Skateboarding platforms crafted from high-quality wood, often maple, provide a durable and responsive surface for riders. These components are fundamental to the sport, enabling users to perform tricks and navigate various terrains. For example, a well-constructed board allows for controlled ollies, grinds, and other maneuvers.

The selection of a quality material impacts both the longevity and the performance characteristics of a skateboard. Durable construction enhances the rider’s stability and confidence, which is important for skill progression and overall safety. Historically, the evolution of these platforms has mirrored advancements in woodworking techniques and material science, leading to improved designs and structural integrity.

This article will delve into the specific properties of wood used in constructing skateboarding platforms, examining the manufacturing processes and exploring the factors that contribute to a superior riding experience. Further, it will analyze design variations and consider their influence on performance and handling.

Guidance for Selecting Skateboarding Platforms

The following recommendations are intended to provide guidance in choosing suitable skateboarding platforms, with a focus on durability, performance, and rider safety.

Tip 1: Assess Wood Quality: Prioritize platforms constructed from high-grade maple. Maple is known for its strength and ability to withstand the stresses associated with skateboarding.

Tip 2: Evaluate Layer Configuration: Investigate the number of plies (layers of wood) used in construction. More plies generally indicate greater strength and resistance to warping. Seven-ply construction is a common standard.

Tip 3: Consider Deck Concavity: The curvature of the platform influences foot placement and control. Experiment with different concavity levels to find the most comfortable and responsive option.

Tip 4: Examine the Finish: Ensure the platform has a smooth, even finish to prevent splinters and ensure proper grip tape adhesion.

Tip 5: Determine Appropriate Size: The width of the platform should be proportionate to the rider’s foot size and preferred style. Wider platforms provide greater stability, while narrower platforms facilitate quicker turns.

Tip 6: Inspect for Delamination: Carefully examine the edges of the platform for signs of delamination (separation of wood layers). Delamination indicates a structural weakness that can lead to premature failure.

Tip 7: Consult Expert Opinions: Seek recommendations from experienced skateboarders or retailers. Their insights can provide valuable perspectives on specific brands and models.

Adhering to these guidelines can assist in selecting a robust and responsive skateboarding platform, maximizing performance and enhancing rider safety.

The subsequent sections of this document will elaborate on specific manufacturing techniques and design considerations relevant to skateboarding platforms.

1. Material Strength

Material strength directly influences the performance and longevity of skateboarding platforms. The wood used in constructing these platforms must withstand significant impact forces during tricks, landings, and general use. Insufficient material strength leads to premature cracking, warping, or complete structural failure. For example, a board constructed from a low-density wood is prone to snapping under the stress of an ollie, while a board using high-quality maple is far more resilient. The choice of material, therefore, dictates the board’s ability to endure the demands of skateboarding.

One illustrative example involves the comparison of boards manufactured with different grades of maple. Lower-grade maple often contains knots or inconsistencies in the grain, creating weak points. In contrast, high-grade maple is characterized by uniform grain and high density, resulting in a stronger and more durable platform. This difference is readily apparent in the board’s responsiveness and resistance to damage. A skater performing a kickflip will notice that a board with greater material strength provides a more consistent and predictable response, increasing the likelihood of landing the trick successfully. Furthermore, the durability of the board significantly extends its lifespan, providing better value for the consumer.

In conclusion, material strength is a paramount consideration in the design and manufacture of skateboarding platforms. The selection of appropriate materials, particularly high-grade maple, is essential for ensuring durability, performance, and rider safety. A board with adequate material strength provides a more consistent, reliable, and long-lasting skateboarding experience. Understanding the relationship between material strength and board performance is crucial for both manufacturers and consumers in the skateboarding industry.

2. Ply Construction

Ply construction, a fundamental aspect of skateboarding platform manufacturing, refers to the layering and bonding of thin wood veneers to create a rigid, durable structure. The number, orientation, and adhesive properties of these plies directly impact the platform’s strength, flexibility, and overall performance characteristics. This approach is central to producing platforms capable of withstanding the stresses associated with skateboarding.

- Number of Plies

The quantity of plies used in a skateboarding platform typically ranges from seven to nine. A higher number of plies generally correlates with increased strength and resistance to warping, but it can also affect the platform’s weight and flexibility. For example, a seven-ply platform is a common standard, balancing durability with a reasonable weight, while a nine-ply platform offers enhanced robustness for heavier riders or aggressive skating styles.

