Unpainted, often unbranded, skateboard platforms provide a canvas for skaters and artists alike. These items, constructed from laminated layers of maple wood, offer a standardized shape and size, enabling customization through graphics, paint, or grip tape designs. They represent the foundational element upon which a personalized skateboarding experience is built.

The absence of pre-applied designs allows for creative freedom and cost-effectiveness. Historically, the use of such platforms has been prevalent within skateboarding subcultures valuing individuality and DIY ethics. Moreover, these products present opportunities for smaller skate companies and individual artists to offer unique designs without the overhead costs associated with in-house deck production.

The subsequent sections will delve into the manufacturing processes involved, the various shapes and sizes available, and the diverse range of customization options applicable to these platforms, offering a thorough understanding of their significance within the skateboarding community.

Tips for Selecting and Utilizing Unbranded Skateboard Platforms

The following guidance aims to inform potential users on optimal selection and preparation techniques when working with unfinished skateboard platforms, ensuring both performance and aesthetic satisfaction.

Tip 1: Wood Quality Assessment: Inspect the deck for delamination, warping, or knots in the wood. These imperfections can compromise structural integrity and negatively impact performance. Quality maple wood with consistent grain is paramount.

Tip 2: Shape and Size Considerations: Choose a deck shape and size that aligns with intended skateboarding style and rider experience level. Wider decks offer greater stability, while narrower decks may be more responsive for technical maneuvers.

Tip 3: Surface Preparation is Crucial: Lightly sand the surface of the deck prior to applying paint or graphics. This enhances adhesion and ensures a smooth, professional finish. Use a fine-grit sandpaper (220-grit or higher) and sand in the direction of the wood grain.

Tip 4: Grip Tape Application Techniques: Apply grip tape carefully, avoiding air bubbles and ensuring complete coverage of the designated area. Use a sharp blade to trim excess material after adhesion, creating clean, defined edges.

Tip 5: Sealing and Protection: After applying graphics, consider applying a clear coat sealant to protect the design from wear and tear. Select a sealant compatible with the chosen paint or graphic medium.

Tip 6: Hardware Compatibility Verification: Ensure compatibility between the deck’s mounting holes and the chosen trucks and hardware. Incorrect hardware can lead to instability and potential equipment failure.

Proper selection and preparation are crucial for achieving optimal performance and longevity from these platforms. Attention to detail during these stages directly influences the overall skateboarding experience.

The subsequent section will explore the artistic and entrepreneurial opportunities these platforms present, furthering the comprehensive understanding of their multifaceted role within the skateboarding ecosystem.

1. Wood Composition

Wood composition constitutes a pivotal determinant of performance and longevity in unfinished skateboard platforms. The selection and arrangement of wood veneers directly affect a deck’s strength, flexibility, and responsiveness.

- Maple Veneer Quality

High-quality maple veneers, typically sourced from North America, provide the requisite strength and resilience for skateboarding. The grade and density of the maple influence the deck’s ability to withstand impact and maintain its shape over time. Lower-quality maple may exhibit inconsistencies, leading to premature breakage or warping.

- Layer Orientation and Adhesive

The orientation of wood grain within each veneer layer contributes significantly to overall deck strength. Cross-grain layering provides resistance to bending and torsional forces. The adhesive used to bond the layers must maintain its integrity under stress and varying environmental conditions. Epoxy-based adhesives are generally preferred for their superior bond strength and water resistance.

- Pressing Process and Curing

The pressing process, which involves applying heat and pressure to the veneer stack, determines the deck’s final shape and density. Inconsistent pressure or temperature can result in structural weaknesses. Proper curing of the adhesive is essential for achieving optimal bond strength and preventing delamination.

- Impact on “Pop” and Durability

The wood composition directly influences a deck’s “pop,” referring to its ability to generate upward force during ollies and other aerial maneuvers. Denser, stiffer wood generally provides greater pop. However, excessive stiffness can reduce a deck’s ability to absorb impact, potentially leading to cracking or breakage. A balance between stiffness and flexibility is desirable for optimal performance and durability.

