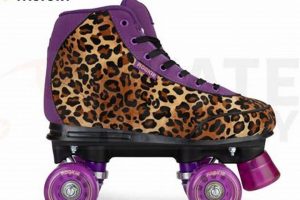

The specialized footwear discussed, often characterized by a low-cut boot and enhanced maneuverability, caters specifically to the demands of a fast-paced, contact sport. Such equipment prioritizes agility and responsiveness, enabling athletes to execute quick turns and maintain stability. A practical illustration involves skaters utilizing the enhanced mobility to navigate tight formations and execute strategic blocking maneuvers.

The value of employing such equipment lies in its contribution to heightened performance and reduced risk of injury. The design facilitates efficient energy transfer, allowing for quicker acceleration and improved control. Historically, modifications to skating equipment have consistently aimed at optimizing athlete safety and competitive advantage. This specific type represents a continued evolution in that trajectory.

The subsequent sections will delve into the specific components contributing to the functionality of this specialized skating equipment, explore the technological advancements influencing its design, and analyze the impact of its adoption on the competitive landscape within the sport.

Optimizing Performance with Specialized Skating Equipment

The following guidance aims to inform users on maximizing the benefits derived from specialized low-cut skating equipment designed for high-agility sports.

Tip 1: Prioritize Proper Fit. Correct sizing is crucial for optimal performance and injury prevention. Ill-fitting boots can lead to blisters, decreased control, and increased risk of ankle sprains. Consult sizing charts and consider professional fitting assistance.

Tip 2: Adjust Plate Positioning. Plate positioning influences maneuverability and stability. Experiment with different plate placements to determine the configuration that best suits individual skating style and positional requirements.

Tip 3: Select Appropriate Wheels. Wheel hardness and size impact grip and roll speed. Softer wheels offer increased grip on slick surfaces, while harder wheels provide greater speed on smoother surfaces. Select wheel durometer based on the skating surface and desired performance characteristics.

Tip 4: Maintain Bearing Hygiene. Clean and lubricate bearings regularly to ensure smooth roll and efficient energy transfer. Debris accumulation can significantly impede performance. Implement a consistent maintenance schedule.

Tip 5: Optimize Lacing Technique. Adjust lacing tightness to provide adequate ankle support and prevent slippage. Experiment with different lacing patterns to find a configuration that optimizes comfort and control.

Tip 6: Regular Hardware Checks: Before each use, examine all nuts, bolts, and cushions for wear and tightness. Loose hardware can compromise stability and increase the potential for accidents. Secure hardware promptly when necessary.

Tip 7: Cushion Selection: Experiment with different cushion durometers. Softer cushions provide greater agility, while harder cushions increase stability. The ideal cushion durometer depends on the skater’s weight, skill level, and preferred skating style.

Adhering to these guidelines can contribute to enhanced performance, increased comfort, and reduced risk of injury when utilizing low-cut skating equipment.

The subsequent section will explore the design innovations and technological advancements that have shaped the evolution of this specialized skating equipment.

1. Agility

The concept of agility constitutes a fundamental performance metric in roller derby, directly impacting a skater’s effectiveness in offensive and defensive maneuvers. The design of specialized skating equipment directly contributes to, or detracts from, this critical attribute. Specifically, the low-cut boot profile, characteristic of “roller derby pixie skates”, allows for an increased range of ankle motion. This increased range directly facilitates quicker lateral movements and sharper turns. The absence of a high boot shaft reduces restriction, permitting more immediate responses to the dynamic and unpredictable nature of gameplay.

The connection between agility and skating equipment becomes demonstrably clear when considering a practical scenario. For example, a jammer attempting to evade a blocker benefits from the enhanced agility afforded by the low-cut design. The capacity to rapidly change direction enables the jammer to navigate around obstacles, maintain momentum, and ultimately score points. Conversely, a blocker must possess the agility to maintain position and react to the jammer’s movements. The ability to pivot and adjust stance quickly is essential for effective defensive play. Equipment that impedes agility, therefore, compromises a player’s ability to perform these fundamental tasks.

