Headgear designed for ice skating provides crucial protection against impacts. This specialized equipment typically features a hard outer shell, often made of polycarbonate or similar materials, coupled with an energy-absorbing inner liner, usually composed of expanded polystyrene (EPS) foam. Such construction is intended to dissipate the force of a fall, reducing the risk of head injury. An example of its application is seen when a skater loses balance and impacts the ice surface, the headgear is designed to absorb the blow.

The implementation of protective head covering is vital for skaters of all skill levels. Benefits include mitigating the severity of concussions, skull fractures, and other traumatic brain injuries. Historically, the use of such gear was less common; however, growing awareness of the potential for severe head trauma has led to increased adoption and, in some organized leagues, mandatory usage policies. The development and refinement of these safety devices has been a continuous process, with improvements in materials, design, and comfort driving advancements.

The subsequent sections will delve deeper into specific aspects, including certification standards, fitting guidelines, various styles and technologies, and considerations for selecting the most appropriate head protection for different skating disciplines.

Essential Guidance for Head Protection on Ice

The following outlines crucial considerations when selecting and using protective headgear for ice skating, aimed at minimizing the risk of head injuries.

Tip 1: Certification Verification: Ensure the headgear meets established safety standards. Look for certifications from organizations such as ASTM International or similar bodies. These certifications indicate rigorous testing has been conducted.

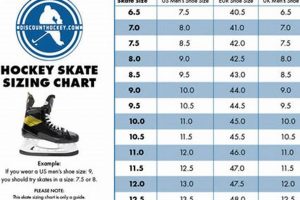

Tip 2: Proper Fit Assessment: The headgear should fit snugly and securely. A loose fit compromises protective capabilities. Measure head circumference and consult the manufacturer’s sizing chart. Adjustments should be made via the internal fitting system.

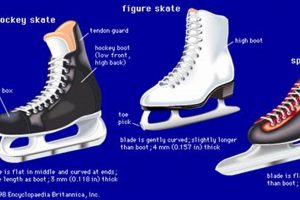

Tip 3: Sport-Specific Design Consideration: Different skating disciplines (e.g., figure skating, hockey, recreational skating) may necessitate varying design features. Hockey-specific headgear, for example, often incorporates additional facial protection.

Tip 4: Impact History Awareness: Following any significant impact, regardless of visible damage, the headgear should be replaced. The energy-absorbing materials may have been compromised, rendering it less effective in subsequent incidents.

Tip 5: Ventilation Importance: Adequate ventilation is crucial for maintaining comfort and preventing overheating. Select headgear with sufficient vents to promote airflow.

Tip 6: Chinstrap Securement: Always ensure the chinstrap is securely fastened. The chinstrap prevents the headgear from dislodging during a fall.

Tip 7: Padding Integrity Inspection: Regularly inspect the internal padding for wear and tear. Damaged or compressed padding reduces the effectiveness of the impact absorption.

Adhering to these guidelines promotes skater safety by ensuring properly certified, fitted, and maintained headgear is consistently used. This proactive approach significantly mitigates the potential for severe head trauma.

The next section will present the conclusion of this article, re-emphasizing key aspects of head protection during ice skating.

1. Impact energy absorption

Impact energy absorption constitutes a critical function of headgear intended for ice skating. When a skater falls and makes contact with the ice, the force of the impact must be managed to minimize trauma to the head. This is primarily achieved through the deformation and compression of the protective equipment’s internal materials, typically expanded polystyrene (EPS) foam. The EPS foam crushes under the impact, converting kinetic energy into other forms, such as heat and deformation, rather than transmitting it directly to the skull. For instance, a fall at even a moderate speed can generate significant force; without effective absorption, this force could result in concussion or more severe head injuries.

The effectiveness of impact energy absorption is directly linked to the materials used and the design of the headgear. Higher-density EPS foams generally provide greater energy absorption capabilities, but they may also increase the overall weight of the equipment. Design features, such as strategically placed vents or channels within the foam, can influence how the material deforms during impact and can therefore affect its performance. Testing standards, such as those established by ASTM International, evaluate the ability of headgear to absorb impact energy by measuring the acceleration experienced by a headform during controlled drop tests. These tests simulate real-world fall scenarios and provide quantifiable data regarding the protective capabilities.

