This equipment facilitates movement and performance across various roller skating disciplines. Constructed with particular attention to fit, support, and maneuverability, the articles are designed to meet the demands of both recreational and competitive skaters. These products are commonly used in artistic skating, roller derby, and recreational skating environments.

The design focuses on providing optimal ankle support and control, thereby enhancing the skater’s ability to execute complex maneuvers and maintain balance. Historically, the brand has been associated with quality and durability, influencing the evolution of roller skating equipment standards. The product’s benefits extend to improved performance, reduced risk of injury, and enhanced overall skating experience.

The following sections will explore the different types, features, and considerations when choosing appropriate equipment for specific skating needs. These factors will provide a comprehensive overview, assisting consumers in making informed purchasing decisions.

Equipment Selection Tips

Choosing appropriate roller skating equipment is crucial for performance, safety, and overall enjoyment. The following guidelines offer essential considerations when selecting suitable models.

Tip 1: Assess Skill Level: Match the equipment’s capabilities to the skater’s experience. Beginners may benefit from models offering enhanced stability, while advanced skaters may require greater responsiveness and customization options.

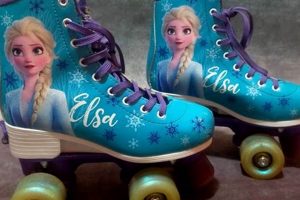

Tip 2: Determine Intended Use: Different skating disciplines demand specific features. Artistic skating necessitates precise control, while roller derby requires durability and maneuverability. Select models designed for the intended activity.

Tip 3: Prioritize Proper Fit: Ensure a snug, comfortable fit to maximize control and prevent injury. Ill-fitting equipment can lead to discomfort, blisters, and compromised performance. Professional fitting services are recommended.

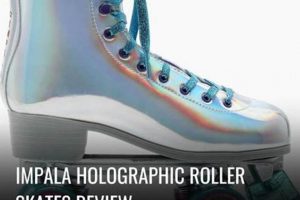

Tip 4: Evaluate Boot Construction: Examine the boot’s materials and construction quality. Leather boots offer superior support and durability, while synthetic options may provide greater flexibility and breathability.

Tip 5: Consider Plate Material: The plate, connecting the boot to the wheels, influences responsiveness. Aluminum plates provide superior energy transfer, while nylon plates offer greater shock absorption.

Tip 6: Inspect Wheel Hardness: Wheel durometer (hardness) affects grip and roll. Softer wheels offer greater grip on smooth surfaces, while harder wheels provide faster roll on smoother surfaces.

Tip 7: Maintain Equipment Regularly: Consistent maintenance, including cleaning bearings and tightening hardware, ensures optimal performance and prolongs the equipment’s lifespan.

Selecting appropriate equipment based on skill level, intended use, fit, and component quality is essential for a positive and safe skating experience. Regular maintenance further ensures long-term performance and reliability.

The subsequent section will delve into specific product features and their impact on skating performance, offering further guidance for informed purchasing decisions.

1. Boot Construction

The construction of the boot is paramount in determining the overall performance and suitability. It significantly impacts support, comfort, and energy transfer from the skater to the skates. The boot directly influences the skater’s ability to maintain balance, execute maneuvers, and endure prolonged skating sessions. Examples include leather boots, providing robust support for advanced techniques, and synthetic boots, offering enhanced flexibility for recreational use. In artistic roller skating, rigid boots are essential for precise control, while derby skaters often favor more pliable boots for agility.

Different materials and manufacturing processes influence the boot’s durability and longevity. Higher-quality leather, for instance, can withstand significant wear and tear, while advanced synthetic materials may offer improved breathability and moisture management. The design of the boot, including padding, lining, and ankle support systems, directly impacts comfort and reduces the risk of injury. Furthermore, customized boot fitting can optimize performance and minimize discomfort, ensuring proper alignment and stability.

Understanding the nuances of boot construction is crucial for selecting equipment that meets specific skating requirements. Selecting boots that prioritize support, comfort, and durability leads to enhanced performance and a reduced likelihood of injuries. This knowledge empowers consumers to make informed decisions, aligning their equipment choices with their skating goals.

