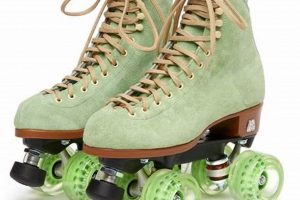

The subject in question comprises recreational footwear designed for gliding movement, distinguished by a specific color. This particular hue is characterized by a blue-green blend, often evoking associations with aquatic environments or gemstones. As an example, one might describe a set of these items as being a vibrant shade, noticeable even at a distance.

Such a products appeal often lies in its aesthetic properties, influencing purchasing decisions for reasons ranging from personal preference to fashion trends. The color choice can also reflect a desire for individuality or alignment with certain subcultures. Historically, color trends in recreational equipment have mirrored broader societal shifts in taste and style.

The following sections will examine various aspects related to these items, including material composition, wheel types, bearing specifications, and maintenance procedures. Considerations for safety and appropriate usage will also be addressed.

Enhancing the Longevity and Performance of Teal Roller Skates

The following guidelines offer essential advice for maintaining the condition and optimizing the performance of these particular recreational devices. Adherence to these principles ensures user safety and extends the product’s lifespan.

Tip 1: Implement Regular Cleaning Protocols: Following each use, meticulously wipe down the exterior surfaces with a damp cloth to remove dirt and debris. Abrasive substances can compromise the integrity of the material and reduce the smoothness of subsequent glides. Example: After skating outdoors, inspect the wheels and chassis for lodged pebbles.

Tip 2: Lubricate Bearings Periodically: Bearings facilitate wheel rotation. Insufficient lubrication increases friction and diminishes speed. Apply appropriate lubricant formulated for bearings according to the manufacturer’s recommendations. Example: Use a needle applicator to introduce lubricant directly into the bearing after removing the wheel.

Tip 3: Inspect and Tighten Fasteners: Regularly check all nuts, bolts, and screws to ensure they are properly secured. Loose components pose a safety hazard. Example: Use a skate tool to tighten axle nuts and plate mounting screws before each skating session.

Tip 4: Rotate Wheels to Promote Even Wear: Wheels experience uneven wear based on skating style and terrain. Rotating wheel positions periodically ensures uniform degradation, maximizing wheel lifespan and maintaining consistent performance. Example: Swap the front and rear wheels on each skate every month.

Tip 5: Store in a Dry, Cool Environment: Exposure to excessive moisture or extreme temperatures can damage materials and components. Store the skates in a controlled environment to prevent degradation. Example: Avoid storing the skates in a car trunk during hot weather.

Tip 6: Replace Worn Components Promptly: Replace worn wheels, bearings, or brake pads without delay. Compromised components reduce performance and increase the risk of accidents. Example: Replace brake pads when the rubber is visibly thin or performance is diminished.

Tip 7: Utilize Protective Gear Consistently: Protective gear, including helmets, wrist guards, elbow pads, and knee pads, is crucial for injury prevention. Always wear appropriate protection when skating. Example: Ensure the helmet fits snugly and the straps are properly fastened before each use.

Consistent adherence to these maintenance and safety protocols ensures optimal enjoyment and longevity for the teal roller skates, while also minimizing potential hazards. These practices are essential for both novice and experienced skaters.

The following article sections will address specific maintenance procedures in greater detail, including disassembly and reassembly instructions for various skate components.

1. Aesthetic Appeal

The visual presentation of roller skates, particularly when specified as teal, significantly influences consumer perception and purchasing decisions. The color’s association with specific styles and its role in self-expression demand careful consideration.

- Color Psychology

Teal evokes feelings of tranquility, sophistication, and balance. Its association with both blue (calmness) and green (growth) makes it a versatile choice. The implications for roller skates teal are that consumers may perceive them as stylish yet reliable, suitable for both recreational and fitness purposes. This contrasts with brighter, more assertive colors that might signal a focus on speed or aggression.

- Fashion Trends

The popularity of teal fluctuates with current fashion trends. Its prevalence in athletic wear and retro styles can significantly boost demand for teal roller skates. Real-world examples include increased sales of teal-colored items when they are featured in popular media or endorsed by influential figures. The impact is that manufacturers must stay attuned to prevailing trends to optimize their product offerings.