Understanding the principles of impact energy absorption allows consumers to make informed decisions when selecting protective headgear. The ability of the device to effectively mitigate the effects of an impact is paramount in preventing head injuries while skating. Continued research and development in materials science and headgear design aim to further improve energy absorption, thereby enhancing skater safety. It is also important to note that the performance of the headgear can degrade over time due to exposure to UV light, heat, and repeated impacts. Therefore, regular inspection and timely replacement are crucial to ensure its continued effectiveness.

2. Certified Safety Standards

The conformance of ice skating headgear to certified safety standards is paramount to minimizing the risk of head injuries. These standards, developed by independent testing organizations, establish minimum performance criteria for impact absorption and structural integrity. Adherence to these standards is not merely a suggestion but a critical indicator of a product’s ability to protect the wearer.

- ASTM F1849: Standard Specification for Helmets Used in Recreational Skateboarding and Trick Roller Skating

While specifically designated for skateboarding and roller skating, this ASTM standard often serves as a benchmark for ice skating headgear due to the similar impact dynamics involved. It mandates rigorous testing procedures to evaluate the helmet’s capacity to mitigate the severity of impacts from various angles and intensities. A helmet certified to ASTM F1849 has undergone controlled drop tests and must meet specific criteria for force transmission to the headform. This testing process simulates real-world fall scenarios, providing a quantifiable measure of the helmet’s protective capabilities.

- CPSC Certification: Consumer Product Safety Commission Standards

The CPSC sets mandatory safety standards for various consumer products, including some types of headgear. While not all ice skating headgear is explicitly mandated to meet CPSC standards, those that are, have undergone testing to ensure they provide a reasonable level of protection against foreseeable hazards. CPSC certification typically involves assessments of the helmet’s construction, materials, and labeling to ensure they comply with federal regulations.

- EN 1078: European Standard for Bicycle and Skateboard Helmets

EN 1078 is a European safety standard applicable to bicycle, skateboard, and roller skate helmets. While not directly applicable in North America, it is frequently used as a benchmark for safety. The standard specifies requirements and testing methods for helmet construction, including impact absorption, retention system strength, and field of vision. Ice skating helmets marketed in Europe often carry EN 1078 certification, indicating compliance with European safety regulations.

- Impact Testing Protocols and Force Attenuation

Central to all certification standards is the impact testing protocol. The helmet is placed on a headform equipped with sensors, and then dropped from a predetermined height onto various surfaces. The sensors measure the force transmitted to the headform during the impact. To pass the certification, the measured force must remain below a specified threshold, demonstrating the helmet’s ability to attenuate the impact. Different standards may employ different impact testing methodologies and force thresholds, reflecting varying levels of stringency.

These facets highlight the significance of independent verification in ensuring the efficacy of ice skating headgear. Skaters are advised to prioritize products bearing certifications from reputable organizations, as this provides assurance that the product has undergone rigorous testing and meets established safety criteria. Selecting certified equipment is a proactive step towards minimizing the risk of head injuries on the ice. The presence of these standards ultimately promotes safer participation and reduces the incidence of serious head trauma.

3. Proper circumferential fit

Achieving a proper circumferential fit is crucial for the effectiveness of ice skating headgear. A helmet that is too large or too small for the wearer’s head circumference cannot provide optimal protection during an impact. The helmet’s intended energy-absorbing properties are contingent upon secure and consistent contact with the skull.

- Accurate Head Measurement

Obtaining an accurate measurement of head circumference is the foundational step in ensuring a correct fit. This measurement, typically taken in centimeters or inches, should be performed using a flexible measuring tape positioned horizontally around the head, approximately one inch above the eyebrows. The measurement obtained should then be compared to the manufacturer’s sizing chart for the specific helmet model. Discrepancies between the head size and the recommended helmet size indicate that an alternative size should be selected. For example, a skater with a head circumference of 56 cm should select a helmet size within the 56 cm range specified by the manufacturer, and not one that accommodates 54-55 cm.

- Internal Adjustment Systems

Most ice skating headgear incorporates internal adjustment systems to fine-tune the fit and accommodate slight variations in head shape. These systems may include adjustable straps, ratcheting mechanisms, or removable padding. The purpose of these systems is to allow the wearer to customize the helmet’s internal dimensions to achieve a snug and secure fit. For instance, a ratcheting mechanism at the rear of the helmet can be tightened or loosened to ensure that the helmet sits firmly on the head without excessive movement. Properly utilizing these adjustment systems enhances the helmet’s stability and minimizes the risk of displacement during a fall.

