The subject of this article refers to a type of recreational footwear incorporating fruit imagery. More specifically, it denotes roller skates featuring a pineapple motif, either in their design, color scheme, or ornamentation. For example, a pair of quad skates might be described using this term if they are predominantly yellow with green accents meant to evoke the appearance of the tropical fruit.

Such themed skates offer a way for individuals to express personal style and creativity within the roller skating community. They can serve as a visual identifier, making skaters easily recognizable at rinks and events. Furthermore, the association with the pineapple, a symbol of hospitality and warmth, may contribute to a positive and welcoming atmosphere within skating groups.

The following discussion will delve into various aspects of these uniquely adorned skates, including their market availability, design considerations, and potential appeal to different demographics within the roller skating world. We will also examine customization options and safety features relevant to this particular style of recreational equipment.

Essential Considerations for Selecting Fruit-Themed Roller Skates

This section offers guidance for individuals considering the purchase of recreational footwear embellished with pineapple designs. Adherence to these recommendations can optimize safety, comfort, and long-term satisfaction.

Tip 1: Prioritize Safety Certifications. Ensure the skates meet recognized safety standards (e.g., ASTM F1849 for roller skates). Verified certification indicates the product has undergone testing for impact resistance and structural integrity.

Tip 2: Evaluate Wheel Durometer. Wheel hardness, measured in durometers, affects grip and roll. Softer wheels (lower durometer) provide better grip on slick surfaces, while harder wheels (higher durometer) offer faster roll on smoother terrains. Choose based on intended skating environment.

Tip 3: Assess Boot Comfort and Support. A well-fitting boot is crucial. It should provide adequate ankle support and prevent excessive movement within the skate. Consider heat-moldable boots for a customized fit.

Tip 4: Inspect Bearing Quality. Bearings impact the smoothness and efficiency of the roll. ABEC ratings indicate bearing precision, with higher numbers generally (but not always) signifying better performance. Regular cleaning and lubrication extend bearing lifespan.

Tip 5: Consider the Frame Material. The frame, also known as the plate, connects the boot to the wheels. Aluminum frames offer superior durability and responsiveness compared to plastic alternatives, but can increase the price. Determine what you are looking for based on the level of usage.

Tip 6: Verify Brake Functionality. A functional brake is essential for controlled stopping. Regularly inspect brake pads for wear and replace as needed. Consider the ease of brake adjustability and replacement when evaluating different models.

Tip 7: Choose Bright Colors for Visibility. When skating outdoors, increasing visibility is key. By choosing the yellow and green colors of our motif, consider incorporating additional bright or reflective elements to enhance visibility for safety.

Careful attention to safety features, comfort, and performance characteristics will contribute to a positive and secure skating experience. Neglecting these aspects can compromise both enjoyment and well-being.

The subsequent sections will explore the stylistic variations and customization options available, providing further insight into the diverse landscape of fruit-themed roller skates.

1. Aesthetics

The aesthetic considerations surrounding specialized recreational footwear, specifically those featuring a pineapple motif, play a critical role in their market appeal and user satisfaction. These visual elements directly influence consumer perception and purchase decisions.

- Color Palette and Visual Appeal

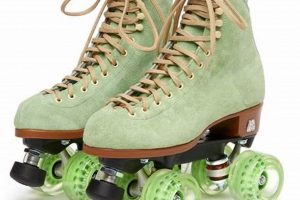

The utilization of specific color palettes directly linked to the pineapple primarily yellows, greens, and browns dictates the immediate visual impact. A balance must be struck between realistically representing the fruit and creating an appealing, contemporary design. Overly bright or garish colors may deter some consumers, while muted tones may lack visual interest. Consider the application of gradients, textures, and shading to add depth and sophistication.

- Graphic Representation and Stylization

The depiction of the pineapple itself, ranging from realistic illustrations to stylized, abstract representations, is crucial. Accurate botanical renderings may appeal to a different demographic than cartoonish or minimalist interpretations. The placement and scale of these graphics on the skate boot also impact the overall aesthetic. A repetitive pattern might create a bold statement, while a single, subtle pineapple emblem offers a more understated look.

