The inherent incompatibility between a particular activity and an unsuitable environment forms the core concept. This incompatibility highlights situations where success is virtually impossible due to the surrounding conditions. For example, attempting a delicate surgery during a loud rock concert would be similarly ill-advised.

Recognizing such inherent mismatches is vital for strategic planning and risk mitigation across diverse fields. Historically, misjudging the environment has led to significant failures in military campaigns, business ventures, and even personal endeavors. Understanding environmental limitations promotes realistic goal setting and efficient resource allocation, preventing wasted effort and potential harm.

Therefore, analyzing specific conditions and identifying potential conflicts is crucial before initiating any course of action. This principle extends to various domains, including project management, resource allocation, and adaptation strategies within complex systems. Subsequent discussion will explore these areas in detail, examining how to effectively identify and address environmental constraints.

The challenge of operating in an environment inherently resistant to a specific activity requires a strategic and informed approach. The following guidelines address key considerations for mitigating risk and maximizing potential for success, even when faced with significant environmental constraints.

Tip 1: Conduct Thorough Environmental Assessments: Prior to any action, meticulously evaluate the prevailing conditions. Identify potential obstacles, resource limitations, and inherent biases that may impede progress. For example, a market analysis must precede the launch of a new product in an unfamiliar region.

Tip 2: Adapt Strategies to Minimize Conflict: Modify approaches to align more closely with the existing environment. If direct confrontation proves unproductive, consider alternative strategies such as indirect influence, gradual integration, or niche exploitation. A software company targeting a low-bandwidth area might develop a lightweight application.

Tip 3: Prioritize Realistic Expectations: Acknowledge the limitations imposed by the environment. Set achievable goals that account for the challenges and constraints inherent within the system. Overly ambitious objectives, disregarding environmental realities, will inevitably lead to failure.

Tip 4: Leverage Existing Resources Strategically: Identify and capitalize on available resources that can facilitate progress. Seek partnerships with established entities, utilize local expertise, and adapt existing infrastructure where possible. Integrating into existing supply chains can provide an advantage.

Tip 5: Implement Robust Monitoring and Feedback Mechanisms: Continuously monitor progress and adapt strategies based on real-time feedback. Implement key performance indicators (KPIs) to track relevant metrics and identify potential deviations from the intended course. This proactive approach allows for course correction and prevents escalation of negative impacts.

Tip 6: Accept the Potential for Inevitable Failure: Despite diligent planning and adaptation, some environments may remain fundamentally incompatible. Acknowledge the possibility of failure and develop contingency plans to mitigate potential losses. This acceptance allows for a more pragmatic and resilient approach.

Tip 7: Consider Alternative Environments: If adaptation proves insufficient, explore alternative environments that are more conducive to the desired activity. Relocating operations or targeting a different demographic may represent a more viable path to success. This proactive repositioning can avoid further resource depletion.

Adherence to these guidelines enhances the likelihood of navigating challenging environments effectively. It promotes informed decision-making, strategic resource allocation, and a realistic perspective on potential outcomes. Recognizing and adapting to environmental limitations is essential for achieving sustainable success.

The subsequent section will examine specific case studies that illustrate the application of these principles in diverse contexts, providing further insight into effective environmental navigation.

1. Inappropriate Activity

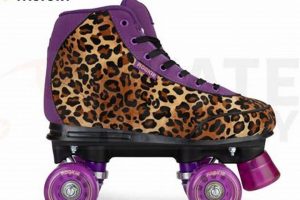

The concept of an “inappropriate activity” forms the foundational layer of the idiom “can’t roller skate in a buffalo herd.” The activity itself, roller skating, requires a smooth, stable surface for successful execution. The environment, a buffalo herd, presents precisely the opposite: uneven terrain, unpredictable movement, and a general lack of suitability. Thus, the incompatibility stems directly from the inherent nature of the activity being fundamentally at odds with the characteristics of its intended surroundings. The consequence of this mismatch is predictable failure and potential harm.

