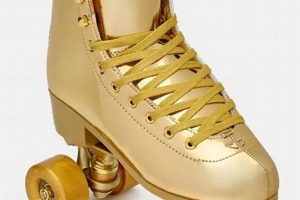

The comparison involves two distinct types of wheeled footwear used for recreational or competitive movement across surfaces. One involves four wheels arranged in a two-by-two configuration under the boot, providing a stable platform. The other features wheels aligned in a single row, offering increased speed and maneuverability. This fundamental design difference impacts balance, agility, and intended use.

Understanding the nuances between these two options is crucial for selecting the appropriate gear based on individual skill level, desired activity, and personal preferences. Historically, the four-wheeled variant emerged first, evolving into the inline design later to cater to speed skating aspirations. The choice significantly influences the skating experience, impacting stability, control, and the types of activities one can comfortably perform.

The following discussion will delve into specific aspects such as stability and control, maneuverability and speed, intended use cases, and skill level considerations, providing a detailed analysis of the factors to consider when choosing between these two forms of wheeled skates.

Guidance on Selecting Wheeled Skates

The following guidelines offer practical advice for choosing between the two types of wheeled skates, based on specific needs and priorities.

Tip 1: Consider the Stability Requirement: Prioritize the four-wheeled option for enhanced stability, especially for beginners or those seeking a more balanced experience. The wider base of support contributes to easier equilibrium.

Tip 2: Evaluate Maneuverability Needs: Opt for the inline configuration if agility and precise turning are paramount. The single row of wheels allows for tighter curves and quicker directional changes.

Tip 3: Assess Intended Use: Select the appropriate skate type based on the intended activity. The four-wheeled version is well-suited for rink skating and recreational use, while the inline design is often preferred for speed skating and aggressive skating.

Tip 4: Account for Skill Level: Novice skaters generally benefit from the stability of four-wheeled skates, allowing them to develop fundamental skating skills. More experienced skaters might find the inline design more challenging and rewarding.

Tip 5: Examine Ankle Support: Compare the ankle support offered by each type. Inline skates typically provide more rigid ankle support, which can be beneficial for maintaining proper form and preventing injuries.

Tip 6: Factor in Comfort: Consider the overall comfort and fit of each skate. Ensure the chosen model provides adequate cushioning and support to prevent discomfort during extended use.

Tip 7: Prioritize Safety Gear: Regardless of the chosen skate type, always wear appropriate safety gear, including a helmet, knee pads, elbow pads, and wrist guards. Safety is paramount for both beginners and experienced skaters.

By carefully considering these factors, individuals can make an informed decision regarding which wheeled skate configuration best suits their needs, preferences, and intended skating activities. A well-informed choice enhances the overall skating experience and minimizes the risk of injury.

The next section provides a conclusion to summarize the key distinctions between the two types of wheeled skates.

1. Stability and Balance

Stability and balance represent crucial factors in the comparison of the two types of wheeled skates. The design and configuration of wheels significantly influence a skater’s ability to maintain equilibrium and control movement. Understanding these differences is paramount for selecting the appropriate skate type based on individual needs and skill level.

- Wheel Configuration and Base of Support

The arrangement of wheels directly impacts stability. The two-by-two wheel configuration in the four-wheeled skate creates a wider base of support, offering greater stability, particularly for beginners. Conversely, the inline arrangement with a single row of wheels results in a narrower base, demanding a higher degree of balance and control.

- Center of Gravity and Equilibrium

Maintaining a low center of gravity is essential for stability on any type of skate. The wider base of support in the four-wheeled skate lowers the center of gravity, making it easier to maintain balance. Inline skates require more precise adjustments to the center of gravity to compensate for the narrower base, demanding better core strength and body awareness.

- Learning Curve and Skill Acquisition

The initial learning curve differs significantly between the two skate types. The enhanced stability of four-wheeled skates facilitates a quicker learning process, enabling beginners to acquire fundamental skating skills more easily. Mastering balance on inline skates requires more practice and coordination, resulting in a steeper initial learning curve.

- Surface Conditions and Terrain

Surface conditions impact stability differently for each skate type. Four-wheeled skates are more forgiving on uneven surfaces due to their wider base of support. Inline skates require smoother surfaces to maintain balance and control, particularly at higher speeds. Terrain selection should align with the capabilities of the chosen skate type.

In summary, stability and balance are inherently linked to the wheel configuration and design. The four-wheeled skate provides inherent stability suitable for beginners and recreational use, while the inline skate demands greater balance and control, catering to more experienced skaters seeking speed and maneuverability. These considerations form a critical part of evaluating the merits of each skate type.

2. Maneuverability and Speed

Maneuverability and speed are differentiating factors when assessing the characteristics of two types of wheeled skates. The inherent design of each skate significantly influences its capacity for agile movement and velocity attainment. These performance attributes are critical considerations for users seeking specific skating experiences.