- Integration with Skate Design Elements

The thematic visuals must harmonize with the existing design elements of the skate, including the boot shape, wheel color, and hardware finishes. Clashing aesthetics can result in a disjointed and unappealing product. For example, a vintage-style skate boot may require a different design approach than a modern, aggressive-style skate. The chosen aesthetic should complement, not compete with, the skate’s overall form and function.

- Target Audience Preferences

Aesthetic choices must align with the preferences of the intended target audience. Younger skaters may gravitate towards bolder, more playful designs, while older skaters may prefer more subtle and sophisticated interpretations. Market research and consumer feedback are essential for informing design decisions and ensuring that the final product resonates with its intended demographic.

Therefore, careful consideration of color, graphic representation, and integration with the skate’s design, guided by target audience preferences, is essential to maximizing the aesthetic appeal and market success of themed recreational footwear featuring the pineapple motif. A cohesive and visually compelling design can significantly enhance the overall user experience and contribute to brand recognition.

2. Customization

The capacity to personalize recreational equipment significantly impacts user engagement and product satisfaction. With roller skates incorporating a pineapple design, customization options directly influence their aesthetic appeal and functional adaptability. The availability of interchangeable components and personalized design elements allows skaters to tailor their equipment to individual preferences and skating styles. This personalization fosters a stronger connection between the user and their skates, enhancing the overall recreational experience. For instance, skaters may choose to alter wheel durometer for specific surfaces, swap bearings for enhanced speed, or apply custom graphics to the boot, thereby creating a unique and personalized skating experience.

Customization of these items extends beyond mere aesthetics, influencing performance characteristics. Modifying truck tightness affects maneuverability, while selecting different boot materials can enhance comfort and support. Consequently, this level of adaptability allows skaters to optimize their equipment for various skating disciplines, such as rhythm skating, jam skating, or outdoor recreational skating. The interplay between aesthetics and functionality is critical; skaters might select brightly colored laces or toe guards to complement the fruit theme while simultaneously improving visibility or protecting the skate from wear and tear.

In summary, customization plays a pivotal role in the market for pineapple-themed roller skates. It addresses the diverse needs and preferences of skaters, creating a more engaging and satisfying recreational experience. Challenges remain in ensuring the availability of high-quality, compatible components and providing clear guidance on safe and effective customization practices. The continued development of innovative customization options will likely drive further growth and diversification within this specialized market.

3. Target Audience

The success of recreational footwear featuring a pineapple motif is fundamentally contingent upon identifying and understanding its target audience. Marketing efforts and product development must align with the specific demographics and psychographics most likely to purchase such items. A misidentification of this audience can lead to ineffective marketing campaigns, inappropriate product features, and ultimately, reduced sales. For example, marketing campaigns focused solely on professional athletes are unlikely to resonate with casual skaters seeking aesthetically pleasing recreational equipment. The importance of accurately defining the target audience is therefore paramount to achieving market penetration and sustained commercial viability.

The primary target audience for these skates often encompasses younger individuals and those with a pronounced interest in visually distinctive and expressive recreational equipment. Social media platforms, with their emphasis on visual content and personal expression, serve as crucial marketing channels for reaching this demographic. Furthermore, skaters participating in roller derby leagues or recreational skating groups represent a viable target segment. These groups often value individuality and are receptive to unique and eye-catching gear. Analyzing purchase patterns, online activity, and feedback from existing skaters provides valuable insights into the preferences and purchasing behaviors of the intended consumer base. Consider how this ties into those who enjoy “Retro” and “vintage” designs.

Challenges remain in predicting evolving consumer trends and preferences. Continuous market research, including surveys, focus groups, and social media analytics, is essential for adapting to shifting demands. Effective communication strategies, tailored to resonate with the target audience’s values and aspirations, are also crucial. By meticulously identifying, understanding, and engaging the target demographic, manufacturers and retailers can maximize the potential of pineapple-themed roller skates and establish a strong presence in the competitive recreational equipment market. Failing to recognize the needs of the target audience can have serious consequences on the success of the merchandise.

