Protective guards designed for footwear used on ice surfaces serve to shield the skater’s boots and blades from damage. These components are typically constructed from durable materials like rubber or plastic and attach securely around the skate. For instance, a skater using a sharp blade on the ice might utilize these guards to protect the blade when walking off the ice on concrete, or to prevent damage to other items in a skate bag.

The utilization of these guards offers multiple advantages. They prolong the lifespan of both the skate boots and the blades by minimizing the impact of abrasive surfaces and accidental collisions. Historically, skaters have devised various methods for protection, ranging from makeshift coverings to more sophisticated, purpose-built solutions. Their implementation contributes to the maintenance of performance quality and reduces the frequency of costly replacements.

This article will further examine the different types of available protection for ice skates, detailing the materials used in their construction and providing guidance on selecting the appropriate option for various skating disciplines.

Protective Ice Skate Equipment Guidance

This section provides essential information for selecting and utilizing protective components for ice skates. Careful consideration of these points will contribute to the longevity and performance of skating equipment.

Tip 1: Material Selection is Crucial: Opt for guards constructed from durable, non-marking materials such as high-density rubber or reinforced plastics. These materials resist abrasion and minimize potential damage to rink surfaces.

Tip 2: Ensure Proper Fit: The protective components should fit snugly around both the skate boot and blade. An ill-fitting guard can slip during use, offering inadequate protection and potentially causing accidents.

Tip 3: Differentiate Between Blade and Boot Guards: Blade guards primarily protect the skate’s edge from damage when walking on surfaces other than ice. Boot guards, conversely, shield the leather or synthetic upper from scuffs and impacts.

Tip 4: Implement Regular Cleaning: Clean protective equipment regularly with mild soap and water. This removes debris and prevents the buildup of corrosive substances that can degrade the material over time.

Tip 5: Inspect for Wear and Tear: Routinely examine all protective components for signs of wear, such as cracks, tears, or deformation. Replace damaged guards immediately to ensure continued protection.

Tip 6: Consider Storage Practices: When not in use, store skates with guards in a dry, well-ventilated area. This prevents the growth of mold and mildew, which can compromise the integrity of the materials.

Tip 7: Prioritize Blade Coverage: Ensure that blade guards fully cover the exposed blade edge, especially during transport. This prevents accidental cuts or damage to surrounding items.

These guidelines emphasize the importance of proactive maintenance and proper selection in maximizing the lifespan and protective capabilities of ice skate equipment. Adhering to these recommendations ensures a safer and more cost-effective skating experience.

The subsequent section will address common misconceptions regarding protective equipment and provide clarification based on current industry best practices.

1. Blade Edge Protection

Blade edge protection constitutes a critical aspect of ice skate maintenance, directly impacting performance and longevity. The relationship between “ice skate fenders,” specifically blade guards, and edge protection is fundamental. This section details essential facets of blade edge protection and its direct correlation to the appropriate use and selection of protective guards.

- Material Composition and Hardness

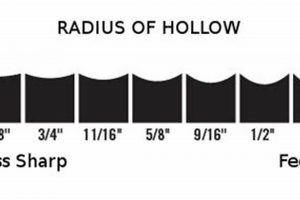

The materials from which blade guards are constructed directly influence their effectiveness in preventing edge damage. Softer materials may offer insufficient resistance to abrasion on concrete or tile, leading to premature dulling. Conversely, overly rigid materials can transmit impacts, potentially causing microscopic fracturing of the blade edge. Optimal materials exhibit a balance of shock absorption and abrasion resistance.

- Coverage Area and Fit Precision

The extent to which a blade guard encapsulates the blade edge is paramount. Partial coverage leaves sections vulnerable to contact with abrasive surfaces. Precise fit is equally crucial; loose guards can shift during movement, exposing the blade, while excessively tight guards may exert undue pressure, altering the blade’s profile. Proper fit and complete coverage ensure comprehensive protection.

- Environmental Contaminant Exclusion

Blade guards act as a barrier against environmental contaminants like dirt, salt, and moisture. These substances, if allowed to accumulate on the blade edge, can accelerate corrosion and degrade sharpness. Effective guards prevent ingress of these contaminants, preserving blade integrity. Regular cleaning of both blades and guards further mitigates the risk of corrosion.

- Impact Energy Dissipation

Accidental impacts, such as those occurring when skates are dropped or collide with other objects, can inflict significant damage on the blade edge. Well-designed blade guards incorporate features that dissipate impact energy, minimizing the force transmitted to the blade. This reduces the likelihood of chipping, bending, or other forms of damage.

These facets of blade edge protection collectively underscore the essential role of “ice skate fenders” in maintaining the performance and extending the lifespan of ice skate blades. The selection of appropriate guards, coupled with diligent maintenance practices, are indispensable for skaters seeking to preserve their equipment and optimize their skating experience.

