A designated period at an ice rink allows the public to utilize the facility for recreational skating. These sessions typically occur at specific times and are often advertised on the arena’s schedule. Individuals of varying skill levels, from beginners to experienced skaters, participate in these activities. Rental skates are usually available for those who do not own their own equipment.

Participation in these recreational skating periods offers several advantages. It provides an accessible form of exercise, promoting physical fitness and cardiovascular health. The activity fosters social interaction and community engagement. Historically, ice skating has been a popular pastime, and these public sessions continue this tradition by providing a safe and controlled environment for individuals to enjoy the sport.

The subsequent sections will detail the varying costs associated with participation, the standard safety regulations enforced during these sessions, and advice for beginners looking to improve their skating abilities. Furthermore, information about specialized events that occur within these public skating times will be provided.

The following guidance aims to optimize the experience during public ice skating sessions at an ice arena. Adherence to these suggestions can enhance safety and enjoyment for all participants.

Tip 1: Check the Schedule: Before arriving, verify the availability and duration of the public skating period. Schedules are often subject to change due to hockey games, private events, or maintenance.

Tip 2: Arrive Early: Arriving before the session’s start allows ample time for skate rental, if needed, and preparation. This minimizes potential crowding at the rental counter and on the ice.

Tip 3: Dress Appropriately: Wear warm, layered clothing. Gloves or mittens are essential to protect hands, and a hat is advisable for maintaining body temperature. Avoid excessively loose clothing that could pose a tripping hazard.

Tip 4: Practice Falling and Getting Up: Familiarize oneself with proper falling techniques to minimize injury. Bending knees and angling to fall on padded areas (such as the buttocks) can reduce impact. Learn how to stand up efficiently from a fallen position.

Tip 5: Be Aware of Surroundings: Maintain awareness of other skaters and their movements. Avoid sudden stops or turns, and yield to more experienced skaters. Refrain from using mobile devices while on the ice.

Tip 6: Utilize Designated Areas: Observe and adhere to any designated areas for beginners or specific activities. Respect these zones to ensure a safe environment for all skill levels.

Tip 7: Skate within Skill Level: Refrain from attempting maneuvers beyond current skating abilities. Seek instruction from qualified instructors to improve skills and techniques.

Implementing these strategies will contribute to a safer, more enjoyable, and productive session at the skating arena. The information presented aims to cultivate a responsible and respectful environment for all participants.

The final portion of this article will delve into the competitive opportunities arising from skills honed during open skate, and how such experiences contribute to participation in ice sports.

1. Schedule Availability

Schedule availability constitutes a critical factor influencing the accessibility and utilization of public ice skating sessions at an ice arena. The posted schedule directly determines when individuals can engage in recreational skating. Without a clear and consistent schedule, participation is severely limited.

- Session Timing

The time of day or week a session is offered directly affects who can attend. Sessions scheduled during standard work or school hours limit access to those with flexible schedules or those not currently employed or enrolled in formal education. Conversely, evening and weekend sessions may cater to a broader audience.

- Frequency of Sessions

The number of available sessions per week impacts the regularity with which individuals can participate. Limited sessions might create high demand and overcrowding, diminishing the overall experience. A greater frequency of sessions provides increased opportunities and potentially reduces congestion.

- Holiday and Seasonal Variations

Schedule availability often fluctuates based on holidays, school breaks, and seasonal demands. Periods of high demand, such as winter holidays, may see increased session frequency, while off-season periods could experience reductions or cancellations. This variability requires participants to consult the schedule regularly.

- Conflicts with Other Events

Public skating session schedules are frequently affected by other ice arena activities, such as hockey games, figure skating practices, and private rentals. These events often take precedence, resulting in the cancellation or rescheduling of public sessions. Monitoring potential conflicts is crucial for planning participation.

The effective management and communication of schedule availability are paramount to maximizing public engagement with ice arena skating. A well-structured schedule that considers the needs of various user groups can foster greater participation and community involvement. Regular updates and transparent communication of schedule changes enhance user experience and prevent potential disappointments.

2. Skill Levels

The spectrum of skill levels present during public skating at an ice arena directly influences the dynamics and safety of the environment. A wide range, from novice to advanced skaters, necessitates a shared understanding of etiquette and spatial awareness. The presence of beginners, for instance, often requires experienced skaters to exercise caution and adjust their speed or maneuvers to avoid collisions. Conversely, advanced skaters may find that congested conditions impede their ability to practice more complex skills. The effective management of this mix of proficiencies constitutes a key challenge for ice arena staff. One example illustrating this is the establishment of designated areas within the ice surface, separating beginners practicing basic movements from those executing more advanced techniques like spins or jumps. This segregation promotes a safer and more enjoyable experience for all participants. The varying skill levels also affect the type of activities permissible during the session, influencing whether specific games or drills can be implemented.