- Customization Options

The base color of teal provides a foundation for various customization options, including contrasting wheel colors, laces, and frame accents. This allows consumers to personalize their skates and express individuality. Examples of successful customization strategies include offering a range of complementary colors and patterns that can be mixed and matched. The result is enhanced consumer engagement and brand loyalty.

- Visual Differentiation

Teal, while not as common as black or white, provides a degree of visual differentiation in the roller skate market. This can be particularly beneficial for brands seeking to establish a unique identity. Real-world examples include using specific shades of teal to create a recognizable brand signature. The consequence is improved brand recognition and a competitive advantage.

The interplay of color psychology, fashion trends, customization options, and visual differentiation directly influences the perceived value and marketability of roller skates teal. Successful integration of these aesthetic elements is critical for achieving consumer appeal and driving sales.

2. Material Durability

The longevity and performance of roller skates, particularly those distinguished by a teal coloration, are intrinsically linked to the durability of their constituent materials. The selection of robust materials directly impacts the skate’s ability to withstand the stresses of regular use, environmental factors, and potential impacts. Inferior materials may lead to premature degradation, compromising both the skate’s functionality and the safety of the user. For instance, a skate constructed with a low-grade plastic chassis is susceptible to cracking under stress, potentially resulting in injury. Conversely, a skate utilizing reinforced polymers or metal alloys in critical stress points offers enhanced resistance to deformation and failure. This relationship underscores the fundamental importance of material selection in ensuring the overall durability of these products.

The practical implications of prioritizing material durability extend beyond mere product lifespan. Durable skates require less frequent replacement, leading to long-term cost savings for the consumer. Furthermore, durable components, such as high-quality wheel bearings and robust axles, contribute to a smoother, more efficient skating experience. Consider the difference between a skate with standard bearings, which may require frequent cleaning and lubrication, and one with sealed, high-precision bearings designed for prolonged performance. Another example is the effect of boot material. A skate boot constructed from a durable leather or synthetic leather will resist abrasions and tears, maintaining its structural integrity and providing consistent support for the skater’s foot, unlike lower-quality fabrics. This is especially important in high-impact skating disciplines.

In summary, material durability is a paramount consideration in the design and manufacturing of roller skates, especially when considering the distinctive attribute of teal coloration. The correlation between material quality and skate lifespan, user safety, and overall performance cannot be overstated. While aesthetic appeal and other features may influence purchasing decisions, the underlying durability of the skate’s materials ultimately determines its long-term value and suitability for its intended purpose. Challenges remain in balancing material durability with cost considerations and aesthetic design preferences. Further research and development in material science are crucial for advancing the performance and longevity of roller skates across all color variations.

3. Wheel Performance

Wheel performance is a critical determinant of the overall user experience when considering roller skates, including those distinguished by a teal coloration. The wheels directly influence speed, maneuverability, grip, and ride comfort. As such, a thorough understanding of the factors contributing to wheel performance is essential for informed skate selection and maintenance.

- Durometer Rating

The durometer rating, measured on the A scale, indicates the hardness of the wheel. Lower numbers denote softer wheels, providing greater grip and shock absorption but reduced speed and durability. Conversely, higher numbers represent harder wheels, offering increased speed and longer lifespan but less grip and a harsher ride. For instance, a skate intended for indoor rink use might employ wheels with a durometer of 88A or higher, while a skate designed for outdoor recreational use might benefit from wheels in the 78A to 82A range. The selection of an appropriate durometer is paramount to matching the wheel characteristics to the intended skating environment.

- Wheel Size

Wheel size, typically measured in millimeters (mm), affects both speed and maneuverability. Larger wheels provide higher top speeds and enhanced roll-over capability on rough surfaces. Smaller wheels offer greater acceleration and maneuverability, making them suitable for agility-focused skating styles. For example, aggressive skating styles often utilize smaller wheels (55-60mm) for tricks and grinds, while speed skating benefits from larger wheels (100mm or greater). The size must be appropriately matched to the skate frame and intended skating activity.

