Wholesale skateboard platforms refer to the acquisition of skateboard decks in large quantities. This procurement method is typically employed by retailers, skate shops, and manufacturers to fulfill their inventory requirements at a reduced per-unit cost. For instance, a skate shop owner may purchase fifty skateboard decks at once from a distributor to ensure a consistent supply for their customers.

Securing these materials in volume offers numerous advantages. Cost savings are a primary motivator, enabling businesses to increase profit margins or offer more competitive pricing. Furthermore, it ensures a stable supply chain, mitigating potential disruptions and allowing for efficient production or retail operations. Historically, the practice of purchasing skateboard components in large quantities has evolved alongside the skateboarding industry’s growth, becoming a standard practice for businesses seeking operational efficiency and economic advantage.

The subsequent discussion will explore specific considerations related to sourcing, selecting, and utilizing these skateboard components for various applications, from retail sales to custom board manufacturing.

Guidance on Procuring Skateboard Decks in Volume

The following guidelines are designed to assist in the informed acquisition of skateboard decks in large quantities, optimizing for cost-effectiveness and quality assurance.

Tip 1: Assess Demand Forecasts: Conduct thorough market analysis to accurately predict sales volume. Avoid overstocking, which can lead to storage costs and potential obsolescence, and understocking, which can result in lost sales opportunities.

Tip 2: Vet Suppliers Rigorously: Research potential suppliers’ reputation, production capacity, and quality control processes. Request samples and inspect them thoroughly to ensure they meet established standards for durability and construction.

Tip 3: Negotiate Pricing Strategically: Leverage the advantage of volume purchasing to negotiate favorable pricing terms with suppliers. Explore opportunities for long-term contracts or bulk discounts to maximize cost savings.

Tip 4: Specify Material and Construction Standards: Clearly define the desired specifications for the skateboard decks, including wood type, ply construction, and pressing techniques. This ensures consistency and minimizes the risk of receiving substandard products.

Tip 5: Implement Quality Control Measures: Establish a robust quality control protocol to inspect incoming shipments for defects, warping, or other inconsistencies. Promptly address any issues with the supplier to maintain product quality.

Tip 6: Optimize Logistics and Storage: Plan for efficient transportation and storage of the skateboard decks. Consider factors such as packaging, handling, and environmental conditions to prevent damage during transit and storage.

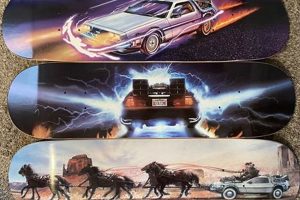

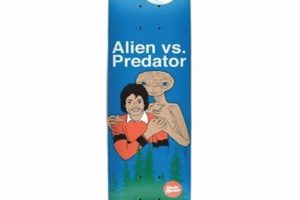

Tip 7: Consider Customization Options: Explore opportunities for customizing the skateboard decks with branding or artwork. This can enhance product differentiation and increase perceived value for customers.

By adhering to these principles, businesses can optimize the process of acquiring skateboard decks in volume, ensuring cost-effectiveness, quality control, and supply chain efficiency.

The concluding sections will delve into the practical applications and market trends influencing the demand for these components.

1. Cost-Effectiveness

Cost-effectiveness is a paramount consideration when acquiring skateboard decks in quantity. The economic advantages derived from purchasing wholesale platforms significantly impact profitability and market competitiveness.

- Volume Discounts

Acquiring skateboard decks in volume enables buyers to negotiate substantially lower per-unit costs. Suppliers typically offer tiered pricing structures, incentivizing larger orders with progressively reduced prices. This direct cost reduction translates to higher profit margins for retailers or lower production expenses for manufacturers.

- Reduced Shipping Costs

Consolidated shipments of bulk skateboard decks often result in lower overall shipping costs compared to individual or smaller orders. Efficiencies in packaging and transportation logistics contribute to these savings, making it economically advantageous to consolidate purchases.

- Inventory Management Efficiency

While requiring upfront capital, purchasing skateboard decks in quantity can streamline inventory management. A consistent supply mitigates the risk of stockouts and allows for more predictable planning, reducing the operational costs associated with frequent reordering and expediting.

- Economies of Scale in Customization

For businesses offering custom-designed skateboard decks, purchasing blanks in bulk allows for economies of scale in the printing or finishing processes. Fixed costs associated with setup and design application are spread across a larger volume of product, reducing the per-unit cost of customization.

The aggregate effect of these cost-saving measures directly influences the financial viability of businesses operating within the skateboard industry. Strategic bulk purchasing decisions are therefore crucial for maintaining competitive pricing and achieving sustainable profitability in this market.

