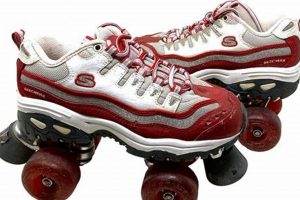

Equipment designed for skating activities but built with enhanced durability and strength constitutes a specific category within the broader recreational equipment market. These items often incorporate robust materials and reinforced construction to withstand rigorous use. A practical application is seen in environments like roller derby or aggressive skating, where standard equipment may quickly degrade under the stress of frequent impacts and demanding maneuvers.

The incorporation of resilient components offers users increased safety margins and longevity of the product. Historically, such reinforced designs have evolved in response to the needs of skaters who push the boundaries of the sport, requiring gear that can keep pace with their skill and intensity. The enhanced resilience also benefits individuals who prioritize long-term value and reliability in their recreational investments.

The following sections will delve into the specific features, construction techniques, and target applications of this robust skating equipment. Key considerations will include frame materials, wheel composition, bearing quality, and closure systems, alongside their implications for performance and safety.

Guidance on Selecting Durable Skating Equipment

The selection of appropriate skating equipment, particularly for demanding applications, necessitates careful consideration of several key factors. Optimal performance and safety hinge on informed choices that align with the intended usage and individual skill level.

Tip 1: Frame Material: Scrutinize the frame material. Extruded aluminum frames offer superior strength and impact resistance compared to plastic or composite alternatives. Inspect for reinforced stress points, particularly around mounting hardware.

Tip 2: Wheel Durometer: Assess the wheel durometer rating. Lower durometer wheels provide increased grip and shock absorption, beneficial for uneven surfaces or aggressive maneuvers. Higher durometer wheels prioritize speed and roll efficiency on smoother surfaces.

Tip 3: Bearing Quality: Evaluate bearing ABEC ratings. Higher ABEC ratings indicate tighter tolerances and smoother rotation, contributing to enhanced speed and reduced friction. Regular maintenance, including cleaning and lubrication, is crucial for bearing longevity.

Tip 4: Closure System Integrity: Examine the closure system. Secure and adjustable closures, such as ratcheting buckles and power straps, provide enhanced ankle support and stability. Ensure the system distributes pressure evenly to avoid discomfort or pressure points.

Tip 5: Boot Construction: Consider the boot construction. Reinforced ankle support and durable outer materials contribute to overall stability and protection. Seek out boots with adequate padding to minimize impact forces.

Tip 6: Axle Material and Design: Investigate the axle material. Steel axles offer superior strength compared to aluminum alternatives. Recessed or countersunk axle designs minimize the risk of snagging or interference.

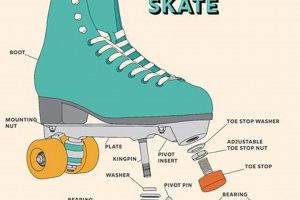

Tip 7: Toe Stop/Block Design: If applicable, analyze the toe stop or block design. Adjustable toe stops offer customizable braking and control. Durable, non-marking materials are essential for preventing damage to skating surfaces.

Adherence to these guidelines enhances the likelihood of selecting skating equipment that provides both sustained performance and reliable protection in demanding environments. Thoughtful assessment of materials, construction, and features ensures that the investment aligns with the intended use and skill level.

The concluding section will summarize the key aspects of maintaining and prolonging the lifespan of such equipment, emphasizing preventative measures and best practices for optimal performance.

1. Reinforced Frame Integrity

Reinforced frame integrity is a paramount design consideration in the manufacturing of equipment intended for rigorous usage. It directly influences the load-bearing capacity, stability, and overall lifespan of the device, rendering it a crucial element in the context of demanding applications. This structural reinforcement ensures that the device can withstand the stresses and impacts associated with intense usage scenarios.