Further compounding the dynamic is the phenomenon of “perceived skill” versus actual ability. Individuals may overestimate their competence, leading to potentially hazardous situations. For example, an inexperienced skater attempting complex moves without proper instruction can endanger themselves and others. Ice arena staff frequently address this challenge through posted safety guidelines, verbal warnings, and occasional interventions. The success of these interventions hinges on the cooperation and responsibility of individual skaters. Regular public skating sessions also present opportunities for informal peer learning, where more experienced skaters may subtly guide or assist those with less proficiency. This informal mentorship can contribute positively to the overall skill development within the skating community. Ultimately, the shared awareness of the diverse skill levels facilitates a more harmonious skating environment.

In summary, the consideration of skill levels is an integral component of ensuring a safe and enjoyable public ice skating experience. The ice arena environment benefits from the proactive management of skill disparities. Strategies include spatial separation of different proficiencies, robust safety enforcement, and reliance on the collective responsibility of participants. Challenges persist in mitigating the risks associated with overestimation of skating ability, necessitating continued emphasis on safety education. This awareness provides a foundation for more comprehensive and equitable management of ice arena resources, benefiting the diverse skating community as a whole.

3. Safety Regulations

Safety regulations constitute a foundational element of public skating sessions at ice arenas. These guidelines are designed to mitigate potential hazards, protect participants from injury, and ensure a positive recreational experience for all individuals, regardless of skill level. Rigorous adherence to established protocols is paramount for maintaining a secure environment within the ice arena.

- Mandatory Protective Gear

The requirement for protective gear, such as helmets, is a common safety regulation. Helmets protect against head injuries resulting from falls or collisions. Some arenas may mandate helmet use for all participants, while others may restrict the requirement to specific age groups or skill levels. The consistent application of this regulation significantly reduces the incidence of serious head trauma.

- Skate Proficiency Guidelines

Regulations concerning skate proficiency aim to prevent reckless behavior. Skating at excessive speeds, performing dangerous maneuvers, or engaging in intentional collisions are typically prohibited. These guidelines are enforced through arena staff monitoring and intervention. The objective is to create an environment where all participants can skate safely and without fear of injury.

- Ice Surface Maintenance Procedures

Regular ice surface maintenance is essential for ensuring a safe skating environment. Imperfections in the ice, such as cracks or ruts, can pose tripping hazards. Arenas employ resurfacing machines to smooth the ice periodically, removing imperfections and restoring a consistent skating surface. The frequency of resurfacing is a critical component of maintaining safety standards.

- Emergency Protocols

Established emergency protocols outline procedures for responding to injuries or other incidents that may occur during public skating sessions. These protocols typically include designated first aid personnel, readily available medical supplies, and clear communication channels for contacting emergency services. A well-defined emergency response system ensures prompt and effective assistance in the event of an accident.

The effective implementation and enforcement of safety regulations are critical for the successful operation of public skating sessions. These protocols, when rigorously observed, minimize the risks associated with the activity. Arenas prioritize safety not only to protect participants from injury but also to foster a welcoming and enjoyable environment for all members of the skating community. The ongoing commitment to safety standards is a testament to the dedication of ice arena operators to providing a positive recreational experience.

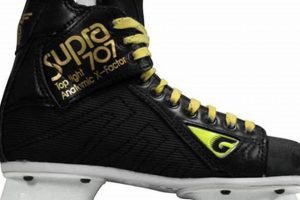

4. Rental Equipment

The availability of rental equipment is a critical component that significantly influences accessibility to recreational skating during public sessions at an ice arena. Without readily available and properly maintained rental skates, a substantial portion of the potential user base would be excluded from participation.

- Skate Sizing and Availability

The range of skate sizes offered directly impacts the breadth of the population able to partake in public skating. Insufficient size options limit participation for individuals with unusually small or large feet. Furthermore, the number of available skates in each size must correspond to anticipated demand to prevent shortages, particularly during peak hours. An insufficient inventory of correctly sized skates undermines accessibility and reduces user satisfaction.

- Skate Quality and Maintenance

The condition of rental skates significantly affects the user experience and safety. Poorly maintained skates with dull blades, broken buckles, or inadequate ankle support compromise performance and increase the risk of injury. Regular sharpening, repairs, and sanitation procedures are essential to ensure the skates are safe, comfortable, and functional. Investing in high-quality skates and consistent maintenance protocols directly contributes to participant satisfaction and minimizes potential accidents.

- Protective Gear Options

In addition to skates, the availability of rental protective gear, such as helmets and wrist guards, promotes safety during public skating. While not always mandatory, providing these options encourages users to prioritize personal safety. Rental helmets should conform to established safety standards and be available in various sizes to accommodate different head circumferences. The availability of such gear demonstrates a commitment to participant well-being and minimizes the severity of potential injuries.

