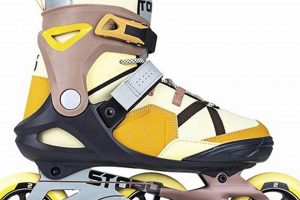

Footwear incorporating integrated rolling elements offers a unique recreational and transportation option. These products, combining the support of a traditional boot with the mobility of wheeled locomotion, are utilized in various disciplines ranging from casual skating to specialized athletic endeavors. A common example includes inline models secured directly to the lower leg and foot.

These devices provide a stable platform for movement, potentially enhancing balance and control compared to conventional roller skates. Historically, the evolution of this equipment reflects advancements in materials and engineering, leading to improved performance and user experience. The rigid structure contributes to efficient power transfer, translating effort into forward motion.

The subsequent sections will detail specific types, construction materials, maintenance procedures, and considerations for selecting the appropriate equipment based on intended use and skill level. Further discussion will explore the related protective gear and safety protocols essential for responsible participation.

Boot Skates

The following provides guidance for those utilizing footwear with integrated rolling mechanisms. Adherence to these recommendations can enhance performance and safety.

Tip 1: Selection Criteria. Evaluate the intended application. Artistic disciplines necessitate a higher boot cut for ankle support, while speed applications often favor a lower profile for increased maneuverability. Verify the wheel durometer and bearing rating match the skating surface.

Tip 2: Proper Fit Assessment. Ensure a snug, yet comfortable fit. Excessive movement within the structure compromises control and increases the likelihood of blisters or chafing. Tighten closures incrementally to avoid over-constriction.

Tip 3: Pre-Skate Inspection Protocol. Conduct a thorough assessment prior to each use. Verify wheel attachment security, bearing functionality, and brake pad integrity. Address any identified deficiencies before engaging in activity.

Tip 4: Surface Condition Awareness. Recognize the impact of the skating environment. Smooth, consistent surfaces promote optimal performance. Avoid areas with debris, cracks, or uneven pavement that could compromise stability.

Tip 5: Gradual Skill Progression. Master fundamental techniques before attempting advanced maneuvers. Practice basic balance, stopping, and turning exercises in a controlled environment. Seek instruction from qualified professionals as needed.

Tip 6: Maintenance Schedule Adherence. Implement a regular cleaning and maintenance program. Remove dirt and debris from wheels and bearings. Lubricate components as recommended by the manufacturer. Replace worn parts promptly.

Tip 7: Protective Gear Utilization. Always employ appropriate safety equipment. A properly fitted helmet, wrist guards, elbow pads, and knee pads are essential for mitigating injury risk. Ensure gear meets relevant safety standards.

Consistent application of these guidelines promotes efficient operation and minimizes potential hazards. Prioritizing safety and proper technique contributes to a more positive and productive experience.

The following sections will delve into advanced techniques and customization options for optimizing individual performance.

1. Structural Integrity

Structural integrity, in the context of footwear with integrated rolling elements, directly influences safety, performance, and longevity. The capacity of the frame and supporting elements to withstand stress and maintain their intended form under load is paramount for optimal function.

- Frame Rigidity and Load Distribution

The rigidity of the frame dictates the efficiency of power transfer from the user to the wheels. A frame that flexes excessively under load dissipates energy and reduces speed. Proper load distribution prevents localized stress concentrations that could lead to premature failure. For example, a high-performance model may utilize a reinforced carbon fiber frame to maximize stiffness and minimize weight.

- Material Selection and Fatigue Resistance

The materials used in construction must possess adequate fatigue resistance to withstand repeated stress cycles. Aluminum alloys are commonly employed due to their favorable strength-to-weight ratio and resistance to corrosion. However, improper heat treatment or poor weld quality can compromise the fatigue life of these components, leading to cracks and eventual failure. A well-designed model will specify materials with documented fatigue properties and employ rigorous quality control procedures.

- Attachment Point Strength and Security

The points where the boot is attached to the frame, and the wheels are attached to the frame, are critical areas for structural integrity. Weak or poorly designed attachment points can lead to loosening, instability, and catastrophic failure. Manufacturers often use threaded fasteners with locking mechanisms or adhesive bonding to ensure secure and durable connections. Regular inspection of these attachment points is essential for identifying potential problems before they escalate.

- Impact Resistance and Energy Absorption

The ability to withstand impacts without permanent deformation or fracture is another crucial aspect of structural integrity. Falls and collisions are inherent risks, and the frame must be capable of absorbing energy and protecting the user from injury. Impact-resistant polymers and composite materials are frequently incorporated into the design to enhance impact protection. The structural design needs to account for both high-energy, low-frequency impacts (e.g., a fall) and low-energy, high-frequency impacts (e.g., skating on rough surfaces).

