A specialized storage apparatus designed to hold and organize wheeled boards used for the recreational activity of gliding. These structures can range from simple wall-mounted hooks to freestanding units capable of accommodating multiple boards. One common application involves securing these items in garages or public spaces to prevent obstruction and potential damage.

The implementation of such a system offers several advantages, including space optimization, enhanced safety, and the prevention of damage to both the boards and the surrounding environment. Historically, makeshift solutions were often employed, but purpose-built options have gained prominence due to their durability and aesthetic appeal. The use of such a system promotes responsible storage practices and contributes to a more organized environment.

The subsequent sections will explore the various types available, their construction materials, installation considerations, and best practices for maintaining them to ensure long-term functionality. These topics will provide a complete understanding of the features and benefits.

Usage and Maintenance Guidelines

The following guidelines provide valuable insights into optimizing the functionality and longevity of your storage solution for wheeled boards, ensuring both the preservation of the equipment and the safety of the surrounding area.

Tip 1: Material Considerations: Evaluate the construction material. Powder-coated steel offers enhanced durability and resistance to corrosion, particularly in outdoor settings. Wood, while aesthetically pleasing, may require regular sealing or treatment to prevent moisture damage.

Tip 2: Weight Capacity Assessment: Before installation, determine the total weight capacity required. Exceeding the recommended load limit can compromise structural integrity and lead to failure, potentially damaging the boards and creating a safety hazard.

Tip 3: Mounting Surface Evaluation: Prior to installation, assess the suitability of the mounting surface. Solid wood studs or concrete walls provide a more secure anchor than drywall alone. Use appropriate anchors designed for the specific wall type.

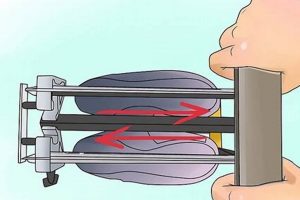

Tip 4: Board Orientation Optimization: When loading, consider the board’s orientation to maximize space efficiency and minimize potential contact between boards. Staggered placement can prevent scratching and other forms of damage.

Tip 5: Regular Cleaning Protocol: Implement a regular cleaning schedule to remove accumulated dirt, dust, and debris. A mild detergent and damp cloth are typically sufficient. Avoid abrasive cleaners that could damage the finish.

Tip 6: Hardware Inspection: Periodically inspect mounting hardware, such as screws and bolts, for signs of loosening or corrosion. Tighten or replace components as needed to maintain stability.

Tip 7: Environmental Protection: If the unit is located outdoors, consider a protective cover to shield it from prolonged exposure to sunlight, rain, and snow. This can extend its lifespan and prevent premature degradation.

Adhering to these recommendations can significantly improve the operational efficiency of the storage system and prolong its service life. Proactive maintenance will contribute to a safer and more organized environment, protecting valuable equipment.

The next section will address different styles, and aesthetic factors associated with the product.

1. Material Durability

The long-term utility and reliability of a wheeled board storage apparatus are intrinsically linked to the durability of the materials used in its construction. The ability to withstand environmental stressors, physical impacts, and prolonged usage is paramount for ensuring both the safety of the stored equipment and the longevity of the system itself.

- Corrosion Resistance

The susceptibility of a material to corrosion significantly impacts the overall lifespan. Outdoor units, in particular, are exposed to moisture, salt, and other corrosive elements. Materials such as powder-coated steel or marine-grade aluminum offer superior protection against rust and degradation, extending the rack’s service life. The absence of adequate corrosion resistance can lead to structural weakening and eventual failure.

- Impact Strength

The capacity to absorb impacts without fracturing or deforming is crucial. Wheeled boards, during placement or removal, may accidentally strike the structure. High-impact polymers or reinforced metals exhibit greater resistance to such forces, preventing cracks or breaks that could compromise the system’s integrity. Low impact strength increases the risk of damage from routine use.

- UV Resistance

Prolonged exposure to ultraviolet (UV) radiation can cause degradation in certain materials, leading to fading, embrittlement, and loss of structural integrity. This is particularly relevant for outdoor units made of plastic or certain types of wood. UV-resistant coatings or the selection of inherently UV-stable materials, such as high-density polyethylene (HDPE), are essential for maintaining the system’s appearance and performance over time.

- Load-Bearing Capacity

The material must possess sufficient strength to support the combined weight of the stored boards without bending, warping, or collapsing. Steel and reinforced composites generally exhibit superior load-bearing capabilities compared to lighter materials like untreated wood or thin-gauge plastics. An inadequate load-bearing capacity poses a significant safety risk and can lead to equipment damage.

