The term describes the wheel options for skates that are engineered with the lowest possible durometer rating. This measurement indicates the wheel’s hardness; a lower number signifies a more pliable, shock-absorbent material. These types of wheels provide a significantly smoother ride, especially on rough or uneven surfaces, due to their capacity to deform and absorb vibrations.

Employing wheels with enhanced softness is advantageous in numerous skating contexts. They offer superior grip, allowing for improved control and maneuverability. Historically, these wheels have been favored in situations where surface conditions are less than ideal, enhancing the skater’s experience and reducing fatigue caused by excessive vibration. This choice is particularly beneficial for beginners or those seeking a more comfortable skating session.

The following sections will delve into the specific applications, performance characteristics, material composition, and considerations for choosing wheels designed for maximum softness. Further topics include maintenance recommendations and a comparison with harder wheel types.

Tips for Selecting Wheels Designed for Maximum Softness

This section offers guidance on choosing wheels engineered for the greatest possible degree of softness, focusing on factors influencing performance and longevity.

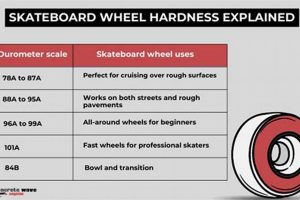

Tip 1: Consider the Durometer Rating: Examine the durometer rating carefully. Lower numbers indicate increased softness; however, exceptionally low values may compromise durability on abrasive surfaces. A range between 74A and 78A often provides a balance between grip and wear resistance.

Tip 2: Evaluate the Skating Surface: The intended skating environment should dictate the degree of softness. Rough asphalt or concrete benefits from softer wheels, while smoother surfaces might accommodate slightly harder options for increased speed.

Tip 3: Assess Riding Style: Individuals prioritizing comfort and control, such as recreational skaters or beginners, typically find softer wheels more suitable than those emphasizing speed or aggressive maneuvers.

Tip 4: Inspect the Core Material: The core material influences the wheel’s performance. Softer wheels with poorly designed cores may exhibit excessive flex, reducing energy transfer and responsiveness. Look for wheels with robust cores that provide adequate support.

Tip 5: Check the Wheel Profile: A rounded wheel profile is generally preferred for softer wheels, as it promotes smooth turning and consistent grip, particularly beneficial on uneven terrain. A flat profile may increase speed but can compromise control.

Tip 6: Prioritize Quality Urethane: The urethane compound’s quality significantly affects wear resistance and overall performance. Opt for wheels manufactured using high-rebound urethane, which offers a better balance of grip, durability, and shock absorption.

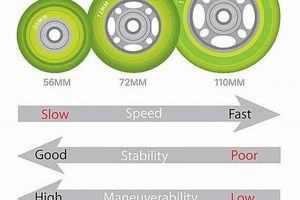

Tip 7: Consider Wheel Diameter: While not directly related to softness, wheel diameter interacts with the durometer. Larger diameter wheels roll over obstacles more easily, complementing the benefits of softer urethane on rough surfaces.

Careful attention to these factors ensures the selection of wheels that provide optimal comfort, control, and longevity based on individual skating needs and environmental conditions.

The following sections will delve into the impact of using specific “softest skate wheels” in varying environments and compare them to harder alternatives.

1. Durometer Rating

The durometer rating serves as the defining characteristic of wheel softness. It quantitatively measures the material’s resistance to indentation, employing the Shore A scale for skate wheels. A lower durometer value correlates directly with increased softness. Therefore, when considering “softest skate wheels,” the primary focus invariably rests on identifying wheels exhibiting the lowest possible durometer rating within a practical range. For instance, a wheel rated 75A will exhibit significantly more pliability and shock absorption than an 85A wheel. The rating influences grip, vibration dampening, and suitability for varied terrain.