The interplay of these factors underscores the critical role of structural integrity in the design and performance. Compromises in any of these areas can negatively impact stability, control, and overall user safety. The selection should prioritize models with demonstrated durability and adherence to industry standards for structural performance.

2. Wheel Durometer

Wheel durometer, measured on the Shore A scale, denotes the hardness of the wheel material integrated into footwear with rolling elements. This property directly influences grip, rolling resistance, and wear characteristics. A lower durometer (e.g., 78A) signifies a softer wheel that offers enhanced grip, suitable for slick surfaces or beginners seeking increased stability. Conversely, a higher durometer (e.g., 88A or greater) indicates a harder wheel, providing lower rolling resistance for increased speed on smooth surfaces. The selection of an inappropriate durometer can compromise performance or safety; excessively hard wheels on a rough surface may lead to loss of control, while overly soft wheels on a smooth surface can feel sluggish.

The impact of wheel durometer extends beyond simple speed or grip considerations. Softer wheels tend to absorb more vibration, resulting in a smoother ride, but also wear down more quickly. Harder wheels provide a more responsive feel, transmitting more feedback from the skating surface, but may be less comfortable over longer distances. Competitive athletes often choose wheel durometer based on the specific track conditions and event requirements; for example, speed skaters on a perfectly smooth indoor track may opt for extremely hard wheels, while aggressive skaters require softer, more forgiving wheels for coping with varied terrain and impacts. The wheel size also play key role with wheel durometer.

In summary, wheel durometer constitutes a critical parameter influencing the performance and suitability of wheeled footwear. Selection should be dictated by the intended usage environment, skill level, and desired balance between grip, speed, comfort, and durability. Understanding this parameter allows for informed equipment choices, optimizing both recreational enjoyment and competitive performance. Overlooking wheel durometer introduces the potential for diminished performance or an elevated risk of accidents.

3. Bearing Precision

In the context of footwear incorporating integrated rolling elements, bearing precision exerts a significant influence on performance characteristics. Specifically, the degree of dimensional accuracy and manufacturing tolerance achieved during bearing fabrication directly affects rolling efficiency, speed, and overall durability. High-precision bearings, characterized by tighter tolerances and smoother internal surfaces, exhibit reduced friction and consequently enable faster and more sustained rolling. This translates to an enhanced user experience, particularly in applications requiring prolonged periods of use or high-speed maneuvers. For instance, a skater utilizing equipment with ABEC 7 or higher-rated bearings will generally experience superior roll compared to one using equipment with lower-rated bearings, assuming all other factors are equal. The quality of the steel used in the bearing raceways also plays a crucial role. For example, some bearings have titanium coating on the race ways. This coating makes the bearing last longer and spin better.

Conversely, bearings with lower precision, often found in entry-level equipment, exhibit higher levels of friction and may be more susceptible to premature wear. This can manifest as reduced speed, increased effort required to maintain momentum, and diminished responsiveness during directional changes. Furthermore, the ingress of contaminants, such as dirt or moisture, into lower-precision bearings can accelerate degradation and further impair performance. Consider a scenario where two identical sets of equipment are used in a sandy environment; the equipment with higher-precision, sealed bearings will likely maintain its performance for a longer duration compared to the one with lower-precision, unsealed bearings. The lower quality bearing allows sand to enter more easily and degrade the internals.

Ultimately, bearing precision represents a critical determinant of performance. Selection criteria should account for the intended application, user skill level, and environmental conditions. While higher-precision bearings command a premium, the resulting improvements in rolling efficiency, speed, and durability can justify the investment, particularly for serious enthusiasts and competitive athletes. Ignoring the role of bearing precision poses the risk of compromised performance, reduced equipment lifespan, and an overall diminished skating experience. This aspect of component selection warrants careful consideration to maximize satisfaction and ensure optimal utilization of the equipment.

4. Boot Material

Boot material exerts a significant influence on the performance, comfort, and safety characteristics of footwear with integrated rolling elements. The selection of specific materials directly impacts the structural support, flexibility, thermal regulation, and durability of the complete assembly. Different materials are employed to address specific requirements across various skating disciplines, ranging from recreational use to competitive applications. For example, stiffer materials, such as carbon fiber composites, are often utilized in speed skating to maximize power transfer and minimize energy loss during propulsion, while more pliable materials, like reinforced leather or synthetic fabrics, are preferred in recreational models to enhance comfort and accommodate a wider range of foot shapes.

