal regulation and moisture management, preventing overheating and reducing the risk of blisters.

- Boot Shell Construction and Rigidity

The boot shell’s construction and rigidity impact support and responsiveness. Stiffer shells provide enhanced ankle support and power transfer, while more flexible shells offer increased comfort and range of motion. The optimal balance between support and flexibility depends on the skater’s skill level and skating style. A shell that is too rigid can restrict movement and cause discomfort, while a shell that is too flexible may lack the necessary support for aggressive maneuvers. Molded shells contribute significantly to a well-adjusted fit.

- Closure Systems and Adjustability

Closure systems, such as laces, buckles, and straps, enable users to customize the fit and secure the foot within the boot. Well-designed closure systems allow for precise adjustments, ensuring a snug and comfortable fit without restricting circulation. The placement and design of buckles and straps minimize pressure points and maximize support. Inadequate closure systems can lead to heel lift, slippage, and decreased control.

- Ventilation and Breathability

Adequate ventilation and breathability are crucial for maintaining thermal comfort and reducing moisture buildup inside the boot. Ventilation systems, such as strategically placed vents and breathable materials, promote airflow and facilitate the evaporation of sweat. Insufficient ventilation can result in overheating, excessive perspiration, and increased discomfort. Proper ventilation contributes to reduced fatigue and enhanced overall comfort, particularly during extended skating sessions.

Boot comfort is a multifactorial attribute that depends on the interplay of liner material, shell construction, closure systems, and ventilation. Skaters should prioritize fit and comfort when selecting athletic skating equipment to maximize performance, minimize the risk of injury, and enhance the overall skating experience. Manufacturers who emphasize ergonomic designs and high-quality materials are more likely to produce boots that offer exceptional comfort and performance.

6. Ankle Support

Ankle support is a critical design element, directly impacting safety, stability, and performance. The structure of the equipment is designed to provide lateral and medial stabilization, preventing excessive pronation or supination during dynamic movements. Insufficient ankle support can lead to increased risk of sprains, strains, and other injuries, particularly during high-intensity activities. The boot’s rigidity, lacing system, and cuff height are all engineered to optimize ankle stability and control.

The significance of robust ankle support is amplified in activities such as roller hockey, where quick turns, sudden stops, and aggressive maneuvers place considerable stress on the ankle joint. A well-designed boot minimizes the likelihood of ankle rolling or twisting, allowing skaters to maintain balance and execute precise movements. For example, professional roller hockey players often prefer models with reinforced ankle cuffs and strategically placed padding to enhance protection and stability. A skate’s ankle support is designed to work synergistically, offering greater protection.

Adequate ankle support is a prerequisite for maximizing performance and minimizing the risk of injury. Skaters should prioritize fit and support when selecting athletic equipment to ensure stability and control during dynamic movements. Proper boot selection, combined with appropriate training and conditioning, contributes to enhanced athletic performance and reduced risk of ankle-related injuries. Skates with high ankle support lead to fewer ankle injuries and more success in athletic activities.

7. Braking System

The integration of a braking system within athletic roller equipment constitutes a crucial safety feature, directly impacting the user’s ability to control speed and prevent collisions. The braking mechanism typically consists of a brake pad attached to the frame near the heel, which is engaged by lifting the toe of the boot. Effective braking systems must provide consistent stopping power across various surface conditions and user weights. For example, a worn brake pad significantly reduces stopping distance and increases the risk of accidents, highlighting the importance of regular inspection and maintenance.

The design and positioning of the braking system influences maneuverability and overall performance. Systems that protrude excessively can hinder agility and interfere with certain skating techniques. Conversely, systems that are too small or poorly positioned may offer insufficient stopping power, compromising safety. Consider a scenario in which a skater encounters an unexpected obstacle; a responsive braking system allows for rapid deceleration, mitigating the potential for a collision. The placement, size, and the material used in the braking system are pivotal to maintaining user safety.

In conclusion, the braking system is an indispensable component, playing a vital role in mitigating risks and ensuring controlled deceleration. Routine maintenance and timely replacement of worn parts are essential for maintaining braking effectiveness. The interplay between braking system design, material selection, and user technique determines the overall safety and performance of athletic skating equipment. Without the braking system in working order, severe injury may occur when using these athletic devices.

Frequently Asked Questions About Athletic Roller Equipment

The following section addresses common inquiries regarding the selection, maintenance, and use of these specialized athletic skates. It aims to provide clear and concise answers to frequently asked questions, promoting informed decision-making and safe usage practices.

Question 1: How frequently should the wheels on these athletic skates be rotated?

Wheel rotation frequency depends on usage intensity and skating surface. Under typical recreational conditions, rotation every 2-4 weeks is recommended to ensure even wear. Competitive skaters may require more frequent rotation based on training volume.

Question 2: What is the recommended method for cleaning the bearings in this type of equipment?

Bearing cleaning involves removing the bearings from the wheels, soaking them in a specialized bearing solvent, and allowing them to air dry completely. Subsequent lubrication with a suitable bearing oil is essential for optimal performance.

Question 3: What are the primary indicators that the brake pad requires replacement?

Brake pad replacement is necessary when the pad thickness is significantly reduced, or the stopping distance is noticeably increased. Visual inspection for wear is a reliable indicator. Regular brake pad checks are recommended.

Question 4: How does wheel durometer affect the performance of athletic roller equipment?

Wheel durometer, measured on the A scale, indicates wheel hardness. Lower durometer wheels offer greater grip and shock absorption, while higher durometer wheels provide increased speed and reduced rolling resistance. The appropriate durometer depends on the skating surface and intended use.

Question 5: What type of ankle support is most suitable for high-intensity roller hockey?

High-intensity roller hockey necessitates robust ankle support. Boots with reinforced ankle cuffs, strategically placed padding, and secure closure systems are recommended to prevent ankle injuries and maintain stability during aggressive maneuvers.

Question 6: What measures can be taken to prevent blisters when using new athletic roller skates?

Preventative measures include wearing moisture-wicking socks, ensuring proper boot fit, and using blister prevention products, such as adhesive bandages or skin lubricants, on friction-prone areas. Gradual break-in of new boots is also advisable.

In summary, adherence to recommended maintenance practices, proper selection of components, and attention to fit and support are essential for maximizing performance, ensuring safety, and prolonging the lifespan of athletic roller skates.

The following sections will explore advanced topics related to customization, performance enhancement, and competitive applications.

Conclusion

This exploration has detailed various aspects of athletic roller equipment, focusing on key features such as durability, wheel composition, bearing precision, frame material, boot comfort, ankle support, and braking systems. A comprehensive understanding of these components is essential for making informed decisions regarding purchase, maintenance, and optimal usage.

As technology advances and user needs evolve, continuous improvements in design and materials will further enhance the performance and safety. Therefore, continued research, development, and user education will be crucial in advancing the field. Ultimately, the ongoing pursuit of excellence will ensure a positive and safe experience for all users, whether they are recreational skaters or competitive athletes.