4. Material Selection

The selection of materials for recreational footwear incorporating a pineapple motif is not merely an aesthetic consideration but a critical determinant of performance, durability, and safety. The materials employed in various components, from the boot to the wheels, directly impact the user experience and the product’s longevity. Therefore, a comprehensive understanding of material properties and their suitability for specific skate elements is essential.

- Boot Composition and Support

The skate boot material dictates the level of support, comfort, and breathability. Leather offers durability and a classic aesthetic, while synthetic materials provide water resistance and lighter weight. The choice often depends on the intended use and the skater’s preference. For instance, a high-top leather boot may be favored for rink skating, while a low-cut synthetic boot might be preferred for outdoor recreational use due to increased flexibility and ventilation. The inclusion of padding materials, such as closed-cell foam, further enhances comfort and impact absorption, contributing to a more positive skating experience.

- Wheel Polymers and Rolling Resistance

The wheel material, typically polyurethane, significantly influences rolling resistance, grip, and wear resistance. Different durometers (hardness levels) cater to varying skating surfaces and styles. Softer wheels provide better grip on slick surfaces, while harder wheels offer faster roll on smoother terrains. The pigment incorporated into the polyurethane can also affect performance; certain additives may enhance grip or durability. For pineapple-themed skates, colored wheels matching the fruit’s aesthetic can be used, but the impact on performance characteristics must be carefully evaluated.

- Frame Alloys and Structural Integrity

The frame, or plate, connecting the boot to the wheels, bears the brunt of the skater’s weight and absorbs impact forces. Aluminum alloys are commonly used due to their high strength-to-weight ratio, providing stability and responsiveness. Plastic frames, while more affordable, may lack the durability and rigidity required for aggressive skating styles. The choice of frame material directly affects the skater’s control and stability, influencing overall safety and performance. Careful consideration must be given to the alloy composition and manufacturing process to ensure adequate structural integrity.

- Bearing Steel and Rotational Efficiency

The bearings, housed within the wheels, facilitate smooth rotation and influence the skate’s speed. High-carbon steel is a common material choice due to its hardness and wear resistance. Precision bearings, manufactured to tighter tolerances, offer superior rotational efficiency and reduced friction. Proper lubrication is essential to maintain bearing performance and prevent premature wear. While the bearing material itself may not be visually apparent, its impact on the skating experience is significant, contributing to a smoother, faster, and more enjoyable ride.

The interconnectedness of these material selections underscores the holistic engineering required in designing and manufacturing recreational footwear incorporating a pineapple design. While aesthetic considerations, such as color matching and visual appeal, are important, they must be balanced with the functional requirements of performance, durability, and safety. A skate that looks appealing but compromises on material quality will ultimately fail to meet the needs of the user and erode brand credibility. The choice of materials is thus a crucial factor in determining the long-term success and user satisfaction of these recreational products.

5. Safety Standards

The adherence to established safety standards is paramount in the design, manufacture, and distribution of recreational footwear, including roller skates featuring a pineapple motif. These standards, developed by organizations such as ASTM International and the Consumer Product Safety Commission (CPSC), aim to minimize the risk of injury associated with the use of such equipment. Compliance with these standards is not merely a legal obligation but a fundamental ethical responsibility for manufacturers and retailers.

- Impact Resistance Testing

Roller skates must undergo rigorous impact resistance testing to ensure that they can withstand the forces generated during falls and collisions. This testing typically involves dropping weighted objects onto various parts of the skate, including the boot, frame, and wheels. The results of these tests determine whether the skate meets minimum safety requirements for structural integrity. Skates that fail to meet these standards may be prone to breakage, increasing the risk of injury to the user. In the context of themed skates, any decorative elements, such as applied pineapple designs, must not compromise impact resistance.

