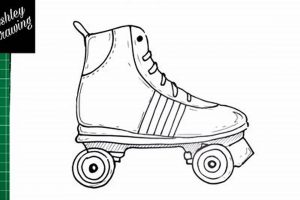

These elongated, typically braided or woven components are employed to secure the foot within the boot of roller skates. Functioning similarly to shoelaces, they pass through eyelets or loops, allowing the skater to adjust tightness for a secure and comfortable fit. The materials used in their construction often include nylon, polyester, or a blend, chosen for durability and resistance to abrasion.

Properly fastened, these components contribute significantly to the skater’s control and stability, mitigating the risk of ankle injury and enhancing overall performance. Historically, variations have existed, ranging from simple leather thongs to the advanced synthetic materials prevalent today. The evolution reflects an ongoing pursuit of enhanced functionality and longevity.

The subsequent sections will delve into the various types available, the optimal methods for lacing and maintaining them, and the factors to consider when selecting replacements to ensure optimal skating experience.

Roller Skate Strings

Effective utilization of these components is critical for both safety and performance. Neglecting their upkeep or employing improper lacing techniques can diminish the skating experience and increase the likelihood of injury.

Tip 1: Consistent Inspection: Routinely examine these items for signs of wear, such as fraying, cuts, or excessive stretching. Early detection allows for timely replacement, preventing potential breakage during use.

Tip 2: Optimal Tension: Achieve a balance between secure foot retention and unrestricted circulation. Overly tight components can cause discomfort and numbness, while excessively loose ones compromise stability.

Tip 3: Proper Lacing Technique: Employ a lacing pattern that distributes pressure evenly across the foot. Experiment with different techniques, such as parallel or criss-cross lacing, to identify the method that provides the best fit and support.

Tip 4: Knot Security: Ensure the knot is securely tied and positioned to prevent slippage. A square knot (also known as a reef knot) is generally recommended for its reliability.

Tip 5: Material Selection: Consider the material properties when choosing replacements. Nylon and polyester offer a balance of durability and abrasion resistance, while waxed options can provide added grip and prevent loosening.

Tip 6: Regular Cleaning: Periodically clean them to remove dirt and debris that can accelerate wear. Gentle hand washing with mild soap and water is typically sufficient.

Tip 7: Length Considerations: Select the appropriate length for the skate boot. Excessively long lengths can create tripping hazards, while lengths that are too short may not allow for adequate tightening.

Adhering to these guidelines ensures prolonged lifespan, enhanced performance, and a safer skating experience. Consistent attention to these details contributes to a more enjoyable and controlled activity.

The concluding sections will address advanced techniques and further resources for maximizing the benefits derived from properly maintained and optimized skates.

1. Material durability

Material durability constitutes a critical factor in the overall performance and longevity of these components. The composition of the materials directly influences their resistance to abrasion, tensile strength, and susceptibility to environmental degradation. Selection of appropriate materials ensures sustained functionality under the stresses inherent in roller skating.

- Tensile Strength and Break Resistance

High tensile strength is paramount to prevent breakage under tension. Materials with superior tensile strength, such as high-tenacity nylon or specialized polyester blends, resist elongation and snapping during vigorous skating maneuvers. Break resistance is also key for reducing the risk of sudden failure, which can lead to instability and potential injury.

- Abrasion Resistance

These components are subjected to constant friction against the eyelets of the skate boot and through repeated tying and untying. Materials with high abrasion resistance, such as tightly woven synthetics, minimize wear and tear, extending the lifespan. Lower-quality materials are prone to fraying and premature failure.

- Environmental Degradation Resistance

Exposure to moisture, UV radiation, and temperature fluctuations can compromise material integrity. Materials treated with UV inhibitors or those naturally resistant to hydrolysis (water damage) maintain their strength and flexibility over time, regardless of environmental conditions. Untreated materials may become brittle or weakened, increasing the risk of breakage.

- Material Flexibility and Knot Retention

Material flexibility affects the ease of tightening and knot security. Materials that are too stiff may be difficult to tie tightly and may loosen easily. Materials that are too pliable may stretch excessively. A balance between flexibility and rigidity ensures that the knots remain secure throughout the skating session, providing consistent support and stability.

The selection of durable materials contributes significantly to the reliability and safety of skating equipment. While cost may influence material choices, prioritizing durability ensures long-term performance and reduces the need for frequent replacements, ultimately providing a more cost-effective and safer skating experience.

2. Lacing patterns

The configuration in which these components are threaded through the eyelets of roller skate boots, significantly impacts foot support, comfort, and overall skating performance. Varied configurations address diverse needs, accommodating different foot shapes, skating styles, and desired levels of ankle flexibility.

