The components of a bladed boot designed for gliding across frozen surfaces consist of several key elements. These elements work together to provide support, stability, and maneuverability for the user. The construction typically includes a rigid boot, a supportive chassis, and a precisely engineered blade.

Understanding the function of each individual section is crucial for maintenance, repair, and optimal performance. Proper care and selection of these components can significantly impact a skater’s experience, enabling greater control and reducing the risk of injury. Historically, advancements in materials and design have led to improved comfort and performance characteristics across various disciplines of skating.

The following sections will detail the specific attributes and purpose of the boot, the blade, and the connecting structures. Each aspect contributes uniquely to the overall effectiveness of the equipment, influencing aspects such as balance, edge control, and speed.

Essential Considerations for Ice Skate Components

Proper understanding and maintenance of bladed boot elements are crucial for both performance and longevity of the equipment. Addressing wear and tear proactively can enhance the skating experience and ensure safety.

Tip 1: Blade Sharpening. Regular sharpening of the steel running surface is paramount. A dull edge compromises grip on the ice, leading to reduced control and increased risk of falls. Frequency depends on usage, but professional sharpening is recommended at least every 20-40 hours of skating.

Tip 2: Boot Support. The rigidity of the boot is essential for ankle support. Inspect the boot for signs of wear, such as cracks or softening of the material. Replacing worn boots prevents injury and maintains proper skating form.

Tip 3: Blade Mounting. The secure attachment of the blade to the sole of the boot is vital. Check regularly for loose screws or separation between the blade and the sole. Tighten screws as needed and consult a professional for significant repairs.

Tip 4: Moisture Control. Dampness can lead to rust on the blade and deterioration of the boot. After each use, thoroughly dry both the blade and the boot’s interior. Using skate guards and boot dryers can further mitigate moisture damage.

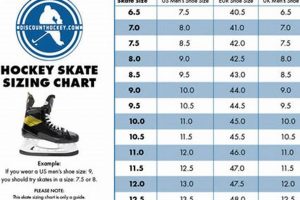

Tip 5: Proper Fit. Ensuring the correct size and fit of the boot is paramount. Ill-fitting footwear can cause discomfort, blisters, and reduced performance. Professional fitting is recommended, especially for serious skaters.

Tip 6: Blade Alignment. Correct blade alignment is critical for efficient skating. Misalignment can lead to uneven wear and strain on the skater’s body. Professional assessment and adjustment of blade alignment can significantly improve performance and comfort.

Consistent attention to these considerations will not only prolong the lifespan of the skating equipment but will also contribute to a safer and more enjoyable skating experience.

The concluding section will summarize the key features and benefits, further emphasizing the importance of understanding the mechanisms of this essential athletic equipment.

1. Blade's Steel

The composition of the blade’s steel is a critical element in ice skate construction, significantly influencing performance characteristics and longevity. Variations in steel type and manufacturing processes directly impact the skater’s ability to glide, maintain edge control, and execute complex maneuvers.

- Steel Hardness and Edge Retention

The hardness of the steel, often measured using the Rockwell scale, dictates the blade’s ability to hold a sharp edge. Harder steels, such as those with a high carbon content, retain their edge longer but may be more brittle and require specialized sharpening techniques. Conversely, softer steels are easier to sharpen but require more frequent maintenance.

- Carbon Content and Corrosion Resistance

The amount of carbon present in the steel affects its strength and resistance to corrosion. Higher carbon content generally increases hardness but can also increase susceptibility to rust. Alloying elements, such as chromium, are often added to enhance corrosion resistance and overall durability, particularly in environments where exposure to moisture is unavoidable.

- Blade Tempering and Flexibility

The tempering process, which involves heating and cooling the steel, affects its flexibility and resistance to stress. Properly tempered blades are less likely to crack or deform under pressure, providing a more consistent and reliable skating experience. Over-tempering can result in brittleness, while under-tempering can lead to excessive flexibility and reduced edge control.

- Manufacturing Techniques and Precision

The manufacturing techniques used to produce the steel blade, such as forging, casting, or machining, influence its dimensional accuracy and surface finish. Precisely manufactured blades, with consistent thickness and a smooth surface, provide optimal glide and edge control. Inconsistencies in blade geometry can lead to uneven wear and reduced performance.