Considering this relationship, the “inappropriate activity” becomes the causative agent for the scenario’s impossibility. Numerous examples illustrate this dynamic. Conducting delicate microsurgery in a field hospital during active combat is an inappropriate activity, the chaotic environment rendering the procedure nearly impossible. Similarly, attempting to implement a complex, high-tech solution in a community lacking basic infrastructure represents an inappropriate activity, doomed by the absence of supporting resources. These examples highlight how the selection of an activity, without due consideration for its environmental fit, creates an insurmountable obstacle.

Understanding this interplay is practically significant for project planning and risk assessment. Thoroughly evaluating the environment’s compatibility with the proposed activity prevents wasted resources and increases the likelihood of success. This requires a shift in focus from simply choosing a desired action to critically assessing whether the conditions support its effective implementation. By acknowledging the potential for “inappropriate activities,” stakeholders can proactively mitigate risks and pursue more realistic, sustainable solutions. The challenge lies in accurately assessing environmental factors and honestly evaluating the suitability of proposed actions.

2. Conflicting Environment

A “conflicting environment” directly embodies the obstacle presented in the concept “can’t roller skate in a buffalo herd.” The buffalo herd, with its unpredictable movement, uneven terrain, and sheer density of large animals, constitutes an environment fundamentally hostile to roller skating. This hostility manifests as an inability to perform the activity safely or effectively. The conflicting nature of the environment is not merely an inconvenience; it is the defining characteristic that renders the situation inherently unworkable. The cause-and-effect relationship is clear: the environment’s incompatibility prevents the successful execution of the activity. Ignoring this conflict leads to predictable failure, and potentially, physical harm to the roller skater.

The importance of recognizing the “conflicting environment” lies in its predictive power. Assessing the environment before undertaking any action can prevent wasted effort and potential setbacks. Consider a business launching a product that requires reliable internet connectivity in an area with limited or unstable access. The lack of infrastructure constitutes a “conflicting environment,” rendering the product largely unusable and the venture potentially unprofitable. Similarly, implementing a standardized educational curriculum in a culturally diverse classroom, without adapting to the specific needs of each student, creates a “conflicting environment” that hinders learning outcomes. The core point is that failure is predictable when an activity is attempted within an environment ill-suited to support it.

Understanding the implications of a “conflicting environment” enables proactive decision-making. Thorough environmental assessments, strategic adaptation, and realistic goal setting become paramount. Challenges arise in accurately predicting environmental factors and honestly evaluating their impact on the proposed activity. However, by acknowledging the potential for conflict and adjusting strategies accordingly, stakeholders can mitigate risks and increase the probability of success. This perspective highlights the value of foresight and the need to prioritize environmental compatibility over preconceived notions or desired outcomes, ensuring a more realistic and sustainable approach to any endeavor.

3. Resource Misallocation

Resource misallocation directly exacerbates the futility inherent in the concept of “can’t roller skate in a buffalo herd.” Attempting to engage in roller skating amidst a buffalo herd represents a fundamental misallocation of effort, time, and potentially, physical resources. The energy expended in trying to maintain balance and navigate the treacherous terrain yields minimal progress and carries a high risk of injury. These resources would be more effectively deployed in a more suitable environment. The situation highlights a broader principle: dedicating resources to an inherently unachievable goal is a wasteful and ultimately counterproductive endeavor. The misallocation arises from a failure to accurately assess the environment and adapt actions accordingly.

The significance of recognizing resource misallocation lies in its potential to inform strategic decision-making. Consider a company investing heavily in a marketing campaign targeting a demographic demonstrably uninterested in the product. The resources dedicated to this campaign represent a clear misallocation, diverting funds from potentially more receptive audiences. Similarly, a government allocating significant funding to a public transportation project in a sparsely populated area with limited demand demonstrates a misallocation of public funds. Recognizing these patterns allows for proactive intervention, redirecting resources toward more productive avenues. The challenge lies in identifying and quantifying the inefficiencies inherent in resource allocation strategies, requiring careful analysis of both the environment and the intended outcomes.

