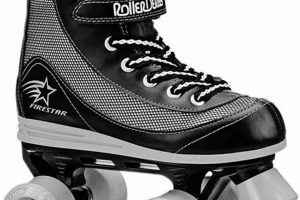

These recreational wheeled boots, known for their retro aesthetic, are offered in a vibrant spectrum of colors, featuring a prominent and visually striking color gradient design. As an example, consumers might select a pair showcasing a vivid transition from red to violet, intended to capture attention and express individual style on the rink or pavement.

The appeal of such designs lies in their capacity to merge functionality with fashion. The use of bright, cheerful colors can enhance the enjoyment of the activity and contribute to a sense of personal expression. Historically, colorful skating equipment has been associated with periods of cultural exuberance and the celebration of individuality, providing a nostalgic link to past eras of roller skating enthusiasm.

The following sections will delve into the specific attributes of these visually distinctive skates, covering aspects such as construction materials, performance capabilities, target audience, and market availability.

Tips for Maintaining Visually Distinctive Roller Skates

Proper care ensures the longevity and sustained aesthetic appeal of multicolored roller skates. These guidelines address maintenance and storage considerations.

Tip 1: Routine cleaning is crucial. After each use, wipe down the skates with a damp cloth to remove dirt and debris. Pay particular attention to the wheels and the boot surface to prevent grime buildup.

Tip 2: Use appropriate cleaning agents. Harsh chemicals can damage the vibrant color finish. Opt for mild soap and water solutions for cleaning the boot and a specialized bearing cleaner for the wheels.

Tip 3: Avoid prolonged exposure to direct sunlight. UV radiation can cause fading and discoloration of the rainbow hues. Store the skates in a cool, dark place when not in use.

Tip 4: Regularly inspect the wheels and bearings. Check for wear and tear and ensure proper lubrication to maintain smooth rolling performance and prevent undue stress on the boot.

Tip 5: When storing, use protective bags or cases. This prevents scratches and damage to the color finish during storage or transport.

Tip 6: Lace maintenance should be a regular activity. Check for fraying or damage to the laces, replace them as needed to maintain a secure and comfortable fit.

Tip 7: Address any repairs promptly. Minor scuffs or tears can be addressed with color-matched repair kits designed for synthetic leather or vinyl, preserving the aesthetic integrity.

Adhering to these maintenance practices helps safeguard the aesthetic integrity of the roller skates, preserving their visual appeal and extending their lifespan. These habits ensures lasting enjoyment for skaters of all levels.

The subsequent section will cover the common issues that user encounter while skating.

1. Color gradient

The color gradient constitutes a prominent design element within the aesthetic framework of the recreational wheeled boots. The visual transition between hues is intentionally implemented to enhance the product’s appeal and differentiate it within the competitive market. This feature can directly influence consumer purchasing decisions, as the aesthetic properties often serve as a primary motivator for selection. For example, a design featuring a smoothly blended spectrum from turquoise to lavender is intended to evoke a sense of fluidity and visual harmony, thereby attracting consumers seeking an aesthetically pleasing recreational item. In contrast, a gradient employing stark transitions between neon shades projects a bold, attention-grabbing image, targeting a different consumer demographic.

The effectiveness of the color gradient relies heavily on the quality of the materials and the precision of the manufacturing process. Substandard materials or imprecise application can result in uneven color distribution or premature fading, detracting from the intended visual impact. Furthermore, the gradient’s design must align with current fashion trends to maintain market relevance. Successful integration of gradient designs requires meticulous attention to color theory and a thorough understanding of consumer preferences. For instance, current trends may favor pastel gradients with a matte finish, while earlier designs favored high-gloss, primary color transitions.

Understanding the connection between color gradient design and consumer preference is paramount for manufacturers seeking to optimize product appeal. Challenges include anticipating shifting trends and ensuring consistent color quality across production batches. By carefully considering the principles of color theory and employing rigorous quality control measures, brands can effectively leverage the color gradient to enhance product desirability and market success.

2. Boot material

The selection of boot material constitutes a critical factor influencing the performance, durability, and aesthetic characteristics of these recreational wheeled boots. The material choice directly affects user comfort, ankle support, and the overall lifespan of the product.