- Wheel Material

The material composition of the wheel significantly influences its performance characteristics. Polyurethane is the most common material, offering a balance of durability, grip, and rebound. However, variations in polyurethane formulations can produce distinct performance attributes. For example, some wheels may incorporate additives to enhance grip in wet conditions, while others may focus on maximizing rebound for increased speed. The specific polyurethane blend should be considered in relation to the intended use of the roller skates teal.

- Bearing Integration

The quality and type of bearings used within the wheel assembly are crucial for smooth and efficient rolling. Bearings reduce friction between the wheel and the axle, allowing for greater speed and prolonged glide. Higher ABEC (Annular Bearing Engineers’ Committee) ratings generally indicate tighter tolerances and improved performance. For example, ABEC 7 or ABEC 9 bearings offer smoother and faster rolling compared to ABEC 3 or ABEC 5 bearings. Correct bearing maintenance, including cleaning and lubrication, is also essential for preserving optimal wheel performance and preventing premature wear.

The interplay of durometer, wheel size, material, and bearing integration collectively determines the performance characteristics of the wheels on roller skates, including those with a teal aesthetic. Selecting the appropriate wheel specifications is crucial for optimizing the skating experience, ensuring safety, and maximizing the lifespan of the skate components. The visual appeal of the teal color is secondary to the performance attributes when considering the overall suitability of the product for a specific application.

4. Bearing Quality

Bearing quality significantly impacts the performance and longevity of roller skates, regardless of their aesthetic features such as a teal coloration. High-quality bearings reduce friction, enabling smoother and faster rolling, while inferior bearings degrade rapidly, diminishing performance and potentially compromising safety. The selection and maintenance of appropriate bearings are therefore crucial for maximizing the usability of roller skates teal.

- ABEC Rating Influence

The Annular Bearing Engineers’ Committee (ABEC) rating system categorizes bearing precision. Higher ABEC ratings (e.g., ABEC 7, ABEC 9) denote tighter tolerances and superior manufacturing, resulting in reduced friction and enhanced speed. While ABEC ratings provide a standardized measure, real-world performance is also influenced by material quality and lubrication. Skates equipped with high ABEC-rated bearings offer a more efficient and enjoyable skating experience, requiring less effort to maintain momentum. This improved efficiency benefits both recreational and competitive skaters using roller skates teal.

- Material Composition Importance

Bearing material directly affects durability and resistance to wear. Stainless steel bearings exhibit superior corrosion resistance compared to carbon steel bearings, making them suitable for outdoor skating environments where exposure to moisture and contaminants is prevalent. Ceramic bearings offer exceptional hardness and heat resistance, further reducing friction and extending bearing lifespan. The choice of bearing material should align with the intended skating conditions and the user’s performance expectations. For instance, skaters who primarily use roller skates teal on smooth indoor surfaces may find carbon steel bearings sufficient, while those skating outdoors in varying conditions would benefit from stainless steel or ceramic bearings.

- Lubrication Impact on Performance

Proper lubrication minimizes friction and prevents premature wear. Different lubricants are formulated for specific skating conditions and bearing types. Grease-based lubricants provide enhanced protection against contaminants and are suitable for high-impact skating, while oil-based lubricants offer lower friction and increased speed. Regular lubrication is essential for maintaining optimal bearing performance and extending lifespan. Neglecting lubrication can lead to increased friction, overheating, and eventual bearing failure. For roller skates teal, selecting and consistently applying the appropriate lubricant ensures consistent and reliable performance.

- Sealed vs. Unsealed Bearings

Sealed bearings incorporate rubber or metal shields to protect the internal components from dirt, debris, and moisture. Sealed bearings require less frequent maintenance compared to unsealed bearings, making them ideal for skaters who prioritize convenience and durability. Unsealed bearings offer lower friction but require regular cleaning and lubrication. The choice between sealed and unsealed bearings depends on the user’s maintenance preferences and the anticipated skating environment. For roller skates teal intended for casual recreational use, sealed bearings provide a practical balance of performance and maintenance.

In conclusion, bearing quality plays a crucial role in the performance and lifespan of roller skates teal. The interplay of ABEC rating, material composition, lubrication, and sealing mechanisms collectively determines the bearings’ ability to provide a smooth, efficient, and reliable skating experience. By carefully considering these factors, users can optimize their investment and maximize their enjoyment of roller skates teal.