The interplay of these factors veneer quality, layer orientation, adhesive type, and pressing process dictates the overall performance characteristics of the skateboard platform. Consequently, understanding wood composition is paramount when selecting an unbranded skateboard platform, enabling informed decisions based on intended use and performance expectations.

2. Deck Concavity

Concavity, a fundamental aspect of skateboard deck design, significantly influences board feel and rider control. When applied to unbranded platforms, concavity becomes a customizable feature, impacting performance and catering to diverse skating styles. Understanding its nuances is essential for selecting the appropriate unfinished deck.

- Definition and Measurement of Concavity

Concavity refers to the curve across the width of the deck, rising from the edges toward the center. It is typically measured in millimeters or inches, with higher values indicating a more pronounced curve. This curvature provides pockets for a rider’s feet, enhancing grip and control during tricks and maneuvers.

- Influence on Foot Placement and Board Feel

The concavity dictates how a rider’s feet interface with the deck. A steeper concavity creates a more locked-in feel, facilitating precise foot placement and responsive board control. Conversely, a mellow concavity allows for greater foot freedom and a looser feel, suitable for cruising and flat ground tricks.

- Types of Concavity: U-Shape, Radial, and Progressive

Various concavity profiles exist, each offering distinct characteristics. U-shaped concavity features a consistent curve across the width of the deck, providing a predictable and uniform feel. Radial concavity, often found on older designs, has a more rounded, less defined curve. Progressive concavity transitions gradually from mellow to steep, offering a balance between foot freedom and control.

- Concavity’s Role in Flick and Board Control

Concavity contributes directly to the “flick” of the board during ollies and other flip tricks. The curve provides a leverage point for the rider’s foot, allowing them to generate spin and control the board’s rotation. A well-chosen concavity can improve consistency and ease of performing technical maneuvers.

The selection of an unfinished skateboard platform with a specific concavity is a crucial decision, influencing the rider’s connection to the board and their ability to execute tricks. The interplay between concavity type, foot placement, and board feel ultimately shapes the skateboarding experience, highlighting the importance of considering this factor when choosing a blank deck.

3. Shape Variation

Shape variation in unfinished skateboard platforms significantly impacts board handling and trick performance. Unbranded decks, available in diverse forms, allow skaters to select shapes best suited to their preferred style. Different forms directly affect turning responsiveness, stability, and foot placement.

For instance, the “popsicle” shape, characterized by symmetrical rounded ends, is prevalent for technical street skateboarding due to its balanced feel and consistent flick for flip tricks. “Old school” shapes, typically wider with a pointed nose and a squared-off tail, offer stability and are favored in transition skating. Cruiser shapes often incorporate a longer wheelbase and softer contours, intended for comfortable transportation. The design choice thus influences the type of skateboarding activity a user can successfully undertake.

In conclusion, shape variation is a critical component of these platforms. Understanding the effect of shape on board handling is vital for skaters selecting an appropriate platform. The diverse selection of shapes allows individuals to tailor equipment to meet specific functional needs and personal preferences, thereby impacting the overall skateboarding experience.

4. Grip Customization

Grip customization is an integral element of unfinished skateboard platforms, influencing board control and rider performance. The application of grip tape, a sandpaper-like material adhered to the deck’s surface, provides necessary friction between the skater’s shoes and the board. The absence of pre-applied grip on these decks allows for personalized application, catering to individual preferences and skateboarding styles. Variations in grip tape texture, coverage, and design contribute to a unique riding experience.

The texture of the grip tape affects the degree of traction. Coarser grit provides a stronger grip, suitable for technical tricks requiring precise foot placement. Finer grit offers a smoother feel, preferred by some for increased foot movement and comfort. Coverage patterns also influence functionality. Full coverage ensures maximum grip across the deck, while partial coverage, such as designs or cutouts, allows for visual customization and reduced weight. Custom grip patterns, incorporating shapes or logos, add a personal touch while maintaining grip performance. Many skaters utilize razors or specialized tools to cut designs directly into the grip tape, revealing the wood beneath. This technique creates a visual statement, while also subtly altering the grip surface.