The selection of appropriate steel for the blade represents a crucial design consideration within the broader context of ice skate engineering. The interplay between hardness, corrosion resistance, tempering, and manufacturing precision directly affects the overall functionality and user experience. Understanding these nuances allows for informed decisions regarding blade maintenance, sharpening, and replacement, ultimately contributing to improved skating performance and safety.

2. Boot's Ankle Support

Within the assembly of bladed footwear, the boot’s ankle support serves as a foundational element, significantly impacting stability, control, and injury prevention. This structural component directly interfaces with the skater’s lower limb, influencing force transmission and kinematic control.

- Lateral Stability and Edge Control

Adequate ankle support minimizes lateral movement, enhancing the skater’s ability to maintain precise edge control. Insufficient support can lead to ankle roll, compromising edge engagement and reducing the effectiveness of maneuvers such as turns and stops. For example, figure skating boots often feature a higher and stiffer ankle structure than hockey skates, reflecting the greater need for precise edge work and controlled landings.

- Force Distribution and Impact Absorption

The boot’s ankle support contributes to the distribution of forces generated during skating, reducing stress on the ankle joint and surrounding tissues. By providing a rigid or semi-rigid structure, the boot helps to absorb impact forces during jumps and landings, minimizing the risk of sprains and fractures. Modern designs often incorporate shock-absorbing materials in the ankle region to further enhance impact attenuation.

- Proprioceptive Feedback and Kinesthetic Awareness

Ankle support influences the skater’s proprioceptive feedback, enhancing kinesthetic awareness and improving balance. A well-fitting and supportive boot provides a more secure and stable platform, allowing the skater to better sense the position and movement of the foot and ankle. This enhanced awareness contributes to improved coordination and control, particularly during complex maneuvers.

- Material Selection and Structural Design

The materials used in the ankle support construction, such as leather, synthetics, and composite materials, influence its stiffness, durability, and weight. Stiffer materials provide greater support and control, while lighter materials reduce overall weight and fatigue. The structural design, including the height, shape, and padding of the ankle support, also plays a critical role in determining its effectiveness. For example, some boots feature adjustable ankle support systems to accommodate individual preferences and anatomical variations.

The multifaceted role of the boot’s ankle support highlights its integral connection to the overall performance and safety profile of the bladed boot. Proper design, fitting, and maintenance of this component are essential for optimizing skating performance and minimizing the risk of injury. Considerations related to lateral stability, force distribution, proprioceptive feedback, and material selection all contribute to the effectiveness of the ankle support system.

3. Rivet Connections

Rivet connections in bladed boots represent a critical mechanical linkage, securing the blade to the boot structure. Their integrity directly impacts the stability and performance of the equipment, affecting both safety and maneuverability.

- Material Composition and Durability

Rivet material, typically steel or aluminum alloys, must withstand repetitive stress and environmental factors. Corrosion-resistant alloys prevent weakening of the connection, ensuring long-term stability. The rivet’s shear strength dictates its ability to resist forces generated during skating maneuvers, such as jumps and sharp turns.

- Distribution and Load Transfer

The number and placement of rivets influence the distribution of load from the boot to the blade. Strategic rivet placement optimizes load transfer, minimizing stress concentrations and preventing premature failure. Even distribution promotes uniform blade contact with the ice, enhancing glide and control.

- Installation Precision and Tolerances

Precise rivet installation is crucial for maintaining structural integrity. Tight tolerances prevent loosening and movement, preserving the intended alignment between the blade and the boot. Incorrectly installed rivets can compromise stability and potentially lead to blade detachment.

- Maintenance and Inspection Protocols

Regular inspection of rivet connections is essential for identifying signs of wear or damage. Visual inspection can reveal loose or corroded rivets, indicating the need for replacement. Proactive maintenance prevents catastrophic failure during use, ensuring user safety.

The functionality and reliability of rivet connections directly correlate with the overall performance of bladed boots. Consistent monitoring and maintenance of these components are paramount for preserving the integrity of the skating equipment and ensuring a safe skating experience.

4. Toe Pick Function

The toe pick, a serrated projection located at the front of the blade, is an integral component, primarily in figure skating. Its geometry and positioning are critical for executing jumps, spins, and footwork. The function of the toe pick directly influences a skater’s ability to initiate and control specific movements on the ice. For example, in a toe loop jump, the skater uses the toe pick to leverage the takeoff. A poorly designed or damaged toe pick compromises the skater’s ability to generate the necessary lift and rotation.