- Vegan Leather Composition

Many models employ vegan leather, typically polyurethane (PU) or polyvinyl chloride (PVC), as the primary boot material. This choice caters to ethical consumer preferences and offers a relatively cost-effective alternative to genuine leather. The specific blend of polymers and the manufacturing process determine the material’s flexibility, resistance to abrasion, and susceptibility to cracking. For example, a thicker PU layer may offer enhanced durability but reduced breathability, potentially leading to discomfort during extended use.

- Impact on Color Integrity

The boot material’s surface properties influence the vibrancy and longevity of the applied color gradient. Materials with a smoother, less porous surface tend to retain color more effectively, resisting fading and discoloration caused by UV exposure and repeated cleaning. Conversely, more porous materials may absorb dyes unevenly, leading to inconsistent color distribution and premature fading. The chemical compatibility between the boot material and the dyes used to create the rainbow effect is crucial for maintaining long-term aesthetic appeal.

- Structural Support and Ankle Stability

The boot material’s inherent stiffness or flexibility directly impacts the level of ankle support provided. Stiffer materials offer greater stability, reducing the risk of ankle sprains during skating. However, excessive stiffness can restrict movement and reduce comfort. Manufacturers often incorporate strategically placed reinforcements or padding to optimize the balance between support and flexibility. The design and placement of these features, coupled with the material’s properties, significantly influence the overall skating experience.

- Influence on Weight and Maneuverability

The density of the boot material contributes to the overall weight of the skate, affecting maneuverability and energy expenditure during use. Lighter materials allow for quicker acceleration and easier transitions, but may compromise durability. Conversely, heavier materials provide a more stable platform but can lead to fatigue during prolonged skating sessions. Material selection is a compromise between performance characteristics and user comfort.

In conclusion, the boot material employed in the construction of these colorful wheeled boots serves as a foundational element influencing comfort, performance, aesthetic longevity, and ethical considerations. Trade-offs inherent in material selection necessitate a balanced approach, weighing the benefits and drawbacks to meet the diverse needs and preferences of the target audience.

3. Wheel Durometer

Wheel durometer, a measurement of a wheel’s hardness, significantly affects the performance characteristics of recreational wheeled boots, including those with vibrant color gradient designs. Durometer is measured on the ‘A’ scale, ranging from softer (lower numbers) to harder (higher numbers). The selection of an appropriate durometer is crucial for optimizing the skating experience based on the intended use and skating surface.

- Grip and Surface Adhesion

Softer wheels (e.g., 78A-85A) offer enhanced grip, particularly on rough or uneven surfaces. This increased adhesion allows for greater control and stability, especially beneficial for novice skaters or those prioritizing outdoor use. However, softer wheels tend to wear down more quickly, requiring more frequent replacement.

- Speed and Roll Efficiency

Harder wheels (e.g., 88A-101A) prioritize speed and roll efficiency on smooth surfaces like skating rinks or polished concrete. The reduced friction allows for faster acceleration and sustained momentum. While harder wheels offer increased speed, they provide less grip and can feel slippery on uneven or rough surfaces.

- Impact Absorption and Comfort

Softer wheels offer superior impact absorption, cushioning the skater from vibrations and bumps encountered on outdoor surfaces. This characteristic enhances comfort and reduces fatigue during longer skating sessions. Harder wheels, conversely, transmit more vibrations, which can be fatiguing on rough terrain but provide a more responsive feel on smooth surfaces.

- Durability and Longevity

Harder wheels generally exhibit greater durability and resistance to wear compared to softer wheels. This increased lifespan makes them a more cost-effective choice for skaters primarily utilizing smooth, indoor surfaces. The lifespan of softer wheels is reduced due to increased friction and wear on rougher terrains.

The choice of wheel durometer should align with the intended skating environment and the skater’s performance priorities. For recreational wheeled boots with colorful designs, a versatile medium-durometer wheel (e.g., 82A-85A) may offer a balanced compromise between grip, speed, comfort, and durability for diverse skating conditions. Selecting the appropriate durometer helps to optimize the skating experience and maintain the aesthetic appeal of the skates.

4. Bearing quality

Bearing quality represents a critical determinant of performance and user experience for recreational wheeled boots, irrespective of aesthetic design elements such as vibrant color gradients. The precision and materials utilized in bearing construction directly influence roll efficiency, speed, and the overall smoothness of the skating experience. In the context of colorfully designed wheeled boots, maintaining high bearing standards is essential to ensure that performance aligns with the product’s visual appeal.