- Rental Process Efficiency

The efficiency of the skate rental process impacts the overall user experience. Long lines, cumbersome paperwork, or unclear instructions can deter potential participants. Streamlined procedures, well-trained staff, and clear signage contribute to a more efficient and user-friendly rental process. Implementing online pre-registration or automated kiosks can further expedite the process, reducing wait times and improving overall satisfaction.

In summary, the provision of a comprehensive, well-maintained, and efficiently managed rental equipment program is crucial for maximizing accessibility to recreational ice skating. Addressing these facets contributes significantly to a positive and inclusive public skating experience, encouraging broader participation and fostering a safer environment for all users. The effectiveness of the rental process reflects directly on the overall quality and accessibility of ice arena public skate sessions.

5. Session Duration

Session duration constitutes a key factor governing the benefits and limitations of participation in public skating at ice arenas. The length of a scheduled session directly impacts physical exertion, skill development, and overall user satisfaction. Optimized session duration balances accessibility with adequate time for engagement in the activity.

- Physical Stamina and Exercise Benefit

The allotted session time dictates the potential for cardiovascular exercise and muscular engagement. Shorter sessions may limit the ability to achieve a sustained level of exertion, while excessively long sessions could lead to fatigue and increased risk of injury. An ideal duration enables participants to warm up, engage in moderate activity, and cool down adequately. For example, a session lasting 90 minutes might permit 60 minutes of active skating, accounting for warm-up and cool-down periods. The physical benefits scale accordingly with sustained activity.

- Skill Acquisition and Practice

Sufficient session duration provides ample opportunity for skill practice and improvement. Novice skaters require time to develop basic balance and coordination, while experienced skaters benefit from extended periods to refine advanced techniques. A brief session may not allow sufficient time to solidify newly learned skills, hindering progress. The timeframe allotted directly influences the extent to which participants can enhance their skating abilities. For instance, a skater attempting to master a new jump may need multiple repetitions over an extended period to achieve proficiency.

- Social Interaction and Leisure

Public skating sessions often serve as a social outlet, providing opportunities for interaction with friends and family. Longer sessions facilitate more extended periods of social engagement and leisure activities. In contrast, shorter sessions may limit the ability to socialize or relax, reducing the overall enjoyment of the experience. Extended durations enable social interaction alongside the physical activity. Families may utilize the extended session for socializing alongside skating.

- Session Capacity and User Turnover

The duration of a session directly affects the number of participants accommodated within a given timeframe. Shorter sessions allow for higher turnover, potentially increasing accessibility for a larger number of individuals. However, this can also lead to increased congestion and reduced skating space. Longer sessions, while potentially limiting overall accessibility, may provide a more spacious and less crowded skating environment. Strategic session planning must balance accessibility with a comfortable user experience. One scenario could involve offering shorter, more frequent sessions during peak times, and longer, less frequent sessions during off-peak hours.

In conclusion, session duration represents a crucial determinant influencing the effectiveness and appeal of public skating at ice arenas. Consideration of physical benefits, skill development opportunities, social interaction, and session capacity is essential for optimizing the session timeframe. The balance of these factors contributes to an enhanced experience for all participants. Session times at the average ice rink are around two hours on weekends, but can extend longer dependent on demand.

6. Accessibility

Accessibility, in the context of ice arena public skating sessions, directly dictates the breadth of community engagement with this recreational activity. Several factors contribute to or detract from accessibility, each impacting the opportunity for individuals to participate. Geographic location, transportation options, affordability, and physical accommodations collectively determine whether a significant segment of the population can readily access and enjoy these sessions. For example, an ice arena located in a suburban area with limited public transportation may be inaccessible to residents of urban centers, particularly those without personal vehicles. Conversely, an arena strategically situated near public transit hubs increases accessibility for a wider demographic. Affordability also plays a crucial role, as high admission fees or equipment rental costs can present a financial barrier, particularly for low-income families. The presence of adaptive skating equipment and trained staff enables the inclusion of individuals with disabilities, expanding the scope of accessibility beyond physical limitations.

Further contributing to access are the scheduling and promotion of these public skate periods. A limited schedule, particularly if confined to weekday afternoons, restricts accessibility for working adults and school-aged children. Actively promoting public skate sessions through community outreach programs, school partnerships, and accessible online platforms ensures that potential participants are aware of the opportunities available. Language barriers can also impede access; therefore, multilingual promotional materials and staff may be necessary in diverse communities. Consider the practical example of a community center collaborating with a local ice arena to provide subsidized skating lessons and transportation for underprivileged youth. Such initiatives directly address accessibility barriers and promote equitable access to recreational opportunities.

