The term describes a specific type of recreational footwear characterized by its design elements that reflect styles and manufacturing techniques prevalent in earlier decades, typically ranging from the mid-20th century to the early 21st century. These skates often feature high-top boots, metal or composite frames, and traditional wheel configurations. As an example, a pair of skates manufactured in the 1970s with bright color schemes and durable construction would fall under this classification.

Collecting and using these items provides benefits beyond mere recreation. These skates offer a tangible connection to past eras, representing historical trends in sport, fashion, and manufacturing. They provide opportunities for physical activity and contribute to a sense of nostalgia. From a historical perspective, these skates illustrate the evolution of design and technology in the skating industry. Their enduring popularity highlights their appeal and relevance across generations.

The subsequent sections will delve into specific aspects, including the identifying characteristics of these items, variations in styles and brands, maintenance and restoration techniques, and considerations for purchasing and utilizing these skates.

Guidance on Acquisition and Maintenance

The following points address key considerations for those interested in acquiring and maintaining skating equipment of this kind.

Tip 1: Authentication is Paramount. Prior to acquisition, thoroughly verify the authenticity of the equipment. Genuine articles often possess unique markings, material compositions, and construction methods specific to their era. Cross-reference identifying features with reputable sources and vintage product catalogs.

Tip 2: Assess Structural Integrity. Examine the boot, frame, and wheels for signs of degradation, such as cracks, rust, or excessive wear. Components made of rubber or plastic may be particularly susceptible to deterioration. Consider professional evaluation for a comprehensive assessment of structural soundness.

Tip 3: Wheel Selection Matters. The wheels significantly impact the skating experience. Original wheels may be brittle or worn. Replacing them with reproduction or contemporary wheels of appropriate hardness and diameter can enhance performance and safety. Consider the skating surface when selecting replacement wheels.

Tip 4: Bearing Maintenance is Essential. Bearings facilitate smooth wheel rotation. Regularly clean and lubricate the bearings to minimize friction and extend their lifespan. Utilize appropriate solvents and lubricants designed for precision bearings.

Tip 5: Boot Care Prolongs Life. The boot provides support and protection. Clean and condition leather or synthetic boots to prevent cracking and maintain flexibility. Replace worn laces and insoles to enhance comfort and support.

Tip 6: Frame Adjustments Enhance Performance. The frame’s alignment and tightness affect stability and maneuverability. Inspect and adjust the frame mounting hardware to ensure proper alignment. Tighten loose bolts and screws to prevent unwanted movement.

Tip 7: Safe Storage Prevents Deterioration. Store the equipment in a cool, dry environment away from direct sunlight and extreme temperatures. Utilize protective bags or cases to shield the equipment from dust and physical damage.

Adhering to these guidelines ensures both the longevity and performance of the equipment, maximizing the enjoyment derived from its use.

The following sections will explore restoration techniques, identify sources for purchasing authentic components, and discuss advanced customization options.

1. Authenticity

The authenticity of items described as “retro vintage roller skates” directly influences their perceived value, historical significance, and desirability among collectors. Scrutinizing potential purchases for genuine features is paramount. This involves verifying manufacturing marks, design specifications, and material compositions against documented historical records. For example, skates claimed to be from the 1940s should exhibit materials and construction techniques consistent with that era, such as specific types of leather, metal alloys, and wheel compositions that predate later synthetic alternatives. Discrepancies in these details can indicate reproduction or modification, impacting the authenticity and therefore the overall worth of the item.

The practical significance of understanding authenticity extends beyond monetary considerations. Authentically constructed equipment provides a more accurate representation of the skating experience during a specific period. This is crucial for historical re-enactments, museum displays, and individuals seeking to connect with the past. In contrast, reproductions, while visually similar, often lack the precise engineering and material properties of originals, leading to differences in performance and durability. For example, a reproduction skate frame might be made from a lighter, less durable alloy compared to its original counterpart, affecting its ability to withstand the rigors of skating.

Ultimately, establishing the authenticity of “retro vintage roller skates” requires careful examination, diligent research, and, in some cases, expert consultation. The challenges lie in the increasing sophistication of reproduction techniques and the natural degradation of materials over time. However, the effort invested in verifying authenticity directly translates to a more informed acquisition, a deeper appreciation for skating history, and the preservation of a valuable cultural artifact. It is an effort that benefits both the collector and the broader community interested in historical preservation.

