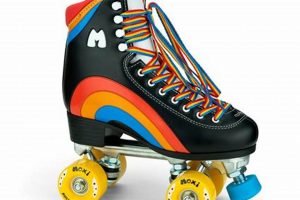

These decorative accessories, often attached to the front of wheeled boots, are crafted from soft, fluffy materials and serve a primarily aesthetic purpose. They add a playful and visually appealing element to the overall appearance of the footwear.

The utilization of these embellishments can enhance the skater’s personal style and create a distinctive look. Historically, similar adornments have been used in various forms of recreational footwear to express individuality and add a touch of whimsy. Their presence can transform functional equipment into a statement of personal expression.

The following discussion will delve into the various types of materials used in construction, attachment methods, customization options, and safety considerations related to these accessories, providing a comprehensive understanding for potential users and enthusiasts.

Enhancing Roller Skates with Decorative Accessories

This section provides practical advice for selecting and utilizing these accessories, ensuring both aesthetic appeal and safety during use.

Tip 1: Secure Attachment is Paramount. Employ durable attachment methods to prevent detachment during skating. A loose accessory presents a tripping hazard.

Tip 2: Material Selection Matters. Opt for materials that are lightweight and resistant to moisture. Heavy or absorbent materials can impede performance and become unsanitary.

Tip 3: Size and Placement Influence Maneuverability. Choose a size that complements the skates without obstructing movement. Incorrect placement can affect balance and control.

Tip 4: Regular Maintenance Prolongs Lifespan. Periodically inspect and clean the accessories to maintain their appearance and prevent the accumulation of debris. Neglect can lead to premature wear and tear.

Tip 5: Color Coordination Enhances Visual Appeal. Select colors that harmonize with the skates and attire. A cohesive color scheme contributes to a polished and professional look.

Tip 6: Consider Reflective Elements for Night Skating. Integrate reflective materials for increased visibility in low-light conditions. Enhanced visibility improves safety and awareness.

Tip 7: Avoid Excessive Embellishment. Maintain a balance between aesthetic enhancement and practicality. Overly elaborate decorations can be distracting and cumbersome.

Proper selection, installation, and maintenance of these accessories are crucial for optimizing both the visual appeal and functional performance of roller skates.

The subsequent segment will address frequently asked questions, offering further clarification and guidance on their appropriate utilization.

1. Aesthetic Customization

Aesthetic customization, in the context of roller skate accessories, specifically those of a decorative nature, refers to the practice of modifying or personalizing the appearance of the skates to reflect individual preferences or stylistic choices. The addition of these fluffy accesories allows for a diverse range of aesthetic modifications, transforming functional equipment into personalized artistic expressions. This is achieved through varying colors, sizes, textures, and attachment methods. For example, a skater might select vibrant neon colors to match a retro-inspired skating outfit, or opt for more subtle, muted tones for a classic, understated look. The impact of aesthetic customization extends beyond mere visual appeal; it fosters a sense of ownership and personal connection with the skating experience.

The significance of aesthetic customization manifests in several practical ways. It allows skaters to differentiate their equipment, reducing the likelihood of misidentification in shared spaces, such as skating rinks or parks. Furthermore, it presents opportunities for self-expression and creativity, fostering a sense of community among skaters who share similar aesthetic sensibilities. Competitive skaters might employ these adornments to enhance their performance attire, creating a more visually engaging and memorable performance for judges and audiences. Companies such as Sure-Grip and Riedell acknowledge this desire for personalization by offering a wide array of customization options and aftermarket accessories.

In summary, aesthetic customization with adornments like this serves a purpose beyond surface-level embellishment. It enhances identity, aids in practical identification, and fuels creative expression. While the visual impact is undeniable, the true importance lies in its contribution to the skater’s overall experience and connection with the sport. Potential challenges include ensuring the selected aesthetic customizations remain safely secured during use and do not impede performance.

2. Attachment Security

The secure attachment of decorative elements is a critical consideration when integrating them with roller skates. The potential for detachment during use presents a tangible safety hazard. A detached accessory can become a tripping obstacle for the skater or other individuals in the vicinity. Furthermore, the sudden loss of a decorative item can distract the skater, potentially leading to loss of balance and subsequent injury. Therefore, robust attachment methods are paramount to mitigating these risks. Examples of secure attachment methods include durable adhesives, strong stitching, or mechanical fasteners designed to withstand the dynamic forces experienced during skating. Failure to prioritize secure attachment can result in accidents and compromise the skater’s safety.