- Material Selection and Properties

Frame reinforcement often involves the strategic selection of materials with high tensile strength and resistance to deformation. Alloys of aluminum or steel, heat-treated for enhanced hardness, are common choices. The material’s ability to absorb and dissipate energy upon impact is critical in preventing catastrophic failure and maintaining structural stability under stress.

- Geometric Design and Load Distribution

Frame geometry plays a vital role in distributing stress effectively. Reinforcement may include strategically placed ribs, gussets, or cross-members to redirect forces away from vulnerable areas. Finite element analysis (FEA) is frequently employed to optimize the frame’s design, ensuring that load is distributed evenly across the structure, minimizing localized stress concentrations that could lead to cracking or bending.

- Welding and Joining Techniques

The integrity of joints and welds is essential for maintaining overall structural strength. Advanced welding techniques, such as TIG welding or laser welding, are often employed to create strong, durable bonds between frame components. Quality control measures, including non-destructive testing (NDT), are implemented to ensure weld integrity and detect any flaws that could compromise the frame’s strength.

- Impact Resistance and Energy Absorption

Beyond static strength, frames must also possess adequate impact resistance to withstand sudden shocks and collisions. Reinforcement strategies may incorporate energy-absorbing materials or design features, such as crumple zones or flexible elements, that dissipate kinetic energy upon impact. This enhances safety by reducing the transmission of forces to the user and preventing structural damage.

These considerations collectively contribute to creating a structurally sound frame capable of withstanding the demands of rigorous activity. The integration of high-strength materials, optimized geometric designs, robust welding techniques, and effective impact resistance mechanisms ensures that the frame can provide the necessary stability, support, and protection under demanding conditions.

2. High-Durometer Wheel Material

The selection of high-durometer wheel material constitutes a critical design parameter influencing performance and longevity. Such materials are particularly relevant in applications requiring sustained speed and resistance to wear, features often sought in heavy-duty skating equipment.

- Reduced Rolling Resistance

Higher durometer compounds, typically ranging from 85A to 101A on the Shore A scale, exhibit decreased rolling resistance compared to softer materials. This characteristic translates to greater efficiency in energy transfer, allowing for enhanced speed and prolonged gliding distances. Consider applications such as speed skating or distance skating, where minimizing energy expenditure is paramount.

- Increased Wear Resistance

High-durometer materials possess inherent resistance to abrasion and deformation. The selection of such materials extends the lifespan of the wheel, particularly under conditions of frequent use or abrasive surfaces. For example, skaters performing frequent slides or skating on rough asphalt would benefit from the increased durability offered by high-durometer wheels.

- Enhanced Grip on Smooth Surfaces

While often perceived as less grippy, high-durometer wheels provide adequate traction on clean, smooth surfaces. The reduced deformation under load maintains a consistent contact patch, promoting predictable handling and control. Indoor skating rinks and polished concrete surfaces represent environments where high-durometer wheels can offer optimal performance.

- Reduced Deformation Under Load

High-durometer compounds exhibit minimal deformation under applied weight or impact forces. This characteristic contributes to improved stability and responsiveness, particularly at higher speeds. This is a crucial factor for heavier skaters or those performing jumps and landings, as it prevents the wheels from compressing excessively and compromising stability.

The strategic implementation of high-durometer wheel material directly addresses the performance and durability demands associated with heavy-duty skating equipment. The reduced rolling resistance, increased wear resistance, sufficient grip on smooth surfaces, and minimal deformation under load collectively contribute to enhanced speed, longevity, and control in demanding skating environments.

3. Precision Bearing Assemblies

The integration of precision bearing assemblies constitutes a critical factor influencing the overall performance and reliability of equipment designed for strenuous use. Specifically, in the context of robust skating equipment, the bearing assembly quality directly impacts speed, efficiency, and the ability to withstand substantial loads and impacts.

- Reduced Friction and Enhanced Speed

Precision bearings, characterized by tight tolerances and highly polished surfaces, minimize frictional losses during rotation. This reduction in friction translates directly into increased speed and reduced energy expenditure for the user. Consider the example of a skater covering long distances or participating in speed-oriented activities; the advantages of precision bearings become readily apparent.