2. Material Durability

The longevity and functionality of these items are directly correlated with the durability of their constituent materials. The selection of materials during manufacturing determined the equipment’s ability to withstand the stresses of use, environmental factors, and the passage of time. Understanding the materials employed and their inherent durability characteristics is crucial for assessing the condition and suitability of these skates for both collection and practical use.

- Boot Construction Materials

The boots were commonly constructed from leather, canvas, or early synthetic materials. Leather, while durable, is susceptible to cracking and drying if not properly maintained. Canvas provides flexibility but offers less protection and support. Early synthetics, although innovative for their time, may degrade or become brittle with age. The type and condition of the boot material directly impact the skate’s structural integrity and user comfort.

- Frame Composition

Frames were primarily manufactured from metal alloys, such as steel or aluminum. Steel frames are robust but prone to corrosion, while aluminum frames offer a lighter weight but may be more susceptible to bending or fatigue under stress. The presence of rust, bends, or cracks in the frame compromises the skate’s stability and safety.

- Wheel Materials

Wheels were historically made from materials like clay, wood, or early forms of polyurethane. Clay and wooden wheels provide a characteristic vintage feel but offer limited grip and durability. Early polyurethane wheels represented an advancement, offering improved performance but were still susceptible to wear and degradation. The condition of the wheels influences the smoothness of the skating experience and the overall safety of the equipment.

- Fastening Components

Rivets, screws, and other fastening components hold the skates together. These components are subject to stress and corrosion, potentially leading to loosening or failure. The integrity of the fastening system directly impacts the structural stability of the entire skate assembly.

The material durability across the various components determines the overall condition and usability of these skates. Evaluating these aspects allows for an informed assessment of a vintage item’s suitability for restoration, collection, or practical use, ensuring that the equipment provides a safe and enjoyable skating experience.

3. Functional Mechanics

The operational effectiveness of “retro vintage roller skates” is intrinsically linked to their functional mechanics. The interplay between the boot, frame, wheels, and bearings dictates performance characteristics such as speed, maneuverability, and stability. Deficiencies in any one of these components can compromise the overall skating experience and potentially lead to safety hazards. For instance, worn bearings increase friction, reducing speed and requiring greater effort for propulsion. Similarly, misaligned or weakened frames can induce instability, making it difficult to maintain balance and control. The relationship between the physical condition of these mechanical elements and the skate’s performance is a direct cause-and-effect scenario.

A practical example illustrating the importance of functional mechanics is the restoration process often undertaken by collectors. Prior to use, these skates frequently require extensive refurbishment to address issues stemming from age and wear. This might involve replacing deteriorated bearings with modern equivalents, reinforcing weakened frame components with welding or bracing, or re-truing wheel alignment to ensure smooth rotation. The successful execution of these repairs hinges upon a thorough understanding of the mechanical principles governing skate operation and the proper techniques for restoring them to a functional state. Failure to address these mechanical shortcomings can result in a diminished skating experience and increase the risk of injury.

In summary, functional mechanics represent a critical component of “retro vintage roller skates,” impacting both their usability and safety. Understanding the interrelationships between individual components, recognizing the signs of mechanical degradation, and implementing appropriate maintenance or restoration procedures are essential for preserving these skates and ensuring their continued functionality. The challenges associated with maintaining vintage equipment underscores the importance of informed decision-making, particularly when considering the acquisition or use of “retro vintage roller skates.”

4. Aesthetic Design

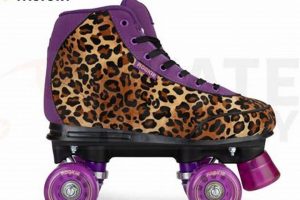

The visual characteristics of “retro vintage roller skates” constitute a significant aspect of their appeal, reflecting specific eras and cultural trends. These design elements, encompassing color palettes, material choices, and stylistic features, contribute substantially to the overall value and collectibility of the skates.

- Color Palettes and Graphics

Dominant color schemes and graphic motifs often denote the period of manufacture. For example, vibrant, contrasting colors and geometric patterns are characteristic of the 1970s, while pastel shades and simpler designs are more typical of earlier decades. These color choices are representative of broader stylistic trends in fashion and design, thereby adding to the skates’ historical context. Consider a pair with bright orange and yellow stripes, immediately placing it within a specific aesthetic era.