2. Material Quality

Material quality serves as a foundational element in the realm of wholesale skateboard platforms. The intrinsic properties of the materials used directly influence the performance, durability, and safety of the final product. Inferior materials, even when acquired at a lower cost, can lead to premature failure, rider injury, and ultimately, diminished brand reputation for manufacturers or retailers. Conversely, high-quality materials contribute to enhanced board performance, extended lifespan, and increased rider satisfaction. For example, the selection of Canadian maple, known for its strength and flexibility, is a common practice among reputable manufacturers when producing bulk decks. This choice directly impacts the deck’s pop, responsiveness, and resistance to breakage. Therefore, material quality must be considered a non-negotiable aspect of any bulk skateboard deck procurement strategy.

A direct consequence of prioritizing material quality is the necessity for rigorous quality control measures. Suppliers offering bulk skateboard decks should be able to provide verifiable documentation regarding the source, grade, and processing of the raw materials. This transparency allows buyers to assess the material’s suitability for its intended application and ensures consistency across large quantities. Furthermore, practical testing, such as flex tests, impact resistance assessments, and lamination integrity evaluations, should be conducted on sample decks to validate the supplier’s claims and identify any potential weaknesses. For instance, a wholesale buyer might request certification confirming the maple used in the decks adheres to specific density and moisture content standards to guarantee structural integrity.

In conclusion, the relationship between material quality and bulk skateboard decks is one of direct causation and significant consequence. The initial selection of high-quality materials sets the stage for a reliable, durable, and safe final product. While cost considerations are undoubtedly important, they should not supersede the imperative of ensuring superior material standards. This understanding is not merely academic; it is critical for preserving brand integrity, fostering customer loyalty, and mitigating potential liabilities within the skateboard industry.

3. Production Capacity

The intersection of production capacity and wholesale skateboard platforms represents a critical nexus for businesses operating within the skateboarding industry. Production capacity, defined as the maximum output a manufacturer can achieve within a given timeframe, directly influences the availability, cost, and responsiveness of suppliers to fluctuations in market demand. A manufacturer with insufficient production capacity may struggle to fulfill large orders, leading to delays, stockouts, and potential loss of business for retailers and distributors relying on bulk purchases. For instance, a sudden surge in demand for a particular deck shape or graphic can strain a manufacturer’s resources if their production capacity is not adequately scaled to accommodate the increased order volume. This scenario underscores the importance of assessing a supplier’s production capacity as a key component of the due diligence process when sourcing wholesale skateboard platforms. Therefore, understanding the manufacturer’s capacity is vital for businesses needing the product.

Furthermore, production capacity impacts the customization capabilities and lead times associated with bulk skateboard deck orders. Manufacturers with higher production capacities often possess the infrastructure and resources to offer a wider range of customization options, including unique concave designs, graphic applications, and material specifications. These manufacturers are also better positioned to handle complex orders involving specific branding requirements or technical modifications. Consequently, businesses seeking to differentiate their product offerings or cater to niche markets may find it advantageous to partner with suppliers boasting substantial production capacity. To illustrate, a skate shop chain looking to release a limited-edition series of decks featuring custom artwork would require a supplier capable of executing the graphic design across a large number of decks within a defined timeframe, a task necessitating significant production bandwidth.

In conclusion, production capacity serves as a linchpin connecting supply chain efficiency, product availability, and customization potential within the wholesale skateboard platform market. A thorough assessment of a supplier’s production capabilities is therefore essential for businesses aiming to secure a reliable source of high-quality skateboard decks, meet customer demands effectively, and maintain a competitive edge in the dynamic skateboarding industry. Failing to consider this aspect can lead to supply chain bottlenecks, lost revenue opportunities, and diminished customer satisfaction.

4. Supplier Reliability

Supplier reliability is a cornerstone in the acquisition of skateboard decks in bulk, representing the consistency and dependability with which a supplier meets agreed-upon obligations. This encompasses product quality, adherence to timelines, communication transparency, and overall business integrity. A reliable supplier mitigates risks associated with supply chain disruptions, ensuring a steady flow of skateboard decks to meet market demands.

- Consistent Product Quality

A reliable supplier maintains consistent quality standards across all bulk orders. This includes adherence to specified material grades, dimensional tolerances, and construction techniques. For instance, a supplier consistently providing decks with uniform ply construction and proper concave ensures predictable performance for end users. Failure to maintain consistency can lead to product returns, damaged brand reputation, and increased operational costs for the buyer.

- Adherence to Timelines and Delivery Schedules

Meeting agreed-upon delivery schedules is crucial for effective inventory management and production planning. A reliable supplier consistently delivers bulk skateboard deck orders on time, minimizing the risk of stockouts and production delays. For example, a supplier consistently adhering to lead times allows retailers to accurately forecast inventory needs and promotional campaigns. Late deliveries can disrupt supply chains, leading to lost sales opportunities and increased holding costs.

