The correlation between footwear dimensions and those required for skates presents a frequent point of inquiry for both novice and experienced skaters. The measurement systems differ significantly; therefore, relying solely on regular footwear dimensions may lead to discomfort, compromised performance, or even injury. For example, an individual who typically wears a size 9 shoe might require a size 8 skate, or potentially a different size altogether, depending on the manufacturer and skate type.

Accurate skate fitting is paramount for optimal control, agility, and comfort. Historically, ill-fitting skates were a common impediment to skill development and a source of considerable discomfort. Understanding the nuances of skate sizing, including variations between brands and models, allows skaters to select equipment that maximizes performance and minimizes the risk of blisters, foot fatigue, and other related issues. Investing time in proper fit assessment yields long-term benefits for the skater’s overall experience.

The subsequent sections will delve into specific methods for determining appropriate skate dimensions, considering factors such as foot shape, skate type (e.g., hockey, figure, inline), and manufacturer-specific sizing charts. Further, guidance will be provided on identifying signs of improper fit and adjusting skates for optimal comfort and performance.

Sizing Insights

The following points offer guidance on navigating the complexities of correlating footwear dimensions with those required for skates. Accurate assessment and careful consideration of these factors are crucial for ensuring optimal fit and performance.

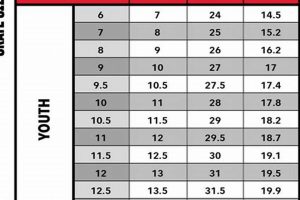

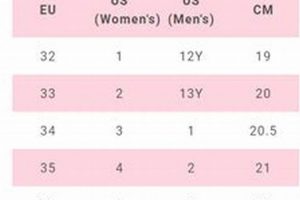

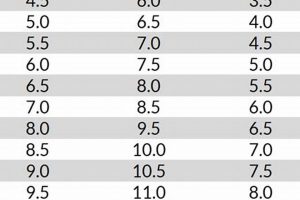

Tip 1: Consultation of Manufacturer Charts: Skate manufacturers frequently provide detailed sizing charts specific to their product lines. These charts typically correlate foot length measurements with corresponding skate sizes. Reliance on these resources is strongly advised, as sizing conventions can vary significantly between brands.

Tip 2: Foot Measurement Accuracy: Precise foot length measurement is essential. Utilize a Brannock device, if available, or a ruler/measuring tape while bearing weight on a flat surface. Measure both feet, as discrepancies in size are common, and prioritize the larger measurement.

Tip 3: Consideration of Skate Type: Different skate types (e.g., hockey, figure, inline) may necessitate distinct fitting approaches. Hockey skates often fit more snugly than recreational skates, while figure skates demand precise heel lock to prevent slippage.

Tip 4: Volume and Width Considerations: Beyond length, foot volume and width are crucial factors. Individuals with wider feet may require skates with a wider last or a specific width designation (e.g., D, EE). Volume can be addressed through lacing adjustments or the use of aftermarket insoles.

Tip 5: Professional Fitting Assistance: Seeking the expertise of a knowledgeable skate fitter can prove invaluable. Experienced fitters possess the ability to assess foot morphology, identify potential pressure points, and recommend appropriate skate models and sizes.

Tip 6: Break-in Period Allowance: New skates typically require a break-in period to conform to the individual’s foot shape. This process may involve some initial discomfort, which should gradually subside with use. Heat molding, if applicable, can accelerate this process.

Tip 7: Sock Thickness Considerations: The thickness of socks worn during skating can influence the overall fit. Consistent use of the same type of socks during the fitting process is recommended to ensure accurate sizing.

Adherence to these guidelines facilitates informed decision-making when selecting skates, promoting comfort, enhancing performance, and minimizing the risk of injury.

The subsequent sections will explore common fitting issues, adjustment techniques, and maintenance practices to prolong the lifespan and optimize the performance of skates.

1. Brand Variations

Significant disparities exist in sizing conventions among skate manufacturers, impacting the correlation between foot dimensions and required skate size. One cannot reliably extrapolate from a general shoe size to determine skate size due to these variations. For instance, a skater who wears a size 9 shoe might require a size 8 skate from one brand, but a size 8.5 or even a size 7.5 from another. This discrepancy arises from differences in the internal molds, or lasts, used to construct the skates.