- Boot Silhouette and Detailing

The shape and construction of the boot are critical aesthetic identifiers. High-top boots with padded collars, common in the 1980s, offer a distinct visual contrast to the lower-cut, more streamlined designs of earlier models. Detailing, such as stitching patterns, logo placement, and the use of decorative elements, further enhances the skate’s aesthetic profile. The boot’s contour and trimmings serve as a visual marker, differentiating models based on design philosophy and market appeal.

- Hardware and Component Finishes

The finish and material of the frame, wheels, and other hardware components significantly contribute to the overall aesthetic. Chrome plating, polished aluminum, and colored plastic wheels each evoke distinct visual impressions. The hardware’s texture and sheen interact with the boot’s design, creating a cohesive aesthetic experience. For example, a brushed steel frame paired with leather boots imparts a sense of rugged durability.

- Branding and Logo Integration

The strategic placement and styling of brand logos and insignias reflect the marketing strategies of the time. Logo designs may incorporate stylized fonts, symbolic imagery, and specific color combinations to convey brand identity and appeal to target demographics. The presence and condition of these brand elements contribute to the skates’ authenticity and historical value, serving as a marker of consumer culture during the era in which the item was released.

The interplay of these aesthetic elements transforms “retro vintage roller skates” from mere recreational equipment into tangible artifacts of design history. These visual characteristics serve as a crucial aspect of preservation and appreciation, enabling the skates to represent specific cultural movements and artistic expressions from past decades. Each item tells a visual story of style and manufacturing trends.

5. Historical Context

The historical context surrounding “retro vintage roller skates” imbues these items with significance beyond their functional purpose. Examining the evolution of roller skate design, manufacturing techniques, and societal trends reveals a rich tapestry of technological innovation, economic shifts, and cultural expression.

- Evolution of Design and Technology

The transformation of roller skates from rudimentary metal-wheeled contraptions to sophisticated recreational equipment reflects significant advancements in materials science, engineering, and manufacturing processes. Early skates often featured simple metal frames and rudimentary wheel bearings. Later models incorporated innovations like adjustable trucks, improved wheel materials (e.g., polyurethane), and ergonomically designed boots. These technological milestones directly influenced skating performance, comfort, and safety.

- Economic Influences on Production and Consumption

Economic factors significantly impacted the production and accessibility of roller skates. During periods of economic prosperity, recreational spending increased, leading to greater demand for and investment in new skate designs. Conversely, economic downturns often resulted in reduced production volumes and a focus on more affordable, utilitarian models. The prevailing economic climate shaped both the types of skates produced and the demographics that could afford them.

- Social and Cultural Trends in Skating

Skating has mirrored broader social and cultural trends throughout history. From the roller rinks of the 1930s and 1940s, which provided a communal gathering space during challenging times, to the roller disco craze of the 1970s, skating has served as a form of social expression and recreation. The emergence of different skating styles (e.g., artistic skating, roller derby, skateboarding) reflects evolving subcultures and recreational preferences.

- Impact of Materials and Manufacturing Processes

The availability and cost of raw materials, along with advancements in manufacturing processes, profoundly influenced skate design and production. The transition from metal to plastic components, for instance, allowed for greater design flexibility, reduced manufacturing costs, and lighter-weight skates. Similarly, the adoption of mass production techniques enabled manufacturers to produce skates on a larger scale, making them more accessible to a wider consumer base.

By understanding these facets of historical context, one gains a deeper appreciation for “retro vintage roller skates” as tangible representations of technological progress, economic forces, and cultural trends. These items serve as historical artifacts, offering insights into the past and reflecting the enduring human desire for recreation and self-expression. They offer a historical perspective that would be unattainable if not for examining the historical context.