The selection of materials with appropriate durability characteristics is not merely an aesthetic consideration but a fundamental requirement for ensuring the safe, reliable, and long-lasting performance of any wheeled board storage system. Investing in durable materials translates to reduced maintenance costs, enhanced safety, and a prolonged service life for the entire unit. Choosing the correct material is essential for outdoor use.

2. Weight Capacity

The weight capacity of a wheeled board storage apparatus is a critical design parameter directly influencing its safe and effective operation. This specification dictates the maximum load the system can support without compromising structural integrity, thereby preventing potential damage to stored boards and ensuring user safety.

- Material Strength and Construction

The materials used in construction, such as steel, aluminum, or reinforced polymers, inherently define the maximum load the can handle. The design and assembly techniques, including welding, bolting, and bracing, further contribute to its overall strength. An apparatus constructed from lightweight materials with inadequate reinforcement will possess a limited weight capacity, restricting the number and type of boards it can safely accommodate. Exceeding weight capacity may cause it to fail.

- Mounting Hardware and Surface Compatibility

The capacity is also dependent on the mounting hardware employed and the structural integrity of the mounting surface. Inadequate anchors or a weak mounting surface, such as drywall without proper reinforcement, can significantly reduce the effective weight capacity. The hardware must be appropriately sized and rated to support the intended load, and the mounting surface must be capable of withstanding the forces exerted by the loaded unit.

- Distribution of Load

The manner in which the weight is distributed across the frame impacts its stability and load-bearing capability. Designs that evenly distribute the load across multiple support points are generally more efficient and can handle greater overall weight. Concentrated loads, on the other hand, can create stress points and increase the risk of failure. Users should arrange boards to maximize weight distribution and avoid overloading specific sections of the unit.

- Safety Factor and Margin of Error

Reputable manufacturers incorporate a safety factor into the design, specifying a maximum weight capacity that is significantly lower than the point at which structural failure would occur. This margin of error accounts for variations in material properties, manufacturing tolerances, and unforeseen loading conditions. Adhering to the stated weight limit ensures a safe and reliable operating range, minimizing the risk of accidents or equipment damage. Ignoring limits is dangerous.

Therefore, selecting a wheeled board storage apparatus with an appropriate weight capacity is paramount. Users must consider the types and quantity of boards to be stored and ensure that the selected unit is adequately rated to handle the anticipated load. Overloading the system not only risks damage to the boards and the unit itself but also poses a potential safety hazard to individuals in the vicinity.

3. Mounting Security

Mounting security represents a pivotal element in the effective deployment of any wheeled board storage system. The relationship between the rack’s attachment to a supporting structure and its ability to perform its intended function is direct and consequential. Insufficient or improperly executed mounting compromises the stability of the unit, leading to potential equipment damage, personal injury, and functional failure. For example, a wall-mounted rack secured only to drywall without proper anchoring will likely detach under load, creating a hazardous situation and damaging the boards stored upon it.

The integrity of the mounting directly impacts the load-bearing capacity. A secure attachment to a structurally sound substrate, such as a wood stud or concrete wall, ensures that the rack can support the intended weight without risk of collapse or deformation. Selecting appropriate mounting hardware, including anchors, screws, and bolts designed for the specific wall type, is crucial. The absence of proper hardware selection and installation techniques negates the benefits of a well-designed rack, rendering it unusable and potentially dangerous. Furthermore, vibrations or accidental impacts can weaken inadequate mountings over time, increasing the risk of sudden failure.

In conclusion, mounting security is not merely a procedural step in the installation process but an integral design consideration. Proper assessment of the mounting surface, selection of appropriate hardware, and adherence to established installation protocols are essential for ensuring the long-term stability and safety. Addressing mounting security proactively mitigates the risk of equipment damage, personal injury, and operational failure, contributing to the overall effectiveness and reliability of the storage system. Careful planning helps.

4. Space Efficiency

The implementation of a wheeled board storage system directly correlates with optimizing available space, particularly in environments where square footage is limited. The uncontrolled storage of these boards can lead to clutter, obstruction of pathways, and inefficient use of available areas. A dedicated rack, whether wall-mounted or freestanding, consolidates storage, reducing the footprint occupied by these items. This, in turn, frees up valuable floor space for other purposes, improving overall functionality and organization. For instance, in a garage setting, securing boards against a wall allows vehicles and other equipment to be stored more effectively.

