Footwear designed for gliding movement, configured with four wheels arranged in a two-by-two pattern, and manufactured to accommodate an individual with relatively large feet, is available. This specific sizing caters to a segment of the population requiring more substantial dimensions for proper fit and performance. For example, an adult male with a U.S. shoe size of 13 would typically seek this particular skate size.

Appropriate fit is paramount for safety, control, and comfort during recreational or competitive skating activities. Ill-fitting skates can lead to discomfort, blisters, and impaired maneuverability, potentially increasing the risk of injury. The availability of diverse sizes, including larger ones, ensures broader accessibility and inclusivity within the skating community. Historically, the range of available sizes in such sporting equipment has expanded to accommodate a wider spectrum of body types.

The subsequent sections of this article will delve into specific models available in the aforementioned size, considerations for selecting the right pair, maintenance procedures, and relevant safety information to optimize the skating experience for individuals requiring such dimensions.

Selecting Appropriately Sized Footwear for Roller Skating

This section provides critical guidelines for individuals seeking skating equipment tailored to larger foot dimensions. Proper selection and maintenance contribute significantly to safety, performance, and longevity of the equipment.

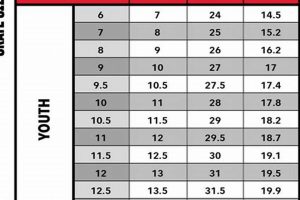

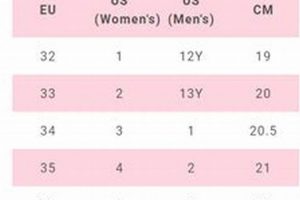

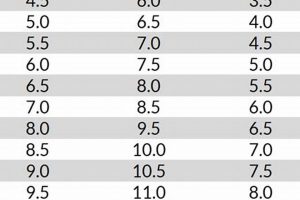

Tip 1: Measure Foot Dimensions Accurately: Prior to purchase, a precise measurement of foot length and width is essential. Employ a Brannock device or utilize a foot tracing method to obtain accurate dimensions. Consult sizing charts provided by manufacturers, as variations may exist between brands.

Tip 2: Prioritize Fit Over Aesthetics: While visual appeal may be a factor, the primary consideration should be a secure and comfortable fit. Ensure adequate toe room without excessive slippage. The heel should remain firmly seated within the skate.

Tip 3: Consider Skate Intended Use: Different skating disciplines, such as recreational skating, aggressive skating, or speed skating, require specific skate designs. Select a model optimized for the intended application to maximize performance and safety.

Tip 4: Evaluate Closure Systems: Various closure systems, including laces, buckles, and straps, offer varying degrees of support and adjustability. Assess the suitability of each system based on individual needs and preferences. A secure closure system enhances stability and control.

Tip 5: Inspect Wheel Durometer and Bearing Quality: Wheel durometer, a measure of hardness, affects grip and speed. Softer wheels offer greater grip, while harder wheels provide increased speed. High-quality bearings contribute to smoother rolling and reduced friction. Evaluate these components based on skating style and surface conditions.

Tip 6: Regular Maintenance is Crucial: Consistent cleaning and lubrication of bearings, coupled with periodic inspection of wheels and closure systems, are vital for maintaining optimal performance and extending the lifespan of the skates. Neglecting maintenance can lead to reduced performance and potential safety hazards.

Tip 7: Utilize Protective Gear: Regardless of skill level, the use of appropriate protective gear, including helmets, wrist guards, elbow pads, and knee pads, is strongly recommended. Protective gear mitigates the risk of injury in the event of a fall or collision.

Adhering to these guidelines ensures a safe, comfortable, and enjoyable skating experience. Proper selection and maintenance minimize the risk of injury and maximize the lifespan of the equipment.

The subsequent section will address common issues encountered with skating equipment and provide troubleshooting strategies.

1. Proper Ankle Support

Adequate ankle support is a critical factor when considering roller skates designed for larger foot sizes. The increased leverage exerted by a larger foot necessitates enhanced stability within the boot to prevent injury and ensure control.

- Lateral Stability Enhancement

Lateral stability directly impacts the skater’s ability to maintain balance and execute turns effectively. Larger feet amplify the forces acting on the ankle during lateral movements, requiring a skate design that counteracts excessive pronation or supination. For example, reinforced boot structures and strategically placed padding can minimize ankle roll and improve control.