The selection of an appropriate attachment method directly influences the longevity and overall effectiveness of the decorative addition. Adhesives, while offering ease of application, may degrade over time due to exposure to moisture, temperature fluctuations, or physical stress. Stitching provides a more robust connection, but requires careful execution to prevent damage to the skate’s structure. Mechanical fasteners, such as screws or rivets, offer a high degree of security but necessitate specialized tools and expertise for proper installation. The choice of method should be informed by the specific materials involved, the anticipated level of stress, and the desired lifespan of the accessory. Regular inspection of the attachment point is also essential to identify and address any signs of wear or loosening before they escalate into a safety concern.

In summary, attachment security is not merely a cosmetic detail; it is a fundamental safety requirement when incorporating decorative elements into roller skates. The consequences of insecure attachment can range from minor annoyances to serious injuries. By employing robust attachment methods, conducting regular inspections, and prioritizing safety over aesthetics, skaters can enjoy the benefits of personalized equipment without compromising their well-being. The challenge lies in striking a balance between creative expression and responsible safety practices, ensuring that the joy of skating is not overshadowed by preventable accidents.

3. Material Lightweight

The selection of lightweight materials is a critical factor in the design and application of decorative elements to roller skates. Excess weight can negatively impact performance, maneuverability, and overall user experience. Therefore, a careful consideration of material properties is essential to ensure both aesthetic appeal and functional integrity.

- Reduced Inertia

Lighter accessories contribute to lower inertia, allowing for quicker acceleration and deceleration. This is particularly important in disciplines such as roller derby or freestyle skating where rapid changes in direction are essential. Utilizing materials such as acrylic yarn or lightweight synthetic fibers minimizes the added mass, preserving the skater’s agility.

- Minimized Fatigue

Increased weight on the skates can lead to premature fatigue, especially during extended skating sessions. Lighter accessories reduce the strain on the skater’s legs and ankles, allowing for longer periods of comfortable use. This is especially relevant for recreational skaters or those engaged in long-distance skating activities. Materials like lightweight nylon or finely spun wool offer a balance of durability and reduced weight.

- Enhanced Maneuverability

The overall maneuverability of the skates is directly affected by the weight distribution. Heavy accessories can shift the center of gravity, making it more difficult to execute complex maneuvers. Lightweight materials help maintain a stable center of gravity, allowing for precise control and enhanced performance. Materials such as thin, flexible plastics or feathers (when appropriately secured) offer minimal impact on maneuverability.

- Preserved Skate Integrity

Excessive weight, particularly when concentrated in a specific area, can place undue stress on the skate’s structure and hardware. Over time, this can lead to premature wear and tear, reducing the lifespan of the skates. Lightweight materials minimize this stress, helping to preserve the integrity of the skates and extend their usability. Choosing materials that distribute weight evenly across the attachment points further mitigates this risk.

In conclusion, the emphasis on lightweight materials for decorative roller skate accessories is not merely an aesthetic preference. It directly impacts the skater’s performance, comfort, and the longevity of their equipment. A careful consideration of material properties is essential for optimizing both the visual appeal and functional attributes of these embellishments.

4. Visibility Enhancement

The integration of visibility-enhancing elements into roller skate accessories directly addresses safety concerns, particularly during low-light conditions. While decorative additions primarily serve an aesthetic function, incorporating reflective materials or light-emitting diodes (LEDs) transforms them into crucial safety features. This intersection of aesthetics and safety is particularly relevant for skaters who utilize public spaces or navigate areas with vehicular traffic. The addition of reflective strands to a decorative pom-pom, for example, significantly increases a skater’s visibility to motorists and pedestrians, reducing the risk of accidents. Therefore, visibility enhancement is not merely a desirable attribute but a potentially life-saving component.

Practical applications of visibility enhancement are diverse. Reflective materials can be woven into the fabric of the decorative accessories, creating a subtle yet effective means of increasing visibility. Alternatively, small, battery-powered LEDs can be integrated into the design, providing a more pronounced visual signal. These LEDs can be programmed to flash or change color, further enhancing their conspicuity. The selection of the appropriate visibility-enhancing method depends on factors such as the intended use environment, the skater’s personal preferences, and the desired level of visibility. For instance, skaters who frequently skate at night may prioritize accessories with high-intensity LEDs, while those who primarily skate during daylight hours may opt for more subtle reflective elements.

In conclusion, while the primary function of certain accessories is decorative, the strategic incorporation of visibility-enhancing elements represents a crucial safety consideration. The synergistic relationship between aesthetics and safety transforms these accessories from mere embellishments into essential components of a skater’s protective gear. The challenge lies in designing accessories that effectively balance aesthetic appeal with functional safety features, ensuring that skaters can express their personal style without compromising their well-being. By prioritizing visibility enhancement, manufacturers and skaters alike can contribute to a safer and more enjoyable skating experience for all.

