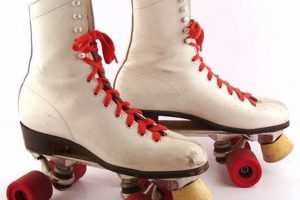

The equipment allows individuals to experience the recreational activity of skating on various surfaces, both inside and outside a building. These are designed with different wheel materials and boot structures to accommodate the specific demands of each environment. For example, polyurethane wheels with varying durometers are common, softer for indoor grip and harder for outdoor durability.

The versatility of these skates provides a convenient means of physical exercise and enjoyment across different locations and seasons. Their history is rooted in the development of skating as both a sport and a leisure pursuit, evolving from rudimentary designs to sophisticated models that offer improved performance and safety. Using appropriate skating equipment allows enthusiasts to enjoy skating safely.

The following sections will elaborate on the specific features and considerations involved in selecting the appropriate type of rolling footwear, including wheel composition, boot support, and bearing quality. These aspects greatly influence the skater’s experience and safety.

Guidance on Roller Skate Usage

The following guidelines are presented to optimize performance and safety when utilizing rolling equipment designed for both interior and exterior environments.

Tip 1: Wheel Selection. Prioritize wheel durometer based on the skating surface. Softer wheels (lower durometer) are recommended for indoor rinks to maximize grip, while harder wheels (higher durometer) are better suited for outdoor surfaces to enhance durability and rolling efficiency.

Tip 2: Bearing Maintenance. Regular cleaning and lubrication of wheel bearings are crucial. Properly maintained bearings contribute to smoother rolling and reduced friction, improving overall performance and extending the lifespan of the equipment.

Tip 3: Boot Support. Ensure the skates offer adequate ankle support. A secure and supportive boot reduces the risk of ankle injuries and enhances control during skating maneuvers.

Tip 4: Protective Gear. Always wear appropriate protective gear, including a helmet, knee pads, elbow pads, and wrist guards. Protective gear significantly mitigates the risk of injuries from falls or collisions.

Tip 5: Surface Inspection. Before initiating any skating session, thoroughly inspect the intended surface for hazards such as cracks, debris, or uneven areas. Identifying and avoiding these obstacles minimizes the potential for accidents.

Tip 6: Skill Assessment. Be realistic about one’s skating abilities. Progress gradually, mastering fundamental skills before attempting advanced maneuvers. This approach promotes safety and reduces the likelihood of accidents.

Tip 7: Regular Inspection. Routinely inspect the entire skating setup, including the boot, frame, wheels, and bearings, for signs of wear or damage. Promptly address any issues to maintain the equipment in optimal condition.

Adhering to these recommendations will contribute to a safer and more enjoyable skating experience, regardless of whether the activity takes place within or outside a structure.

The succeeding discussion will delve into specific techniques for enhancing skating proficiency and exploring various skating styles.

1. Wheel Durometer

Wheel durometer, a measurement of a wheel’s hardness, is a critical factor in determining the suitability of rolling equipment for either indoor or outdoor use. A lower durometer indicates a softer wheel, offering enhanced grip on the smooth, polished surfaces typically found in indoor skating rinks. This increased grip maximizes maneuverability and control, allowing for precise movements and minimizing slippage. Conversely, outdoor surfaces, such as asphalt or concrete, necessitate harder wheels (higher durometer) to withstand abrasion and maintain rolling efficiency. Softer wheels used outdoors would degrade rapidly, leading to decreased performance and a shortened lifespan.

The interplay between wheel durometer and surface type demonstrates a clear cause-and-effect relationship. Using wheels with inappropriate durometers not only compromises performance but also poses potential safety risks. For instance, hard wheels on an indoor surface offer minimal grip, increasing the likelihood of falls. Alternatively, soft wheels on an outdoor surface heat up faster due to increased friction, potentially leading to wheel failure. Therefore, selecting the correct durometer is imperative for both safety and optimal skating experience. A concrete example involves indoor roller derby, which often utilizes softer wheels to facilitate quick stops and turns, while outdoor recreational skating favors harder wheels for distance and durability.

In summary, the connection between wheel durometer and the intended environment for skating equipment is paramount. The hardness of the wheel directly influences grip, durability, and overall performance. By carefully considering the surface conditions, skaters can select wheels that optimize their experience and minimize potential hazards. Misjudging this crucial aspect inevitably leads to suboptimal skating and potentially unsafe conditions.