2. Boot Surface Preservation

Boot surface preservation constitutes a significant aspect of ice skate maintenance, directly influencing the aesthetic appearance and structural integrity of the footwear. The protective devices, often referred to within the context of this discussion, as safeguarding implements, are instrumental in mitigating the wear and tear associated with regular use. These devices function as a barrier, shielding the boot’s surface from abrasion, impacts, and environmental contaminants.

The correlation between boot surface integrity and these protective implements is evident in various scenarios. For example, skaters traversing abrasive surfaces, such as concrete or rubber matting, risk scuffing or tearing the boot’s outer layer. The implementation of protective boot shields minimizes this risk, preserving the original finish and preventing the ingress of moisture or debris. Further, during storage and transport, these devices prevent contact with other equipment, averting scratches or indentations. The efficacy of these measures depends on material composition, secure fit, and consistent application.

In summary, protective components contribute substantially to the longevity and aesthetic appeal of ice skate boots. The proactive use of these shields minimizes the risk of surface damage, preserving the investment in skating equipment. This is particularly relevant for skaters who prioritize equipment appearance and structural soundness, both of which influence the overall performance and user experience.

3. Material Durability Standards

The longevity and protective capabilities of ice skate guards are directly contingent upon adherence to stringent material durability standards. These standards dictate the properties of the materials used in their construction, influencing resistance to abrasion, impact, and environmental degradation. Non-compliance with these standards can result in premature failure, compromising the protection afforded to the skate blades and boots. For instance, a blade guard constructed from low-grade plastic may crack or shatter upon impact, leaving the blade vulnerable. Similarly, a boot protector made from non-UV-resistant material can degrade and discolor when exposed to sunlight, reducing its aesthetic appeal and potentially weakening its structure.

The importance of material durability is further underscored by the diverse range of conditions to which these guards are subjected. Skaters may encounter abrasive surfaces, extreme temperatures, and corrosive substances during regular use and storage. Guards that meet established material durability standards are engineered to withstand these challenges, maintaining their protective properties over extended periods. Examples include the use of high-density polyethylene (HDPE) for blade guards, offering excellent impact resistance and low-temperature flexibility, and the application of durable, waterproof coatings to boot protectors, preventing moisture damage and staining. The selection of appropriate materials, verified through rigorous testing and certification, ensures consistent performance and reduces the risk of equipment failure.

In summary, adherence to material durability standards is a critical factor in determining the effectiveness and lifespan of protective implements for ice skates. These standards address key properties such as abrasion resistance, impact strength, UV resistance, and chemical inertness. Failure to meet these standards can compromise the protective function of the guards, increasing the risk of damage to skate blades and boots. Proper material selection and manufacturing processes, guided by established standards, are essential for ensuring that these components provide reliable and long-lasting protection.

4. Accidental Damage Mitigation

Accidental damage mitigation is an essential consideration in the maintenance of ice skates. Protective components, often termed in this context as “ice skate fenders,” play a critical role in minimizing the impact of unforeseen events on the integrity of both the blade and the boot. This section outlines key facets of accidental damage mitigation as it relates to these protective devices.

- Impact Absorption Capacity

The primary function of “ice skate fenders” in accidental damage mitigation is the absorption of impact energy. These components are designed to cushion the skate from collisions with hard surfaces or other objects. For example, a skater accidentally dropping their skates onto a concrete floor benefits from the shock-absorbing properties of the blade guards, which reduce the likelihood of blade damage. This capacity is directly related to the material composition and structural design of the guards.

- Abrasion Resistance during Transport

During transport, skates are susceptible to abrasion from contact with other items in a skate bag or vehicle. Blade guards and boot protectors, acting as “ice skate fenders,” provide a protective barrier against scratching and surface wear. This is particularly relevant for skaters who frequently travel to different rinks or competitions. The effectiveness of this function depends on the durability and surface finish of the protective components.

- Environmental Element Insulation

Accidental exposure to environmental elements, such as moisture or corrosive substances, can damage skate blades and boots. “Ice skate fenders” help to insulate the skates from these elements, preventing rust, corrosion, and material degradation. For example, blade guards made of moisture-resistant materials can prevent rust from forming on the blades after skating. This insulating effect is crucial for maintaining the long-term performance of the skates.

- Prevention of Adjacent Object Damage

Beyond protecting the skates themselves, “ice skate fenders” also mitigate the risk of damage to surrounding objects. Sharp skate blades can inadvertently cut or scratch surfaces they come into contact with. Blade guards prevent this type of accidental damage, protecting skate bags, car interiors, and other equipment from damage. This preventative measure contributes to a safer and more responsible skating environment.