- Parallel Lacing (Ladder Lacing)

Characterized by parallel lines running directly across the boot, this pattern distributes pressure evenly, minimizing friction points. Often favored for skaters seeking a comfortable and secure fit without excessive tightness, it is commonly employed in recreational skating. A practical example involves skaters with wider feet who benefit from the even pressure distribution, preventing localized discomfort.

- Criss-Cross Lacing

This pattern involves diagonally crossing the components from one eyelet to the opposite side, creating a secure and supportive fit. It is well-suited for skaters requiring enhanced ankle stability, particularly in disciplines such as roller derby or aggressive skating. The interlaced design provides robust support during lateral movements, reducing the risk of ankle roll and injury.

- Over-Under Lacing

Alternating the passage of components over and under each eyelet creates a balance between support and flexibility. This technique allows for localized adjustments in tension, accommodating specific areas of the foot that may require more or less support. An illustrative case is a skater with a high instep who may loosen the strings in that area to alleviate pressure while maintaining overall tightness elsewhere.

- Skipping Eyelets (Zone Lacing)

Strategically skipping eyelets in specific regions of the boot allows for customized fit and enhanced flexibility. This technique is frequently employed to address pressure points or to provide greater range of motion in the ankle. For example, a skater experiencing discomfort on the top of the foot may skip the corresponding eyelets to reduce pressure and improve comfort without sacrificing overall support.

The selection of a suitable lacing pattern is integral to optimizing the fit and performance of roller skates. By understanding the characteristics and implications of various configurations, skaters can tailor the fit to their individual needs and skating style, enhancing comfort, stability, and overall control.

3. Optimal tension

The concept of optimal tension, as it relates to roller skate strings, represents a critical balance between secure foot containment and unrestricted circulation. The applied force, dictated by the tightness of these components, directly influences the skater’s control, comfort, and risk of injury. Insufficient tension compromises stability, increasing the likelihood of ankle sprains and diminished maneuverability. Conversely, excessive tension restricts blood flow, potentially causing numbness, discomfort, and long-term circulatory issues. Therefore, achieving an ideal level of tightness is paramount for maximizing performance and minimizing adverse effects.

Real-world examples illustrate the significance of this balance. A speed skater, for instance, may require a tighter fit to ensure immediate responsiveness and precise control during high-velocity turns. However, extended periods of such tightness can lead to foot fatigue and reduced endurance. Recreational skaters, on the other hand, typically benefit from a more relaxed tension, prioritizing comfort over maximum responsiveness. The selection of lacing patterns, knot placement, and component material directly contributes to the ability to achieve and maintain optimal tension. Proper technique ensures that the applied force is distributed evenly across the foot, preventing localized pressure points and promoting consistent support.

In summary, optimal tension in roller skate strings is not a static value but rather a dynamic adjustment based on individual anatomy, skating style, and duration of use. Regular assessment of fit and adjustments as needed are essential for ensuring both performance and safety. Failure to address these considerations can result in diminished skating experiences and heightened risk of injury, underscoring the importance of understanding and applying appropriate tension management techniques.

4. Knot Security

The reliability of knots tied in roller skate strings directly influences skater safety and performance. A compromised knot can lead to loosening, diminished support, and potential injury, highlighting the necessity for secure and dependable knotting techniques.

- Square Knot (Reef Knot) Stability

The square knot, recognized for its balance and stability when correctly tied, serves as a foundational knot for securing roller skate strings. When improperly tied, it can transform into a granny knot, prone to slippage and instability. Ensuring proper executionright over left, then left over rightis crucial. Its stability is particularly important in preventing unexpected loosening during dynamic skating maneuvers, where rapid changes in direction and force are common.

- Friction and Material Influence

The material composition of roller skate strings impacts knot security. Slick synthetic materials, such as nylon or polyester, possess inherently lower friction coefficients compared to natural fibers. This necessitates the use of tighter knots and potentially the addition of friction-enhancing techniques, such as overhand loops or binding hitches, to prevent slippage. Waxed strings address this issue by increasing friction, thus improving knot retention.

- Knot Placement and Load Distribution

Positioning the knot strategically on the tongue of the skate boot minimizes pressure points and reduces the likelihood of the knot being subjected to external forces. Centering the knot prevents uneven load distribution, which can lead to premature wear on the strings or discomfort for the skater. Careful knot placement contributes to both comfort and longevity.

- Periodic Inspection and Retightening

Even with secure knotting techniques, roller skate strings are subject to dynamic stress and environmental factors that can gradually compromise knot integrity. Regular inspection of the knot for signs of loosening or fraying is imperative. Retightening the knot before each skating session maintains optimal support and reduces the risk of sudden failure. Neglecting this routine can lead to instability and potential falls.