The relationship between durometer and performance is causal. A lower durometer translates to increased deformation upon contact with the skating surface. This deformation increases the contact patch, enhancing grip and control, particularly on rough or uneven terrain. However, this increased deformation also accelerates wear and reduces rolling efficiency. Real-world examples include longboarders selecting softer wheels (78A or lower) for downhill runs, prioritizing grip and control over speed, or recreational skaters choosing moderately soft wheels (78A-82A) for smoother rides on sidewalks and paved trails. Harder wheels, conversely, are preferred for skate parks and smooth surfaces where speed and durability are paramount.

In summary, the durometer rating is the key performance indicator for assessing “softest skate wheels.” Understanding this relationship enables skaters to make informed decisions based on their skating style, terrain preferences, and desired balance between grip, comfort, and longevity. A critical challenge is finding the optimal durometer that balances these factors. This understanding is crucial because it directly affects safety, enjoyment, and the overall skating experience.

2. Surface Conditions

Surface conditions exert a considerable influence on the performance characteristics of skate wheels, particularly concerning wheels designed for maximum softness. The interaction between wheel durometer and surface texture directly impacts grip, rolling efficiency, and overall ride quality. Rough or uneven surfaces demand softer wheels, while smooth, polished surfaces favor harder compositions. This distinction stems from the ability of softer materials to conform to irregularities, thereby increasing contact area and improving traction on less-than-ideal terrain. Conversely, harder wheels maintain their shape more readily, reducing rolling resistance and maximizing speed on even surfaces. The consideration of surface conditions is, therefore, paramount when selecting skate wheels that offer the desired balance of comfort and control.

The selection of wheels engineered for maximum softness in response to prevailing surface conditions is not merely a matter of preference but a critical determinant of safety and performance. For instance, utilizing hard wheels on coarse asphalt significantly reduces grip, elevating the risk of slippage and loss of control. In contrast, implementing softer wheels in such environments enhances maneuverability and reduces the impact of surface imperfections, thereby mitigating rider fatigue. Consequently, recreational skaters often opt for softer wheels when navigating city streets, sidewalks, or paved trails characterized by varying degrees of roughness. Similarly, longboarders frequently choose softer wheels for downhill skating, prioritizing grip and stability when executing high-speed turns on undulating roads.

In summary, the relationship between surface conditions and wheel durometer is bidirectional and inextricably linked. The prevailing surface texture dictates the optimal durometer rating required for safe and efficient skating, while the chosen durometer, in turn, influences the skater’s ability to navigate the environment effectively. Overlooking the significance of surface conditions when selecting skate wheels can compromise performance, increase the risk of injury, and diminish the overall skating experience. Therefore, skaters should prioritize a thorough assessment of surface conditions before selecting wheels engineered for maximum softness.

3. Grip Enhancement

Grip enhancement is a primary functional benefit derived from utilizing wheels engineered for maximum softness in skating applications. The pliability of the urethane compound directly correlates with its capacity to conform to surface irregularities, thereby maximizing the contact area between the wheel and the ground. This increased contact area translates directly into elevated traction, which subsequently impacts a skater’s ability to control their movement, execute maneuvers, and maintain stability.

- Conformity to Surface Imperfections

Softer wheels, characterized by lower durometer ratings, exhibit enhanced flexibility, enabling them to conform more readily to minor imperfections on the skating surface. This property is particularly advantageous on asphalt, concrete, or other terrains with inherent roughness. By effectively “filling in” these surface variations, softer wheels minimize slippage and enhance control. For instance, on a cracked sidewalk, a hard wheel might lose contact momentarily, whereas a softer wheel maintains continuous grip.

- Increased Contact Patch

The deformability of wheels engineered for maximum softness directly increases the contact patch the area of the wheel in direct contact with the ground. A larger contact patch generates a greater frictional force, improving grip. This effect is especially pronounced during turning and carving, where maintaining traction is essential for controlled movements. The greater the contact, the more reliable the grip, especially when a skater leans into a turn.