2. Bearing Precision

Bearing precision is a critical, though often overlooked, aspect of rolling equipment performance. The tolerances to which bearings are manufactured directly influence the smoothness and efficiency of the roll, translating into noticeable differences in speed and effort required for propulsion. Bearings with higher precision ratings exhibit tighter tolerances, reducing friction and allowing for a longer, smoother glide. This is particularly crucial for outdoor skating where longer distances and varied terrain demand efficient energy transfer. Conversely, while still important, the effects of lower-precision bearings may be somewhat masked by the smoother surfaces and shorter distances encountered in indoor rink settings.

The ABEC (Annular Bearing Engineers’ Committee) scale is a common, though not universally adopted, standard for rating bearing precision. Higher ABEC numbers (e.g., ABEC-7, ABEC-9) indicate tighter tolerances and, consequently, smoother and faster rolling characteristics. However, factors beyond the ABEC rating, such as materials and lubrication, also significantly impact performance. For example, a well-maintained ABEC-5 bearing might outperform a poorly maintained ABEC-7 bearing. Furthermore, the demands of different skating styles influence the optimal bearing choice. Speed skaters prioritize high-precision bearings for maximum speed, while recreational skaters may find that the marginal performance gains do not justify the increased cost.

In summary, bearing precision plays a tangible role in the overall performance of rolling equipment, with its impact being more pronounced in outdoor environments where efficiency and distance are key considerations. While the ABEC rating provides a useful guideline, factors such as maintenance, materials, and intended skating style must be taken into account to make an informed decision. Ultimately, understanding the nuanced relationship between bearing precision and the demands of specific skating conditions contributes to a safer, more efficient, and more enjoyable experience.

3. Boot Support

Boot support directly influences the stability and control achievable while using rolling equipment, whether indoors or outdoors. Inadequate support can lead to ankle strain, reduced maneuverability, and an increased risk of injury, while excessive rigidity can restrict movement and diminish comfort. The design and materials employed in boot construction are therefore critical considerations, impacting not only performance but also the overall safety and enjoyment of the skating experience. Consider, for instance, figure skates, which often necessitate rigid ankle support for executing complex jumps and spins on smooth, indoor surfaces. Conversely, recreational skates designed for outdoor use may prioritize a more flexible boot to enhance comfort during extended skating sessions on varied terrain.

The connection between boot support and intended environment is evident in the construction of different types of skating equipment. Indoor skates often feature a lower cut and a more streamlined design to facilitate agility and responsiveness within the confined space of a rink. Outdoor skates, on the other hand, may incorporate higher cuffs and reinforced padding to provide additional ankle stability on uneven surfaces and to protect against impacts. The choice of materials also plays a significant role, with leather or synthetic materials offering varying degrees of support, breathability, and durability. Furthermore, the lacing system or closure mechanism contributes to the overall fit and security, allowing skaters to customize the level of support based on their individual needs and preferences.

In summary, boot support is an integral component of rolling equipment, significantly impacting both performance and safety across diverse skating environments. The level of support required is contingent upon the intended application, ranging from the demanding maneuvers of indoor figure skating to the recreational pursuits on outdoor surfaces. Therefore, careful consideration of boot design, materials, and closure system is essential when selecting equipment to ensure a comfortable, controlled, and injury-free skating experience. A failure to properly evaluate boot support may compromise stability, reduce maneuverability, and ultimately, detract from the overall enjoyment of the activity.

4. Frame Material

The material used in the construction of the frame directly affects the performance characteristics of rolling equipment, influencing weight, durability, and responsiveness. Frame material selection must align with the intended skating environment to ensure optimal performance and longevity.

- Aluminum Alloys

Aluminum alloys offer a balance of strength and lightweight properties, making them suitable for both indoor and outdoor applications. Higher-grade aluminum frames provide increased rigidity and power transfer, beneficial for aggressive skating styles and speed skating. In outdoor settings, aluminum frames exhibit good resistance to corrosion and impact, extending the lifespan of the equipment. Lower-grade alloys, while more affordable, may be more prone to bending or cracking under stress.