- Material Composition and Durability

Bearing construction typically involves steel balls encased within inner and outer races. The grade of steel used directly impacts durability and resistance to corrosion. Higher-grade steel bearings exhibit reduced friction and increased lifespan, contributing to a smoother and more consistent roll. For example, bearings manufactured with chromium steel offer superior hardness and resistance to deformation compared to those utilizing lower-grade alloys. The implications for colorful wheeled boots are that despite the aesthetic focus, users expect reliable and long-lasting performance from all components, including bearings.

- ABEC Rating and Precision

The Annular Bearing Engineers’ Committee (ABEC) rating system defines the tolerances and precision of bearings, ranging from ABEC-1 (least precise) to ABEC-9 (most precise). Higher ABEC ratings indicate tighter tolerances and smoother operation, resulting in improved roll efficiency and reduced vibration. While higher ABEC ratings often correlate with higher cost, the investment can be justified by enhanced performance and reduced maintenance requirements. Users seeking optimal performance from their visually distinctive wheeled boots may opt for higher ABEC-rated bearings to maximize roll speed and minimize friction.

- Lubrication and Maintenance

Proper lubrication is essential for maintaining bearing performance and preventing premature wear. Bearing lubricant reduces friction between the balls and races, allowing for smoother rotation and increased speed. Regular cleaning and re-lubrication are necessary to remove dirt and debris that can accumulate within the bearing, degrading performance. For example, applying a synthetic lubricant specifically designed for bearings can extend their lifespan and maintain optimal roll efficiency. Users should adhere to recommended maintenance practices to ensure the longevity and performance of the bearings in their colorful wheeled boots.

- Seals and Protection

Bearing seals protect the internal components from contamination by dirt, moisture, and other environmental factors. Sealed bearings offer increased protection and reduced maintenance requirements compared to unsealed bearings. However, sealed bearings may exhibit slightly increased friction due to the presence of the seal. The choice between sealed and unsealed bearings depends on the intended usage environment and the user’s willingness to perform regular maintenance. For outdoor skating, sealed bearings are generally preferred to minimize the risk of contamination and maintain consistent performance.

In conclusion, bearing quality plays a crucial role in determining the overall performance and user satisfaction associated with visually distinctive wheeled boots. While aesthetic design elements such as vibrant color gradients contribute to the product’s appeal, users expect reliable and consistent performance from all components, including bearings. Investing in high-quality bearings and adhering to recommended maintenance practices ensures a smooth, efficient, and enjoyable skating experience, aligning the product’s performance with its visual aesthetics.

5. Chassis strength

Chassis strength is a foundational element directly impacting the safety, performance, and longevity of recreational wheeled boots, including those distinguished by vibrant color gradient designs. It provides the structural support necessary for stable skating and influences how effectively forces are transferred from the skater to the wheels.

- Material Composition and Load Bearing Capacity

The chassis materialtypically aluminum, reinforced nylon, or composite materialsdictates its ability to withstand stress and impact. Aluminum chassis offer superior strength and rigidity, making them suitable for aggressive skating styles and heavier users. Nylon or composite chassis, while lighter, may be more prone to flexing under stress. Insufficient chassis strength can lead to deformation or breakage, compromising stability and potentially causing injury. The material selected must balance strength with weight to optimize performance.

- Design Geometry and Stress Distribution

The physical design of the chassis influences how stress is distributed throughout the structure during skating maneuvers. Well-designed chassis incorporate features such as reinforcing ribs or strategic curvature to minimize stress concentrations and improve overall strength. Poorly designed chassis may be susceptible to failure at stress points, particularly near axle mounts or attachment points to the boot. Finite element analysis (FEA) is often employed to optimize chassis geometry and ensure adequate strength under various loading conditions.

- Attachment Method and Boot Integration

The manner in which the chassis is attached to the boot significantly affects the overall strength and stability of the wheeled boot assembly. Secure and robust attachment methods, such as through-bolting with reinforced plates, distribute forces evenly and minimize the risk of detachment. Weak or inadequate attachment points can lead to premature failure and compromised performance. The integration between the chassis and the boot must be carefully engineered to ensure a cohesive and structurally sound system.