- Load Distribution and Durability

The internal components of precision bearings, including the ball bearings, retainers, and races, are engineered to distribute applied loads evenly. This uniform load distribution minimizes stress concentrations and contributes to increased bearing lifespan. In equipment subjected to frequent impacts or heavy loads, such as that used in aggressive skating or roller derby, robust bearing assemblies are essential for preventing premature failure.

- Material Selection and Corrosion Resistance

Precision bearing assemblies frequently incorporate high-grade materials, such as hardened steel or ceramic composites, to enhance durability and corrosion resistance. These materials maintain their structural integrity even under demanding conditions, such as exposure to moisture or debris. The selection of appropriate materials ensures reliable performance and minimizes the need for frequent maintenance or replacement.

- Sealing and Contamination Prevention

Effective sealing mechanisms are integral to precision bearing assemblies, preventing the ingress of contaminants such as dirt, dust, and moisture. These contaminants can significantly increase friction and accelerate bearing wear. High-quality seals maintain lubrication and protect internal components, ensuring consistent performance and extending the bearing’s service life.

The aforementioned facets illustrate the critical role of precision bearing assemblies in enhancing the performance and durability of equipment intended for rigorous use. By minimizing friction, distributing loads effectively, incorporating durable materials, and preventing contamination, these assemblies contribute significantly to the overall efficiency and reliability of heavy-duty skating equipment, ensuring a safer and more enjoyable experience for the user.

4. Durable Boot Construction

The structural integrity of skating equipment is fundamentally contingent upon the durability of its boot construction. In the context of equipment designed for strenuous use, the boot serves as the primary interface between the user and the apparatus, directly influencing stability, control, and protection. The following details elucidate key facets of boot construction relevant to this equipment type.

- Reinforced Ankle Support

Ankle support is paramount in mitigating the risk of injury during intense activity. Reinforced materials, such as rigid polymers or composite laminates, provide lateral stability and prevent excessive ankle flexion or extension. For instance, skaters engaged in aggressive maneuvers or high-impact landings rely on robust ankle support to maintain balance and avoid sprains or fractures. The absence of adequate support compromises control and increases the likelihood of injury.

- Abrasion-Resistant Outer Materials

The external surface of the boot is subjected to considerable wear and tear, particularly in environments involving abrasive surfaces. Durable outer materials, such as ballistic nylon or reinforced leather, resist abrasion and protect the underlying boot structure from damage. Abrasions can compromise the structural integrity of the boot, leading to premature failure and reduced performance. Skaters who frequently engage in outdoor activities or encounter rough surfaces require boots constructed from highly abrasion-resistant materials.

- Impact-Absorbing Padding

Impact-absorbing padding is strategically integrated into the boot design to mitigate the transmission of forces to the foot and ankle. Materials such as closed-cell foam or gel inserts provide cushioning and reduce the risk of contusions or stress fractures. Skaters performing jumps, landings, or navigating uneven terrain benefit from effective impact absorption. Padding density and placement are critical factors in optimizing comfort and protection.

- Secure Closure Systems

The boot’s closure system plays a vital role in ensuring a secure and customized fit. Ratcheting buckles, power straps, and lacing systems provide adjustable tension and prevent slippage during activity. A secure closure system enhances stability, control, and responsiveness. Boots with inadequate closure systems can lead to instability and increase the risk of injury. Properly functioning closures are essential for maximizing performance and minimizing discomfort.

The aforementioned elements underscore the significance of durable boot construction in equipment engineered for demanding applications. Reinforced ankle support, abrasion-resistant outer materials, impact-absorbing padding, and secure closure systems collectively contribute to enhanced stability, protection, and control. Neglecting these aspects compromises the equipment’s performance and increases the risk of user injury. The selection of appropriate boot construction materials and design features is therefore essential in maximizing the equipment’s functionality and ensuring user safety.

