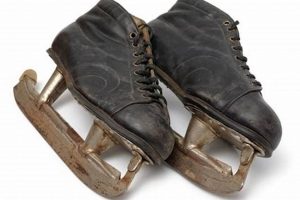

Devices affixed to footwear that facilitate gliding across frozen water surfaces are essential equipment for both recreational skating and competitive ice sports. These specialized pieces of equipment typically comprise a boot securely attached to a blade, allowing for efficient movement and maneuverability on the ice. Examples range from models designed for figure skating, with a toothed toe pick for jumps and spins, to hockey skates, built for speed and protection during gameplay.

These items are crucial for participating in various activities, offering a unique form of exercise, entertainment, and athletic competition. Throughout history, their design and construction have significantly evolved, reflecting advancements in materials science and manufacturing techniques. This progression has led to improved performance, comfort, and safety for users of all skill levels. The development of more durable and responsive materials has also widened the range of activities that can be enjoyed on frozen surfaces.

The subsequent sections will delve into the diverse types of skating equipment available, the essential features to consider when selecting appropriate models, and the maintenance procedures necessary to ensure longevity and optimal performance. Detailed analysis will also be provided regarding the biomechanics of skating and the impact of different equipment designs on skating efficiency.

Optimizing Performance and Longevity

The following guidelines offer practical advice for selecting, maintaining, and utilizing skating equipment to maximize performance and ensure extended product lifespan.

Tip 1: Proper Sizing and Fit: Ensuring the equipment fits correctly is paramount. Ill-fitting skates can cause discomfort, blisters, and impede performance. Consult sizing charts and, ideally, seek professional fitting assistance.

Tip 2: Blade Sharpening: Regular blade sharpening is crucial for maintaining edge control and glide. The frequency of sharpening depends on usage, but typically, professional sharpening is recommended after 10-20 hours of skating.

Tip 3: Moisture Management: After each use, thoroughly dry the blades with a soft cloth to prevent rust. Remove the insoles from the boots to allow for complete aeration and moisture evaporation.

Tip 4: Boot Maintenance: Periodically inspect the boots for signs of wear and tear, such as loose stitching or damaged eyelets. Address any minor repairs promptly to prevent further deterioration.

Tip 5: Storage Considerations: Store equipment in a cool, dry place, away from direct sunlight and extreme temperatures. Using blade guards when not in use protects the blade’s edges from damage.

Tip 6: Lacing Technique: Employ a consistent lacing technique that provides adequate support without restricting ankle movement. Experiment with different lacing patterns to find the most comfortable and effective configuration.

Tip 7: Consider the Blade Radius: The blade’s radius of hollow (ROH) impacts edge bite and glide. Experiment with different ROH values to determine the optimal setting for individual skating style and skill level.

Adhering to these recommendations will contribute to enhanced skating performance, prolonged equipment durability, and a more enjoyable skating experience.

The next section will explore advanced skating techniques and training methodologies designed to elevate skating proficiency.

1. Blade Material

The selection of blade material is paramount to the performance characteristics of skating equipment. This choice influences factors ranging from edge retention and glide efficiency to corrosion resistance and overall durability, thereby significantly impacting the user’s skating experience.

- Carbon Steel Composition

Carbon steel offers a high degree of hardness, enabling the creation of a fine, durable edge that provides exceptional grip on the ice. While advantageous for its sharpening capabilities and initial performance, carbon steel is susceptible to corrosion and requires meticulous maintenance to prevent rust formation. Its use is often favored by skaters prioritizing edge control over long-term durability and reduced maintenance.

- Stainless Steel Alloys

Stainless steel alloys offer superior corrosion resistance compared to carbon steel, mitigating the need for rigorous post-use drying procedures. Although typically softer than carbon steel, advancements in metallurgy have resulted in stainless steel blades capable of achieving adequate edge hardness and acceptable wear characteristics. This material is commonly selected by skaters prioritizing convenience and reduced maintenance over the ultimate edge sharpness attainable with carbon steel.