These brand-specific sizing differences necessitate careful attention to manufacturer-provided sizing charts. Reputable skate brands typically offer detailed charts that correlate foot length measurements in millimeters or inches with their corresponding skate sizes. Using these charts is paramount, as failure to do so can result in selecting skates that are either too small, leading to discomfort and potential injury, or too large, compromising control and performance. The influence of brand variations can be observed across different skate types, including hockey, figure, and inline skates, highlighting the universality of this factor.

In summary, the influence of brand variations is a crucial component in determining the appropriate skate size. Direct conversion from standard shoe dimensions is unreliable, and reliance on manufacturer-specific sizing charts is essential. A thorough understanding of this aspect ensures a more accurate fit, which ultimately contributes to enhanced comfort, performance, and a reduced risk of injury. Ignoring brand-specific sizing can lead to ill-fitting skates, negating the benefits of technological advancements in skate design and materials.

2. Foot length matters

Accurate determination of foot length is paramount when correlating shoe dimensions with appropriate skate size. This measurement serves as the foundational element in selecting skates that offer optimal comfort, support, and performance. Deviation from an accurate foot length measurement introduces a cascade of potential fitting errors.

- Primary Metric for Sizing Charts

Manufacturer sizing charts universally utilize foot length as the primary determinant for skate size recommendations. These charts provide a direct correlation between measured foot length, typically in millimeters or inches, and the suggested skate size within a specific brand’s product line. Without an accurate foot length measurement, reliance on these charts is rendered ineffective.

- Internal Skate Dimensions

Skate manufacturers design internal skate dimensions based on specific foot length parameters. An individual’s foot length must align with the internal dimensions of the skate boot to ensure proper fit. Insufficient length leads to toe crowding and discomfort, while excessive length compromises control and stability.

- Weight Distribution and Balance

Correct foot length within the skate boot facilitates proper weight distribution across the foot and blade. This is essential for maintaining balance and executing skating maneuvers effectively. Discrepancies between foot length and skate size disrupt this balance, leading to compromised performance and an increased risk of falls.

- Customization and Adjustments

While minor adjustments, such as lacing modifications and insole additions, can compensate for slight fitting discrepancies, they cannot overcome significant errors resulting from inaccurate foot length measurement. Custom skate fitting, often reserved for professional athletes, still relies on a precise initial foot length assessment.

The inherent relationship between foot length and skate size mandates meticulous measurement techniques. The use of appropriate tools, such as a Brannock device or a calibrated ruler, is crucial. Measurements should be taken with the individual bearing weight to replicate the foot’s expansion under load. Prioritizing accuracy in foot length measurement is the first and most critical step in achieving a well-fitted skate, which directly influences comfort, performance, and safety.

3. Skate type impacts

The intended purpose of the skate significantly influences the correlation between general footwear dimensions and the appropriate skate size. Hockey skates, figure skates, and inline skates each possess distinct design characteristics that necessitate unique fitting considerations. Therefore, direct translation of shoe size to skate size without accounting for skate type is unreliable. The effects of skate type range from expected fit to blade construction, that can affect performance.

For instance, hockey skates are typically designed for a snug, performance-oriented fit. This close fit enhances responsiveness and control during rapid movements. As such, the hockey skate size may be one to one and a half sizes smaller than the individual’s standard shoe size. Conversely, recreational inline skates often prioritize comfort over performance, resulting in a more relaxed fit, potentially aligning more closely with shoe size or even requiring a slightly larger skate. Figure skates, demanding precise foot positioning for intricate maneuvers, may necessitate a fitting approach that emphasizes heel lock and minimizes internal movement, potentially leading to a size that differs significantly from regular footwear. Different skate types have different blade construction, which also affect performance.

In summary, understanding how skate type influences required dimensions is crucial in ensuring a comfortable and high-performing experience. Blindly applying shoe size conventions can lead to poorly fitting skates, hindering skill development and increasing the risk of injury. Accurate skate selection requires consideration of the specific application and adherence to manufacturer-provided guidelines, which account for the nuances of each skate type. Recognizing the importance of skate type ensures the dimensions are optimized for its intended performance attributes.

4. Width consideration

Foot width is a critical, often overlooked, component in determining the appropriate skate dimensions relative to standard shoe dimensions. Footwear is typically manufactured in standardized widths, frequently designated as narrow, medium, or wide. However, skate sizing, while also considering length, must account for variations in foot width to ensure a comfortable and performance-enhancing fit. Failure to adequately consider foot width during skate selection frequently results in discomfort, impaired circulation, and compromised skating technique. The industry’s varying sizing standards for width make it an essential parameter in evaluating skate size vs shoe size.”