2. Plate Material

The plate, a critical component connecting the boot to the wheels, significantly influences the performance characteristics of equipment. Different materials impart distinct handling qualities, affecting responsiveness and stability. Aluminum plates, frequently found in high-end configurations, offer exceptional rigidity and energy transfer, allowing for precise control and efficient power delivery. This is particularly advantageous in disciplines such as artistic skating, where nuanced movements require immediate response. Alternatively, nylon or composite plates provide greater shock absorption, reducing impact stress on the skater’s joints. The choice of material directly impacts the skater’s ability to execute complex maneuvers and maintain balance. For instance, a skater performing a spin requires a rigid plate for maximum control, while a derby skater might prefer a more flexible plate for agility and impact resistance.

Considerations such as weight, durability, and cost also factor into the selection of plate materials. Aluminum plates, while providing superior performance, tend to be heavier and more expensive than their nylon counterparts. The durability of the plate is crucial, as it must withstand repetitive stress and potential impacts. Material selection should align with the skater’s skill level, skating discipline, and budget. For example, a recreational skater may find a nylon plate sufficient, while a competitive skater will likely benefit from the enhanced performance of an aluminum plate. Proper maintenance, including regular inspection and cleaning, extends the lifespan of the plate, regardless of the material.

Understanding the characteristics of different plate materials is essential for making informed purchasing decisions and optimizing skating performance. Selecting the appropriate plate material, based on specific needs and preferences, contributes to enhanced control, stability, and overall skating experience. This knowledge also enables skaters to customize their equipment, tailoring it to their individual skating style and discipline, further maximizing their potential. The plate’s contribution extends from improved performance to better handling, influencing the enjoyment of skating, and should be examined carefully.

3. Wheel Durometer

Wheel durometer, a measure of a wheel’s hardness, significantly influences the performance characteristics of equipment. The selection of an appropriate durometer rating is paramount in optimizing maneuverability, grip, and speed for specific skating disciplines and surfaces. Understanding its influence is crucial when configuring these setups.

- Grip and Control

Softer wheels, typically ranging from 78A to 88A on the durometer scale, offer increased grip and control. These wheels are advantageous on slick or uneven surfaces, providing enhanced traction for executing precise turns and stops. This configuration is commonly employed in artistic roller skating, where controlled movements are essential for performance. The increased grip enables skaters to maintain stability and execute intricate footwork with confidence.

- Speed and Roll

Harder wheels, generally ranging from 90A to 103A, prioritize speed and roll. These wheels are suitable for smooth, polished surfaces, where minimal friction is desired. Roller derby often utilizes harder wheels to achieve maximum velocity and agility during gameplay. The reduced grip allows skaters to glide effortlessly, facilitating rapid acceleration and quick changes in direction. However, the decreased grip may compromise control on less-than-ideal surfaces.

- Surface Compatibility

The ideal wheel durometer depends heavily on the skating surface. Indoor rinks typically favor harder wheels, while outdoor environments often necessitate softer wheels to compensate for imperfections. Selecting the appropriate durometer ensures optimal performance and minimizes the risk of slippage or instability. For instance, a skater transitioning from an indoor rink to an outdoor track may need to switch to a softer wheel to maintain adequate grip.

- Wear and Durability

Wheel durometer also affects wear and durability. Softer wheels tend to wear down more quickly than harder wheels, particularly on abrasive surfaces. Harder wheels, while offering greater longevity, may exhibit reduced grip over time. The choice between durability and grip depends on the frequency and intensity of use, as well as the skater’s personal preferences. Regular inspection and maintenance are crucial for maximizing the lifespan of the wheels.

Selecting the appropriate wheel durometer is a critical aspect of customizing equipment for optimal performance. Whether prioritizing grip for artistic skating or speed for roller derby, the durometer rating directly impacts the skater’s ability to execute maneuvers and maintain control. Factors such as surface conditions, skating style, and personal preferences should be carefully considered when choosing wheels. Regular evaluation of wheel wear and performance ensures ongoing optimization of equipment for sustained performance benefits. Wheel durometer is a key element that impacts skating, demanding careful assessment.

4. Bearing Quality

The bearing quality within equipment directly influences rolling efficiency and speed. High-quality bearings minimize friction, allowing wheels to rotate more freely and for longer durations with each push. This enhances overall skating performance, reducing exertion and improving the skater’s ability to maintain momentum. Inferior bearings introduce friction, hindering speed and requiring increased effort. Given their inherent design towards specialized skating, the bearing quality within these models significantly impacts the skaters performance. For example, a skater using equipment with precision bearings can achieve higher speeds with less effort, contributing to competitive success in speed skating events. Conversely, a recreational skater using inferior bearings might experience sluggish performance, diminishing the enjoyment of the activity.