- Transparent Communication and Responsiveness

Open and transparent communication is essential for building trust and resolving potential issues. A reliable supplier proactively communicates any potential delays, material changes, or production challenges. They are also responsive to inquiries and concerns, providing timely and accurate information. For instance, a supplier promptly notifying a buyer of a raw material shortage allows for proactive adjustments to production schedules. Lack of communication can erode trust and hinder effective collaboration.

- Financial Stability and Business Integrity

A supplier’s financial stability and ethical business practices are indicators of long-term reliability. Suppliers with sound financial footing are less likely to experience disruptions due to financial difficulties. Adherence to ethical labor practices and environmental standards demonstrates a commitment to responsible business operations. For example, a supplier with a history of fair labor practices and environmental compliance signals a commitment to sustainable business practices. Instability or unethical conduct can pose significant risks to the buyer’s supply chain and brand reputation.

The interplay of these factors underscores the importance of thorough due diligence when selecting a supplier for bulk skateboard decks. Investing in a reliable supplier is an investment in long-term stability, consistent product quality, and reduced risk within the skateboarding industry’s competitive landscape. A dependable supply chain partner ultimately contributes to enhanced customer satisfaction and sustained profitability.

5. Customization Options

The capacity for customization fundamentally alters the value proposition of skateboard decks acquired in volume. While bulk purchasing inherently focuses on cost reduction through economies of scale, the integration of customization options transforms standardized products into differentiated offerings tailored to specific market segments or brand identities. For example, a skate shop chain may procure blank skateboard decks in bulk to then apply proprietary graphic designs, creating a unique product line that distinguishes them from competitors carrying generic boards. This approach balances the economic benefits of bulk acquisition with the enhanced market appeal of customized products.

Customization options encompass a range of features, including graphic design, concave shape, material composition, and dimensions. The selection of specific customization parameters directly influences the perceived value and performance characteristics of the skateboard decks. A manufacturer supplying bulk decks may offer various concave molds to cater to different riding styles or preferences. Similarly, the choice of wood veneer and lamination process can be tailored to optimize deck strength, flex, and responsiveness. The implementation of these customization choices, while increasing initial production costs, can ultimately yield higher profit margins through premium pricing and enhanced customer loyalty. For instance, a brand specializing in longboards might source maple veneer bulk decks, then customize them with a unique fiberglass lamination for improved durability and flex, targeting a niche market of downhill riders.

The effective integration of customization options into bulk skateboard deck procurement requires careful planning and collaboration between the buyer and the supplier. Clear communication of design specifications, quality control standards, and production timelines is essential to ensure that the final product aligns with the intended market positioning and brand identity. Challenges include managing the increased complexity of customized orders, maintaining consistent quality across large volumes, and optimizing production processes to minimize lead times. Despite these challenges, the strategic application of customization options can transform bulk skateboard decks into a powerful tool for differentiation and value creation within the skateboarding industry. It allows businesses to address specialized customer needs, build brand loyalty, and ultimately, enhance profitability.

6. Market Demand

Market demand exerts a definitive influence on the procurement and distribution strategies within the skateboard deck industry. The fluctuating needs and preferences of consumers dictate the volume, style, and characteristics of skateboard decks businesses choose to acquire in bulk.

- Seasonal Variations and Trends

Market demand experiences distinct seasonal variations and is heavily influenced by emerging trends. Increased participation in skateboarding during warmer months typically leads to higher demand for skateboard decks, prompting retailers to increase inventory through bulk purchases. Similarly, the resurgence of retro skateboard styles or the adoption of new riding disciplines can create surges in demand for specific deck shapes or materials. These fluctuations necessitate agile supply chain management and responsive procurement strategies to capitalize on opportunities and avoid overstocking unpopular items. For example, the rise in popularity of longboarding has led to increased demand for larger, more flexible decks, requiring retailers to adjust their bulk purchasing to accommodate this shift.

- Demographic and Geographic Factors

Market demand is further shaped by demographic and geographic factors. Regions with strong skateboarding cultures or youth populations tend to exhibit higher demand for skateboard decks compared to areas with limited skateboarding infrastructure or participation. Similarly, demographic segments with specific riding preferences or skill levels may require specialized deck features, such as narrower decks for technical street skating or wider decks for stability in vert riding. Businesses targeting these specific demographics must tailor their bulk purchasing decisions to align with the unique demands of their target markets. A retailer located near a skate park frequented by experienced riders may prioritize purchasing decks with advanced concave shapes and durable construction, while a retailer in a suburban area with primarily beginner skateboarders may focus on more affordable and beginner-friendly decks.