The design of the storage apparatus further influences its space-saving capabilities. Vertical storage solutions maximize the utilization of vertical space, minimizing the impact on floor area. Modular systems offer adaptability, allowing the user to customize the configuration based on the quantity of boards and the specific dimensions of the storage area. Folding or collapsible designs provide additional flexibility, enabling the system to be stowed away when not in use. Considerations of depth, width, and height are crucial in selecting a unit that aligns with the available space and storage requirements. Proper planning ensures optimal space usage.

Ultimately, the selection and implementation of a wheeled board storage unit should prioritize space efficiency as a key criterion. By consolidating storage, maximizing vertical space utilization, and considering the specific dimensions of the environment, users can significantly enhance the functionality and organization of their spaces. Failure to address space considerations can result in continued clutter and inefficient use of available areas, negating the potential benefits of a dedicated storage system. Space-saving design is highly recommended.

5. Corrosion Resistance

Corrosion resistance is a critical design consideration for wheeled board storage apparatus, particularly for units intended for outdoor use or installation in environments with high humidity. The materials used in the construction of the rack are directly exposed to environmental factors such as moisture, salt spray, and atmospheric pollutants, all of which accelerate the corrosion process. The presence of corrosion can compromise the structural integrity of the rack, reducing its load-bearing capacity and ultimately leading to premature failure. A rusted rack, for instance, might break at the joints causing stored boards to fall and potentially injure someone.

The selection of corrosion-resistant materials and protective coatings directly mitigates these risks. Powder-coated steel, galvanized steel, and aluminum alloys are commonly employed due to their inherent resistance to oxidation and other forms of corrosion. Powder coating provides a durable barrier that prevents moisture and corrosive substances from directly contacting the underlying metal. Galvanization involves coating steel with a layer of zinc, which acts as a sacrificial anode, protecting the steel even if the coating is scratched or damaged. The proper selection and application of these materials significantly extend the service life of the rack, reducing the need for frequent replacements and minimizing maintenance costs. A poorly treated rack will have a short lifespan.

In summary, corrosion resistance is not merely an aesthetic consideration but a fundamental requirement for ensuring the long-term durability, safety, and cost-effectiveness of wheeled board storage systems. The proper selection of materials and protective coatings is essential for preventing structural degradation and maintaining the rack’s functionality over time. Choosing a high-quality, corrosion-resistant product is a prudent investment, particularly for outdoor installations or in environments prone to corrosion. Ignoring this aspect can lead to costly replacements and potential safety hazards. The long-term advantages are compelling.

6. Accessibility

Accessibility, in the context of wheeled board storage apparatus, denotes the ease with which users can retrieve and store their boards. A poorly designed rack, positioned at an inconvenient height or requiring complex maneuvers, impedes use, discouraging proper storage habits and potentially leading to damage of the board or injury to the user. The height of the rack, the spacing between storage slots, and the overall design contribute to the user experience. A rack placed too high may be difficult for shorter individuals to reach, while closely spaced slots can make it challenging to remove boards without bumping into each other. A well-designed rack prioritizes ergonomic considerations.

Consider a public skate park: a wheeled board rack installed near the entrance, at a height accessible to both adults and children, and with clearly defined slots, encourages users to store their boards safely while not in use. This simple action reduces tripping hazards and keeps the skating area clear. Conversely, a rack located far from the skating area, requiring users to carry their boards a significant distance, or a rack that is difficult to use due to its design, will likely be ignored. The placement must be convenient. In residential settings, accessibility ensures that boards are readily available for use and easily stowed away after use, preventing them from becoming obstacles within the home.

The key insights regarding accessibility highlight the critical interplay between design, placement, and user experience. Challenges to accessibility include accommodating users of varying heights and physical abilities, optimizing spacing for different board sizes, and maintaining ease of use over time as the storage environment evolves. Overcoming these challenges requires careful consideration of ergonomic principles and user feedback. Prioritizing accessibility fosters responsible storage habits, enhances safety, and maximizes the utility of the wheeled board storage apparatus. Accessibility should be at the forefront when choosing.

7. Aesthetic Integration

Aesthetic integration, when applied to wheeled board storage systems, considers the harmony between the rack’s design and its surrounding environment. This involves more than mere visual appeal; it encompasses how the unit’s form, materials, and color palette complement the architectural style, landscape, or interior design of the space where it is located. Failure to consider aesthetic integration can result in a discordant element that detracts from the overall visual coherence of the environment.