- Ply Orientation

Alternating the grain direction of each ply is crucial for maximizing the platform’s structural integrity. This cross-grain lamination technique distributes stress evenly across the platform, preventing localized weaknesses and minimizing the risk of breakage. If the grain direction were uniform throughout, the platform would be significantly more prone to splitting along the grain lines.

- Adhesive Properties

The adhesive used to bond the plies together plays a critical role in the platform’s overall strength and resistance to delamination (separation of the plies). High-quality epoxy resins are often preferred due to their superior bonding strength and resistance to moisture. Inadequate adhesive can lead to ply separation, rendering the platform unusable and potentially hazardous.

- Wood Species

The type of wood used in the plies also influences the overall characteristics of the platform. Maple, particularly hard rock maple, is commonly chosen due to its high density, strength, and resistance to impact. Other wood species, such as birch or bamboo, may be used in combination with maple to achieve specific performance characteristics, such as increased flexibility or reduced weight. However, substituting weaker woods entirely can compromise the platform’s durability.

In summary, ply construction is a multifaceted process that directly affects the quality and performance of skateboarding platforms. Careful consideration of the number of plies, their orientation, the adhesive properties, and the wood species is essential for creating platforms that meet the demands of skateboarding. Optimizing these factors results in a durable, responsive, and safe product for skateboarders of all skill levels.

3. Deck Concavity

Deck concavity, a critical design element in skateboarding platforms, directly influences rider control and trick execution. Variations in concavitythe curvature across the width of the platformalter foot positioning and leverage, affecting the board’s responsiveness. The relationship between deck concavity and the wood material is a significant factor in determining a platforms performance.

- Foot Lock-In

Concavity creates a pocket for the rider’s feet, enhancing grip and control during tricks. A deeper concavity provides a more secure hold, crucial for technical maneuvers like kickflips and heelflips. For example, a steep concave allows a skater to maintain precise foot placement even during rapid rotations.

- Board Feel and Responsiveness

The degree of concavity impacts the board’s sensitivity to subtle movements. A mellow concave offers a more relaxed feel, suitable for cruising and carving, while a steeper concave provides immediate responsiveness for executing complex tricks. Skilled riders can leverage concavity to fine-tune their board’s reaction to their movements.

- Edge Control

Concavity enhances edge control, particularly during grinds and slides. The curvature facilitates a more secure grip on rails and ledges, improving stability and control. For example, a concave deck allows for greater precision when locking into a boardslide on a round rail.

- Influence on Wood Stress

The concavity shape affects how stress is distributed throughout the wood when the board flexes. A well-designed concavity can help to strengthen the board against breakage by evenly distributing the forces. Conversely, a poorly designed concavity can create weak points that lead to premature failure.

These concavity characteristics, combined with the wood’s inherent properties, determine the overall performance of skateboarding platforms. Manufacturers meticulously engineer concavity to optimize board feel, control, and durability. Riders select platforms with specific concavity levels to match their individual skating styles and preferences.

4. Resin Type

Resin type constitutes a critical element in the production of durable and high-performing skateboarding platforms. The adhesive properties of the resin directly impact the structural integrity of the board by bonding the wood plies together. Inadequate resin selection can result in delamination, compromising the board’s ability to withstand impact forces. Conversely, appropriate resin selection ensures long-term durability, enhancing the board’s overall lifespan and performance capabilities. For example, epoxy resins, known for their high strength and water resistance, are frequently employed in manufacturing high-quality skateboarding platforms. These resins provide a robust bond between the wood layers, enabling the board to endure repeated stresses associated with skateboarding maneuvers.

Further illustrating the significance of resin type, consider the differences between water-based and solvent-based resins. While water-based options are environmentally friendlier, they often lack the bonding strength and water resistance of solvent-based counterparts. The implications for skateboarders are evident: a board constructed with inferior resin is more likely to suffer structural failure upon exposure to moisture or during high-impact landings. Manufacturers, therefore, must carefully balance environmental concerns with the need for a durable and reliable product. The performance characteristics of the chosen resin also influence the board’s flexibility and responsiveness. A more rigid resin can result in a stiffer board, while a more flexible resin can enhance the board’s ability to absorb impact.