- Injury Prevention Mechanisms

Inadequate ankle support significantly elevates the risk of sprains, strains, and fractures. The additional weight and momentum associated with a larger foot size compound these risks. Features such as high-cut boots and adjustable straps serve as preventative measures by providing customized support and limiting excessive ankle movement. Professional skaters often use custom-molded boots to achieve optimal ankle stabilization.

- Power Transfer Optimization

Efficient power transfer from the leg to the wheels is essential for propulsion and maneuverability. Insufficient ankle support can result in energy loss and diminished performance. A secure fit around the ankle ensures that the skater’s force is directly translated into movement, maximizing efficiency and control. For instance, a stiff boot material and a well-designed lacing system can enhance power transfer during acceleration and braking.

- Customization and Adjustability

Given the variability in individual foot shapes and ankle strengths, customization and adjustability are highly desirable in larger-sized skates. Adjustable straps, heat-moldable liners, and replaceable components allow skaters to fine-tune the fit and support to meet their specific needs. This level of personalization optimizes comfort, performance, and long-term satisfaction.

In conclusion, proper ankle support is not merely a comfort feature but a fundamental requirement for safety, performance, and overall skating enjoyment, particularly for individuals utilizing equipment designed for larger foot sizes. Prioritizing this aspect during selection and maintenance significantly mitigates injury risks and maximizes the benefits of the skating experience.

2. Wheel Durometer Variance

Wheel durometer, measured on the Shore A scale, quantifies the hardness of the wheel material used in roller skates. This factor significantly influences the skating experience, particularly for individuals using size 13 skates, due to the correlation between foot size, applied force, and wheel performance. A higher durometer rating indicates a harder wheel, resulting in less rolling resistance and increased speed on smooth surfaces. Conversely, a lower durometer signifies a softer wheel, providing enhanced grip and shock absorption on rougher terrain. The selection of appropriate wheel durometer is therefore a critical consideration for users of larger-sized skates, impacting both performance and comfort. For instance, a larger individual using size 13 skates for outdoor recreational skating may benefit from a softer durometer (e.g., 78A-82A) to compensate for uneven surfaces and increased body weight, thus maintaining control and minimizing vibrations.

The relationship between wheel durometer and skate size is further complicated by the influence of skating style. Aggressive skaters, regardless of foot size, often prefer harder wheels (e.g., 88A-92A) for grinds and slides in skate parks. However, an individual with size 13 skates engaging in aggressive skating may require an even harder durometer to withstand the increased stress on the wheels during such maneuvers. Conversely, speed skaters, regardless of foot size, typically opt for the hardest wheels available (e.g., 98A-101A) to maximize speed and minimize energy loss. Therefore, understanding the intended use of the skates is paramount in determining the optimal wheel durometer, particularly for users of larger-sized equipment.

In summary, the appropriate wheel durometer for size 13 skates is contingent upon a combination of factors, including skater weight, skating surface, and skating style. Failure to consider these factors may result in compromised performance, reduced comfort, and accelerated wear and tear on the wheels. Careful consideration of these variables is essential for optimizing the skating experience and ensuring the longevity of the equipment. Further research into specific wheel formulations and user reviews is recommended for informed decision-making.

3. Bearing Precision (ABEC)

Bearing precision, as defined by the Annular Bearing Engineers’ Committee (ABEC) scale, is a critical attribute affecting the performance and longevity of roller skates, particularly those designed for larger foot sizes. The ABEC rating system quantifies the manufacturing tolerances of bearings, with higher ratings indicating tighter tolerances and potentially smoother, faster rolling. The relationship between ABEC rating and performance becomes increasingly relevant in size 13 skates due to the increased leverage and force exerted on the bearings by a larger individual.

- Rolling Efficiency and Speed Maintenance

Higher ABEC-rated bearings, characterized by their precise construction, reduce friction and enhance rolling efficiency. This translates to improved speed maintenance, requiring less effort to sustain a given velocity. For individuals utilizing size 13 skates, the increased mass necessitates bearings that minimize energy loss due to friction. Example: An ABEC 7 bearing in a size 13 skate will likely provide a noticeable improvement in rolling efficiency compared to an ABEC 3 bearing under the same conditions.