- Enhanced Responsiveness

While hardness is often associated with responsiveness, the enhanced grip provided by softer wheels can indirectly improve responsiveness in specific contexts. The increased traction allows skaters to apply force more effectively, translating intentions into action with greater precision. The skater feels more connected with the terrain and has improved control over direction and speed. This characteristic proves particularly valuable in scenarios requiring quick adjustments and precise movements, such as navigating obstacles or performing technical slides.

- Mitigation of Vibration

Although primarily associated with ride comfort, the vibration-dampening properties of wheels designed for maximum softness also contribute to grip enhancement. By absorbing vibrations, softer wheels maintain more consistent contact with the surface, reducing the likelihood of wheel chatter or bounce, which can disrupt traction. The skater is more planted, resulting in increased control over their skating equipment. Vibration dampening allows for optimal grip even on rough surfaces.

The facets discussed above underscore the instrumental role that wheels with maximized softness play in optimizing grip. By conforming to imperfections, expanding the contact patch, improving responsiveness, and mitigating vibrations, these wheels enhance a skater’s capacity to control their movement and maintain stability. As a result, the implementation of wheels engineered for maximum softness contributes to a safer and more enjoyable skating experience, especially when navigating varied or imperfect terrain.

4. Vibration absorption

Vibration absorption is a key characteristic directly linked to the use of “softest skate wheels.” Lower durometer urethanes deform more readily upon encountering surface irregularities, dissipating energy in the form of heat rather than transmitting it to the skater’s body. This energy dissipation reduces the amplitude and frequency of vibrations experienced by the skater, enhancing comfort and control, especially over extended periods or on uneven surfaces. The effectiveness of vibration absorption depends on urethane formulation and wheel design, with some softer wheels engineered to maximize dampening properties.

The benefits of vibration absorption are particularly pronounced in scenarios involving rough terrain or longer skating sessions. Skaters traversing cracked sidewalks, cobblestone streets, or other uneven surfaces experience a substantial reduction in discomfort and fatigue when utilizing softer wheels. This allows for extended periods of skating with less strain on joints and muscles. For example, a skater commuting across a city with varied road surfaces may opt for softer wheels to minimize the physical impact of the ride. Similarly, long-distance skaters often prioritize vibration absorption to maintain comfort and efficiency over extended journeys.

In summary, the ability to absorb vibrations is a defining advantage of utilizing “softest skate wheels.” The dampening effect enhances comfort, reduces fatigue, and improves control in various skating environments. While softer wheels may compromise speed and durability compared to harder options, the benefits of vibration absorption make them a preferred choice for skaters prioritizing comfort and stability, especially when navigating challenging terrain or engaging in prolonged skating activities. The trade-off between these factors requires careful consideration based on individual skating needs and preferences.

5. Riding comfort

The connection between riding comfort and wheels engineered for maximum softness is a direct and substantial one. Wheels with lower durometer ratings, indicative of increased softness, deform more readily upon contact with the skating surface. This deformation absorbs a significant portion of the vibrations and impacts that would otherwise be transmitted to the skater. As a result, the skater experiences a smoother, less jarring ride, directly enhancing comfort. This is not merely a subjective preference; it is a measurable reduction in physical stress, particularly on joints and muscles, leading to reduced fatigue over extended skating sessions. For instance, individuals using inline skates for urban commuting often select softer wheels to mitigate the effects of rough pavement, sidewalk cracks, and other surface imperfections common in urban environments. This choice directly contributes to a more comfortable and sustainable commuting experience.

The importance of riding comfort as a component of “softest skate wheels” cannot be overstated. It extends beyond mere enjoyment to encompass factors such as injury prevention and performance optimization. Prolonged exposure to vibration and impact can lead to joint pain, muscle fatigue, and even long-term musculoskeletal issues. Soft wheels, by minimizing these stresses, contribute to the skater’s overall well-being and reduce the risk of injury. Furthermore, reduced fatigue allows skaters to maintain focus and control, ultimately enhancing their performance and safety. Consider a recreational skater engaging in a long-distance trail ride. The selection of soft wheels enables them to cover greater distances with less discomfort, maintaining a higher level of performance and enjoyment throughout the activity.