Bearing quality also contributes to the longevity and reliability of the equipment. High-quality bearings are typically manufactured with tighter tolerances and utilize durable materials, increasing resistance to wear and tear. Proper bearing maintenance, including cleaning and lubrication, further extends their lifespan and ensures consistent performance. Conversely, low-quality bearings are prone to premature failure, requiring frequent replacement and potentially causing damage to the wheels or other components. The selection of bearings therefore represents a balance between initial cost and long-term value. A higher initial investment in quality bearings translates into reduced maintenance costs and enhanced performance over the equipment’s lifespan.

In summary, bearing quality is a critical determinant of the performance, durability, and overall value. Choosing equipment incorporating high-quality bearings optimizes rolling efficiency, minimizes exertion, and enhances the skating experience. Regular maintenance is essential for sustaining optimal bearing performance and maximizing equipment lifespan. Despite the availability of cost-effective alternatives, investing in quality bearings represents a pragmatic approach for enhancing skating performance and extending equipment durability. These models, known for customization and performance, benefit significantly from the quality of their bearings, adding to the value that this equipment brings.

5. Ankle Support

Ankle support constitutes a critical design element influencing performance and safety. Within this line of equipment, its proper implementation is crucial for optimizing control, stability, and injury prevention across diverse skating disciplines.

- Lateral Stability

The provision of lateral stability is paramount for executing controlled turns and maintaining balance during dynamic movements. Ankle support systems, often incorporating reinforced materials and strategic padding, minimize ankle roll and prevent excessive pronation or supination. An example includes the use of a stiff counter in the boot’s heel region, which restricts lateral movement and enhances stability. Inadequate lateral support can lead to ankle sprains and compromised performance, particularly during high-intensity maneuvers.

- Range of Motion

While stability is essential, maintaining an appropriate range of motion is equally important for executing complex skating techniques. Ankle support should be designed to allow for sufficient dorsiflexion and plantarflexion, enabling skaters to perform jumps, spins, and other maneuvers that require ankle flexibility. A hinged cuff design, for example, can provide both support and a degree of unrestricted movement. Overly restrictive support can hinder performance and limit the skater’s ability to execute techniques effectively.

- Customization and Fit

Effective ankle support often requires customization to accommodate individual anatomical variations and skating styles. Adjustable straps, laces, and heat-moldable materials enable skaters to fine-tune the fit and level of support to their specific needs. A skater with a history of ankle instability, for instance, might benefit from a more rigid and supportive boot, while a skater prioritizing agility might prefer a more flexible and adaptable design. Proper fitting by a qualified professional is crucial for optimizing ankle support and minimizing the risk of discomfort or injury.

- Injury Prevention

Ankle support plays a pivotal role in mitigating the risk of ankle injuries, particularly sprains and fractures. By limiting excessive ankle movement and providing structural reinforcement, well-designed ankle support systems can absorb impact forces and prevent the ankle joint from exceeding its physiological limits. Ankle support also provides proprioceptive feedback, enhancing the skater’s awareness of their body position and improving their ability to react to unexpected movements. Comprehensive ankle support is key to ensuring skaters are secured and confident when skating.

The integration of effective ankle support is integral to the design philosophy of this equipment. Prioritizing lateral stability, range of motion, customization, and injury prevention results in enhanced performance, safety, and skater satisfaction. Equipment manufacturers continuously refine ankle support systems through research and development, seeking to optimize the balance between support, comfort, and performance. Ankle support is not just an adjunct, it is integral to the design and proper usage of any equipment of this type.

6. Closure System

The closure system within equipment significantly influences fit, security, and performance. As an integral component, it ensures the boot remains firmly attached to the skater’s foot, directly impacting control and responsiveness. Variations in design, ranging from traditional lacing to buckle systems and hybrid combinations, cater to diverse preferences and skating styles. For example, a skater engaged in artistic routines may favor a lace-based system for its adjustability, allowing precise calibration of tension across the foot and ankle. Conversely, a derby skater might prioritize a buckle system for rapid tightening and release during gameplay.

The effectiveness of the closure system is inherently linked to the quality of materials and construction. Durable laces, robust buckles, and secure Velcro straps are essential for withstanding the stresses of repetitive motion and impact. A poorly designed or constructed closure system can lead to slippage, discomfort, and even injury. Real-world examples include lace breakage during a critical maneuver, buckle malfunction at high speed, or Velcro failure under strenuous conditions. The choice of closure system should therefore align with the skater’s intended usage and performance requirements. Regularly maintaining closure system components is essential for preventing issues and preserving performance.