The facets of knot security collectively emphasize the need for a proactive approach to maintaining roller skate strings. By understanding the interplay between knot type, material properties, knot placement, and periodic inspection, skaters can significantly enhance their safety and performance on the rink.

5. Regular Maintenance

The sustained performance and safety of roller skates hinge significantly on regular maintenance procedures, particularly regarding the condition of the strings. These seemingly simple components are subject to considerable stress and wear during skating, necessitating vigilant upkeep to prevent failure and ensure optimal functionality.

- Fraying and Abrasion Inspection

Consistent inspection for fraying and abrasion is essential for identifying compromised strings. Regular use causes friction against the skate boot’s eyelets, leading to wear over time. Early detection of these issues allows for timely replacement, preventing potential breakage during a skating session, which can result in instability and injury. A practical example includes examining the strings after each use, paying particular attention to areas where the strings contact the eyelets or the knot.

- Cleaning and Debris Removal

Accumulated dirt, grime, and debris can accelerate the deterioration of roller skate strings. Regular cleaning removes these contaminants, preserving the material’s integrity and preventing premature wear. Gentle hand washing with mild soap and water, followed by thorough drying, is generally sufficient. Skaters who frequently use their skates outdoors should prioritize this aspect of maintenance due to increased exposure to environmental elements. This simple procedure extends the lifespan of the strings and maintains their functional capacity.

- Tension Adjustment and Knot Security

Optimal tension is crucial for secure foot containment and effective skating performance. Regular maintenance includes verifying and adjusting the tension of the strings before each use. Additionally, ensuring knot security prevents loosening during activity, which can compromise stability and control. Re-tying knots that exhibit signs of wear or slippage is essential. Skaters should also evaluate the effectiveness of the knot type being used, considering alternatives if slippage is a recurring issue.

- Timely Replacement Strategies

Despite diligent maintenance, roller skate strings inevitably degrade over time. Establishing a proactive replacement strategy is vital for preventing unexpected failures. A visual inspection of wear, even after cleaning, should be considered. The frequency of replacement depends on the intensity and frequency of skating, as well as the quality of the strings. However, it is recommended to replace the strings every few months with frequent use.

These maintenance facets, collectively, ensure that roller skate strings remain in optimal condition. Consistent application of these practices extends the strings’ lifespan, maximizes skating performance, and minimizes the risk of injury. Such attention to detail underscores a commitment to safety and responsible equipment management within the context of roller skating.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, maintenance, and utilization of these components, aiming to provide clear and concise information to enhance the skating experience.

Question 1: How often should roller skate strings be replaced?

The frequency of replacement is contingent upon skating frequency, intensity, and environmental conditions. Strings exhibiting fraying, cuts, or significant wear should be replaced immediately. As a general guideline, replacement every 3-6 months is advisable for regular skaters.

Question 2: What materials are best suited for roller skate strings?

Nylon and polyester are common choices due to their balance of durability, abrasion resistance, and tensile strength. Waxed strings can enhance grip and prevent loosening. The optimal material depends on individual skating needs and preferences.

Question 3: What is the correct method for cleaning roller skate strings?

Gentle hand washing with mild soap and water is generally sufficient. Abrasive cleaners should be avoided. Thorough drying after washing is essential to prevent material degradation.

Question 4: What lacing pattern is recommended for optimal ankle support?

Criss-cross lacing is often favored for enhanced ankle stability. This pattern provides a secure and supportive fit, minimizing the risk of ankle roll during dynamic movements. Experimentation with various patterns is encouraged to determine the most suitable option for individual needs.

Question 5: How tight should roller skate strings be fastened?

The tension should be sufficient to provide secure foot containment without restricting circulation. Excessive tightness can cause discomfort and numbness. Achieving a balance between support and comfort is paramount.

Question 6: Can damaged roller skate strings be repaired?

While minor fraying may be addressed with temporary measures, such as trimming, damaged strings should be replaced entirely. Attempting to repair compromised strings can compromise safety and is not recommended.

The information provided in this FAQ section aims to clarify common concerns and misconceptions regarding roller skate strings. Adherence to these guidelines promotes both safety and performance on the rink.

The subsequent section will delve into resources for sourcing high-quality roller skate strings and related accessories.

Conclusion

This article has explored various facets of roller skate strings, including material composition, lacing techniques, tension management, knot security, and maintenance protocols. Proper understanding and application of these concepts are essential for optimizing performance, ensuring safety, and prolonging the lifespan of skating equipment. Neglecting these fundamental aspects can lead to compromised stability, increased risk of injury, and diminished skating experiences.

Therefore, informed selection, meticulous maintenance, and diligent application of appropriate techniques concerning roller skate strings represent a fundamental responsibility for all skaters. Continuous learning and adaptation to individual needs remain paramount for maximizing the benefits derived from this crucial component and fostering a safer, more enjoyable skating environment.