Understanding the interplay between specialized skating equipment and agility is paramount for skaters seeking to optimize their performance. Selection of equipment that prioritizes maneuverability and responsiveness directly translates to an enhanced ability to react to game dynamics. This understanding is not merely theoretical; it has practical significance for competitive success and injury prevention. Enhanced agility reduces the likelihood of collisions and missteps, contributing to overall safety and performance longevity. While agility is not solely determined by equipment, the proper selection significantly amplifies a skaters natural abilities.

2. Maneuverability

Maneuverability, the capacity to execute rapid and precise directional changes, constitutes a critical attribute for success in roller derby. The selection of appropriate skating equipment, particularly the type known as “roller derby pixie skates,” significantly influences a skater’s ability to achieve optimal maneuverability on the track.

- Low-Profile Boot Design

The low-cut design inherent in this type of skate facilitates an increased range of ankle flexion and extension. This enhanced range allows for quicker transitions between edges, enabling skaters to execute tighter turns and react more rapidly to changes in game dynamics. In practical terms, this allows a blocker to quickly adjust their position to cut off a jammer’s path.

- Plate Angle and Truck System

The geometry of the skate plate and truck system directly impacts responsiveness. Steeper plate angles generally translate to greater agility but can reduce stability at high speeds. Softer truck cushions allow for easier leaning and turning, while stiffer cushions provide greater stability. This adjustability is crucial, for instance, when a jammer is weaving through a tight pack of blockers.

- Wheelbase Length

The distance between the front and rear axles, known as the wheelbase, influences turning radius and stability. Shorter wheelbases generally offer enhanced maneuverability at the expense of stability. Conversely, longer wheelbases provide greater stability but can reduce agility. This trade-off becomes important as a skater determines equipment setup, balancing the need for agile moves with the confidence of stability.

- Wheel Hardness and Profile

Wheel durometer, measured on the Shore A scale, affects grip and roll speed. Softer wheels offer increased grip, allowing for tighter turns and quicker stops, particularly on slick surfaces. Wheel profile, whether rounded or flat, also impacts maneuverability. Rounded profiles promote smoother transitions between edges, while flatter profiles offer greater stability on straightaways. For example, a blocker might choose harder wheels with a flatter profile to maintain a stable base while bracing against a jammer.

The interplay of these elements underscores the critical role that specialized skating equipment plays in facilitating maneuverability. The specific configuration of “roller derby pixie skates,” encompassing boot design, plate geometry, wheelbase length, and wheel characteristics, directly impacts a skater’s ability to navigate the track effectively and strategically, impacting both offensive and defensive capabilities.

3. Low-cut boot

The “roller derby pixie skates” are characteristically defined, in part, by their low-cut boot design. This design choice is not arbitrary; it directly impacts the skater’s agility and range of motion. The reduction in boot height, compared to traditional figure or hockey skates, allows for greater ankle flexion and extension. The increased range of motion is essential for executing the quick turns and lateral movements inherent in roller derby. For example, a skater performing a “transitions” maneuver, quickly changing from forward to backward skating, requires substantial ankle mobility. The low-cut boot facilitates this action by minimizing restriction on the ankle joint.

The importance of the low-cut boot is further underscored when considering the blocking and jamming roles within roller derby. Blockers often engage in close-quarters contact, requiring rapid adjustments to maintain position and impede opponents. The greater ankle mobility afforded by the low-cut boot allows for faster pivots and stance adjustments, contributing to more effective blocking. Jammers, tasked with scoring points, benefit from the enhanced agility in navigating tight packs of opposing players. Their low-cut boots allow the rapid acceleration and agile dodges required to break through the pack. Without the low-cut design, skaters would experience a noticeable decrease in responsiveness and maneuverability, negatively impacting their performance.

In summary, the connection between the low-cut boot and “roller derby pixie skates” is causative and critical. The design choice directly enables the enhanced agility required for successful roller derby performance. While other factors, such as plate type and wheel durometer, contribute to overall skate performance, the low-cut boot serves as a fundamental component, impacting every aspect of the skater’s movement. The challenges associated with this design include potential reduction in ankle support, requiring skaters to develop stronger ankle musculature or utilize specialized bracing. However, the benefits in maneuverability outweigh the drawbacks for most roller derby skaters, solidifying the low-cut boot as a defining feature of specialized skating equipment.