- Braking Efficiency Evaluation

Effective braking is essential for controlling speed and preventing accidents. Safety standards dictate minimum braking efficiency requirements, typically measured by the distance required to stop from a given speed. Testing procedures involve evaluating the performance of the brake mechanism under various conditions, including wet and dry surfaces. Skates must be equipped with a reliable braking system that allows the user to stop quickly and safely. The design and placement of the brake must not interfere with normal skating movements or increase the risk of tripping.

- Material Composition and Toxicity Limits

The materials used in the manufacture of roller skates must meet stringent safety standards regarding toxicity and flammability. These standards limit the allowable concentrations of hazardous substances, such as lead, phthalates, and formaldehyde, in the materials used in the boot, wheels, and other components. Testing procedures involve analyzing material samples to ensure compliance with regulatory limits. Furthermore, materials must be resistant to ignition and flame propagation to minimize the risk of fire-related injuries. Compliance with these standards safeguards the health and well-being of skaters, particularly children, who may be more vulnerable to the effects of toxic substances.

- Structural Integrity and Load Capacity

Roller skates must be designed and manufactured to withstand the stresses and strains of normal use without failing structurally. Safety standards specify minimum load capacity requirements for various components, including the frame, axles, and bearings. Testing procedures involve subjecting the skates to static and dynamic loads to simulate the forces generated during skating. The skates must be able to support the skater’s weight without bending, breaking, or collapsing. The design and construction of the skate must also prevent components from loosening or detaching during use, which could lead to loss of control and injury.

The integration of pineapple-themed aesthetics into roller skate design must not compromise adherence to these established safety standards. Manufacturers must prioritize safety over aesthetics, ensuring that the finished product meets all applicable regulations and provides adequate protection for the user. Independent testing and certification can provide additional assurance of product safety and quality. Ultimately, the safety and well-being of skaters should be the paramount consideration in the design, manufacture, and marketing of recreational footwear. While it is tempting to focus on aesthetics alone, one must remember to take all things into consideration.

6. Wheel Performance

Wheel performance is a critical element in the overall functionality and user satisfaction of any roller skate, including those incorporating a pineapple design motif. The interplay between wheel characteristics and skating surface directly influences speed, maneuverability, and stability. Consequently, the selection of appropriate wheels is not merely a cosmetic decision but a crucial factor determining the skate’s suitability for various skating environments and styles. For example, a skater using these items primarily on smooth indoor rinks would require wheels with different properties compared to someone skating on rough outdoor surfaces.

The wheel durometer, measured on the A scale, dictates the wheel’s hardness and directly affects grip and roll. Softer wheels (lower durometer values) offer increased grip and shock absorption, making them suitable for uneven surfaces but potentially sacrificing speed. Harder wheels (higher durometer values) provide faster roll and increased durability on smooth surfaces, but may offer less grip and a harsher ride. Similarly, wheel size influences rolling resistance and acceleration. Larger diameter wheels generally provide greater speed and momentum, while smaller wheels offer quicker acceleration and maneuverability. Consider that skaters who plan to participate in roller derby may not choose skates with pineapple themes, or any visual elements that interfere with performance or safety.

Therefore, understanding the relationship between wheel performance characteristics and intended skating applications is essential for maximizing the functionality and enjoyment of themed roller skates. Manufacturers and retailers have a responsibility to provide clear and accurate information regarding wheel specifications and their suitability for different skating conditions. Ultimately, informed wheel selection contributes significantly to a safe, efficient, and satisfying skating experience, regardless of the skate’s aesthetic design.

7. Retail Availability

The extent to which “pineapple roller skates” are accessible to consumers through various retail channels directly influences their market penetration and overall sales volume. Limited retail availability, whether due to exclusive distribution agreements, niche market targeting, or supply chain constraints, can significantly restrict consumer access and hinder widespread adoption. Conversely, broad retail availability, encompassing online marketplaces, specialty skate shops, and large sporting goods retailers, expands the potential customer base and facilitates increased sales. For example, if “pineapple roller skates” are sold exclusively through a single online vendor, geographical limitations and shipping costs may deter potential buyers. The inverse is true if they are available at a local skate shop, it is more likely to be purchased. Therefore, retail availability functions as a critical determinant of market reach and revenue generation for this specific product category. The more accessible they are, the higher the liklihood of them being purchased.