5. Secure Closure Systems

Secure closure systems are a critical component in the design and functionality of heavy duty roller skates, impacting safety, performance, and overall user experience. These systems ensure a snug and stable fit, preventing slippage and maintaining control during demanding activities.

- Ankle Stability and Injury Prevention

Robust closure mechanisms provide essential ankle support, mitigating the risk of sprains or fractures during high-impact maneuvers. For instance, skaters engaged in aggressive skating or roller derby require closure systems that firmly secure the ankle, preventing excessive lateral movement and enhancing stability during quick turns and landings. A well-designed system minimizes the potential for injury, allowing skaters to confidently execute challenging techniques.

- Enhanced Power Transfer and Responsiveness

A secure fit maximizes power transfer from the skater’s foot to the skate, improving responsiveness and control. Closure systems that evenly distribute pressure across the foot eliminate dead space and ensure a direct connection between the skater and the equipment. This is particularly crucial for speed skating and other disciplines that require precise control and efficient energy transmission. A secure closure system allows for quicker reactions and more controlled movements.

- Customizable Fit and Comfort

Advanced closure systems often incorporate adjustable features, allowing skaters to customize the fit to their individual foot shape and preferences. Ratcheting buckles, power straps, and lacing systems enable precise adjustments, ensuring a comfortable and secure fit that minimizes pressure points and hotspots. This is especially important for extended skating sessions, where discomfort can compromise performance and increase the risk of blisters or other foot-related issues. A personalized fit enhances comfort and allows skaters to focus on their performance without distractions.

- Durability and Reliability

Heavy-duty skating applications demand closure systems that can withstand significant stress and wear. High-quality materials and robust construction are essential for ensuring long-term reliability and preventing premature failure. Metal buckles, reinforced straps, and durable laces contribute to the overall lifespan of the closure system, providing skaters with consistent performance and peace of mind. A durable closure system is a worthwhile investment, ensuring continued safety and performance over time.

The integration of secure closure systems in heavy duty roller skates is essential for optimizing performance, enhancing safety, and maximizing user satisfaction. These systems provide the necessary support, stability, and adjustability to meet the demands of rigorous skating activities. The selection of a high-quality closure system is a critical factor in ensuring a positive and rewarding skating experience.

6. Impact-Resistant Components

In the realm of heavy duty roller skates, the integration of impact-resistant components is not merely an enhancement; it is a foundational requirement for ensuring user safety and equipment longevity. These components are specifically engineered to absorb and dissipate kinetic energy generated during falls, collisions, and other high-stress scenarios, safeguarding the skater and maintaining the structural integrity of the skate.

- Toe Stops and Heel Brakes

Toe stops and heel brakes, typically constructed from durable rubber or polyurethane compounds, provide primary stopping mechanisms. Their impact resistance directly affects braking efficiency and lifespan. For example, a high-durometer toe stop will resist wear during repeated use on abrasive surfaces, maintaining consistent braking performance over time. Conversely, a low-quality toe stop may deform or disintegrate rapidly, compromising stopping power and increasing the risk of accidents.

- Boot Shell Reinforcement

The boot shell, often fabricated from rigid polymers or composite materials, encases the foot and ankle, providing critical support and protection. Impact-resistant boot shell reinforcement, such as strategically placed ribs or energy-absorbing inserts, minimizes the transmission of forces to the skater’s lower extremities during impacts. For instance, a reinforced boot shell can protect the ankle from fractures or sprains sustained during a fall, significantly reducing the severity of potential injuries.

- Frame Construction and Mounting Hardware

The frame, typically constructed from aluminum alloys or reinforced polymers, connects the boot to the wheels, providing a stable platform for skating. Impact-resistant frame construction involves the use of robust materials and reinforced mounting hardware to withstand the stresses of aggressive skating. For example, a forged aluminum frame can resist bending or cracking under high-impact loads, ensuring consistent wheel alignment and maintaining control. Conversely, a weak or poorly designed frame may fail under stress, leading to instability and potential accidents.