- Durability and Load Capacity

While ABEC rating primarily reflects manufacturing precision, it indirectly impacts the durability and load capacity of the bearing. Tighter tolerances reduce internal stress and wear, extending the bearing’s lifespan. This is particularly important for larger skaters using size 13 skates, as they place greater stress on the bearings. Bearings with higher ABEC ratings are therefore less prone to premature failure under heavy loads. Real-world scenario: A larger skater using ABEC 9 bearings in size 13 skates may experience fewer bearing failures compared to using ABEC 5 bearings.

- Vibration Reduction and Ride Comfort

Precise bearings contribute to reduced vibration during skating, enhancing ride comfort. The smoother rolling action minimizes the transmission of road imperfections and impacts to the skater’s feet and ankles. This effect is magnified for individuals using size 13 skates, where the larger foot acts as a greater lever arm for transmitting vibrations. Higher ABEC ratings contribute to a smoother, more comfortable skating experience, particularly on uneven surfaces. For instance, ABEC 7 or 9 bearings will offer a smoother ride compared to lower-rated bearings on rough asphalt.

- Maintenance Requirements and Longevity

While higher ABEC bearings offer performance advantages, they may also require more frequent maintenance to preserve their precision. Contaminants, such as dirt and moisture, can compromise the performance of tightly toleranced bearings. Proper cleaning and lubrication are essential for maintaining optimal performance and maximizing bearing lifespan, especially for individuals using size 13 skates in varied environmental conditions. Example: Regular cleaning and lubrication of ABEC 9 bearings used in size 13 skates will prevent premature wear and maintain rolling efficiency.

In conclusion, the ABEC rating of bearings plays a significant role in the overall performance, durability, and comfort of size 13 roller skates. While higher ABEC ratings generally translate to improved rolling efficiency and reduced vibration, skaters must consider their individual weight, skating style, and environmental conditions to select the optimal bearing precision for their specific needs. Furthermore, proper maintenance is crucial for maximizing the lifespan and performance of high-precision bearings, particularly for individuals placing greater demands on their equipment.

4. Boot Material Durability

The structural integrity of the boot material directly influences the performance and longevity of size 13 roller skates. A larger foot size necessitates a more robust boot construction to withstand the increased stress and leverage exerted during skating. Insufficient durability leads to premature wear, compromising support and potentially increasing the risk of injury. For example, repeated stress on the ankle region of a poorly constructed boot can result in material fatigue, causing the boot to lose its shape and provide inadequate lateral support. This is especially problematic for size 13 skates where the lever arm is significantly longer, magnifying the forces acting on the boot material. The selection of appropriate boot materials and construction techniques is therefore a critical factor in ensuring the reliable performance of these skates.

Different skating disciplines impose varying demands on boot material durability. Aggressive skating, characterized by jumps, grinds, and slides, requires boots constructed from highly abrasion-resistant materials such as reinforced polymers or composite materials. Recreational skating, while less demanding, still necessitates a durable boot material capable of withstanding repetitive flexing and impacts. Speed skating boots prioritize lightweight construction and aerodynamic efficiency, but must also provide adequate support and resist deformation at high speeds. Selecting boot materials appropriate for the intended skating style is essential for optimizing performance and extending the lifespan of size 13 skates. For instance, a size 13 skate used for aggressive skating will degrade faster than a size 13 used for recreational skating. A higher initial investment in durable materials will pay dividends by reducing frequency for repair or replace.

In summary, boot material durability is a crucial consideration in the design and selection of size 13 roller skates. A robust and well-constructed boot ensures adequate support, withstands the stresses associated with larger foot sizes, and contributes to the overall longevity and performance of the skates. Understanding the relationship between boot material properties, skating style, and foot size is essential for making informed purchasing decisions and maximizing the skating experience while ensuring safe skating practices. Material selections should be reviewed based on skating preference and should consider all safety practices before use.

5. Closure System Security

The integrity of a roller skate’s closure system is paramount, particularly in models designed to accommodate larger foot sizes. Inadequacies in this area directly compromise stability, control, and safety. A secure closure system effectively transmits forces from the skater’s leg to the skate, facilitating efficient propulsion and maneuverability. For size 13 roller skates, where the lever arm created by the foot is greater, this becomes increasingly critical. A loose or poorly designed closure system allows for excessive foot movement within the boot, leading to instability and increased risk of ankle sprains or other injuries. An illustrative example includes laces that repeatedly loosen during use, necessitating frequent readjustments and disrupting the skater’s concentration and balance. The absence of a reliably secure closure renders even high-quality skates potentially hazardous.