- Economic Conditions and Consumer Spending

Prevailing economic conditions and consumer spending patterns directly impact the demand for skateboard decks. During periods of economic prosperity, consumers tend to have more disposable income to spend on recreational activities and sporting goods, leading to increased demand for skateboard decks. Conversely, economic downturns can result in reduced consumer spending and decreased demand, requiring businesses to adjust their procurement strategies to mitigate risks. The price sensitivity of consumers also influences the demand for different types of skateboard decks. Budget-conscious consumers may prioritize more affordable decks, while affluent consumers may be willing to pay a premium for high-performance or custom-designed decks. A retailer operating in a region experiencing economic hardship may focus on sourcing competitively priced decks in bulk to cater to budget-conscious consumers, while a retailer in a wealthier area may prioritize higher-end decks with premium materials and advanced features.

- Influence of Marketing and Brand Awareness

Marketing campaigns and brand awareness significantly contribute to shaping market demand for skateboard decks. Effective marketing strategies can generate consumer interest, create brand loyalty, and drive sales. Endorsements from professional skateboarders, collaborations with influential artists, and visually appealing advertising campaigns can all contribute to increased demand for specific brands or deck models. Similarly, positive reviews and word-of-mouth referrals can enhance brand reputation and influence consumer purchasing decisions. Businesses must leverage marketing and branding effectively to create demand for their products and justify their bulk purchasing decisions. A skateboard deck manufacturer collaborating with a popular skateboarder for a signature deck model may experience a surge in demand due to the athlete’s endorsement, requiring them to ramp up production and distribution to meet the heightened interest.

These intertwined elements highlight how astute analysis of consumer desires and shifts in the skateboarding landscape are paramount for businesses strategizing regarding bulk deck acquisition. Adaptation and informed decision-making, driven by keen market insight, ensure both consumer satisfaction and sustained commercial success.

Frequently Asked Questions

The following addresses common inquiries concerning the acquisition of skateboard decks in large quantities, providing clarification on key considerations.

Question 1: What factors determine the optimal quantity for a bulk skateboard deck purchase?

The ideal quantity is dictated by projected sales volume, storage capacity, and available capital. Conducting thorough market analysis and carefully evaluating these factors will facilitate an informed decision.

Question 2: How is the quality of skateboard decks assessed prior to a large-scale purchase?

Quality assessment involves requesting samples from potential suppliers and subjecting them to rigorous testing. Evaluation criteria include wood type, ply construction, concave depth, and overall durability.

Question 3: What are the typical cost components associated with bulk skateboard deck orders?

Cost components encompass the per-unit price of the decks, shipping charges, customs duties (if applicable), and any associated customization fees, such as graphic application.

Question 4: How can one effectively negotiate pricing with suppliers when purchasing skateboard decks in bulk?

Negotiation strategies include leveraging volume discounts, exploring long-term contracts, and comparing quotes from multiple suppliers to secure the most favorable terms.

Question 5: What are the common challenges encountered when sourcing skateboard decks from overseas manufacturers?

Challenges may include language barriers, differing quality control standards, longer lead times, and potential logistical complications related to international shipping and customs clearance.

Question 6: What considerations are crucial when selecting a supplier for bulk skateboard deck purchases?

Key considerations encompass the supplier’s reputation, production capacity, quality control processes, pricing structure, communication transparency, and adherence to ethical business practices.

In summary, informed decision-making, meticulous quality assessment, and strategic negotiation are paramount for successful bulk skateboard deck acquisitions.

The subsequent section will delve into emerging trends shaping the future of the bulk skateboard deck market.

Conclusion

This exploration of bulk skate decks has underscored several critical aspects for businesses operating within the skateboarding industry. The analysis has emphasized the importance of understanding market demand, prioritizing material quality, assessing supplier reliability, and strategically leveraging customization options. Careful consideration of these factors contributes to cost-effective procurement strategies and ensures the availability of high-quality products.

The strategic acquisition of these components in volume presents both opportunities and challenges. A proactive approach, characterized by diligent planning, informed decision-making, and a commitment to quality, is essential for maximizing profitability and maintaining a competitive edge. The future success of businesses engaged in the skateboard deck market hinges on their ability to adapt to evolving consumer preferences, navigate global supply chains effectively, and uphold the principles of ethical and sustainable business practices.

![Best 9 Inch Skate Deck [Guide] For Stability & Tricks Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Best 9 Inch Skate Deck [Guide] For Stability & Tricks | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://cruzskateshop.com/wp-content/uploads/2025/06/th-3401-300x200.jpg)