- Material Consistency

The selection of materials should align with the existing aesthetic. A modern, minimalist home might benefit from a sleek, metal rack, while a rustic, wooden structure might be more appropriate for a traditional garage or outdoor setting. Inconsistent material choices can create visual friction and disrupt the intended ambiance. For instance, using brightly colored plastic in a sophisticated office environment would likely be incongruous.

- Color Palette Harmony

The color of the should complement the existing color scheme. Neutral tones often provide versatility, blending seamlessly with a variety of environments. Alternatively, a carefully chosen accent color can create a focal point or enhance the existing design elements. Clashing colors can create visual discord and detract from the overall aesthetic appeal. A bright, neon-colored rack in a muted, earth-toned landscape would likely be visually jarring.

- Form and Style Compatibility

The overall form and style of the should be compatible with the architectural style of the building or the design aesthetic of the space. A contemporary, geometric design might suit a modern home, while a more ornate, traditional design might be appropriate for a Victorian-era building. Mismatched styles can create visual dissonance and detract from the overall coherence of the design. A highly stylized, futuristic in a historic building would likely appear out of place.

- Scale and Proportion Appropriateness

The size and proportions of the should be appropriate for the scale of the surrounding environment. An overly large unit can overwhelm a small space, while an undersized unit can appear insignificant and ineffective. Careful consideration of scale and proportion ensures that the unit integrates seamlessly into the environment without disrupting the visual balance. A massive rack in a small apartment balcony would appear disproportionate and impractical.

Integrating wheeled board storage apparatus harmoniously into its surroundings requires a thoughtful consideration of material consistency, color palette harmony, form and style compatibility, and scale and proportion appropriateness. By aligning these elements with the existing aesthetic, one can ensure that the unit not only serves its functional purpose but also enhances the overall visual appeal of the environment. Ignoring aesthetic considerations can result in a jarring and discordant element that detracts from the overall design.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, installation, and maintenance of specialized storage apparatus for wheeled boards. These answers aim to provide clarity and guidance on the responsible management of such equipment.

Question 1: What factors determine the appropriate size for a wheeled board storage apparatus?

The required size depends on the number and type of boards to be stored. Measure the length and width of the largest board and ensure the rack dimensions accommodate it with sufficient clearance. Also, consider future expansion needs.

Question 2: What are the primary differences between wall-mounted and freestanding wheeled board storage solutions?

Wall-mounted units save floor space and offer a clean aesthetic but require secure attachment to a structurally sound wall. Freestanding units provide flexibility in placement and do not require wall mounting, but occupy floor space.

Question 3: Which materials are most suitable for constructing a durable storage system?

Powder-coated steel, galvanized steel, and aluminum alloys are recommended due to their resistance to corrosion and ability to withstand heavy loads. Avoid materials prone to rust or degradation when exposed to the elements.

Question 4: How does one ensure proper installation of a wall-mounted apparatus to prevent collapse?

Locate wall studs using a stud finder and attach the rack directly to the studs with appropriate screws. If studs are not accessible, use heavy-duty drywall anchors rated for the intended weight. Verify the stability of the installation before loading boards.

Question 5: What maintenance practices prolong the lifespan of a wheeled board storage rack?

Regularly clean the rack to remove dirt and debris. Inspect mounting hardware for looseness or corrosion and tighten or replace as needed. Apply protective coatings or sealants to prevent rust or weathering, particularly for outdoor units.

Question 6: How can one optimize space efficiency when utilizing a wheeled board storage system?

Employ vertical storage solutions to maximize the use of vertical space. Consider modular designs that can be customized to fit the available area. Stagger board placement to minimize wasted space between boards.

Effective management of wheeled boards involves selecting a suitable storage system, installing it correctly, and adhering to regular maintenance practices. These steps ensure the safety of the equipment and the surrounding environment.

The following will address the types of materials.

Skate Board Rack

This exploration has examined the multifaceted aspects of the wheeled board rack, encompassing design considerations, material properties, installation protocols, and long-term maintenance. The analyses underscored the importance of load capacity, structural integrity, and environmental resilience in ensuring safe and effective board storage. Furthermore, optimization strategies related to space efficiency, accessibility, and aesthetic integration were presented to enhance user experience and environmental harmony.

Therefore, proper implementation of a wheeled board storage system requires due diligence in assessing storage needs, selecting appropriate materials, adhering to installation guidelines, and maintaining the system regularly. These measures will preserve the lifespan of the system and protect valuable equipment. The selection of a rack merits careful consideration.