Various closure systems exist, each offering distinct advantages and disadvantages. Traditional laces provide a customizable fit but can be time-consuming to adjust and may loosen unevenly. Buckle systems offer quicker and more consistent tightening but may lack the precise adjustability of laces. Hybrid systems, combining laces with buckles or straps, seek to optimize both convenience and fit. Regardless of the specific system employed, the key determinant of its effectiveness is its ability to maintain consistent pressure across the foot and ankle, preventing slippage and ensuring a secure, responsive connection between skater and equipment. The practical implication of a secure closure system is enhanced confidence and control, enabling the skater to execute maneuvers with greater precision and minimizing the likelihood of accidents.

In summary, closure system security is not merely a convenience feature, but an essential safety component of size 13 roller skates. Its primary function is to ensure a stable and responsive interface between the skater and the equipment, thereby maximizing control and minimizing the risk of injury. Challenges in achieving optimal closure system security include accommodating the unique anatomical variations of individual feet and developing systems that are both easy to use and reliably secure. Continuous advancements in materials and design are essential to further enhance the safety and performance of roller skate closure systems for all sizes.

Frequently Asked Questions Regarding Size 13 Roller Skates

This section addresses common inquiries pertaining to skating equipment designed for individuals requiring larger sizes. The information provided aims to clarify concerns related to fit, performance, and maintenance of such equipment.

Question 1: Is the sizing of roller skates consistent across different manufacturers?

Sizing discrepancies may exist between brands. Footwear sizing standards are not universally enforced. It is recommended to consult sizing charts provided by individual manufacturers and, if possible, physically try on the skates before purchase. Measurement of foot length in centimeters or inches provides a more accurate basis for comparison.

Question 2: What are the key considerations when selecting skates for recreational versus aggressive skating?

Recreational skating prioritizes comfort and stability. Aggressive skating emphasizes durability and maneuverability. Recreational skates typically feature softer wheels and more flexible boots. Aggressive skates incorporate reinforced boots, harder wheels, and specialized components for performing tricks and grinds. The intended purpose of the skates should dictate the selection of specific features.

Question 3: How frequently should the bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage and environmental conditions. Skates used in dusty or wet environments require more frequent cleaning. As a general guideline, bearings should be cleaned and lubricated every 20-40 hours of skating. Signs of increased friction, such as reduced rolling speed or unusual noises, indicate the need for immediate maintenance.

Question 4: What protective gear is essential for safe skating practices?

A helmet is the most critical piece of protective gear. Wrist guards, elbow pads, and knee pads are also highly recommended. The use of mouthguards is advisable, particularly for aggressive skating. Protective gear should fit properly and be in good condition to provide adequate protection in the event of a fall or collision.

Question 5: How do wheel durometer and bearing ABEC ratings influence skating performance?

Wheel durometer affects grip and speed. Softer wheels (lower durometer) offer greater grip on smooth surfaces. Harder wheels (higher durometer) provide increased speed. ABEC ratings quantify bearing precision. Higher ABEC ratings generally indicate smoother and faster rolling, but may also require more frequent maintenance. The optimal selection depends on skating style and surface conditions.

Question 6: What are the common indicators that skates may be improperly sized?

Common indicators of improper sizing include excessive toe cramping, heel slippage, pressure points, and numbness. Ill-fitting skates can lead to discomfort, blisters, and impaired control. It is crucial to ensure a snug and comfortable fit without compromising circulation. Consultation with a qualified skate technician can assist in determining the correct size and fit.

Proper selection, maintenance, and safe usage practices are paramount for maximizing the benefits and minimizing the risks associated with roller skating equipment. Adherence to these guidelines promotes a more enjoyable and secure skating experience.

The subsequent section will address advanced techniques and strategies for optimizing skating performance.

Conclusion

This article has comprehensively explored key considerations pertaining to footwear equipped with rolling chassis intended for individuals requiring larger dimensions. Specifically, it has addressed the significance of ankle support, wheel durometer variance, bearing precision, boot material durability, and closure system security as they relate to these specific skating apparatuses. Proper selection and maintenance of these components are paramount for ensuring safety, performance, and longevity.

Given the critical role that properly fitted and maintained equipment plays in mitigating injury risk and optimizing the skating experience, it is incumbent upon both manufacturers and users to prioritize these factors. Continued research and development in materials and design are essential to further enhance the safety and performance of these skating devices, particularly for those requiring the aforementioned specific dimensions. Careful consideration of these factors will contribute to a more secure and enjoyable skating endeavor.