The specific types of retail outlets stocking “pineapple roller skates” also affect consumer perception and purchasing decisions. Placement within high-end department stores may convey a sense of premium quality, while availability solely at discount retailers could signal a lower price point, potentially influencing perceived value. Targeted distribution strategies, focusing on retailers catering to specific demographics or skating styles, can optimize sales by aligning product placement with consumer preferences. For example, advertising to retail outlets with high volume in “retro” and “vintage” styles may prove benificial. Furthermore, the availability of sizing options, replacement parts, and related accessories within these retail environments contributes to a more complete and satisfying customer experience.

In conclusion, retail availability represents a crucial component in the commercial success of “pineapple roller skates.” Strategic distribution across diverse retail channels, tailored to the target audience and product positioning, can maximize market reach and sales potential. Challenges remain in managing inventory levels, coordinating supply chains, and ensuring consistent product availability across different retail locations. However, a well-executed retail strategy is essential for establishing a strong market presence and achieving sustained growth in this niche market segment. With the use of analytics, sellers can monitor which outlets are selling which product and the product’s percieved quality, therefore adjusting accordingly.

Frequently Asked Questions

The following section addresses common inquiries regarding roller skates featuring a pineapple design. These questions are intended to provide clarity and dispel potential misconceptions.

Question 1: Are pineapple roller skates suitable for professional use?

The suitability of these skates for professional use depends on their construction and compliance with relevant safety standards. While some models may meet the necessary requirements, others are designed primarily for recreational purposes. A thorough assessment of the skate’s features and intended application is essential.

Question 2: How does the pineapple design affect the skate’s performance?

The pineapple design itself should not inherently impact the skate’s performance, assuming it is implemented without compromising structural integrity or aerodynamic properties. However, the materials used in the design and their placement could potentially influence weight distribution or airflow. All decorative and visual augmentations are carefully selected.

Question 3: What safety precautions should be taken when using pineapple roller skates?

Standard safety precautions for roller skating apply, including wearing appropriate protective gear (helmet, knee pads, elbow pads, wrist guards), skating in designated areas, and adhering to local traffic laws. Regular inspection of the skates for signs of wear or damage is also crucial.

Question 4: How should pineapple roller skates be maintained to ensure longevity?

Proper maintenance involves regular cleaning, lubrication of bearings, inspection for loose components, and replacement of worn parts. Specific maintenance procedures may vary depending on the skate’s materials and construction. Following the manufacturer’s recommendations is advisable.

Question 5: Are pineapple roller skates available in different sizes and models?

The availability of different sizes and models varies depending on the manufacturer and retailer. It is essential to consult size charts and product specifications to ensure a proper fit and appropriate model selection based on individual needs and preferences. Measure one’s foot before ordering.

Question 6: What is the typical price range for pineapple roller skates?

The price range depends on factors such as materials, construction quality, brand reputation, and design complexity. Lower-end models may be available at a lower price point, while high-end models with advanced features and premium materials command a higher price. Please conduct market research.

This FAQ section provides a foundational understanding of key considerations related to roller skates featuring a pineapple design. For more specific information, consulting product documentation or seeking expert advice is recommended.

The next section will delve into the future trends and potential innovations in the market for themed recreational footwear. A new visual trend can emerge at any time.

Conclusion

This exploration has considered various facets of “pineapple roller skates,” encompassing their aesthetic appeal, customization options, target audience, material selection, safety standards, wheel performance characteristics, and retail availability. Each element contributes to the overall market positioning and consumer perception of this specialized recreational product. Considerations of safety, performance, and target demographic alignment are paramount.

The market for themed recreational footwear remains dynamic, necessitating continuous adaptation to evolving consumer preferences and technological advancements. As such, ongoing research, adherence to safety regulations, and a commitment to product innovation are crucial for sustained success. The future of “pineapple roller skates,” like all consumer goods, hinges on its ability to meet the demands of a discerning market.