In conclusion, the choice of resin type is a decisive factor in the construction of high-quality skateboarding platforms. This choice directly influences structural integrity, durability, and overall performance. While environmental considerations are increasingly important, manufacturers must prioritize the selection of resins that provide the necessary bonding strength and water resistance to ensure a safe and reliable skateboarding experience. Continuous research and development in resin technology are vital for improving the performance and longevity of skateboarding platforms.

5. Pressing Technique

Pressing technique is a pivotal element in the creation of robust and consistently shaped skateboarding platforms. The method by which wood veneers are formed and bonded significantly impacts the deck’s structural integrity, concavity, and overall performance characteristics. Proper pressing techniques are crucial for realizing the potential of high-quality wood in skateboarding platforms.

- Cold Press vs. Hot Press

Cold pressing employs adhesives that cure at room temperature, generally resulting in a longer production time. Hot pressing utilizes heat to accelerate the adhesive curing process, increasing production speed. However, excessive heat can compromise wood strength and adhesive properties. The choice between cold and hot pressing influences the final product’s durability and consistency; improper heat application can lead to warping or delamination.

- Mold Design and Precision

The mold used during pressing dictates the platform’s concavity, kicktail angles, and overall shape. Precise mold design is paramount for achieving consistent and predictable performance across multiple decks. Imperfections in the mold translate directly into variations in the finished product, affecting rider control and board feel.

- Pressure Distribution

Uniform pressure distribution during pressing ensures consistent bonding across all wood plies. Uneven pressure can create weak spots, leading to premature failure. Hydraulic presses are often employed to achieve precise and controlled pressure application, maximizing the bond strength between each layer of wood.

- Curing Time and Environment

The duration and environmental conditions during the curing process significantly impact the adhesive’s strength and the platform’s dimensional stability. Insufficient curing time can result in incomplete bonding, while improper humidity levels can induce warping or cracking. Controlled curing environments are crucial for optimizing the adhesive’s performance and ensuring long-term deck durability.

The interplay of these pressing technique facets profoundly affects the quality and performance of skateboarding platforms. Optimized pressing processes maximize the inherent strength of wood, resulting in decks that are durable, responsive, and consistent. Skilled manufacturers prioritize these techniques to deliver a superior skateboarding experience, ensuring that the platform effectively translates a rider’s intentions into action.

6. Shape Variation

Shape variation is a critical design parameter influencing the performance characteristics of skateboarding platforms. The contour of the platform directly impacts rider control, trick execution, and overall stability. Consequently, careful consideration of shape variation is essential in the design and manufacture of these components.

- Nose and Tail Geometry

The shape of the nose and tail significantly affects ollie height, pop, and trick versatility. Steeper angles and larger surface areas facilitate higher ollies and more responsive board control. Different skateboarding disciplines, such as street or vert, often necessitate distinct nose and tail geometries tailored to specific trick requirements. For example, a square tail often provides more stable landing platforms for street skating, while a rounded tail might be preferred for transition skating due to its smoother feel.

- Width and Length Proportions

The width and length of the platform must be proportionate to the rider’s foot size and riding style. Wider platforms offer greater stability and are often preferred by larger riders or those who prioritize cruising, while narrower platforms facilitate quicker turns and are favored by skaters who emphasize technical maneuvers. Length impacts the overall feel of the board, influencing its responsiveness and ability to perform certain tricks. Generally, longer decks provide more stability at higher speeds, while shorter decks are more maneuverable.

- Concave Profiles

Concave profiles, referring to the curvature across the width of the platform, influence foot lock-in and edge control. Deeper concaves enhance grip and control, aiding in technical tricks. Milder concaves provide a more relaxed feel, suitable for cruising. There are several common concave profiles: radial, progressive, and asymmetrical, each influencing foot placement and board feel differently. The choice of concavity profile greatly depends on rider preference and the type of skating being performed.

- Wheelbase Length

The wheelbase, the distance between the inner mounting holes for the trucks, directly affects the board’s turning radius and stability. Shorter wheelbases result in quicker, more responsive turns, while longer wheelbases increase stability at higher speeds. The ideal wheelbase length is influenced by rider size, skating style, and personal preference. It is one of the key factors influencing the board’s feel and responsiveness.

The interplay of these shape variations, combined with the inherent properties of wooden materials, dictates the overall performance and handling of skateboarding platforms. Understanding these relationships allows manufacturers to fine-tune designs and produce boards tailored to specific rider preferences and skating disciplines, optimizing the skateboard’s functionality and rider experience.