In summary, the closure system is a crucial element affecting fit, security, and performance. It ensures a secure connection between the foot and boot, directly impacting the skater’s ability to control movement and prevent injuries. Selection and maintenance of the closure system are vital for optimized and safe equipment use. The effectiveness of the closure system is often overlooked, but the importance of its role is unarguable.

7. Model Suitability

Model suitability refers to the alignment between specific product features and the needs of individual skaters. Within the context of equipment selection, this concept underscores the importance of choosing a configuration that complements the skater’s skill level, skating discipline, and physical characteristics. A mismatch between product capabilities and user requirements can lead to compromised performance, increased risk of injury, and diminished overall satisfaction. For example, an inexperienced skater utilizing a high-performance model designed for advanced maneuvers may struggle with control and stability, potentially leading to falls and injuries. Conversely, an advanced skater using a basic model may find their progress limited by the equipment’s capabilities.

The product line offers a diverse range of models, each engineered to cater to specific skating styles and skill levels. Recreational models prioritize comfort, stability, and ease of use, making them suitable for beginners and casual skaters. Artistic models, on the other hand, emphasize precision, responsiveness, and ankle support, catering to the demands of advanced figure skating routines. Roller derby models are designed for durability, maneuverability, and impact resistance, meeting the rigorous requirements of competitive gameplay. The selection of a suitable model necessitates a thorough assessment of the skater’s abilities, goals, and physical attributes. A professional fitting service can provide valuable guidance in identifying the ideal product for individual needs, ensuring optimal performance and minimizing the risk of injury. Real-world examples include selecting a boot and plate combination optimized for jump landings or choosing a wheel durometer that matches the grip requirements of a particular skating surface.

In conclusion, the concept of model suitability is paramount in the selection of equipment. A comprehensive understanding of the relationship between product features and user needs enables skaters to make informed purchasing decisions, optimizing performance, safety, and enjoyment. Recognizing the importance of aligning equipment capabilities with individual requirements ensures that skaters can fully realize their potential and avoid the pitfalls of mismatched equipment. Ensuring a good match results in not only greater safety but greater enjoyment from the equipment.

Frequently Asked Questions

This section addresses commonly encountered inquiries regarding these models. The information provided aims to offer clarity and informed guidance for consumers.

Question 1: What factors determine the appropriate equipment size?

Foot length and width are primary determinants. A snug, yet comfortable fit is essential. Professional fitting services are recommended to ensure accurate sizing and prevent discomfort or injury.

Question 2: How frequently should bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage and environmental conditions. Routine cleaning and lubrication every 10-20 hours of skating is generally advisable. Dusty or wet conditions may necessitate more frequent maintenance.

Question 3: What is the expected lifespan of the product?

Lifespan varies based on usage intensity, maintenance practices, and component quality. With proper care, quality equipment can provide several years of service. Component replacement may be necessary over time.

Question 4: Are replacement parts readily available?

Replacement parts, including wheels, bearings, and toe stops, are generally accessible through authorized dealers and online retailers. Compatibility with specific models should be verified prior to purchase.

Question 5: How does wheel durometer affect performance?

Wheel durometer, or hardness, influences grip and roll. Softer wheels (lower durometer) offer greater grip, while harder wheels (higher durometer) provide faster roll. Selection should align with skating discipline and surface conditions.

Question 6: What are the key considerations for selecting equipment for roller derby?

Durability, maneuverability, and ankle support are critical considerations. Reinforced boots, sturdy plates, and wheels optimized for indoor surfaces are recommended.

These FAQs address fundamental aspects of this equipment, encompassing sizing, maintenance, lifespan, component availability, wheel durometer, and suitability for roller derby. Understanding these considerations empowers consumers to make informed decisions and optimize equipment performance.

The subsequent section delves into advanced customization options and troubleshooting tips for enhancing your skating experience.

Conclusion

This exploration has presented a detailed analysis of these roller skates, emphasizing critical elements such as boot construction, plate material, wheel durometer, bearing quality, ankle support, and closure systems. Model suitability, aligning equipment features with skater needs, was also underscored. The comprehensive discussion of these facets aims to empower consumers with the knowledge necessary for informed decision-making.

Continued advancements in materials and design promise further enhancements in performance, safety, and durability. A thorough understanding of the information presented herein will enable skaters to optimize their equipment selection, maximizing both their potential and enjoyment of the sport. Diligent consideration of these factors is essential for achieving peak performance and ensuring a safe skating experience.