- Composite Materials

Composite frames, typically constructed from reinforced polymers, offer vibration dampening and a lighter weight compared to aluminum. This can improve comfort, especially during longer skating sessions. Composite frames are often favored for recreational skating, where comfort and ease of use are prioritized over maximum power transfer. However, composite materials may not be as durable as aluminum, particularly in harsh outdoor environments where they are susceptible to abrasion and impact damage.

- Steel

Steel frames are less common due to their increased weight compared to aluminum and composite materials. While steel offers exceptional strength, the added weight can reduce maneuverability and increase fatigue. Steel frames may be found in older or entry-level models. Stainless steel offers corrosion resistance, making it a viable option for wet conditions. However, the added weight generally makes steel a less desirable choice for recreational or performance skating.

- Magnesium Alloys

Magnesium alloys provide an even lighter alternative to aluminum. Magnesium offers excellent vibration damping qualities, increasing comfort when traversing uneven surfaces. However, magnesium is more susceptible to corrosion than aluminum and may require protective coatings. Additionally, magnesium alloys tend to be more expensive than aluminum, limiting their use to high-end or specialized skating equipment.

The choice of frame material is a critical decision that significantly impacts the performance and suitability of rolling equipment for specific environments. Whether prioritizing lightweight agility, robust durability, or vibration dampening comfort, understanding the characteristics of different frame materials enables informed selection and ensures a satisfying skating experience. The frame is the anchor of the entire skate.

5. Surface Compatibility

Surface compatibility is a critical determinant of the performance and safety of rolling equipment, directly influencing grip, speed, wear, and overall maneuverability. The suitability of specific skate configurations for indoor versus outdoor environments depends significantly on the interaction between wheel material, frame design, and the characteristics of the skating surface.

- Friction Coefficient

The friction coefficient between the wheels and the skating surface dictates the level of grip achievable. Indoor surfaces, typically polished concrete or wood, demand wheels with higher friction coefficients to prevent slippage and enable precise control. Outdoor surfaces, such as asphalt or rough concrete, require wheels designed to maintain grip while minimizing wear and maximizing roll distance. Incompatibility results in either loss of control or rapid wheel degradation.

- Surface Roughness

Surface roughness directly affects wheel wear and vibration. Smooth indoor surfaces minimize wear and vibration, allowing for the use of softer, grippier wheels. Conversely, rough outdoor surfaces necessitate harder, more durable wheels to withstand abrasion and absorb vibrations. Mismatched surface roughness and wheel type compromises ride quality and equipment lifespan.

- Debris and Obstacles

The presence of debris and obstacles is a greater concern in outdoor environments. Wheel size and frame clearance play a crucial role in navigating these challenges. Larger wheels with adequate frame clearance allow for rolling over small obstacles, while smaller wheels are more susceptible to catching or stopping abruptly. Indoor rinks are generally free of debris, permitting the use of smaller wheels and lower frame clearances.

- Surface Composition

The chemical composition of the skating surface impacts wheel wear and grip. Certain outdoor surfaces may contain oils or chemicals that degrade specific wheel compounds, reducing grip and lifespan. Indoor surfaces are typically more consistent in composition, allowing for predictable wheel performance. Understanding the surface composition is essential for selecting wheels that maintain optimal performance and durability.

These considerations highlight the fundamental link between surface characteristics and the selection of appropriate rolling equipment. Failing to address surface compatibility can result in diminished performance, increased wear, and elevated risk of injury. Therefore, a thorough understanding of the skating environment is paramount for maximizing safety and optimizing the skating experience.

6. Maintenance Schedule

A structured maintenance schedule is integral to preserving the functionality, safety, and longevity of rolling equipment. The environment in which skates are used dictates the frequency and intensity of maintenance required. Outdoor usage exposes skates to contaminants such as dirt, water, and debris, accelerating wear on bearings, wheels, and frames. Neglecting a rigorous cleaning and lubrication schedule leads to decreased performance, potential component failure, and an increased risk of accidents. For example, particulate matter accumulating within bearings increases friction, reducing roll speed and potentially causing bearing seizure. Routine cleaning and lubrication counteract this degradation, restoring optimal performance.

Indoor skating, while less demanding, still necessitates regular maintenance. Dust accumulation and the breakdown of lubrication within bearings occur even in controlled environments. Furthermore, wheel wear is inevitable regardless of the skating surface. Regular inspection for loose hardware, worn wheels, and frame damage is essential for preventing mechanical failures. A practical application of this understanding involves implementing a logbook system to track maintenance activities, documenting cleaning dates, lubrication types, and component replacements. This record-keeping allows for proactive identification of recurring issues and optimization of the maintenance schedule.