7. Grip Integration

Grip integration, referring to the application of a high-friction surface to skateboarding platforms, is critical for rider control and safety. This surface, commonly composed of silicon carbide grit bonded to an adhesive backing, provides the necessary traction for executing tricks and maintaining balance. The quality of the wood substrate directly impacts the effectiveness of grip integration; a smooth, properly prepared surface allows for optimal adhesion, preventing peeling or bubbling of the grip tape. For example, a skateboard platform with a rough or uneven surface will result in a compromised grip, increasing the risk of slippage and injury.

The adhesion process involves several key steps: surface preparation, application, and curing. Proper surface preparation, often involving sanding or cleaning, removes contaminants and creates a uniform surface for bonding. The grip tape is then carefully applied, ensuring complete contact with the platform. Pressure is applied to eliminate air pockets and secure the bond. Finally, a curing period allows the adhesive to fully set, maximizing grip strength. Deviations from these steps can lead to reduced grip performance and premature wear. The proper integration of grip tape, therefore, is an essential aspect of skateboarding platform construction that directly influences rider safety and performance.

In summary, the connection between grip integration and skateboarding platforms is intrinsic. Effective grip integration enhances rider control, safety, and trick execution. Optimizing surface preparation, application techniques, and adhesive selection is crucial for achieving a reliable and long-lasting bond. The continued development of both grip tape materials and application processes aims to enhance the performance and safety of skateboarding platforms, contributing to the advancement of the sport.

Frequently Asked Questions About Skateboarding Platforms

The following addresses prevalent inquiries and dispels misunderstandings regarding the selection and maintenance of skateboarding platforms, with a focus on durability and performance.

Question 1: What constitutes an acceptable level of flex in a skateboarding platform?

Excessive flex indicates potential structural weakness, compromising stability and control. Minimal flex, allowing for energy absorption during landings, is generally preferable.

Question 2: How does humidity affect skateboarding platform performance and longevity?

Elevated humidity levels can cause wood warping and adhesive degradation, reducing structural integrity. Proper storage and maintenance procedures are crucial in humid environments.

Question 3: Is it possible to repair a cracked skateboarding platform?

Minor cracks can sometimes be repaired with epoxy resin and clamping. However, extensive damage typically warrants platform replacement to ensure rider safety.

Question 4: What is the recommended frequency for replacing skateboarding platforms?

Replacement frequency depends on usage intensity, rider weight, and skating style. Regular inspection for signs of wear or damage is crucial for determining appropriate replacement intervals.

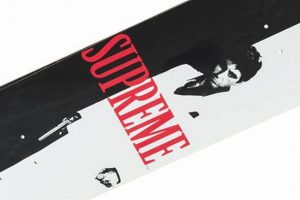

Question 5: Does the graphic design on a skateboarding platform influence its performance?

Graphic design typically has negligible impact on performance. However, heavy applications of ink or paint can add weight and slightly alter the platform’s flex characteristics.

Question 6: What role does grip tape play in skateboarding platform performance, and how frequently should it be replaced?

Grip tape provides essential traction for rider control and trick execution. Its replacement depends on wear; diminished grip necessitates immediate replacement.

In summary, understanding these factors contributes to informed decision-making regarding skateboarding platform selection, maintenance, and replacement, ultimately enhancing rider safety and performance.

The subsequent section will examine specific materials commonly used in the manufacture of skateboarding platforms, detailing their respective properties and advantages.

Conclusion

This exploration of skateboarding platforms crafted from wood has highlighted the critical factors influencing their performance and longevity. From material selection and ply construction to pressing techniques and shape variations, each element contributes to the overall riding experience and durability of these platforms. The interplay of these variables determines the suitability of a given platform for specific skating styles and rider preferences. The performance and safety aspects heavily rely on quality build.

As skateboarding evolves, continued innovation in material science and manufacturing processes remains essential for advancing platform design. A thorough understanding of these principles will empower skaters and manufacturers alike to make informed decisions, ensuring the availability of high-quality, durable, and responsive platforms that support the progression of the sport. Further inquiry into the characteristics of “goodwood skate decks” will support this positive trend.

![Shop Peralta Skate Decks: Vintage & New | [Year] How to Skateboard: A Beginner's Guide to Your First Board & Tricks Shop Peralta Skate Decks: Vintage & New | [Year] | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/01/th-613-300x200.jpg)