- Wheel Core Materials

The wheel core, typically made from rigid plastic or nylon composites, provides structural support for the polyurethane tire. Impact-resistant wheel core materials resist deformation or cracking under high-impact loads, maintaining wheel integrity and performance. For example, a high-density nylon core can withstand the stresses of landing jumps or navigating rough terrain, ensuring consistent wheel shape and preventing premature failure. Conversely, a weak or brittle core may crack or shatter under stress, compromising wheel performance and increasing the risk of accidents.

The strategic incorporation of impact-resistant components represents a fundamental aspect of heavy duty roller skate design. From toe stops and boot shells to frames and wheel cores, each element plays a critical role in absorbing and dissipating energy, protecting the skater from injury and extending the lifespan of the equipment. The selection of appropriate materials and construction techniques is therefore essential in maximizing the safety and performance of these skates, enabling users to confidently engage in demanding activities.

Frequently Asked Questions

This section addresses common inquiries concerning robust roller skates, providing detailed and informative responses to clarify key aspects of their design, application, and maintenance.

Question 1: What distinguishes heavy-duty roller skates from standard recreational models?

Heavy-duty roller skates incorporate reinforced construction, utilizing more durable materials in the frame, boot, and wheel components. This enhanced construction enables them to withstand higher impact forces and sustained use in demanding environments.

Question 2: What are the primary applications for heavy-duty roller skates?

These skates are typically used in applications requiring increased durability and support, such as roller derby, aggressive skating, recreational skating on uneven surfaces, and by individuals requiring enhanced ankle support.

Question 3: What materials are commonly used in the construction of heavy-duty roller skate frames?

Aluminum alloys and reinforced polymers are frequently employed in the construction of heavy-duty roller skate frames due to their high strength-to-weight ratio and resistance to deformation under stress.

Question 4: What factors should be considered when selecting wheels for heavy-duty roller skates?

Wheel durometer, size, and material composition are critical factors. Higher durometer wheels offer increased speed and durability on smooth surfaces, while larger wheels provide improved roll-over capability on rough terrain. Polyurethane is the most common material due to its balance of grip and wear resistance.

Question 5: How does one properly maintain heavy-duty roller skates to ensure longevity?

Regular cleaning to remove dirt and debris, lubrication of bearings, inspection for wear and tear, and timely replacement of worn components are essential for maintaining the performance and extending the lifespan of heavy-duty roller skates.

Question 6: What safety precautions should be observed when using heavy-duty roller skates?

Protective gear, including a helmet, wrist guards, elbow pads, and knee pads, is strongly recommended. Skaters should also be aware of their surroundings, adhere to posted regulations, and skate within their skill level.

In summary, heavy-duty roller skates are designed for demanding applications requiring enhanced durability and support. Proper selection, maintenance, and adherence to safety precautions are crucial for maximizing their performance and ensuring user safety.

The subsequent section will examine specific product recommendations and reviews, providing insights into available options within the heavy-duty roller skate market.

Conclusion

This exploration has detailed the construction, applications, and maintenance of heavy duty roller skates. The reinforced components, durable materials, and secure closure systems distinguish these skates from standard recreational models, enabling them to withstand rigorous use in demanding environments. The selection of appropriate materials and consistent maintenance are critical for optimizing performance and ensuring safety.

The continued development of advanced materials and engineering techniques promises further advancements in heavy duty roller skate design. A commitment to informed purchasing decisions and responsible usage will maximize the benefits of this equipment, promoting both performance and safety in demanding skating activities.

![Choosing: Rollerblades or Roller Skates Guide [2024] How to Skateboard: A Beginner's Guide to Your First Board & Tricks Choosing: Rollerblades or Roller Skates Guide [2024] | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/01/th-107-300x200.jpg)