The adoption of a comprehensive maintenance schedule for rolling equipment presents a direct correlation to user safety and cost-effectiveness. Ignoring maintenance procedures accelerates component degradation, leading to premature replacements and increased overall expenses. More critically, neglected equipment can compromise skater safety, leading to accidents resulting from component failure or reduced maneuverability. While the implementation of a rigorous maintenance schedule requires an initial investment of time and resources, the long-term benefits of enhanced performance, reduced repair costs, and improved safety far outweigh the perceived burden. The challenge lies in educating users on the importance of proactive maintenance and providing clear, accessible guidelines for proper care.

Frequently Asked Questions About Rolling Equipment

The subsequent section addresses common inquiries regarding the selection, maintenance, and appropriate usage of rolling equipment for both interior and exterior applications.

Question 1: How does wheel durometer impact performance in different environments?

Wheel durometer, a measure of hardness, directly affects grip and durability. Softer wheels (lower durometer) are optimal for smooth indoor surfaces, providing enhanced grip and maneuverability. Harder wheels (higher durometer) are designed for outdoor surfaces, offering increased resistance to abrasion and prolonged lifespan.

Question 2: What are the key considerations when selecting bearings for rolling equipment?

Bearing precision, often indicated by the ABEC rating, influences the smoothness and efficiency of the roll. Higher ABEC ratings signify tighter tolerances and reduced friction. However, factors such as bearing material, lubrication, and maintenance practices also contribute significantly to overall performance. Selection should align with the intended skating style and environment.

Question 3: Why is boot support a critical factor in rolling equipment selection?

Adequate boot support provides ankle stability, enhancing control and reducing the risk of injuries. The level of support required varies depending on the skating environment and intended maneuvers. Stiffer boots are generally recommended for activities requiring precise movements and high impact, while more flexible boots prioritize comfort during recreational skating.

Question 4: What are the advantages and disadvantages of different frame materials?

Aluminum frames offer a balance of strength and lightweight properties, making them suitable for various skating styles. Composite frames provide vibration dampening and reduced weight, enhancing comfort, but may be less durable than aluminum. Steel frames offer exceptional strength but add considerable weight, impacting maneuverability. Frame material selection should consider the intended skating environment and performance requirements.

Question 5: How does the skating surface affect the choice of rolling equipment?

The skating surface dictates the optimal wheel type, frame design, and bearing selection. Smooth indoor surfaces allow for softer wheels and lower frame clearances. Rough outdoor surfaces necessitate harder wheels, higher frame clearances, and robust frame construction to withstand abrasion and navigate obstacles.

Question 6: What are the essential components of a comprehensive maintenance schedule for rolling equipment?

A comprehensive maintenance schedule includes regular cleaning and lubrication of bearings, inspection for loose hardware and frame damage, and replacement of worn wheels. The frequency of maintenance depends on the skating environment and usage intensity. Proactive maintenance enhances performance, extends equipment lifespan, and promotes skater safety.

The preceding responses underscore the multifaceted considerations involved in selecting, maintaining, and utilizing rolling equipment effectively across diverse skating environments. A thorough understanding of these principles promotes informed decision-making and optimizes the skating experience.

The subsequent section will explore advanced techniques for enhancing skating proficiency and expanding one’s repertoire of skating skills.

Conclusion

The preceding discussion has meticulously examined various aspects of rolling equipment, emphasizing the distinctions crucial for both indoor and outdoor usage. The selection of appropriate wheel durometer, bearing precision, boot support, frame material, and a rigorous maintenance schedule are paramount for maximizing performance and ensuring user safety. The analysis underscores that rolling equipment is not a monolithic entity, but rather a system requiring careful configuration based on the intended application.

The knowledge presented herein serves as a foundation for making informed decisions, ultimately enhancing the skating experience and minimizing potential hazards. Continued adherence to best practices and a commitment to proactive maintenance are essential for sustaining the longevity and functionality of rolling equipment, regardless of the environment in which it is utilized.

![Best Roller Skate Helmet [Safe & Stylish] Guide How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Roller Skate Helmet [Safe & Stylish] Guide | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-108-300x200.jpg)