In summary, the relationship between riding comfort and “softest skate wheels” is a fundamental consideration for any skater prioritizing well-being and performance. Soft wheels offer a tangible and measurable improvement in riding comfort by absorbing vibrations and reducing physical stress. This enhancement not only increases enjoyment but also contributes to injury prevention and improved performance, particularly during prolonged skating sessions or on challenging terrain. While other factors such as wheel size and core design also influence ride quality, the durometer rating, indicative of softness, remains a primary determinant of comfort, making it a crucial consideration when selecting skate wheels.

6. Wheel longevity

The correlation between wheel longevity and wheels designed for maximum softness is demonstrably inverse. Softer urethane compounds, engineered for enhanced grip and vibration absorption, exhibit a lower resistance to abrasion compared to their harder counterparts. This decreased resistance to abrasion stems from the material’s increased pliability, resulting in more rapid wear rates, especially on rough or abrasive surfaces. Consequently, wheels designed for optimal softness typically exhibit reduced lifespans when subjected to comparable usage scenarios as harder wheels. The extent of this reduction in longevity depends on the specific durometer rating, urethane formulation, and the severity of the skating environment.

The practical significance of understanding this inverse relationship lies in making informed decisions regarding wheel selection. Skaters prioritizing comfort, grip, and vibration dampening must acknowledge the trade-off in wheel lifespan. For example, a recreational skater primarily utilizing asphalt surfaces may experience a significantly shorter wheel lifespan compared to a skater using harder wheels on smoother indoor surfaces. Longboarders performing sliding maneuvers will also observe accelerated wear due to the increased friction and abrasion involved. Therefore, recognizing the limitations of softer wheels is essential for effective budgeting and maintenance planning, ensuring that wheel replacements are anticipated and accommodated.

In summary, the relationship between wheel longevity and wheels engineered for maximum softness is characterized by an inherent compromise. While softer wheels offer undeniable advantages in terms of grip, comfort, and vibration absorption, they inherently exhibit reduced resistance to abrasion, leading to decreased lifespans. Awareness of this trade-off is crucial for skaters to make informed decisions, aligning their wheel selection with their individual skating needs, environmental conditions, and maintenance expectations. The optimal choice necessitates a careful evaluation of the relative importance of performance characteristics and long-term cost considerations.

7. Core integrity

Core integrity constitutes a critical factor in the performance and durability of skate wheels, particularly those designed for maximum softness. The core provides structural support to the urethane, influencing energy transfer, stability, and resistance to deformation. Wheels engineered for enhanced pliability often require meticulously designed cores to mitigate the inherent compromises associated with lower durometer compounds.

- Material Composition

The core’s material composition significantly impacts its overall strength and rigidity. High-density plastics or composite materials are often employed to provide adequate support to softer urethane. Insufficient core strength can result in excessive flex, reducing rolling efficiency and responsiveness. Real-world examples include premium wheels utilizing glass-filled nylon or reinforced polymers to maintain structural integrity under high stress. The selection of appropriate materials is crucial for preventing core deformation and ensuring consistent performance.

- Design and Geometry

The core’s design and geometry play a pivotal role in distributing stress and preventing premature failure. Ribbed or spoked designs are commonly incorporated to maximize strength-to-weight ratios while promoting airflow for heat dissipation. A poorly designed core can lead to localized stress concentrations, resulting in cracking or delamination. Examples of successful core designs include those with strategically placed reinforcing ribs that enhance torsional stiffness and prevent ovalization under load. The geometry must complement the soft urethane to optimize energy transfer and prevent distortion.