- Heat Treatment and Hardness

The heat treatment process applied to blade materials substantially affects their hardness and wear resistance. Precise heat treatment techniques can optimize the hardness of both carbon and stainless steel blades, enhancing their ability to maintain a sharp edge over extended periods. Improper heat treatment, however, can compromise blade integrity, leading to premature dulling or even fracture. This treatment significantly influences the longevity and performance consistency.

- Blade Coating Technologies

Surface coatings, such as chrome plating or specialized polymers, can be applied to blade materials to further enhance corrosion resistance and reduce friction. These coatings create a protective barrier against moisture and environmental contaminants, extending the blade’s lifespan. Furthermore, low-friction coatings can improve glide efficiency, allowing for smoother and faster skating. Such technologies represents a refinement of material properties for enhanced durability and performance.

In summary, the selection of blade material is a critical decision that directly impacts the skating experience. Balancing the trade-offs between edge sharpness, corrosion resistance, and maintenance requirements is essential for optimizing performance and ensuring the longevity. Advances in metallurgy and coating technologies continue to refine blade materials, offering skaters enhanced options tailored to their specific needs and preferences.

2. Boot Construction

The design and manufacturing of the boot component are integral to the overall performance and safety of skating equipment. The boot provides the structural foundation for foot support, ankle stability, and efficient energy transfer, directly influencing control, comfort, and injury prevention.

- Material Composition and Rigidity

The selection of materials for boot construction significantly impacts rigidity and responsiveness. Leather boots, while traditionally favored for comfort and moldability, may lack the stiffness required for advanced maneuvers. Synthetic materials, such as reinforced polymers and carbon fiber composites, offer increased rigidity, providing enhanced support and energy transfer for skilled skaters. The choice depends on skating style and performance goals.

- Ankle Support and Cuff Design

The height and contour of the boot cuff, along with internal padding and reinforcement, determine the level of ankle support provided. Higher cuffs offer greater stability, reducing the risk of ankle sprains and providing more control during lateral movements. Lower cuffs allow for increased range of motion, preferred by some skaters for artistic expression and intricate footwork. The ideal cuff design balances support and flexibility based on skating discipline and skill level.

- Lacing System and Closure Mechanisms

The lacing system plays a vital role in securing the foot within the boot and distributing pressure evenly. Traditional lacing systems allow for customized fit adjustments, while alternative closure mechanisms, such as buckles, straps, and BOA systems, offer quick and convenient tightening. Hybrid systems combining laces and buckles provide a balance of customization and ease of use. Proper lacing technique is essential for optimizing fit and preventing discomfort or pressure points.

- Heat Moldability and Customization

Some boots feature heat-moldable materials that conform to the individual skater’s foot shape when heated, creating a custom fit and minimizing pressure points. Customization options, such as aftermarket footbeds and orthotics, further enhance comfort and support. Proper fit, achieved through heat molding and customization, improves power transfer, reduces fatigue, and enhances overall skating performance.

In conclusion, the boot’s construction is a multifaceted aspect of skating equipment, encompassing material selection, support features, closure systems, and customization options. Selecting a boot that aligns with individual foot anatomy, skating style, and performance requirements is crucial for maximizing comfort, control, and safety. Proper boot construction optimizes the connection between the skater and the blade, enabling efficient energy transfer and a more enjoyable skating experience.

3. Ankle Support

Ankle support, an integral element of the design, significantly influences stability, control, and injury prevention. The rigid structure surrounding the ankle joint provides crucial resistance against lateral movements, thereby minimizing the risk of sprains and other related injuries. A well-designed system enables skaters to execute complex maneuvers with greater confidence, translating to enhanced performance across various disciplines.

Insufficient support can result in ankle instability, leading to compromised performance and an increased susceptibility to injury. Conversely, excessively rigid support may restrict ankle mobility, hindering the skater’s ability to perform intricate footwork and achieve optimal balance. The optimal level of support depends on the skater’s skill level, skating style, and physical condition. For example, figure skaters often require a greater range of motion in the ankle compared to hockey players who prioritize stability and protection.

The integration of advanced materials and design features, such as contoured padding and adjustable straps, allows for customized ankle support tailored to individual needs. Properly fitted equipment, incorporating appropriate support, enhances overall skating efficiency, reduces fatigue, and contributes to a safer and more enjoyable experience. Neglecting the significance can have detrimental consequences, underscoring the importance of careful consideration and professional fitting during the selection process.