- Influence on Energy Transfer and Responsiveness

Chassis strength directly affects the efficiency of energy transfer from the skater’s foot to the wheels. A rigid chassis minimizes energy loss due to flexing, resulting in a more responsive and efficient skating experience. Conversely, a flexible chassis may absorb energy, reducing acceleration and responsiveness. The balance between rigidity and flexibility is crucial for optimizing performance based on the intended skating style. A stronger chassis generally enhances control and power transfer, particularly during demanding maneuvers.

In summary, the chassis strength represents a fundamental performance parameter for recreational wheeled boots. The selected material, design geometry, and attachment method collectively determine its ability to withstand stress, maintain stability, and facilitate efficient energy transfer. These factors must be carefully considered in the design and manufacture of these colorful boots to ensure a safe, enjoyable, and long-lasting skating experience.

6. Closure system

The closure system, a critical functional element, secures the foot within the roller skate boot. Its design and effectiveness directly influence the skater’s comfort, stability, and control, irrespective of the skate’s aesthetic features such as a vibrant color gradient.

- Lace Configuration and Customization

Laces, a traditional closure method, allow for a highly customizable fit. Skaters can adjust tension across various points of the foot to achieve optimal comfort and support. The material and weave pattern of the laces influence their durability and resistance to loosening during use. For “impala roller skates rainbow,” the lace color often complements the overall aesthetic, contributing to the visual design. However, laces require manual adjustment and may loosen during extended skating sessions, potentially affecting performance and safety.

- Buckle and Strap Systems for Enhanced Security

Buckles and straps offer a more secure and convenient closure option compared to laces alone. Ratcheting buckles allow for precise tension adjustments, while Velcro straps provide quick and easy fastening. These systems enhance ankle support and prevent heel lift, improving stability and control. Integrating buckles and straps into the design of “impala roller skates rainbow” requires careful consideration of ergonomics and aesthetics. The placement and design of these components should not detract from the overall visual appeal of the skate while providing reliable functionality.

- Hybrid Closure Systems Combining Laces, Buckles, and Straps

Hybrid closure systems, incorporating a combination of laces, buckles, and straps, offer a versatile solution that balances customization, security, and convenience. Laces provide a personalized fit across the foot, while buckles and straps enhance ankle support and ease of use. This configuration is often found in higher-performance skates, where precise fit and secure closure are essential for optimal performance. The implementation of a hybrid closure system in “impala roller skates rainbow” represents a commitment to both functionality and style, catering to skaters who prioritize both performance and aesthetics.

- Impact of Closure System on Fit and Performance

The effectiveness of the closure system directly affects the overall fit and performance of the skate. A poorly designed or improperly adjusted closure system can lead to discomfort, instability, and reduced control. Conversely, a well-designed and properly fitted closure system enhances comfort, improves stability, and maximizes power transfer. The choice of closure system for “impala roller skates rainbow” should consider the target audience and their skating preferences, balancing functionality, aesthetics, and ease of use.

In conclusion, the closure system is a crucial element determining the fit and performance of roller skates. For visually distinctive models, integrating a closure system that balances functionality with the overall aesthetic is key. Whether utilizing laces, buckles, straps, or a hybrid configuration, the chosen closure system must provide secure and comfortable fit to optimize the skating experience.

7. Size availability

Size availability represents a crucial factor in the market accessibility and consumer satisfaction associated with recreational wheeled boots featuring distinctive designs. A comprehensive range of sizes ensures that a broader spectrum of potential customers can acquire and utilize these visually appealing products.

- Market Reach and Inclusivity

A limited size range restricts the potential customer base. Disproportionate availability, such as focusing solely on sizes typically associated with younger individuals, excludes adults or those with larger feet. Offering a wide range, including both smaller and larger sizes, promotes inclusivity and expands market penetration. For example, if a brand offers its colorful wheeled boots only in sizes US 5-8, it excludes a significant portion of the adult population. Extending the range to US 4-12 would cater to a more diverse clientele.

- Fit and Comfort Considerations

Accurate sizing is essential for achieving a comfortable and secure fit. Inadequate size availability forces consumers to compromise, potentially selecting skates that are either too tight or too loose. Ill-fitting skates can lead to discomfort, reduced performance, and an increased risk of injury. For instance, a skater forced to use a size too small may experience blisters or numbness, while one using a size too large may lack adequate ankle support and control.