The chosen material also plays a crucial role in thermal management and moisture control. Extended periods of use can generate significant heat and perspiration, potentially leading to discomfort and reduced performance. Breathable materials, such as ventilated mesh or perforated leather, facilitate air circulation and wick away moisture, maintaining a more comfortable internal environment. The type of liner used within the boot further contributes to these properties; liners incorporating moisture-wicking fabrics and antimicrobial treatments enhance hygiene and prevent the build-up of odors. The placement of the liner is also important, the liner must contour to the foot. This makes for maximum fit. This helps the rider feel confident when performing. The better the fit the more the confidence.

Ultimately, the selection of boot material represents a critical design consideration that balances competing demands for support, comfort, and durability. Understanding the properties of various materials and their suitability for specific skating applications is essential for making informed equipment choices. Manufacturers often employ a combination of materials to optimize performance and cater to the diverse needs of end-users. Ignoring the significance of boot material can result in compromised comfort, reduced performance, and an increased risk of injury.

5. Closure System

The closure system on footwear integrating rolling elements directly impacts fit, support, and overall performance. The effectiveness of the closure mechanism dictates the security and stability of the foot within the boot, influencing control, comfort, and injury prevention. A well-designed system optimizes power transfer and minimizes unwanted movement.

- Lace Configurations

Traditional lacing systems provide customizable fit adjustment along the length of the foot. Variations include speed lacing, which facilitates quick tightening and loosening, and zonal lacing, allowing independent adjustment of different sections of the boot. Improperly tightened laces can lead to pressure points or insufficient ankle support, affecting performance and comfort.

- Buckle Mechanisms

Buckle systems offer secure and easily adjustable closure, often used in conjunction with laces or straps. Ratchet buckles provide incremental tightening, ensuring a precise fit. Cam buckles offer quick release and adjustment. Buckle failure or improper adjustment can compromise stability and increase the risk of ankle injury.

- Strap Placement and Materials

Straps, typically made of nylon or Velcro, provide additional support and secure the heel within the boot. The placement and width of straps influence ankle stability and power transfer. Weak or poorly positioned straps can lead to heel lift and reduced control.

- Power Straps and Cuffs

Power straps, often positioned at the upper cuff, enhance ankle support and responsiveness. These straps improve forward lean and enable more efficient power transfer during acceleration. Insufficiently tightened power straps can diminish control and increase the risk of ankle strain.

These closure system elements collectively determine the effectiveness in securing the foot within footwear. A comprehensive system, incorporating laces, buckles, and straps, offers optimal fit and support, contributing to enhanced performance, comfort, and safety. Neglecting the importance of a functional closure mechanism can compromise stability and increase the risk of injuries during use.

6. Ankle Support

Ankle support constitutes a critical element in the design and functionality of footwear with integrated rolling elements. Its presence or absence directly influences stability, control, and the potential for injury during use. Sufficient ankle support mitigates the risk of sprains and strains, enabling more effective power transfer and precise maneuvering.

- Boot Height and Cuff Design

The height of the boot and the design of the cuff directly influence the degree of lateral and medial support provided to the ankle joint. Higher boot cuffs, extending further up the lower leg, offer greater stabilization and resistance to ankle roll. For example, aggressive models often feature reinforced cuffs designed to withstand high-impact forces and prevent ankle instability during jumps and grinds. The specific contour of the cuff also contributes to overall support and freedom of movement.

- Material Stiffness and Reinforcement

The materials used in the construction of the boot and cuff significantly impact ankle support. Stiffer materials, such as carbon fiber or reinforced polymers, provide greater rigidity and resistance to deformation, minimizing ankle movement and enhancing stability. Strategic reinforcement in key areas, such as the lateral and medial sides of the ankle, further strengthens support. Consider the differences between a recreational model with a soft, flexible boot and a high-performance model with a rigid, carbon fiber shell; the latter offers substantially greater ankle support.

- Closure System Integration

The closure system works in conjunction with the boot and cuff to provide secure and customizable ankle support. Laces, buckles, and straps can be adjusted to achieve a snug and supportive fit, preventing excessive ankle movement within the boot. A well-integrated closure system ensures that the ankle is properly positioned and stabilized, minimizing the risk of injury. For instance, a power strap positioned at the upper cuff can significantly enhance ankle support and responsiveness during forward lean.

- Liner Padding and Contouring

The internal liner of the boot contributes to ankle support through padding and contouring. Strategically placed padding provides cushioning and conforms to the shape of the ankle, enhancing comfort and stability. A well-designed liner minimizes pressure points and prevents the ankle from shifting within the boot. Heat-moldable liners offer a customized fit, further optimizing ankle support and comfort.