5. Skating Style

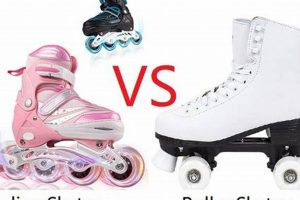

Skating style directly influences the suitability and integration of decorative pom poms. Different skating disciplines, ranging from artistic roller skating to aggressive inline skating, demand varying levels of functionality and aesthetic expression. The selection and application of these accessories must align with the specific requirements and conventions of each style. For instance, a figure skater might utilize delicate, intricately designed adornments to complement their performance attire, while a park skater would likely forgo such additions due to concerns about safety and interference with technical maneuvers. The relationship is causal: skating style dictates accessory choice.

The importance of aligning aesthetic choices with skating style extends beyond mere visual harmony. In competitive environments, judges often assess the overall presentation, including the cohesiveness of the skater’s attire and accessories. A mismatch between accessory style and skating discipline can detract from the overall score. Conversely, a well-coordinated ensemble can enhance the skater’s performance and contribute to a more positive impression. For example, a roller derby skater opting for durable, low-profile accessories demonstrates a practical understanding of the demands of their sport, signaling a commitment to both performance and safety.

Understanding the nuances of this connection allows skaters to make informed decisions regarding their equipment and presentation. Challenges arise when skaters prioritize aesthetic appeal over functionality, potentially compromising their safety or performance. By carefully considering the demands of their chosen skating style, skaters can effectively integrate decorative additions that enhance their overall experience without detracting from their abilities. The thoughtful application of these accessories demonstrates an understanding of the sport’s traditions and a commitment to both form and function.

Frequently Asked Questions Regarding Decorative Accessories for Roller Skates

This section addresses common inquiries concerning the selection, maintenance, and safe usage of decorative accessories on roller skates, providing clarity and guidance for informed decision-making.

Question 1: What is the recommended method for attaching decorative accessories to roller skates to ensure maximum security?

The selection of an appropriate attachment method is paramount for safety. Durable adhesives, reinforced stitching, or mechanical fasteners such as screws or rivets are viable options. The chosen method should be compatible with the materials involved and capable of withstanding the stresses associated with skating. Regular inspection of the attachment points is essential to detect and address any signs of loosening or wear.

Question 2: Are there specific material types that are better suited for decorative accessories on roller skates, considering factors such as weight and weather resistance?

Lightweight, weather-resistant materials are preferable. Acrylic yarn, synthetic fibers, and treated fabrics offer a balance of durability and minimal weight. Avoid absorbent materials like cotton, as they can retain moisture and become heavy, impacting performance and potentially compromising hygiene.

Question 3: How does the size and placement of decorative accessories affect the skater’s balance and maneuverability?

Excessively large or poorly placed accessories can negatively impact balance and maneuverability. The size should be proportionate to the skate, and the placement should avoid obstructing movement or shifting the center of gravity. Careful consideration of these factors is crucial for maintaining control and preventing accidents.

Question 4: What maintenance procedures are recommended for preserving the appearance and extending the lifespan of decorative accessories?

Regular cleaning is essential for maintaining appearance and preventing the accumulation of dirt and debris. Gentle washing with mild soap and water is generally sufficient. Avoid harsh chemicals or abrasive cleaners, as they can damage the materials. Store the skates and accessories in a dry, well-ventilated area to prevent mold or mildew growth.

Question 5: Can reflective materials or lighting be incorporated into decorative accessories to enhance visibility during low-light conditions?

The integration of reflective materials or light-emitting diodes (LEDs) is highly recommended for enhancing visibility during low-light conditions. Reflective strips, embedded LEDs, or illuminated designs can significantly increase a skater’s visibility to motorists and pedestrians, reducing the risk of accidents.

Question 6: Are there specific regulations or guidelines governing the use of decorative accessories on roller skates in public skating venues?

Regulations regarding decorative accessories vary by venue. It is advisable to consult the specific rules and guidelines of the skating rink or public space before utilizing such adornments. Some venues may restrict the use of accessories that could pose a safety hazard or damage the skating surface.

In summary, informed decision-making regarding the selection, attachment, maintenance, and safe usage of these embellishments is critical for optimizing both the aesthetic appeal and functional performance of roller skates.

The subsequent section will provide a concluding overview, reinforcing key concepts and offering final recommendations.

Conclusion

This exploration has examined “pom poms for roller skates” from various perspectives, emphasizing their aesthetic value, the criticality of secure attachment, the importance of lightweight materials, the benefits of visibility enhancement, and the influence of skating style on their appropriate use. Safe integration and informed decision-making are paramount.

As skaters pursue personalization, adherence to safety standards remains essential. The thoughtful application of “pom poms for roller skates,” balancing individual expression with responsible practices, ensures an enjoyable and secure skating experience. Future innovations should prioritize both aesthetic appeal and enhanced safety features for these accessories.