- Impact on Brand Perception

Size availability contributes to overall brand perception. A brand that offers a limited range may be perceived as less committed to customer satisfaction or as catering to a niche market. Conversely, a brand that prioritizes comprehensive size options signals a commitment to inclusivity and customer needs. If the vibrantly designed wheeled boots are not available in a consumer’s size, that consumer may shift their interest to brands that offer broader sizing.

- Inventory Management and Production Planning

Size availability directly impacts inventory management and production planning. Accurately forecasting demand across different sizes is crucial for optimizing production runs and minimizing excess inventory or stockouts. Failing to accurately predict demand for specific sizes can lead to lost sales and reduced profitability. For example, manufacturers must analyze historical sales data and market trends to determine the optimal production quantities for each size of their “impala roller skates rainbow” line.

In conclusion, ensuring adequate size availability is essential for maximizing market reach, promoting customer satisfaction, and optimizing inventory management for recreational wheeled boots. Brands must prioritize offering a comprehensive range of sizes to cater to diverse customer needs and maintain a positive brand image.

Frequently Asked Questions

The following questions and answers address common inquiries regarding these visually distinctive roller skates. The information provided aims to offer clarity and guidance to prospective purchasers.

Question 1: What factors determine the durability of the boot material used in these skates?

Boot material durability depends primarily on the composition of the synthetic leather or PVC utilized. Thicker materials and higher-grade polymers generally exhibit greater resistance to abrasion and cracking. However, regular maintenance and proper storage practices are also critical in extending the lifespan of the boot.

Question 2: How does wheel durometer impact skating performance on different surfaces?

Wheel durometer dictates grip and speed. Softer wheels (lower durometer numbers) provide enhanced grip on rough surfaces but may wear down more quickly. Harder wheels (higher durometer numbers) prioritize speed on smooth surfaces but offer reduced grip on uneven terrain. Selection should align with the intended skating environment.

Question 3: What are the key differences between ABEC-5 and ABEC-7 rated bearings?

ABEC (Annular Bearing Engineers’ Committee) ratings indicate bearing precision. Higher ABEC ratings signify tighter tolerances and smoother operation. ABEC-7 bearings offer improved roll efficiency and reduced friction compared to ABEC-5 bearings. However, the performance difference may be negligible for casual recreational skating.

Question 4: How does chassis material influence the overall stability of the roller skates?

Chassis material directly affects stability. Aluminum chassis offer superior strength and rigidity, providing a more stable platform for heavier users or aggressive skating styles. Nylon or composite chassis are lighter but may exhibit greater flexibility, potentially reducing stability.

Question 5: What maintenance is required to preserve the vibrant color gradients?

To preserve the color gradient, avoid prolonged exposure to direct sunlight, which can cause fading. Clean the boot regularly with a mild soap and water solution. Harsh chemicals can damage the finish. Store the skates in a cool, dark place when not in use.

Question 6: Are these roller skates suitable for outdoor use?

Suitability for outdoor use depends on the wheel durometer and the skating surface. Softer wheels are generally preferred for outdoor skating due to their enhanced grip and impact absorption. Regular inspection and maintenance are essential for prolonging the lifespan of the skates when used outdoors.

In summary, the selection and maintenance of these recreational wheeled boots require careful consideration of factors such as boot material, wheel durometer, bearing quality, chassis strength, color preservation, and intended usage. These considerations ensure both performance and longevity.

The subsequent section will offer tips for purchasing roller skates online.

Concluding Remarks on Recreational Wheeled Boots

The preceding analysis has explored various facets of “impala roller skates rainbow,” from aesthetic design elements to functional components that influence performance and longevity. Key aspects examined included color gradient application, boot material selection, wheel durometer considerations, bearing quality assessment, chassis strength evaluation, closure system effectiveness, and the importance of comprehensive size availability. These elements collectively define the quality and appeal of these visually distinctive products.

The information provided serves to equip consumers with the knowledge necessary to make informed purchasing decisions. Further research into specific models and individual needs is encouraged to ensure optimal satisfaction. Understanding these attributes empowers users to select equipment that aligns with their performance requirements, aesthetic preferences, and long-term expectations.