The interrelationship among boot height, material stiffness, closure system integration, and liner design collectively determines the level of ankle support offered by different models of footwear with integrated rolling elements. Selecting appropriate support levels, contingent upon skating style, skill level, and individual anatomical factors, is a critical consideration for minimizing the risk of injury and maximizing performance.

7. Braking Mechanism

The braking mechanism integrated into footwear with rolling elements constitutes a critical safety component, directly influencing the operator’s capacity to control speed and avoid collisions. Without a reliable braking system, these devices present a significant risk of uncontrolled acceleration, particularly on downhill gradients or in congested areas. The functionality of the braking mechanism, therefore, is not merely an accessory but a fundamental aspect of safe operation. The most common system employs a heel-mounted brake pad that engages with the ground upon plantar flexion of the foot. The effectiveness of this system depends on the pad material, surface area, and the user’s ability to apply consistent pressure.

Variations in braking system design exist to accommodate different skating styles and user preferences. Some models incorporate inline braking systems, where the brake pad is positioned in line with the wheels, offering a more responsive braking action. Others utilize friction-based systems engaging directly with the wheel surface, providing enhanced stopping power, particularly in wet conditions. The design and placement of the braking mechanism must consider ergonomic factors to minimize user fatigue and ensure consistent activation under varying conditions. For example, improper positioning of a heel brake can lead to muscle strain and reduced braking effectiveness, especially during emergency stops. Furthermore, the material used needs to be durable enough to withstand continuous friction.

Ultimately, the braking mechanism’s effectiveness and reliability are paramount for safety. Regular inspection and maintenance are essential to ensure proper functionality. Worn brake pads must be replaced promptly to maintain adequate stopping power. A thorough understanding of the braking system’s operation and limitations is crucial for all users, promoting responsible operation and minimizing the risk of accidents. Future advancements could see integration with electronic systems, however at this moment, material technology has not gotten to this point yet.

Frequently Asked Questions

The following addresses common inquiries concerning equipment incorporating rolling chassis attached to footwear. The purpose is to clarify aspects relating to usage, maintenance, and safety.

Question 1: What constitutes the primary advantage of footwear with integrated rolling elements compared to traditional roller skates?

Footwear with integrated rolling elements, particularly models with a boot structure, generally provides enhanced ankle support and stability. This can facilitate greater control and potentially reduce the risk of ankle injuries, particularly for novice users.

Question 2: What factors determine the appropriate wheel durometer for a specific application?

Wheel durometer selection should align with the skating surface and the user’s skill level. Softer wheels offer improved grip on slick surfaces, while harder wheels provide lower rolling resistance on smooth surfaces. Experience level should also dictate choice with experienced users often opting for harder wheels.

Question 3: How frequently should bearings be cleaned and lubricated?

Bearing maintenance frequency depends on usage conditions. Regular cleaning and lubrication are recommended after exposure to dirt, moisture, or abrasive environments. A consistent schedule ensures optimal performance and extends bearing lifespan.

Question 4: What measures mitigate the risk of injury during use?

Employing appropriate protective gear, including a helmet, wrist guards, elbow pads, and knee pads, significantly reduces the risk of injury. Additionally, adherence to safe skating practices and awareness of surrounding conditions are crucial.

Question 5: How does boot material selection impact performance?

Boot material influences support, comfort, and durability. Stiffer materials, such as carbon fiber, maximize power transfer, while more flexible materials enhance comfort. Selection depends on individual needs and skating style.

Question 6: What are the indicators of brake pad wear requiring replacement?

Diminished stopping power and visible reduction in brake pad thickness indicate the need for replacement. Regular inspection of the brake pad is essential for maintaining braking effectiveness.

These answers provide essential guidance. Further investigation and practical experience will offer a more comprehensive understanding.

The subsequent section details advanced techniques and modification possibilities for enhanced operation.

Conclusion

The preceding sections have examined the constituent elements and operational considerations relevant to footwear incorporating integrated rolling components, commonly referred to as boot skates. Emphasis has been placed on the interplay between structural integrity, wheel durometer, bearing precision, boot material, closure mechanisms, ankle support, and braking system functionality. A comprehensive understanding of these factors is essential for informed selection, responsible use, and effective maintenance.

Continued adherence to established safety protocols and diligent attention to equipment condition are paramount for mitigating risk and maximizing the utility of these devices. Further research and technological advancements may yield improvements in performance, safety, and accessibility. It is the responsibility of manufacturers and users alike to prioritize safety and promote the responsible enjoyment of this form of locomotion.