6. Collectibility

The collectibility of “retro vintage roller skates” is governed by a confluence of factors, including rarity, condition, historical significance, and aesthetic appeal. Rarity, often determined by limited production runs or short periods of availability, significantly elevates an item’s desirability among collectors. Condition directly impacts value, with well-preserved or expertly restored skates commanding higher prices. Historical significance, such as association with notable events or figures in skating history, contributes to a skate’s collectibility. Aesthetic appeal, encompassing design elements representative of specific eras or styles, further enhances its attractiveness to collectors. The interaction of these elements dictates the demand and valuation within the collector’s market. A real-world example is a pair of Chicago Roller Skates from the 1930s in original packaging. Their rarity and condition result in high demand from collectors.

The practical significance of understanding collectibility extends to both buyers and sellers within the vintage market. For buyers, recognizing the key attributes that contribute to collectibility enables informed purchasing decisions, mitigating the risk of overpaying for misrepresented or less desirable items. For sellers, accurately assessing the collectibility of their skates allows for appropriate pricing strategies, maximizing potential returns. Furthermore, knowledge of market trends and collector preferences facilitates the identification of valuable items that might otherwise be overlooked. This understanding allows for investment in quality preservation.

In summary, the collectibility of “retro vintage roller skates” is a multifaceted concept driven by a combination of objective and subjective factors. Accurate assessment of rarity, condition, historical significance, and aesthetic appeal is crucial for both buyers and sellers seeking to navigate the vintage market effectively. The enduring interest in these items underscores their cultural significance and provides tangible opportunities for investment and preservation. Without this collectibility, there would be less incentive to restore and protect these historic recreational artifacts.

Frequently Asked Questions about Retro Vintage Roller Skates

The following section addresses common inquiries and clarifies potential misconceptions regarding equipment of this nature.

Question 1: What constitutes a genuinely “retro vintage” pair of roller skates?

A determination of genuineness hinges on factors such as the manufacturing era, materials utilized, and design characteristics. Skates produced prior to the widespread adoption of modern plastics and featuring distinctive design elements specific to past decades (e.g., high-top leather boots, metal frames) are generally considered authentically retro vintage.

Question 2: Are skates of this type safe for use in contemporary skating environments?

Safety depends largely on the condition of the skates and the user’s skill level. Thorough inspection for structural integrity (e.g., frame cracks, wheel wear) is crucial. Replacing worn components, such as wheels and bearings, with modern equivalents can enhance safety. It’s recommended to employ appropriate safety gear, regardless of skate model. User discretion is advised.

Question 3: How does one properly maintain and preserve these items?

Maintenance involves regular cleaning to remove dirt and debris, lubrication of bearings, and protection from moisture and extreme temperatures. Leather components require periodic conditioning to prevent drying and cracking. When not in use, skates should be stored in a protective bag or case to minimize dust accumulation and physical damage.

Question 4: What are the primary factors influencing the value of these skates?

Value is influenced by rarity, condition, originality, and historical significance. Skates produced in limited quantities, those in excellent condition, and models associated with specific events or personalities in skating history command higher prices. Skates in original condition are typically more valuable than restored models.

Question 5: Where can one reliably acquire authentic examples of these skates?

Potential sources include antique shops, vintage clothing stores, online auction sites specializing in vintage goods, and estate sales. Thorough research and careful examination of the skates prior to purchase are essential to verify authenticity and condition.

Question 6: Can reproduction skates be considered “retro vintage”?

Reproduction skates, while designed to resemble vintage models, are not genuinely “retro vintage.” They lack the historical provenance and original materials that define authentic examples. While reproductions may offer a similar aesthetic, they should be clearly identified as such and are typically valued considerably lower than original skates.

These answers provide a basic understanding of items described by the term. For specific advice, consulting with experts specializing in vintage sporting goods is recommended.

The following sections will detail information about the future and impact on vintage skates.

Conclusion

The preceding examination has illuminated various facets of “retro vintage roller skates,” ranging from their historical context and material composition to their aesthetic design and collectibility. An understanding of these elements is crucial for both enthusiasts and those seeking to acquire or preserve these artifacts. Furthermore, awareness of maintenance requirements and safety considerations ensures their continued usability and longevity. The preceding information gives a detailed picture of this recreational artifact.

The enduring appeal of these skates underscores their significance as tangible representations of technological innovation, economic influences, and cultural trends. Preservation efforts, whether focused on meticulous restoration or careful documentation, contribute to the ongoing appreciation of these items and their role in shaping the history of recreational pursuits. As cultural symbols, these items show us glimpses into the past, and we are to preserve these items for the future.