4. Blade Sharpening

Blade sharpening constitutes a critical maintenance procedure directly impacting the performance characteristics of skating equipment. The interaction between the blade’s edge and the ice surface determines the skater’s ability to execute maneuvers with precision and control. A dull blade compromises this interaction, resulting in reduced grip and an increased risk of slippage. This deterioration directly affects a skater’s ability to accelerate, turn, and stop effectively. For example, a hockey player with dull blades may struggle to maintain speed during a rush, while a figure skater may find it difficult to execute precise edges during a routine. The sharpness of the blade dictates the efficiency of energy transfer from the skater to the ice, and a properly sharpened blade provides optimal glide and control.

The sharpening process involves restoring the blade’s edge to its optimal profile, creating two distinct edges, an inside edge and an outside edge, separated by a “hollow.” The depth of this hollow, known as the radius of hollow (ROH), is a critical parameter that influences the blade’s bite into the ice. A deeper hollow provides more grip but increases friction, while a shallower hollow provides less grip but smoother glide. Sharpening techniques vary, employing specialized machinery to precisely grind and hone the blade’s edge. The selection of an appropriate ROH requires careful consideration of the skater’s skill level, skating style, and the specific demands of the discipline. Proper sharpening not only enhances performance but also extends the blade’s lifespan by removing minor imperfections and preventing the formation of excessive rust or corrosion.

In summary, blade sharpening is not merely a cosmetic procedure but an essential maintenance requirement for achieving optimal performance and safety. It affects edge control, glide efficiency, and the skater’s overall ability to execute maneuvers effectively. Consistent and professional sharpening ensures that skating equipment functions as intended, maximizing the skater’s potential and minimizing the risk of accidents. Understanding the relationship between sharpening, blade profile, and ice interaction is paramount for both recreational and competitive skaters seeking to maintain peak performance.

5. Fit Precision

The concept of fit precision directly influences the performance, comfort, and safety associated with specialized skating equipment. A precise fit ensures optimal energy transfer, stability, and control, while minimizing the risk of injury. The intricate relationship between the skater’s foot and the equipment is paramount for maximizing athletic potential and preventing discomfort or long-term complications.

- Biomechanical Efficiency

A precisely fitted skate allows for efficient transfer of force from the skater’s muscles to the ice surface. Gaps or excessive pressure points within the boot can impede this transfer, leading to energy loss and reduced skating speed and agility. For example, a loose heel pocket can cause the foot to slip within the boot during push-offs, diminishing the propulsive force applied to the ice. Optimizing fit through proper sizing and customization enhances biomechanical efficiency, allowing skaters to achieve greater performance with less effort.

- Ankle Stability and Support

Proper fit contributes directly to ankle stability and support, reducing the risk of sprains and other ankle-related injuries. A snug fit around the ankle joint provides necessary reinforcement, preventing excessive lateral movement during turns and jumps. Conversely, a poorly fitted skate may offer inadequate support, increasing the likelihood of instability and injury. For instance, a skate that is too wide may allow the ankle to roll inward or outward, compromising balance and control. Achieving precise fit optimizes ankle support and minimizes the risk of injury.

- Pressure Distribution and Comfort

A precise fit ensures even distribution of pressure across the foot, minimizing the development of pressure points and discomfort. Ill-fitting equipment can create concentrated pressure on specific areas, such as the toes, heel, or instep, leading to blisters, calluses, and other foot ailments. For example, a skate that is too narrow may compress the toes, causing pain and potentially leading to long-term foot problems. Proper fit optimizes pressure distribution, enhancing comfort and allowing skaters to train and compete for extended periods without discomfort.

- Customization and Moldability

Modern skating equipment often incorporates heat-moldable materials that allow for customized fitting. This process involves heating the boot to soften the materials, then allowing it to conform to the unique contours of the skater’s foot. This customization enhances fit precision, minimizing gaps and pressure points. Furthermore, aftermarket footbeds and orthotics can be used to further refine the fit, providing additional support and cushioning. These customization options improve the overall comfort, performance, and safety of the equipment.