5. Size Availability

The correlation between size availability and roller skates teal represents a critical factor in market accessibility and consumer satisfaction. Without a comprehensive range of sizes, the potential consumer base for these items is significantly limited. This restriction directly impacts sales volume and brand perception. Real-world examples include manufacturers who initially offer a limited size range experiencing reduced sales and negative consumer feedback, particularly in online reviews. Consequently, size availability operates as a primary determinant of market reach and overall product viability for roller skates teal.

The practical significance of adequate size availability extends beyond mere commercial considerations. Properly fitted roller skates are essential for user safety and comfort. Ill-fitting skates can lead to instability, increased risk of injury (e.g., ankle sprains, falls), and compromised control. For instance, skates that are too large may cause the foot to slip, hindering braking and turning. Conversely, skates that are too small can cause discomfort, blisters, and restricted blood flow. Therefore, a comprehensive size range is not merely a marketing strategy but a fundamental requirement for ensuring a positive and safe skating experience. Moreover, niche markets, such as children or individuals with larger-than-average shoe sizes, are particularly sensitive to size limitations, emphasizing the importance of inclusive sizing practices.

In summary, the availability of a broad and well-calibrated size range is an indispensable component of the roller skates teal product offering. This factor directly affects market penetration, consumer safety, and overall product success. Challenges remain in accurately predicting demand across all size ranges and efficiently managing inventory. Addressing these challenges requires ongoing market analysis, robust quality control procedures, and a commitment to meeting the diverse needs of the skating community. Prioritizing size availability ensures that roller skates teal are accessible, safe, and enjoyable for a wider spectrum of potential users.

6. Safety Standards

The adherence to established safety standards directly influences the integrity and usability of roller skates, including those characterized by a teal coloration. Non-compliance poses significant risks to users, increasing the likelihood of accidents and injuries. For instance, a skate lacking proper ankle support or a secure fastening system can result in instability and falls. Therefore, a commitment to safety standards is not merely a regulatory requirement but a fundamental ethical obligation for manufacturers and distributors of roller skates teal. These standards often encompass specific requirements for material strength, impact resistance, braking effectiveness, and overall structural integrity. Failure to meet these benchmarks undermines the product’s functionality and jeopardizes user well-being.

Practical examples of safety standards in action include certifications from recognized organizations such as ASTM International (formerly the American Society for Testing and Materials) and EN (European Norm). These certifications indicate that the product has undergone rigorous testing and meets established criteria for safety and performance. Consumers should actively seek out roller skates teal bearing such certifications as a mark of assurance. Furthermore, adherence to safety standards extends beyond the manufacturing process to include clear and comprehensive user instructions regarding proper usage, maintenance, and protective gear recommendations. Insufficient guidance can lead to misuse and subsequent injuries. The legal ramifications of neglecting safety standards can be substantial, potentially resulting in product recalls, lawsuits, and reputational damage for manufacturers.

In conclusion, safety standards are an indispensable component of roller skates teal, impacting both user safety and product viability. The enforcement of these standards necessitates a collaborative effort involving manufacturers, regulatory bodies, and consumers. Challenges remain in ensuring consistent application of standards across global markets and adapting to evolving technologies. Ongoing research and development are essential for refining safety standards and mitigating emerging risks associated with roller skate usage. Ultimately, a proactive commitment to safety fosters consumer confidence and promotes a safer and more enjoyable skating experience.

7. Maintenance Needs

The operational lifespan and performance efficacy of roller skates, irrespective of aesthetic features such as a teal coloration, are inextricably linked to consistent and appropriate maintenance. Neglecting necessary maintenance procedures precipitates premature degradation of components, diminished performance characteristics, and potential safety hazards. For example, the accumulation of dirt and debris within wheel bearings increases friction, reducing speed and requiring more physical exertion from the user. Similarly, failure to regularly inspect and tighten axle nuts can lead to wheel detachment, posing a significant risk of accidents. Therefore, a proactive maintenance regimen constitutes an essential element in ensuring the longevity, safety, and optimal functionality of roller skates teal. The correlation between proper maintenance and sustained performance underscores the practical significance of adhering to recommended maintenance protocols.