In summary, accessibility is not merely a peripheral consideration but an intrinsic component of a successful and inclusive ice arena public skate program. Barriers to access can inadvertently exclude segments of the population, limiting the potential benefits of physical activity and community engagement. Addressing these challenges through strategic location planning, affordability initiatives, inclusive programming, and effective communication strategies is crucial for ensuring that these recreational opportunities are available to all members of the community. Prioritizing accessibility enhances social equity and fosters a healthier, more connected community. Understanding this crucial point can lead to a more holistic and inviting recreational environment in the ice arena.

7. Cost Considerations

Financial implications represent a primary determinant in the accessibility and utilization of public skating sessions at ice arenas. A comprehensive understanding of associated expenses is essential for both individuals and facility operators to optimize participation and resource allocation.

- Admission Fees

The price of admission directly impacts the affordability of participation. High fees may discourage attendance, particularly among low-income individuals and families. Conversely, subsidized rates or discounted family passes can promote broader community engagement. The pricing structure must balance revenue generation for the arena with accessibility for diverse populations.

- Equipment Rental Costs

The cost of renting skates and protective gear constitutes a significant expense for those who do not own their own equipment. Elevated rental fees can create a barrier to entry, especially for infrequent skaters. Affordable rental options, coupled with well-maintained equipment, encourage participation and promote safety. Some arenas offer package deals combining admission and rental fees to reduce the overall cost.

- Travel Expenses

The cost of transportation to and from the ice arena must be factored into the overall expense of participation. Public transportation fares or gasoline costs for personal vehicles can add to the financial burden, particularly for individuals residing far from the facility. Strategic location planning and accessible public transportation options mitigate these expenses.

- Additional Expenses

Beyond admission and equipment rental, other costs may include parking fees, locker rentals, and the purchase of refreshments. These ancillary expenses can accumulate, further impacting the overall affordability of the activity. Transparent pricing and affordable options enhance user satisfaction and encourage repeat visits.

The interplay of these financial factors significantly shapes the accessibility and appeal of public skating sessions. Strategic pricing policies, affordable equipment rentals, and consideration of ancillary expenses contribute to a more inclusive and economically viable recreational opportunity. Addressing cost considerations fosters greater community engagement and promotes the long-term sustainability of ice arena public skating programs.

Frequently Asked Questions Regarding Ice Arena Open Skate

This section addresses common inquiries concerning public skating sessions at ice arenas. The information provided aims to clarify procedures and enhance understanding for potential participants.

Question 1: What constitutes “ice arena open skate?”

The term refers to designated periods during which an ice arena is accessible to the general public for recreational skating. These sessions typically occur at scheduled times and are subject to associated fees and regulations.

Question 2: Are there age restrictions for participation in public skating sessions?

Age restrictions vary depending on the specific policies of the ice arena. Some facilities may impose age limits for unaccompanied skaters, while others may require parental supervision for younger participants. It is advisable to consult the arena’s guidelines for clarification.

Question 3: Is prior skating experience necessary to participate in open skate?

Prior skating experience is not mandatory for participation. Public skating sessions accommodate individuals of varying skill levels, from beginners to advanced skaters. However, novice skaters should exercise caution and consider utilizing designated beginner areas.

Question 4: What type of attire is appropriate for ice arena open skate?

Appropriate attire includes warm, layered clothing, gloves or mittens, and a hat. Avoid excessively loose clothing that could pose a tripping hazard. Long pants are recommended to provide protection in the event of a fall.

Question 5: Are rental skates available at the ice arena?

Most ice arenas offer skate rental services for individuals who do not own their own skates. Rental skates are typically available in a range of sizes. It is advisable to arrive early to ensure skate availability.

Question 6: What safety precautions should be observed during public skating?

Safety precautions include skating at a controlled speed, maintaining awareness of surroundings, avoiding reckless behavior, and adhering to posted safety guidelines. Consider wearing a helmet to mitigate the risk of head injuries.

The information presented addresses common inquiries regarding public skating. It is recommended to consult the specific policies of the ice arena for detailed information.

The subsequent discussion will transition to competitive skating opportunities arising from the skills honed during open skate.

Concluding Remarks on Ice Arena Open Skate

This article has explored various facets of the term “ice arena open skate,” encompassing its definition, benefits, operational considerations, safety protocols, and frequently asked questions. Key points addressed include the importance of schedule availability, the accommodation of diverse skill levels, adherence to safety regulations, the role of rental equipment, session duration considerations, accessibility challenges, and cost implications. Thorough examination of these elements provides a comprehensive understanding of the dynamics surrounding public skating sessions at ice arenas.

The continued availability and accessibility of ice arena open skate sessions are crucial for promoting physical activity, fostering community engagement, and providing recreational opportunities for individuals of all ages and abilities. Strategic planning and resource allocation are essential to ensure the long-term viability and inclusivity of these programs. The proactive management and oversight of these recreational opportunities benefits both the participants and the wider community, and furthers the value of ice sports.