Individuals with wider feet may encounter significant challenges when attempting to correlate their shoe dimensions with skate size. A skater whose shoe size is appropriate in length but inadequate in width will likely experience lateral compression of the foot within the skate boot. This compression can lead to numbness, blistering, and long-term foot problems. Conversely, attempting to compensate for inadequate width by selecting a longer skate size can result in excessive heel slippage and a loss of control. Several manufacturers offer skates in multiple width options, often designated by letters such as D (standard), EE (wide), and EEE (extra wide). Utilizing these options, in conjunction with accurate foot width measurements, is crucial for achieving an optimal fit. Some skate types, designed to be molded, help to solve this issue.

In conclusion, foot width is an indispensable factor in the skate selection process. The interplay between foot length and width dictates the overall fit and comfort of the skate. Ignoring width considerations while prioritizing length can have detrimental effects on skating performance and foot health. Individuals with atypical foot widths should seek professional fitting assistance and prioritize brands that offer a range of width options to ensure a harmonious balance between foot length and width within the skate boot. Selecting a skate that suits both measurements allows for superior performance.

5. Sock thickness counts

The thickness of the socks worn during skating directly influences the available volume within the skate boot, thereby affecting the correlation between footwear dimensions and the appropriate skate size. Sock thickness is not merely an ancillary detail; it is a fundamental factor that must be considered to ensure a secure and comfortable fit, ultimately impacting performance and minimizing the risk of discomfort or injury.

- Impact on Internal Volume

Sock thickness directly reduces the internal volume within the skate boot. Thicker socks occupy more space, effectively making the skate feel tighter. Conversely, thinner socks provide more room, potentially causing the skate to feel too loose. This volume displacement necessitates adjustments to skate size selection, particularly for individuals who typically wear thicker socks for warmth or cushioning.

- Influence on Fit Assessment

An accurate skate fitting requires replicating the conditions under which the skates will be used. Therefore, the socks worn during the fitting process should be representative of those typically worn during skating sessions. Using a different sock thickness during fitting than during actual use will lead to an inaccurate assessment of the skate’s fit, potentially resulting in discomfort or compromised performance.

- Considerations for Skate Type

The ideal sock thickness can vary depending on the type of skating. Hockey skaters often prefer thinner, moisture-wicking socks to maximize responsiveness and control, while figure skaters may opt for slightly thicker socks for added cushioning and support. Recreational skaters may prioritize comfort and warmth, leading them to choose thicker socks. These preferences must be factored into the overall skate sizing decision.

- Adjustments and Compensations

In some cases, minor discrepancies in sock thickness can be compensated for through adjustments to the skate’s lacing or the addition of aftermarket insoles. However, significant variations in sock thickness necessitate a more fundamental reassessment of the skate size. Attempting to force a comfortable fit by solely relying on adjustments can compromise the structural integrity of the skate or impede proper foot support.

The interplay between sock thickness and skate size highlights the importance of a holistic fitting approach. The selection of skates should not be based solely on shoe dimensions or foot length measurements; rather, it should incorporate the sock thickness as a crucial variable. By carefully considering this factor, skaters can ensure a more accurate and comfortable fit, ultimately enhancing their skating experience and minimizing the risk of foot-related problems. Furthermore, it emphasizes the inseparability of appropriate sock selection and the achievement of optimal skate dimensions.

6. Professional fitting advised

The correlation between shoe dimensions and skate dimensions presents a complex challenge for skaters of all skill levels. Seeking guidance from a professional fitter mitigates the inherent uncertainties associated with self-assessment and ensures a more accurate determination of the appropriate skate size. This service transcends mere measurement, encompassing a holistic evaluation of foot morphology, skating style, and performance goals.

- Enhanced Accuracy in Measurement and Sizing

Professional fitters possess specialized tools, such as Brannock devices, and expertise in their application, enabling precise foot length and width measurements. They can accurately interpret manufacturer sizing charts, accounting for brand-specific variations and nuances that may not be readily apparent to the average consumer. Professional fitters minimize errors in the selection process.

- Assessment of Foot Morphology and Biomechanics

Beyond basic measurements, professional fitters evaluate foot shape, arch height, and other morphological characteristics that influence skate fit. They observe gait patterns and skating biomechanics to identify potential pressure points, areas of friction, and other factors that may contribute to discomfort or injury. These assessments help fitters recommend skate models and sizes that accommodate the individual’s unique foot structure and movement patterns.