In summary, grip customization is a critical process that enables skaters to tailor the functionality and appearance of their unfinished skateboard platforms. Through choices in grip tape texture, coverage, and design, riders can optimize board control and express individuality. The possibilities for creative expression are limitless; from basic functional grip placement to elaborately designed patterns and cutouts. This interplay between form and function makes grip customization a key aspect of the culture surrounding unfinished skateboard platforms.

5. Graphic Application

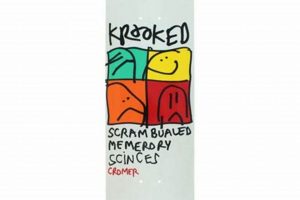

Graphic application on unfinished skateboard platforms provides a distinct avenue for personalization and artistic expression. The blank surface serves as a canvas, enabling individuals and brands to impart custom designs directly onto the deck. This process ranges from simple paint applications to sophisticated screen-printed graphics. The absence of pre-existing designs allows for complete creative control, fostering individuality within the skateboarding community. The resultant visual representation can communicate brand identity, personal beliefs, or simply aesthetic preferences.

The process itself involves careful preparation of the wood surface, often requiring sanding and sealing to ensure proper adhesion of paints or inks. Various techniques, including spray painting, stenciling, and digital printing, are employed to achieve desired effects. The durability of the graphic is paramount, necessitating the use of durable, weather-resistant materials. For example, professional skateboard companies frequently utilize heat-transfer graphics or multi-layered screen printing to withstand the rigors of skateboarding. These methods ensure that the design remains intact, resisting abrasion from shoes and environmental factors. Conversely, amateur designs might employ less durable paints, resulting in quicker degradation of the image.

In conclusion, graphic application is a defining characteristic of the blank skateboard platform. It transforms a functional object into a personalized statement. The methods used and the resulting aesthetic impact directly contribute to the value and appeal of the customized skateboard. This artistic process represents a tangible intersection of skateboarding culture, individual expression, and commercial branding, solidifying the connection between blank skate decks and visual design.

6. Truck Compatibility

Truck compatibility represents a critical consideration when assembling a skateboard using unfinished platforms. The proper alignment and fit between trucks and the deck’s mounting hardware directly impact the board’s stability, turning responsiveness, and overall safety. Mismatched components can lead to compromised performance and potential equipment failure.

- Mounting Hole Patterns (New School vs. Old School)

Skateboard decks adhere to standardized mounting hole patterns for trucks. The “New School” pattern, characterized by a tighter hole spacing, is prevalent on contemporary decks. Older decks may utilize the “Old School” pattern, featuring wider spacing. Ensuring the truck’s mounting holes align with the deck’s pattern is paramount. Utilizing incorrect mounting patterns can necessitate drilling new holes, potentially weakening the deck’s structure.

- Deck Width and Truck Hanger Width

The width of the deck should correspond appropriately with the truck hanger width. Trucks that are too narrow can result in instability and reduced leverage. Conversely, excessively wide trucks can create wheel bite, where the wheels make contact with the deck during turns. A suitable truck width generally allows the wheels to align closely with the deck’s edges, optimizing stability and maneuverability.

- Riser Pads and Wheel Clearance

Riser pads, typically constructed from plastic or rubber, are placed between the deck and trucks to increase wheel clearance and prevent wheel bite. These pads are particularly important when using larger wheels or decks with a lower ride height. Selecting the appropriate riser pad thickness ensures adequate clearance without compromising stability or board feel.