Beyond jump initiation, the toe pick also facilitates certain spin variations and intricate footwork sequences. The skater may utilize the toe pick for balance and stability during complex maneuvers. Different blade designs incorporate variations in toe pick size, shape, and angle to accommodate different skating styles and skill levels. A larger toe pick provides greater purchase on the ice but can also increase the risk of unintentional contact, whereas a smaller toe pick offers less grip but allows for smoother transitions. Skaters specializing in specific disciplines, such as freestyle or ice dance, often prefer specific toe pick configurations tailored to their performance demands.

In summary, the toe pick serves a specialized, yet critical, function within the broader context of skating. Its design and condition directly influence a skater’s ability to execute advanced maneuvers. Understanding the relationship between toe pick function and skating technique is essential for optimizing performance and minimizing the risk of injury. Its precise use requires considerable skill, demonstrating its importance in advanced skating disciplines.

5. Lace System

The lace system of a bladed boot is a critical component directly influencing fit, support, and performance. As an integral part of the overall structure, the lace system allows for precise adjustment, securing the foot and ankle within the boot. The effectiveness of the bladed boot hinges on its ability to provide proper support, and the lace system is the primary mechanism for achieving this. Insufficiently tightened laces can lead to ankle instability and reduced control, while excessively tight laces can cause discomfort and impede circulation. The design and material of the lacing system also factor into its overall effectiveness, with variations in hook placement, lace material, and closure mechanisms influencing the distribution of pressure across the foot and ankle.

Proper lacing technique and maintenance are essential for maximizing the benefits of the lace system. Skaters often employ specific lacing patterns to address individual anatomical variations or performance requirements. For example, skipping a hook or loop in the lacing pattern can alleviate pressure points or accommodate bony prominences. Similarly, using waxed laces can improve grip and prevent slippage, maintaining consistent tension throughout the skating session. The lace system also serves as a point of adjustment, allowing skaters to fine-tune the fit of the boot based on factors such as sock thickness or changes in foot volume during extended periods of activity.

In summary, the lace system of the bladed boot is more than a simple fastener; it is a dynamic component that contributes significantly to fit, support, and overall performance. Its proper functioning and adjustment are essential for maximizing comfort, control, and safety on the ice. Regular inspection and maintenance of the lacing system are critical for preventing failures that could compromise the skater’s performance or lead to injury.

6. Sole Rigidity

Sole rigidity, within the context of bladed boot construction, represents a critical design parameter influencing stability, power transfer, and overall performance. Its significance stems from its direct impact on the skater’s ability to control the blade and execute maneuvers effectively.

- Lateral Stability and Edge Control

The degree of lateral stiffness in the sole directly affects the skater’s ability to maintain a consistent edge. A rigid sole resists torsional forces, preventing unwanted flexing that can compromise edge engagement. Insufficient rigidity results in energy loss and reduced control, particularly during turns and complex footwork. For example, figure skating boots typically feature a stiffer sole than recreational skates, reflecting the greater demands for precise edge control.

- Power Transfer and Efficiency

Sole rigidity plays a crucial role in transmitting force from the skater’s leg muscles to the blade. A stiff sole minimizes energy dissipation, ensuring that a greater proportion of the skater’s effort is translated into forward momentum and acceleration. Conversely, a flexible sole absorbs energy, reducing skating efficiency and increasing fatigue. Racing speed skates prioritize sole stiffness to maximize power output.

- Impact Absorption and Joint Protection

While rigidity is essential for performance, a degree of flexibility is also necessary for absorbing impact forces and protecting joints. The sole must provide sufficient cushioning to mitigate the stress of landings and repetitive movements. The optimal balance between rigidity and flexibility depends on the skating discipline and the skater’s individual needs. For example, hockey skates may incorporate more shock-absorbing materials in the sole than figure skates.

- Material Selection and Construction Techniques

The materials and construction techniques used in the sole directly determine its rigidity characteristics. High-density plastics, carbon fiber composites, and layered constructions are commonly employed to achieve the desired stiffness and durability. The sole’s design, including its thickness, shape, and reinforcement features, also plays a significant role in its overall performance. Advancements in material science have enabled the creation of soles that offer both high rigidity and impact absorption, optimizing performance and comfort.