In conclusion, accidental damage mitigation is a multi-faceted benefit provided by protective components. These “ice skate fenders” not only safeguard the skates from impact, abrasion, and environmental factors but also prevent damage to surrounding objects. The proper selection and use of these devices are essential for skaters seeking to minimize the risk of accidental damage and maintain the longevity of their equipment.

5. Equipment Longevity Extension

The operational lifespan of ice skates is directly correlated with the implementation of protective measures, specifically the utilization of “ice skate fenders”. These components, encompassing blade guards and boot protectors, serve to mitigate the detrimental effects of environmental exposure, physical abrasion, and accidental impact. Consequently, the investment in such protective devices manifests as an extension of the equipment’s usability period, delaying the need for replacement and reducing long-term costs. The causal relationship is evident: minimized damage translates to prolonged functionality. The significance of “Equipment Longevity Extension” as a primary attribute of “ice skate fenders” cannot be overstated; it underpins the economic and practical rationale for their adoption. For instance, a figure skater who consistently employs blade guards during off-ice transit will experience less frequent blade sharpening, thereby conserving blade material and maintaining optimal performance characteristics over a longer duration.

Further analysis reveals the practical applications of this understanding. Consider the context of a skating club managing a fleet of rental skates. The consistent application of robust blade guards and boot protectors across the entire inventory would demonstrably reduce the incidence of blade dulling, boot scuffing, and structural damage. This, in turn, would decrease the frequency of repairs, replacements, and associated labor costs, ultimately enhancing the club’s operational efficiency and financial sustainability. Similarly, recreational skaters who prioritize the regular cleaning and maintenance of their skates, coupled with the use of appropriate protective gear, can significantly extend the life of their equipment, realizing a greater return on their initial investment. This principle applies equally to high-performance skates used in competitive disciplines, where even minor damage can compromise performance and necessitate costly repairs or replacements.

In conclusion, the connection between “Equipment Longevity Extension” and “ice skate fenders” is firmly established through a combination of theoretical reasoning, practical examples, and economic considerations. The challenges associated with maintaining ice skate equipment namely, the inherent vulnerability of blades and boots to damage are effectively addressed through the strategic deployment of these protective devices. Understanding and implementing these principles contributes directly to the long-term performance, cost-effectiveness, and sustainability of skating activities across all levels of participation.

Frequently Asked Questions

This section addresses common inquiries regarding protective equipment for ice skates, specifically focusing on their function, selection, and maintenance.

Question 1: What constitutes “ice skate fenders” and what purpose do they serve?

The term encompasses protective coverings for ice skates, primarily blade guards and boot protectors. Blade guards shield the blades from damage when walking on non-ice surfaces, while boot protectors prevent scuffs and abrasions to the skate boot itself.

Question 2: Are “ice skate fenders” necessary for all levels of skaters?

While beneficial for all skaters, the necessity increases with the frequency of skating and the type of surfaces encountered off the ice. Competitive skaters and those regularly traversing abrasive surfaces will derive the greatest benefit.

Question 3: What materials are most suitable for “ice skate fenders” and why?

Durable, non-marking materials such as high-density rubber or reinforced plastics are preferred for blade guards due to their abrasion resistance. Boot protectors often utilize flexible synthetics or reinforced fabrics to provide protection without restricting movement.

Question 4: How frequently should “ice skate fenders” be inspected and/or replaced?

Regular inspection is recommended, ideally before each skating session. Replacement is warranted upon the appearance of cracks, tears, or significant wear that compromises their protective function.

Question 5: Is there a distinction between “ice skate fenders” designed for figure skates versus hockey skates?

While the fundamental purpose remains the same, specific designs may vary to accommodate the different blade geometries and boot shapes of figure and hockey skates. Ensure compatibility with the specific skate type.

Question 6: Can “ice skate fenders” negatively impact blade sharpness?

Improperly fitted or poorly maintained blade guards can potentially dull the blade edge. Select guards that fit snugly and are free of abrasive debris to minimize this risk.

The informed selection and diligent maintenance of protective equipment are crucial for preserving the performance and longevity of ice skates.

The subsequent section will delve into the economic considerations associated with investing in and maintaining protective gear.

Conclusion

This exposition has detailed the role and importance of protective coverings in ice skate maintenance. Through examination of material standards, damage mitigation, and longevity extension, the value of “ice skate fenders” becomes clear. Their utilization contributes directly to the sustained performance and reduced replacement costs associated with ice skating equipment.

The informed selection and consistent application of “ice skate fenders” represent a responsible approach to equipment management. This practice, benefiting both recreational and competitive skaters, ensures a safer and more cost-effective skating experience. Continued adherence to these principles will serve to prolong the lifespan of valuable skating assets.