Addressing resource misallocation necessitates a shift towards evidence-based decision-making and rigorous evaluation of resource allocation strategies. Implementing robust monitoring systems, conducting thorough cost-benefit analyses, and fostering a culture of adaptability are essential steps. The ability to accurately assess the suitability of an environment for a given activity, and to allocate resources accordingly, is crucial for maximizing efficiency and achieving sustainable success. Ultimately, avoiding the trap of resource misallocation requires a commitment to rational resource management and a willingness to adapt strategies based on empirical data, preventing the wasteful pursuit of inherently unachievable goals.

4. Unrealistic Expectations

The futility described by “can’t roller skate in a buffalo herd” is often rooted in unrealistic expectations. This phrase highlights a mismatch between desired outcomes and the limitations imposed by the surrounding environment, a discrepancy arising from an overestimation of capability and an underestimation of contextual constraints. The subsequent points elaborate on specific aspects of this disconnect.

- Ignoring Environmental Constraints

Setting expectations without considering the inherent limitations of the environment leads to inevitable disappointment. Expecting to successfully implement a complex technology solution in an area lacking the necessary infrastructure, for example, demonstrates a disregard for environmental realities. This disconnect creates a foundation for failure, rendering even the most meticulously planned efforts ineffective.

- Overestimating Personal or Team Capabilities

An inflated sense of skill or competence contributes significantly to unrealistic expectations. Believing that personal or team abilities can overcome insurmountable environmental obstacles is a common pitfall. This overconfidence often results in underpreparedness and a failure to adapt strategies to the actual demands of the situation. The result is often costly, both in terms of resources and time.

- Failing to Account for Unforeseen Circumstances

Unrealistic expectations frequently stem from a failure to anticipate potential challenges and setbacks. Assuming a smooth and predictable progression, without acknowledging the possibility of unforeseen circumstances, is a recipe for disaster. This lack of contingency planning leaves individuals and organizations vulnerable to unexpected disruptions, derailing even the most promising endeavors.

- Ignoring Historical Data and Precedents

Setting expectations in isolation, without considering relevant historical data or past experiences, often leads to inaccurate assessments of feasibility. Ignoring precedents and failing to learn from past mistakes creates a cycle of repeated failures. Analyzing previous attempts, both successful and unsuccessful, provides valuable insights for establishing more realistic and attainable goals.

The interconnectedness of these elements emphasizes the importance of grounded, data-driven planning. By acknowledging environmental constraints, accurately assessing capabilities, anticipating unforeseen circumstances, and learning from historical precedents, individuals and organizations can mitigate the risk of setting unrealistic expectations and increase the likelihood of achieving desired outcomes. Recognizing the limitations of a situation, much like the impracticality of roller skating among buffalo, promotes a more pragmatic and sustainable approach to goal setting and execution.

5. Ineffective Adaptation

The scenario depicted in “can’t roller skate in a buffalo herd” is fundamentally exacerbated by ineffective adaptation. It is not merely the initial mismatch between activity and environment that leads to failure, but the inability to meaningfully adjust strategies in response to that mismatch. The assumption that standard roller skating techniques, equipment, or mindset can be applied successfully within a chaotic and unpredictable buffalo herd represents a critical oversight. This inflexibility demonstrates a failure to recognize the need for modified approaches, thus cementing the impossibility of the task.

The importance of effective adaptation is highlighted by considering alternative scenarios. Perhaps the roller skater attempts to use specialized equipment designed for uneven terrain, or employs a strategy focused on minimizing risk and maintaining stability rather than achieving speed or performance. While success may still be unlikely, these adaptive measures represent a significant departure from the rigid adherence to unsuitable methods. Ineffective adaptation, therefore, transforms a challenging situation into an inherently futile one. For example, a business entering a new market with a pre-defined product and marketing strategy, failing to adapt to local preferences or cultural nuances, will likely experience the same outcome. The initial mismatch is compounded by the refusal or inability to modify the approach based on feedback.