The interrelationship between sole rigidity, material composition, and construction techniques underscores the complexity of bladed boot design. Optimizing sole rigidity is essential for achieving the desired balance between stability, power transfer, and impact absorption. The specific requirements of each skating discipline dictate the ideal sole characteristics, highlighting the importance of selecting equipment that is appropriate for the intended use.

7. Heel Counter

The heel counter, an often-overlooked yet crucial structural element of bladed footwear, provides essential support and stability to the rearfoot. Its primary function is to maintain the alignment of the heel bone (calcaneus) within the boot, thereby influencing ankle stability and overall skating performance. The heel counter operates as a semi-rigid cup or brace, encapsulating the heel and resisting deformation under stress. Its presence within the broader assembly of ice skate components directly affects force transmission and kinematic control during skating.

Material composition and design directly impact the effectiveness of the heel counter. Typically constructed from rigid plastics, reinforced polymers, or layered composites, the counter must withstand repetitive impact and shear forces. A well-designed heel counter minimizes lateral movement of the heel, reducing the risk of ankle sprains and promoting efficient power transfer. In hockey skates, for instance, a robust heel counter is paramount for resisting the forces generated during rapid acceleration and deceleration. Conversely, a poorly constructed or damaged heel counter can lead to instability, compromised skating technique, and increased susceptibility to injury.

Ultimately, the heel counter’s contribution to the functionality of the skating boot underscores its importance as an integral part of the overall system. Maintaining the heel counter’s structural integrity through proper care and timely replacement is essential for optimizing performance and ensuring skater safety. Its role extends beyond mere support; it directly influences alignment, stability, and power transfer, making it a key determinant in the overall efficacy of the bladed footwear.

Frequently Asked Questions

The following section addresses common inquiries regarding the features and maintenance of ice skate components. Understanding these aspects is crucial for optimizing performance and ensuring the longevity of the equipment.

Question 1: What is the expected lifespan of an ice skate blade?

The lifespan of an ice skate blade is contingent on several factors, including frequency of use, skating style, and maintenance practices. Regular sharpening and proper storage can extend blade life. However, blades subjected to frequent use or harsh conditions may require replacement more frequently.

Question 2: How often should ice skate blades be sharpened?

Blade sharpening frequency depends on usage. Competitive skaters typically require more frequent sharpening than recreational users. A general guideline is to sharpen blades after every 20-40 hours of skating. However, signs of dullness, such as difficulty maintaining edges, indicate the need for more frequent sharpening.

Question 3: What are the key indicators that an ice skate boot needs replacement?

Key indicators of boot replacement include loss of ankle support, cracks or tears in the boot material, and significant wear in the sole or heel. Diminished support compromises stability and increases the risk of injury.

Question 4: How does toe pick design influence figure skating performance?

The toe pick’s size and shape impact a skater’s ability to execute jumps and spins. A larger toe pick provides greater purchase for takeoffs but can hinder smooth transitions. A smaller toe pick offers greater agility but requires more precise technique. The optimal toe pick design depends on the skater’s specific discipline and skill level.

Question 5: What is the purpose of skate guards, and how should they be used?

Skate guards protect the blade from damage during storage and transport. Hard guards are used for walking off the ice, while soft guards, typically made of terry cloth, absorb moisture after use, preventing rust. Blades should always be dried thoroughly before placing them in guards.

Question 6: How does sole rigidity affect skating performance?

Sole rigidity influences power transfer and edge control. A stiffer sole transmits more force from the skater’s leg to the blade, enhancing efficiency. However, excessive stiffness can reduce comfort and impact absorption. The optimal sole rigidity depends on the skating discipline and the skater’s individual preferences.

Understanding these facets of ice skate components contributes to safer and more effective utilization of the equipment. Consistent attention to maintenance and timely replacement of worn components are essential for optimal performance.

The next section will provide expert advice on selecting the appropriate equipment and optimizing its fit.

Parts of an Ice Skate

This exposition has detailed the fundamental components that comprise bladed ice footwear. From the steel of the blade to the structure of the boot, each element contributes to the overall functionality and performance characteristics. Understanding the individual roles and interdependencies of these constitutes a critical foundation for proper maintenance, informed selection, and safe utilization.

Continued advancements in materials and design methodologies will likely yield further refinements in ice skate technology. Diligent attention to component integrity remains paramount, ensuring both peak performance and minimizing the risk of injury. The discerning skater should prioritize thorough understanding and proactive maintenance to realize the full potential of their equipment.