4. Plate Material

The selection of plate material in “roller derby pixie skates” directly influences the skate’s weight, strength, and responsiveness. The plate, connecting the boot to the wheels, is a critical structural component. A lightweight plate enhances agility and reduces skater fatigue, while a strong plate withstands the high-impact forces inherent in roller derby. The material’s stiffness also impacts energy transfer; a stiffer plate generally provides a more immediate response to skater input, facilitating quicker acceleration and sharper turns. For example, a plate constructed from aircraft-grade aluminum offers a favorable balance of weight and strength, allowing skaters to maintain agility without compromising durability during intense gameplay.

Common materials employed in skate plate construction include aluminum alloys, nylon, and carbon fiber. Aluminum alloys offer a blend of strength, weight, and cost-effectiveness, making them a popular choice for many skaters. Nylon plates, typically reinforced with fiberglass, provide a lighter weight alternative but may exhibit less stiffness than aluminum. Carbon fiber plates, while offering the highest strength-to-weight ratio, are generally the most expensive option. The practical implications of material choice are evident in scenarios where skaters repeatedly execute forceful crossovers or endure collisions. A plate constructed from a weaker material may flex excessively or even fracture under stress, compromising stability and potentially leading to injury.

Understanding the interplay between plate material and skate performance is essential for skaters seeking to optimize their equipment. The selection of plate material should align with the skater’s weight, skating style, and budget. While lightweight and responsive plates can enhance agility, they may not be suitable for heavier skaters or those who prioritize stability. Ultimately, the choice of plate material represents a trade-off between performance characteristics, requiring skaters to carefully consider their individual needs and preferences. Challenges associated with plate selection include assessing the material’s long-term durability and resistance to fatigue. However, the performance benefits and influence of plate material on “roller derby pixie skates” are significant to consider when buying.

5. Wheel Durometer

Wheel durometer, a measure of a wheel’s hardness, fundamentally influences the performance of specialized skating equipment used in roller derby. The durometer rating, typically expressed on the Shore A scale, dictates a wheel’s grip, roll speed, and durability. “Roller derby pixie skates,” characterized by their low-cut design and emphasis on agility, rely on carefully selected wheel durometer to optimize maneuverability and control. Softer wheels, with lower durometer ratings, provide enhanced grip, enabling skaters to execute tighter turns and maintain stability on slick surfaces. Conversely, harder wheels, with higher durometer ratings, offer increased roll speed, facilitating faster acceleration and sustained momentum. A practical example involves a jammer, attempting to break through a pack, who might opt for harder wheels to maximize speed and momentum. Blockers, on the other hand, might select softer wheels to maintain grip and stability while holding their position.

The selection of appropriate wheel durometer is further complicated by the diverse range of skating surfaces encountered in roller derby venues. Surfaces can vary significantly in terms of smoothness and grip, necessitating adjustments to wheel selection. Indoor tracks, often coated with polished concrete or sealed wood, typically require softer wheels to provide adequate grip. Outdoor surfaces, which may be rougher and less consistent, may benefit from harder wheels that can withstand wear and tear. Furthermore, skater weight and skating style also influence optimal wheel durometer. Heavier skaters may prefer harder wheels to prevent excessive compression and maintain roll speed, while lighter skaters may find softer wheels more responsive. The relationship between wheel durometer and performance is not linear; rather, it is a complex interplay of factors that requires careful consideration.

Understanding the implications of wheel durometer is paramount for skaters seeking to maximize their performance and safety. The challenges associated with wheel selection include assessing surface conditions, accommodating individual skating styles, and balancing the trade-offs between grip and roll speed. Ultimately, the optimal wheel durometer for “roller derby pixie skates” is contingent upon a multitude of variables, necessitating a personalized approach to equipment selection. However, the underlying principle remains constant: wheel durometer is a critical determinant of skate performance in roller derby.

6. Bearing Precision

Bearing precision significantly impacts the performance of specialized skating equipment, most notably affecting the roll speed and efficiency of skates commonly employed in roller derby. The precision of bearings within “roller derby pixie skates,” measured using the ABEC (Annular Bearing Engineering Committee) scale or similar ratings, correlates directly with the smoothness of rotation and minimization of friction. Higher precision bearings, characterized by tighter tolerances and superior surface finishes, facilitate faster and more effortless rolling. This enhanced efficiency translates to increased speed and reduced skater fatigue during prolonged periods of gameplay. Consider, for instance, a skater executing a long sprint; the enhanced roll provided by high-precision bearings conserves energy and allows for greater sustained velocity. The absence of precise bearings causes increased drag, which directly impedes skater performance.