- Bonding Interface

The interface between the core and the urethane is a critical area for ensuring long-term durability. A robust bonding process is essential to prevent separation or slippage, especially under high stress. Surface treatments or chemical bonding agents are often employed to enhance adhesion. Instances of core-urethane separation can lead to catastrophic wheel failure, compromising safety and performance. A well-executed bonding process creates a strong, unified structure that withstands the rigors of skating.

- Heat Resistance

Heat generated during skating, particularly during sliding or aggressive maneuvers, can compromise core integrity. Elevated temperatures can soften or deform certain core materials, leading to reduced structural support and premature wear. Heat-resistant polymers or ventilation strategies are often implemented to mitigate this effect. Wheels intended for high-performance applications or use in warmer climates often incorporate specialized core materials designed to withstand elevated temperatures. Efficient heat dissipation is crucial for maintaining core stiffness and preventing irreversible damage.

These facets collectively demonstrate that core integrity is indispensable for realizing the full potential of wheels engineered for maximum softness. A robust and well-designed core provides essential support, enabling softer urethane to deliver enhanced grip and vibration absorption without sacrificing performance or durability. Careful consideration of material composition, design, bonding interface, and heat resistance is crucial for selecting wheels that offer an optimal balance of comfort, control, and longevity.

Frequently Asked Questions About Softest Skate Wheels

This section addresses common inquiries and provides concise information regarding wheels engineered for maximum softness, focusing on performance characteristics, applications, and considerations for optimal use.

Question 1: What defines a “soft” skate wheel?

A soft skate wheel is characterized by a low durometer rating on the Shore A scale. Values typically range from 74A to 82A, although some wheels may fall slightly outside this range. The lower the number, the softer the wheel and the greater its ability to absorb vibrations and enhance grip.

Question 2: What are the primary benefits of using wheels engineered for maximum softness?

The primary benefits include enhanced grip, improved vibration absorption, increased riding comfort, and enhanced control on rough or uneven surfaces. These wheels conform more readily to imperfections, providing a smoother and more stable skating experience.

Question 3: In what skating disciplines are wheels designed for maximum softness most commonly used?

These wheels are frequently employed in recreational skating, longboarding (particularly for cruising and downhill), and urban inline skating where riders encounter varied and often uneven terrain. They are also favored by beginners seeking enhanced stability and control.

Question 4: How does the durometer rating impact the wheel’s performance?

The durometer rating dictates the wheel’s pliability and its ability to deform upon contact with the skating surface. Lower durometer values increase grip and vibration absorption but also reduce rolling speed and potentially decrease wheel lifespan.

Question 5: What are the potential drawbacks of utilizing wheels engineered for maximum softness?

Potential drawbacks include reduced rolling speed, decreased lifespan on abrasive surfaces, and a potentially “mushy” feel for skaters accustomed to harder wheels. Soft wheels also require more frequent replacement due to increased wear.

Question 6: How does core integrity influence the performance of wheels designed for maximum softness?

Core integrity is crucial for maintaining wheel stability and preventing deformation under stress. A robust core ensures efficient energy transfer and prevents the urethane from flexing excessively, which can compromise performance and handling.

In summary, wheels engineered for maximum softness offer a unique set of advantages and disadvantages. A thoughtful assessment of the intended skating environment and individual performance priorities is essential for making an informed decision.

The subsequent section will provide a comparative analysis of soft and hard wheels, outlining their respective strengths and weaknesses in various skating contexts.

Conclusion

This exploration has illuminated the characteristics, benefits, and limitations associated with utilizing wheels engineered for maximum softness. The durometer rating, surface conditions, grip enhancement, vibration absorption, riding comfort, wheel longevity, and core integrity were all key parameters outlined as defining aspects of the topic.

Ultimately, the selection of appropriate wheel durometer requires careful consideration of individual skating needs and environmental factors. Informed choices can maximize performance and user satisfaction, while neglecting these considerations can result in compromised handling, premature wear, or diminished enjoyment. Therefore, it is incumbent upon skaters to evaluate their specific requirements before selecting “softest skate wheels” or any other option.