- Wheel Arrangement and Turning Radius

The wheel configuration dictates the turning radius achievable. The inline arrangement, with wheels aligned in a single row, permits tighter turns and quicker directional changes due to its narrower profile. The two-by-two arrangement in four-wheeled skates necessitates a wider turning radius, limiting agility in confined spaces. This directly impacts the skate’s suitability for activities requiring rapid maneuvering.

- Wheel Size and Velocity Potential

Wheel size correlates positively with potential speed. Inline skates typically accommodate larger wheels, facilitating higher velocities on smooth surfaces. The smaller wheels on four-wheeled skates limit maximum speed but can enhance stability and control at lower speeds. The choice of wheel size influences the overall skating experience and suitability for different terrains.

- Frame Length and Responsiveness

The length of the skate frame affects responsiveness and control. Shorter frames, often found on four-wheeled skates, offer increased maneuverability at the expense of top-end speed. Longer frames, common on inline speed skates, provide greater stability at high velocities but may reduce agility in tighter spaces. Frame length represents a trade-off between responsiveness and stability.

- Skating Technique and Skill Level

Achieving optimal maneuverability and speed requires different skating techniques for each skate type. Inline skating relies on edge control and efficient stride techniques to maximize velocity. Four-wheeled skating often involves more subtle weight shifts and variations in foot placement to maintain balance and control during turns. Skill level and technique proficiency directly impact the performance capabilities of each skate type.

In summary, the attributes of maneuverability and speed are intrinsically linked to the design and configuration of these wheeled skates. Inline designs generally prioritize speed and agile turning, while the four-wheeled arrangement prioritizes stability and controlled movement. The choice depends on the intended skating activity and the user’s desired performance characteristics.

3. Intended Use Cases

The intended application of wheeled skates is a primary determinant when choosing between the roller skate and roller blade. The design characteristics of each skate type lend themselves to specific activities and environments. Understanding these applications facilitates informed decision-making for prospective users.

- Rink Skating and Recreational Use

The stability offered by roller skates makes them well-suited for rink skating and general recreational use. The wider base provides a forgiving platform for beginners and casual skaters navigating crowded rinks or uneven surfaces. Roller rinks often feature smooth, predictable surfaces that complement the controlled movement characteristics of roller skates, making them a popular choice for social skating activities.

- Speed Skating and Distance Training

Inline skates, particularly those with larger wheels and longer frames, are favored for speed skating and distance training. The inline configuration allows for efficient energy transfer and higher velocities, essential for competitive speed events and long-distance skating on paved trails. The aerodynamic profile and specialized boot designs further enhance performance in these applications.

- Aggressive Skating and Stunt Performance

Aggressive skating, which involves performing stunts and tricks on ramps and rails, often utilizes specialized inline skates designed for impact resistance and maneuverability. These skates feature reinforced frames, smaller wheels for greater control, and grind plates for executing slides and stalls. Roller skates are less commonly used in aggressive skating due to their lower ankle support and limited maneuverability.

- Urban Skating and Commuting

Inline skates can also be employed for urban skating and commuting, particularly on smooth, paved surfaces. The ability to cover distances quickly and efficiently makes them a viable transportation option for short to medium commutes. However, the user must consider factors such as traffic conditions, surface quality, and the need for protective gear to ensure safety and practicality. The four-wheeled skate offers less speed for commuting purpose.

The diverse range of applications highlights the importance of aligning the chosen skate type with the intended use. While roller skates excel in recreational and rink environments, inline skates dominate speed skating and aggressive skating disciplines. Careful consideration of the activity’s demands ensures optimal performance and user satisfaction.

4. Skill Level Requirement

The dichotomy between roller skates and roller blades is intrinsically linked to the skill level of the user. The design characteristics of each type dictate the learning curve and proficiency necessary for safe and effective use. A mismatch between skill level and skate type can lead to frustration, injury, and a diminished skating experience. Consequently, assessing one’s current abilities is paramount before selecting a skating apparatus.

Roller skates, with their four-wheeled configuration, offer a wider base of support, inherently promoting stability. This characteristic makes them suitable for novice skaters who are developing fundamental balance and coordination skills. The lower center of gravity reduces the likelihood of falls, allowing beginners to focus on mastering basic movements such as gliding and stopping. For example, a child learning to skate for the first time is often started on roller skates due to their forgiving nature. Conversely, roller blades, with their inline wheel arrangement, demand a higher degree of balance and control from the outset. The narrower base requires skaters to engage core muscles and maintain precise body alignment. Attempting to learn on roller blades without sufficient balance and coordination can result in frequent falls and a prolonged learning process. An experienced ice skater might transition more easily to roller blades due to pre-existing balance skills.

The connection between skill level and skate type extends beyond the initial learning phase. Advanced maneuvers, such as speed skating or aggressive skating, require specialized skills that are typically developed over time. While roller blades offer greater speed potential, mastering the necessary techniques for safe high-speed skating demands significant practice and expertise. Similarly, aggressive skating on roller blades necessitates proficiency in performing jumps, grinds, and other complex tricks. In essence, selecting the appropriate skate type hinges on aligning the equipment’s capabilities with the skater’s current skill set and intended activities. A judicious choice enhances the skating experience and minimizes the risk of injury, underscoring the practical significance of understanding this relationship.