The various facets of fit precision underscore its critical role in optimizing the performance and well-being of skaters. Proper fit enhances biomechanical efficiency, provides adequate ankle support, promotes even pressure distribution, and allows for customization. Consequently, prioritizing fit precision during the selection process is paramount for achieving optimal results and minimizing the risk of injury. The synergistic relationship between the skater’s foot and well-fitted equipment enables enhanced control, comfort, and overall skating experience.

6. Usage Type

The intended usage significantly influences the selection and configuration of specialized skating equipment. Varying skating disciplines impose distinct demands on the equipment, requiring specific design features and performance characteristics. The correlation between usage type and equipment attributes is crucial for optimizing performance, safety, and longevity.

- Figure Skating

Figure skating necessitates equipment designed for intricate footwork, jumps, and spins. These devices typically feature a shorter, more curved blade with a pronounced toe pick to facilitate complex maneuvers. Boot construction emphasizes ankle flexibility to allow for expressive movements, while providing adequate support for landing jumps. The selection of specific blade profiles and boot stiffness varies based on the skater’s skill level and preferred style.

- Hockey

Hockey demands equipment built for speed, agility, and protection. Hockey skates feature a longer, straighter blade for enhanced acceleration and maneuverability. Sturdy boot construction, often incorporating reinforced materials, provides impact resistance and ankle support to withstand the rigors of gameplay. The design prioritizes protection against pucks, sticks, and collisions with other players.

- Recreational Skating

Recreational skating encompasses a wide range of activities, from leisurely gliding to informal games. Equipment for recreational use typically emphasizes comfort and ease of use. Boots are often constructed with softer materials and feature ample padding. Blades may be shorter and less aggressively profiled than those used in competitive disciplines. The design aims to provide a stable and comfortable skating experience for individuals of varying skill levels.

- Speed Skating

Speed skating requires specialized equipment designed for maximum velocity and efficiency. Speed skates feature exceptionally long, thin blades that minimize friction and maximize glide. Boots are typically low-cut to allow for greater ankle mobility and facilitate the distinctive speed skating stride. The design prioritizes aerodynamic efficiency and minimizes weight to optimize speed.

The diverse requirements of different skating disciplines necessitate a careful consideration of equipment features and specifications. Selecting equipment that aligns with the intended usage optimizes performance, enhances safety, and prolongs the lifespan of the equipment. A comprehensive understanding of the relationship between usage type and equipment attributes is essential for both recreational and competitive skaters seeking to maximize their skating experience.

7. Maintenance

The sustained functionality and longevity of skating equipment are directly contingent upon diligent maintenance practices. The harsh conditions inherent in ice skating, including exposure to moisture, ice debris, and repetitive stress, necessitate regular care to prevent degradation and ensure optimal performance. Neglecting proper maintenance can lead to compromised safety, reduced performance, and premature equipment failure. The interaction of the blade with the ice causes it to dull over time, diminishing grip and glide efficiency. Boot components, exposed to moisture and stress, are susceptible to material breakdown and structural weakening. Therefore, regular maintenance is not merely a suggestion, but a necessity for preserving the integrity of skating equipment.

Practical maintenance procedures encompass several key areas. Post-use blade drying prevents rust formation, extending the blade’s lifespan and maintaining edge sharpness. Regular sharpening restores the blade’s profile and ensures optimal grip on the ice, enabling precise maneuvers and efficient energy transfer. Boot maintenance involves cleaning, drying, and inspecting for signs of wear and tear. Laces should be inspected regularly and replaced when frayed or damaged. Addressing minor repairs promptly prevents further deterioration and extends the boot’s lifespan. Furthermore, proper storage in a cool, dry place protects the equipment from environmental damage. Failure to implement these practices will result in diminished performance, increased risk of injury, and the need for more frequent equipment replacement. For example, a hockey player neglecting blade sharpening may experience reduced speed and control, increasing the risk of collisions. Similarly, a figure skater with poorly maintained boots may suffer ankle instability, compromising jump landings and potentially leading to injury.