- Helmet Stability and Movement

A correctly fitted ice skating helmet should remain stable on the head during normal activity and should not exhibit excessive movement or slippage. To assess the fit, the wearer can perform a simple test by shaking the head gently from side to side and front to back. If the helmet shifts significantly or obscures vision, it is likely too large or not properly adjusted. Similarly, if the helmet feels excessively tight or causes discomfort, it may be too small. Stable positioning is critical for ensuring that the helmet’s protective features are correctly aligned to safeguard the head in the event of an impact. For example, if the helmet slides backward during a fall, the forehead may be left exposed, increasing the risk of injury.

- Compatibility with Additional Equipment

In some skating disciplines, particularly hockey, additional equipment such as visors or face masks are often used in conjunction with headgear. It is essential to ensure that the helmet is compatible with these accessories and that their addition does not compromise the fit or stability of the helmet. For example, a visor that is improperly attached to a helmet may exert pressure on certain areas of the head, causing discomfort or affecting the helmet’s ability to absorb impacts. Similarly, a face mask that is too large or too small can interfere with the helmet’s retention system. Proper integration of additional equipment is necessary to maintain the overall effectiveness of the protective system.

The accurate measurement of head circumference, the utilization of internal adjustment systems, the assessment of helmet stability, and the consideration of compatibility with other equipment, each contribute to ensuring a proper circumferential fit. When these aspects are correctly addressed, the headgear can provide optimal protection for the wearer, minimizing the risk of head injuries during ice skating. Failure to achieve a proper fit undermines the effectiveness of the protective device, regardless of its inherent design or certification status. Consequently, prioritizing fit is a fundamental aspect of skater safety.

4. Ventilation system design

The integration of a ventilation system into ice skating headgear directly addresses the physiological demands placed on skaters during physical activity. Ice skating, whether recreational or competitive, generates substantial body heat. Enclosing the head within a protective shell, while essential for safety, can impede natural heat dissipation, leading to elevated core temperatures and increased perspiration. Effective ventilation systems counteract this effect by promoting airflow across the scalp, facilitating evaporative cooling. Without adequate ventilation, skaters may experience discomfort, reduced performance due to overheating, and an increased risk of heat-related illnesses. For instance, during prolonged practice sessions or intense competitions, the absence of a functional ventilation system can lead to a noticeable decline in skater agility and focus.

The design of ventilation systems in ice skating headgear typically involves strategically placed vents on the outer shell and internal channels within the energy-absorbing liner. These vents and channels work in concert to draw cool air in and exhaust warm, moist air. The size, shape, and placement of vents can influence the system’s overall effectiveness. Some designs incorporate adjustable vents, allowing skaters to modulate airflow based on ambient conditions and activity level. Furthermore, the materials used in the liner can impact ventilation. Moisture-wicking fabrics enhance evaporative cooling, while breathable padding materials promote airflow. The presence of a well-designed ventilation system is a distinguishing factor between basic and premium ice skating headgear. High-end models often feature more sophisticated ventilation designs, incorporating larger vents, optimized channel geometries, and advanced materials.

In summary, the ventilation system design is an integral component of ice skating headgear, directly affecting skater comfort, performance, and safety. By facilitating heat dissipation and promoting airflow, ventilation systems mitigate the negative effects of overheating, ensuring that skaters can maintain optimal physical and mental performance. Although the specific design parameters may vary across different models, the underlying principle of efficient heat management remains constant. The continued refinement of ventilation system designs is a crucial aspect of advancing ice skating headgear technology, enhancing both protection and user experience. The potential for blockage of vents due to hair or accessories presents an ongoing challenge requiring design and user awareness.