- Hardware Selection (Bolt Length and Type)

The hardware used to secure the trucks to the deck must be of the correct length and type. Bolts that are too short may not fully engage the truck’s baseplate, compromising stability. Overly long bolts can protrude beyond the nut, posing a safety hazard. Counter-sunk bolts are designed to sit flush with the deck’s surface, preventing interference with foot placement. Selecting the correct hardware is essential for ensuring a secure and safe connection between the trucks and the unfinished skateboard platform.

The interrelationship between mounting patterns, deck width, riser pads, and hardware defines the overall truck compatibility of a skateboard. Careful attention to these factors when pairing trucks with these platforms ensures optimal performance characteristics and rider safety. The integration of these components transforms a blank platform into a functional and personalized skateboarding instrument.

Frequently Asked Questions

The following questions address common inquiries concerning the selection, preparation, and customization of unfinished skateboard platforms. These answers aim to provide clarity and informed decision-making for both novice and experienced skateboarders.

Question 1: What is the typical lifespan of an unbranded skateboard platform?

The lifespan of a skateboard deck is contingent upon usage frequency, skateboarding style, and the quality of materials. Aggressive skateboarding, involving frequent impacts and street obstacles, typically reduces the deck’s lifespan compared to recreational cruising. High-quality maple decks, properly maintained, can last several months under normal use, while lower-quality decks may exhibit premature wear or breakage.

Question 2: How does deck concavity affect skateboarding performance?

Deck concavity dictates the rider’s foot placement and board feel. Steeper concavity provides a more locked-in feel, facilitating precise foot control for technical tricks. Mellow concavity allows for greater foot freedom and a looser feel, suitable for cruising and flat ground maneuvers. The selection of concavity is largely subjective and dependent on individual skating style.

Question 3: What are the advantages of applying grip tape to an unbranded skateboard platform?

Grip tape provides essential traction between the skater’s shoes and the deck surface, enhancing board control and stability. Custom application allows for personalized grip patterns and coverage levels, catering to individual preferences. Furthermore, grip tape can be easily replaced or adjusted to suit changing needs.

Question 4: What type of paint is recommended for customizing a blank skateboard platform?

Acrylic-based paints, specifically formulated for use on wood surfaces, are generally recommended for customizing decks. These paints offer good adhesion, durability, and a wide range of color options. A clear coat sealant is advised after painting to protect the graphic from wear and tear.

Question 5: How does the wood composition influence the deck’s performance characteristics?

Wood composition directly impacts a deck’s strength, flexibility, and responsiveness. High-quality maple veneers provide the requisite strength and resilience for skateboarding. The arrangement of wood grain and the adhesive used to bond the layers also contribute significantly to overall deck performance. Denser woods often lead to greater “pop”, while appropriate flexibility allows for impact absorption.

Question 6: What is the significance of proper truck alignment when assembling a skateboard?

Proper truck alignment ensures optimal stability, turning responsiveness, and safe operation. Mismatched mounting hole patterns or incorrect truck widths can compromise the board’s handling and potentially lead to equipment failure. Careful attention to truck compatibility is essential for creating a functional and reliable skateboard.

Understanding these fundamental aspects of unfinished skateboard platforms enables informed decisions and optimal customization. The interplay between material selection, deck design, and component integration directly impacts the skateboarding experience.

The subsequent section will explore various resources and suppliers for acquiring these platforms, furthering the comprehensive understanding of the market dynamics surrounding their production and distribution.

Conclusion

The preceding exploration of unfinished skateboard platforms has elucidated the multifaceted nature of these components within the skateboarding ecosystem. From material composition and design variations to customization techniques and compatibility considerations, a thorough understanding of these elements empowers informed decision-making. The functionality, durability, and aesthetic potential are directly influenced by choices made in selection and preparation.

As skateboarding continues to evolve, the significance of these platforms endures. Whether for artistic expression, personalized performance, or entrepreneurial ventures, the potential remains considerable. Further investigation into innovative materials, sustainable manufacturing practices, and evolving design trends will undoubtedly shape the future trajectory. A commitment to quality, safety, and responsible sourcing is paramount to ensuring continued relevance and positive impact within the skateboarding community.