Specific maintenance tasks encompass several critical areas. Wheel bearing cleaning and lubrication are paramount for minimizing friction and maintaining smooth rolling. Regular inspection and tightening of all fasteners, including axle nuts, mounting bolts, and toe stop screws, prevent loosening and potential component failure. Wheel rotation ensures even wear distribution, maximizing wheel lifespan and maintaining consistent grip. Cleaning the skate boot and chassis prevents the accumulation of dirt and debris, preserving the aesthetic appearance and preventing material degradation. The selection of appropriate cleaning agents and lubricants is crucial to avoid damaging sensitive materials. Consider the differential maintenance requirements of indoor versus outdoor skating. Outdoor skating exposes the skates to a greater variety of contaminants, necessitating more frequent and thorough cleaning. Moreover, the type of skating activity influences maintenance needs. Aggressive skating, characterized by jumps and grinds, places greater stress on components, requiring more frequent inspection and potential replacement.

In conclusion, maintenance needs constitute a critical consideration in the ownership and operation of roller skates teal. Neglecting these needs results in diminished performance, reduced lifespan, and heightened safety risks. A comprehensive maintenance strategy, encompassing bearing care, fastener inspection, wheel rotation, and general cleaning, is essential for preserving the skates’ functionality and ensuring a safe and enjoyable skating experience. Challenges remain in educating consumers about the importance of proactive maintenance and providing accessible resources for performing these tasks. Ultimately, a commitment to proper maintenance maximizes the investment in roller skates teal and contributes to a sustainable skating practice.

Frequently Asked Questions

This section addresses common inquiries regarding roller skates characterized by a teal coloration. The information provided aims to clarify misconceptions and offer guidance for informed decision-making.

Question 1: What factors contribute to variations in the shade of teal observed in different roller skate models?

Variations in teal coloration arise from differences in pigment formulations, manufacturing processes, and material composition. Lighting conditions can also influence the perceived hue. Precise color matching across different models or brands is often difficult to achieve.

Question 2: How does the teal coloration of roller skates affect their performance or durability?

The teal coloration itself has no direct impact on performance or durability. These attributes are primarily determined by material quality, construction techniques, and component specifications, such as wheel durometer and bearing rating.

Question 3: Are roller skates teal more susceptible to fading or discoloration compared to other colors?

The susceptibility to fading or discoloration depends on the specific pigments and dyes used in the manufacturing process, as well as the skate’s exposure to ultraviolet radiation and environmental factors. High-quality coloring agents and proper storage practices mitigate these effects.

Question 4: Do roller skates teal require special cleaning or maintenance procedures compared to other colors?

Roller skates teal do not necessitate specialized cleaning or maintenance beyond standard procedures applicable to all roller skates. Regular cleaning with mild soap and water, along with proper lubrication of bearings, is generally sufficient.

Question 5: Are there specific safety considerations associated with roller skates teal due to their color?

The teal coloration itself does not present any unique safety concerns. Standard safety precautions, including the use of protective gear such as helmets, wrist guards, and knee pads, should always be observed regardless of the skate’s color.

Question 6: How does the price of roller skates teal typically compare to that of roller skates in other colors?

The price of roller skates teal is typically comparable to that of roller skates in other colors, assuming similar specifications and features. Price variations are primarily driven by brand, material quality, and component specifications, rather than coloration.

This FAQ section underscores that the teal coloration of roller skates is primarily an aesthetic consideration. Performance, durability, and safety depend on other factors.

The following section explores the historical evolution of roller skate design and manufacturing techniques.

Conclusion

This exposition has detailed various facets of roller skates teal, encompassing aesthetic considerations, material durability, performance characteristics, safety imperatives, and maintenance protocols. The preceding analysis has demonstrated that while coloration contributes to visual appeal, the underlying functionality and longevity of these recreational devices hinge on factors beyond superficial aesthetics. Understanding the interplay between these elements is paramount for informed consumer decisions and responsible product stewardship.

Ultimately, the responsible use and appropriate maintenance of roller skates teal, guided by the principles outlined herein, will contribute to a safer and more enriching skating experience. Continued vigilance regarding safety standards and advancements in material science remain crucial for optimizing the design and performance of future roller skate iterations. The onus rests on both manufacturers and consumers to prioritize safety and quality in the pursuit of this enduring recreational activity.