- Customization and Adjustment Expertise

Professional fitters are proficient in customizing and adjusting skates to optimize fit and performance. They can perform heat molding, punch out areas of localized pressure, and recommend appropriate insole modifications to achieve a more personalized fit. Their expertise extends to lacing techniques and other adjustments that can fine-tune the fit and enhance comfort.

- Mitigation of Risk and Enhancement of Performance

Improperly fitted skates can lead to a range of problems, including blisters, foot pain, numbness, and compromised skating performance. Professional fitting minimizes these risks by ensuring that the skates provide adequate support, stability, and comfort. A well-fitted skate allows skaters to focus on their technique and performance without being distracted by discomfort or pain.

The advantages of professional skate fitting are manifest in enhanced comfort, improved performance, and reduced risk of injury. While self-assessment may suffice for some skaters, the complexities inherent in correlating shoe dimensions with skate dimensions often necessitate the expertise of a trained professional. The investment in a professional fitting service yields long-term benefits, promoting a more enjoyable and productive skating experience.

Frequently Asked Questions

This section addresses common inquiries regarding the relationship between standard footwear dimensions and the appropriate dimensions for skates. The information presented aims to clarify misconceptions and provide a foundation for informed decision-making.

Question 1: Is there a direct conversion formula to determine skate dimensions from shoe dimensions?

No universally applicable conversion formula exists. Skate sizing varies significantly across manufacturers, models, and skate types (e.g., hockey, figure, inline). Reliance on manufacturer-specific sizing charts, which correlate foot length with skate size, is essential.

Question 2: If shoe dimensions are a specific size, will that correspond to the same skate dimension?

Not necessarily. A size relationship between shoe and skate dimensions is unreliable. Factors such as internal boot construction, sock thickness, and intended fit (e.g., snug for performance, relaxed for recreation) necessitate independent assessment of appropriate skate size, irrespective of footwear dimensions.

Question 3: What is the most crucial factor in determining appropriate skate dimensions?

Foot length is the primary determinant. Accurate measurement of foot length, in millimeters or inches, is the foundation for selecting skates that offer optimal comfort, support, and performance. Utilize a Brannock device if one is accessible, or use a ruler to measure. Measure both feet.

Question 4: Is skate type considered when selecting skate dimensions?

Yes. Hockey skates, figure skates, and inline skates each possess distinct design characteristics that necessitate unique fitting considerations. For instance, hockey skates are often designed for a snug, performance-oriented fit, potentially requiring a smaller dimension than standard footwear, while figure skates may require a different fitting strategy. Prioritize the skate type.

Question 5: If discomfort is experienced despite selecting the recommended skate dimension, what steps should be taken?

Assess sock thickness, lacing tightness, and the presence of any pressure points. Minor adjustments, such as heat molding (if applicable to the skate model) or the addition of aftermarket insoles, can alleviate localized discomfort. Persistent discomfort warrants re-evaluation of skate dimensions and consultation with a professional fitter.

Question 6: Can the same skate dimension work if a different sock thickness is used?

Potentially, but it is not advisable. Sock thickness influences the internal volume of the skate boot. Consistent use of the same sock thickness during the fitting process and subsequent skating sessions is recommended. Significant variations in sock thickness may necessitate an adjustment to the skate dimension.

Accurate skate selection depends on many interconnected components. For the best fit, you should not underestimate the importance of a professional fitting service.

The subsequent section will delve into specific techniques for maintaining skates and prolonging their lifespan, ensuring continued performance and comfort.

Concluding Remarks

This discussion has rigorously explored the complex relationship between footwear dimensions and the dimensions required for skates. The assessment highlighted the significant disparities between sizing conventions, emphasizing the unreliability of direct conversion methods. Factors such as brand variations, foot length, skate type, width considerations, and sock thickness were identified as critical determinants in selecting appropriate skate dimensions. Moreover, the value of professional fitting services was underscored as a means of mitigating fitting errors and optimizing comfort and performance.

Accurate skate dimensions directly influence the skater’s experience, affecting performance, comfort, and safety. The information provided here is a resource for informed decision-making. Responsible skate selection requires diligent consideration of the nuanced factors outlined, promoting a positive and injury-free experience for skaters of all levels. Prioritizing proper fit is an investment that yields significant long-term benefits.