The practical significance of bearing precision extends beyond mere speed enhancement. Precise bearings exhibit increased durability and longevity. Reduced friction minimizes wear and tear, extending the lifespan of the bearings and reducing the need for frequent replacements. This increased reliability is particularly critical during high-stakes competitive events, where equipment malfunctions can significantly impact the outcome. Regularly maintained, high-precision bearings consistently outperform lower-grade alternatives, offering a tangible competitive advantage. Consider the maintenance demands of a roller derby team; the consistent use of high-precision bearings translates to decreased equipment management requirements and fewer instances of performance-limiting equipment failure.

The connection between bearing precision and “roller derby pixie skates” is causative and substantive. While other components, such as wheel durometer and plate material, contribute to overall performance, bearing precision represents a critical factor affecting roll speed and energy efficiency. Challenges associated with utilizing high-precision bearings include the comparatively higher initial cost and the potential for increased sensitivity to dirt and debris. The integration of high-precision bearings represents an investment in enhanced performance, increased equipment longevity, and, subsequently, improved competitiveness within the demanding sport of roller derby.

Frequently Asked Questions

The following section addresses common inquiries regarding the specialized skating equipment often identified by the term “roller derby pixie skates”. These questions aim to provide clarity on various aspects, from design features to performance considerations.

Question 1: What distinguishes “roller derby pixie skates” from other types of roller skates?

The defining characteristic is the low-cut boot design, which offers a greater range of ankle motion, prioritizing agility. This contrasts with the higher boot profiles of figure or inline skates. The focus is on maneuverability rather than ankle support.

Question 2: Are “roller derby pixie skates” suitable for beginners?

While adaptable, the low-cut boot provides less ankle support. Novice skaters may benefit from starting with skates offering more support before transitioning. Strength and control are crucial factors.

Question 3: How does wheel durometer affect the performance of “roller derby pixie skates”?

Wheel durometer dictates grip and roll speed. Softer wheels offer greater grip, beneficial on slick surfaces, while harder wheels maximize roll speed on smoother surfaces. Optimal selection depends on skating surface and style.

Question 4: What materials are commonly used in the construction of skate plates for “roller derby pixie skates”?

Aluminum alloys, nylon, and carbon fiber are prevalent. Aluminum offers a balance of strength and weight; nylon is lighter but potentially less stiff, carbon fiber provides optimal strength-to-weight, at a higher cost.

Question 5: How important is bearing precision in “roller derby pixie skates”?

Bearing precision, measured by ABEC ratings, affects roll speed and efficiency. Higher precision minimizes friction, facilitating faster, smoother rolling. This influences energy conservation and sustained speed.

Question 6: Do “roller derby pixie skates” require specialized maintenance?

Regular maintenance is essential. Bearing cleaning and lubrication, hardware checks, and wheel replacement are crucial for optimal performance and longevity. Neglecting maintenance compromises performance and safety.

These answers offer a foundational understanding of “roller derby pixie skates”. The intricacies of skate selection and maintenance are paramount for skaters seeking optimal performance and safety.

The following section will discuss the historical development and evolution of skating equipment used in roller derby.

Conclusion

This exploration has elucidated the defining characteristics and performance implications of the specialized skating equipment referred to as “roller derby pixie skates.” The low-cut boot design, material selection, wheel durometer, and bearing precision each contribute significantly to a skater’s agility, maneuverability, and overall performance within the demanding sport of roller derby. A comprehensive understanding of these elements enables informed equipment selection and optimization for individual skating styles and competitive requirements.

Continued advancements in materials science and engineering promise further refinements in skating equipment design, potentially yielding enhanced performance characteristics and improved safety standards. Skaters are encouraged to remain informed about technological developments and prioritize informed decision-making when selecting and maintaining equipment. The future of roller derby performance will be partially shaped by the ongoing evolution of the equipment used within the sport, demanding a constant pursuit of optimized technology for maximum athletic potential.