5. Ankle Support Design

Ankle support design represents a critical divergence between the two forms of wheeled skates, influencing stability, control, and injury prevention. The structural configuration surrounding the ankle joint directly impacts the skater’s ability to maintain balance, execute maneuvers, and withstand the forces generated during skating activities. A comparative analysis reveals key distinctions in design philosophy and functional implications.

- Boot Height and Cuff Stiffness

Inline skates generally feature higher boot heights and stiffer cuffs compared to traditional roller skates. This design provides enhanced lateral stability and limits excessive ankle flexion or extension, reducing the risk of sprains. The rigid cuff acts as an external support, particularly beneficial for high-impact activities like aggressive skating or speed skating, where ankle stability is paramount. Traditional roller skates often employ lower-cut boots with less rigid construction, prioritizing flexibility and range of motion over maximal ankle support.

- Lacing Systems and Closure Mechanisms

The lacing systems and closure mechanisms contribute significantly to the overall ankle support. Inline skates typically incorporate a combination of laces, buckles, and straps to achieve a secure and customizable fit. These systems allow skaters to fine-tune the level of support based on their individual needs and skating style. Roller skates may utilize simpler lacing systems or buckle closures, offering less adjustability but potentially greater ease of use. The precision of the closure system directly impacts the degree to which the ankle is stabilized and protected.

- Internal Padding and Anatomical Contouring

The internal padding and anatomical contouring within the skate boot influence comfort and support. Inline skates often feature denser padding and more sculpted footbeds to provide a snug and supportive fit around the ankle. This reduces friction and prevents excessive movement within the boot, minimizing the risk of blisters and discomfort. Roller skates may employ less sophisticated padding, focusing on cushioning rather than precise anatomical support. The quality and distribution of internal padding play a crucial role in maintaining ankle stability and preventing injuries.

- Material Composition and Structural Integrity

The material composition and structural integrity of the skate boot impact its ability to withstand stress and provide lasting ankle support. Inline skate boots are often constructed from durable materials like reinforced plastics or carbon fiber, offering a high degree of rigidity and resistance to deformation. This ensures that the ankle remains properly supported even under high loads. Roller skate boots may utilize softer materials like leather or synthetic fabrics, prioritizing flexibility and comfort over maximal structural support. The choice of materials influences the overall durability and protective capabilities of the skate.

In summary, the ankle support design constitutes a significant point of differentiation. Inline skates prioritize robust ankle support through higher cuffs, sophisticated closure systems, and rigid materials, catering to activities demanding high stability and impact resistance. Roller skates often favor flexibility and comfort with lower-cut designs and less rigid materials, suitable for recreational skating. A thorough understanding of these distinctions enables skaters to select the appropriate skate type based on their individual needs, skating style, and risk tolerance.

Frequently Asked Questions

The following addresses common inquiries regarding the distinctions between two types of wheeled skates.

Question 1: What fundamental design differences distinguish these two types of wheeled skates?

The primary difference lies in the wheel configuration. One features four wheels arranged in a two-by-two pattern, while the other has wheels aligned in a single row.

Question 2: How does wheel arrangement impact stability?

The four-wheeled configuration generally offers greater stability due to the wider base of support. The inline configuration requires more inherent balance.

Question 3: Which type is more suitable for beginners?

Due to the enhanced stability, the four-wheeled variant is often more appropriate for novice skaters learning basic balance and coordination.

Question 4: What are the activity applications for each type?

The four-wheeled variant is typically used for recreational rink skating. The inline type is often employed for speed skating, aggressive skating, and distance skating.

Question 5: How does ankle support differ between the two skate types?

Inline skates generally provide more rigid ankle support compared to the four-wheeled design, offering enhanced stability and protection.

Question 6: Does the choice of skate impact maneuverability and speed?

The inline configuration generally facilitates greater maneuverability and higher potential speeds. The four-wheeled design offers controlled movement and stability at lower speeds.

Selecting the most appropriate skate type depends on individual needs, skill level, and intended activity. A thoughtful evaluation ensures an optimal skating experience.

The next section delves into more detailed comparisons of performance characteristics.

Conclusion

The preceding analysis has explored fundamental differences in design, stability, maneuverability, and intended applications of two distinct wheeled skate configurations. The four-wheeled roller skate, characterized by its two-by-two wheel arrangement, prioritizes stability and ease of use, making it well-suited for beginners and recreational rink skating. Conversely, the inline roller blade, featuring wheels aligned in a single row, emphasizes speed and agility, catering to more experienced skaters engaged in activities such as speed skating, aggressive skating, and distance training. Ankle support and frame design further differentiate the two, impacting performance and injury prevention.

The selection between these two wheeled recreational devices necessitates careful consideration of individual skill level, intended use, and desired performance characteristics. While no single choice universally prevails, a comprehensive understanding of the inherent strengths and limitations of each type empowers informed decision-making. Continued advancements in materials and design are likely to further refine these wheeled skate technologies, potentially blurring the lines between the two categories and expanding the range of applications for both.