In summary, maintenance is a non-negotiable aspect of owning and utilizing specialized skating equipment. It is a proactive approach to preserving performance, ensuring safety, and maximizing the lifespan of the equipment. A consistent maintenance regimen, encompassing blade care, boot maintenance, and proper storage, mitigates the detrimental effects of harsh environmental conditions and repetitive stress. By prioritizing maintenance, skaters can prolong the functionality of their equipment, enhance their skating experience, and minimize the risk of injury. The long-term benefits of diligent maintenance far outweigh the minimal time and effort required, making it an indispensable practice for all skaters.

Frequently Asked Questions About Skating Equipment

The following addresses common inquiries and misconceptions regarding the selection, usage, and maintenance of specialized devices used for gliding across frozen surfaces.

Question 1: What factors dictate the lifespan of skating blades?

The longevity of blades is influenced by several factors, including blade material, frequency of use, ice conditions, and maintenance practices. High-quality blades, manufactured from durable materials and subjected to proper heat treatment, typically exhibit extended lifespans. Regular sharpening and diligent drying after each use further contribute to blade longevity. Conversely, skating on abrasive ice surfaces and neglecting maintenance can significantly shorten blade life.

Question 2: How does boot stiffness affect skating performance?

Boot stiffness dictates the level of support and responsiveness provided to the skater’s foot and ankle. Stiffer boots offer greater stability and control, enabling more precise execution of complex maneuvers. However, excessively stiff boots can restrict ankle mobility and hinder agility. Softer boots provide increased flexibility but may lack the necessary support for advanced skating techniques. The ideal boot stiffness depends on the skater’s skill level, skating style, and the specific demands of the discipline.

Question 3: What constitutes proper lacing technique?

Proper lacing technique involves achieving a snug and secure fit without restricting circulation or causing discomfort. The laces should be tightened progressively, starting from the toes and working upwards towards the ankle. The degree of tightness should be adjusted based on individual preference and the level of support required. Over-tightening can cause pressure points and discomfort, while under-tightening can compromise stability and control. Experimentation with different lacing patterns may be necessary to find the optimal configuration.

Question 4: Why is blade sharpening necessary?

Blade sharpening is essential for maintaining optimal edge control and glide efficiency. The blade’s edge gradually dulls with use, diminishing its ability to grip the ice and execute precise maneuvers. Sharpening restores the blade’s edge to its optimal profile, creating two distinct edges that provide the necessary grip for acceleration, turning, and stopping. Regular sharpening enhances performance, minimizes the risk of slippage, and extends the blade’s lifespan.

Question 5: How does the Radius of Hollow (ROH) impact skating?

The Radius of Hollow (ROH) refers to the concavity ground into the blade’s bottom surface during sharpening. The ROH affects the blade’s grip on the ice, with a deeper ROH providing more bite and a shallower ROH offering smoother glide. Selecting an appropriate ROH requires careful consideration of the skater’s skill level, skating style, and the specific demands of the discipline. Experimentation with different ROH values may be necessary to determine the optimal setting.

Question 6: What are the signs of ill-fitting skating equipment?

Signs of ill-fitting equipment include discomfort, pressure points, blisters, and reduced performance. Equipment that is too tight can restrict circulation and cause pain, while equipment that is too loose can compromise stability and control. Excessive heel slippage, toe cramping, and ankle instability are also indicators of improper fit. Professional fitting assistance is recommended to ensure proper sizing and configuration.

Adherence to these insights promotes informed decisions and extends product value and enjoyment.

The next segment will address advanced skating techniques and strategic training methodologies.

Conclusion

This exposition has presented a comprehensive overview of specialized devices crucial for navigating frozen surfaces, emphasizing the diverse factors that influence their performance, safety, and longevity. From the intricacies of blade material and boot construction to the critical considerations of fit precision and maintenance, each aspect contributes significantly to the overall skating experience. Understanding these elements is paramount for both recreational enthusiasts and competitive athletes seeking to optimize their abilities and minimize the risk of injury.

As technology advances and materials science evolves, continued innovation in skating equipment is anticipated. Further research and development will likely focus on enhancing performance characteristics, improving comfort, and increasing durability. Individuals engaged in activities requiring these devices are encouraged to remain informed about the latest advancements and prioritize the selection and maintenance of appropriate equipment to ensure a safe and rewarding experience on the ice.