5. Chinstrap securement mechanism

The chinstrap securement mechanism is a critical component of ice skating headgear, serving to maintain the helmet’s position on the head during a fall or impact. The securement mechanism’s primary function is to prevent dislodgement of the protective device, ensuring that the headgear remains in place to absorb and dissipate impact forces. Failure of the chinstrap system can render the headgear ineffective, as the device may shift or detach completely, leaving the head vulnerable to injury. Real-life examples illustrate the importance of this mechanism; in instances where skaters have fallen and the chinstrap has failed, the helmet has come off, resulting in head trauma that might have been mitigated had the securement remained intact. This highlights the direct cause-and-effect relationship between a functional chinstrap and effective head protection.

Practical application of this understanding extends to proper adjustment and maintenance of the chinstrap. A chinstrap that is too loose offers minimal resistance to displacement, while one that is too tight can cause discomfort or even restrict breathing. The ideal adjustment allows for a snug fit against the chin, preventing excessive movement without causing undue pressure. Regular inspection of the chinstrap and its attachment points is also vital. Over time, the strap material may degrade, or the fasteners may loosen, compromising the system’s integrity. Replacement of worn or damaged components is essential to ensure continued functionality. The design of the securement mechanism itself can also vary, with some systems incorporating quick-release buckles or adjustable straps for enhanced ease of use and customization. However, regardless of the specific design, the fundamental principle remains the same: to maintain the helmet’s position during impact.

In summary, the chinstrap securement mechanism is not merely an ancillary feature of ice skating headgear but an integral element that directly influences its protective capabilities. Proper adjustment, regular maintenance, and awareness of potential failure points are crucial for ensuring that the helmet remains in place to perform its intended function. The challenges associated with securement system design include balancing ease of use with robustness and ensuring compatibility with various head shapes and sizes. Ultimately, a well-functioning chinstrap securement mechanism contributes significantly to the overall safety and well-being of ice skaters by minimizing the risk of head injuries.

Frequently Asked Questions

The following addresses common inquiries regarding protective headgear for ice skating, providing clarity on essential aspects of safety and equipment selection.

Question 1: Are helmets mandatory for ice skating?

Mandatory helmet regulations vary depending on the skating venue, league, or organization. While not universally required, usage is strongly recommended for all skaters, regardless of skill level, due to the inherent risks of falls and potential head injuries.

Question 2: What certifications should be sought when purchasing a helmet?

Look for certifications from reputable organizations such as ASTM International (specifically ASTM F1849, although designed for skateboarding/roller skating, is often used as a benchmark), CPSC, or EN 1078. These certifications indicate the helmet has undergone testing and meets established safety standards.

Question 3: How should an ice skate helmet fit properly?

The helmet should fit snugly and securely, without excessive movement. Measure head circumference and consult the manufacturer’s sizing chart. Adjust internal fitting systems to achieve a firm, comfortable fit. A chinstrap must be used at all times.

Question 4: How often should an ice skate helmet be replaced?

Replacement is recommended after any significant impact, even if there is no visible damage. The energy-absorbing materials may have been compromised. Routine replacement every five years, or as recommended by the manufacturer, is also advised.

Question 5: What is the purpose of ventilation in an ice skate helmet?

Ventilation systems promote airflow, facilitating evaporative cooling and preventing overheating. Adequate ventilation enhances comfort and reduces the risk of heat-related issues during skating.

Question 6: Can any type of helmet be used for ice skating?

No. Helmets designed for other activities (e.g., bicycling, construction) may not provide adequate protection for the specific impact forces encountered in ice skating. Only helmets specifically designed for ice skating or those meeting relevant safety standards should be used.

These FAQs underscore the importance of informed decision-making regarding head protection. Prioritizing safety and selecting appropriate equipment can significantly reduce the risk of head injuries.

The subsequent section offers a concise summary of the key points discussed in this comprehensive article.

Conclusion

This article has comprehensively explored the significance of the ice skate helmet, emphasizing its role in mitigating head injuries during skating activities. Key points include adherence to certified safety standards, achieving a proper circumferential fit, understanding the impact energy absorption capabilities of the materials, and recognizing the importance of a functional chinstrap securement mechanism. Furthermore, the impact of effective ventilation on skater comfort and performance has been highlighted.

Given the potential for severe head trauma associated with ice skating, consistent and informed utilization of appropriate head protection is paramount. The continued development and adoption of improved ice skate helmet technologies, coupled with increased awareness of safety protocols, are essential for fostering a safer environment for all participants. The ultimate goal remains the prevention of avoidable injuries and the promotion of responsible participation in ice skating activities.