Understanding the link between ineffective adaptation and the buffalo herd principle has practical significance. It underscores the need for agility, flexibility, and a willingness to abandon preconceived notions in the face of overwhelming environmental constraints. Implementing robust feedback mechanisms, fostering a culture of experimentation, and prioritizing adaptability in strategic planning are essential steps for mitigating the risks associated with mismatched environments. Acknowledging that even the most well-planned strategies may require significant adjustments in response to unforeseen circumstances is crucial for navigating complex and challenging situations. Ultimately, effective adaptation, even if it cannot guarantee success, at least offers a chance to mitigate the inherent impossibility of the task, turning the initial problem into a manageable challenge.

Frequently Asked Questions

This section addresses common inquiries regarding the application of the concept embodied by “can’t roller skate in a buffalo herd,” focusing on its relevance to strategic decision-making and environmental assessment.

Question 1: What constitutes a ‘conflicting environment’ in practical terms?

A conflicting environment represents any set of conditions that fundamentally impede the success of a specific activity. This could involve physical barriers, resource limitations, cultural incompatibilities, or even regulatory constraints. The key characteristic is an inherent resistance to the intended outcome, making success highly improbable.

Question 2: How can organizations effectively assess the suitability of an environment before initiating a project?

A comprehensive environmental assessment should be conducted, encompassing both internal and external factors. This assessment should include a thorough analysis of available resources, potential obstacles, regulatory frameworks, and competitive landscapes. The goal is to identify potential conflicts early in the planning process, enabling proactive adaptation or the selection of alternative environments.

Question 3: Is adaptation always possible, or are some situations inherently untenable?

While adaptation is often crucial, some situations are inherently untenable. When the fundamental characteristics of an environment are fundamentally incompatible with the requirements of an activity, adaptation alone may not suffice. Recognizing these limitations is essential for preventing wasted resources and potential setbacks.

Question 4: How does resource misallocation contribute to failure in mismatched environments?

Resource misallocation occurs when resources are directed towards an activity that is demonstrably unlikely to succeed due to environmental constraints. This wasteful deployment of resources diverts them from potentially more productive avenues, exacerbating the negative impact of the initial mismatch.

Question 5: What strategies can be implemented to mitigate the risks associated with unrealistic expectations?

Mitigating unrealistic expectations requires a grounded approach to goal setting, based on realistic assessments of both capabilities and environmental constraints. Implementing robust monitoring systems, conducting thorough cost-benefit analyses, and learning from historical precedents are essential steps.

Question 6: How does understanding this concept improve decision-making in complex situations?

Understanding the principles underlying the concept allows for a more pragmatic and informed approach to decision-making. By recognizing the potential for incompatibility between activities and environments, stakeholders can proactively mitigate risks, allocate resources more effectively, and pursue more sustainable strategies.

In summary, recognizing and addressing potential conflicts between activities and environments is crucial for effective strategic planning and risk management. A proactive approach, grounded in thorough environmental assessments and realistic expectations, can significantly improve the likelihood of achieving desired outcomes.

The subsequent section explores specific case studies that illustrate the practical application of these principles across diverse contexts.

Synthesis

The exploration of the inherent incompatibility represented by the phrase “can’t roller skate in a buffalo herd” reveals a fundamental principle applicable across diverse domains. From strategic planning to resource allocation, recognizing the potential for conflict between activities and environments is paramount. This analysis underscores the importance of thorough environmental assessments, realistic expectations, and adaptive strategies, highlighting the need to avoid resource misallocation and acknowledge the limitations imposed by context. Failure to do so results in predictable setbacks and the inefficient deployment of resources.

Therefore, a continued focus on environmental awareness and adaptable strategies is crucial for navigating complex challenges. Integrating this understanding into decision-making processes enables stakeholders to mitigate risks, enhance efficiency, and pursue more sustainable outcomes. The principles embodied by the buffalo herd serve as a constant reminder of the critical interplay between action and environment.