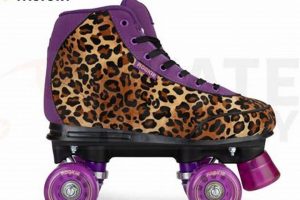

The outer material of certain wheeled boots designed for gliding or rolling movement may consist of a particular type of leather. This leather is characterized by a napped finish on one side, resulting in a soft, velvety texture. It is often employed in footwear, including recreational equipment, to enhance aesthetics and provide a comfortable feel.

Using this leather offers potential advantages such as enhanced grip and flexibility compared to other materials. Historically, the material has been associated with a refined appearance and perceived quality. Its incorporation into boot construction can contribute to a more secure and responsive experience for the user. The inherent flexibility of this material can aid in comfort during extended use.

The following sections will delve deeper into the specific grades and characteristics of leather used in wheeled boots, the maintenance procedures required to preserve their integrity, and the comparative advantages against alternative construction materials.

Maintenance and Care for Suede Roller Skates

Proper upkeep is crucial to maximizing the lifespan and performance of roller skates constructed using napped leather. Neglecting maintenance can lead to premature wear, reduced performance, and aesthetic degradation.

Tip 1: Implement Regular Brushing: Use a specialized suede brush after each use to remove loose dirt and debris. This prevents particles from becoming embedded in the nap, which can cause abrasion over time.

Tip 2: Utilize a Suede Protector Spray: Apply a protective spray specifically designed for napped leather. This creates a barrier against moisture and stains, mitigating potential damage from spills and environmental exposure. Reapply the spray periodically, following the manufacturers instructions.

Tip 3: Address Stains Promptly: Attend to stains immediately. Blot the affected area with a clean, absorbent cloth. Avoid rubbing, as this can spread the stain and damage the nap. For persistent stains, consider using a suede cleaner specifically formulated for the material.

Tip 4: Avoid Excessive Moisture: Exposure to excessive moisture can lead to stiffness and discoloration. If the roller skates become wet, allow them to air dry naturally away from direct heat or sunlight. Stuffing them with newspaper can help maintain their shape during the drying process.

Tip 5: Store Appropriately: When not in use, store the roller skates in a cool, dry place away from direct sunlight. A breathable storage bag can help protect them from dust and scratches. Avoid storing them in damp or humid environments.

Tip 6: Rotate Usage: If possible, alternate between multiple pairs of roller skates. This allows each pair to air out and rest, extending their overall lifespan and preventing the development of persistent odors.

Tip 7: Professional Cleaning: For thorough cleaning or restoration, consider consulting a professional leather cleaning service specializing in delicate materials. They possess the expertise and equipment to address complex cleaning challenges without damaging the leather.

Adhering to these maintenance practices will preserve the aesthetics and structural integrity of roller skates. Consistent care translates to extended product life, superior performance, and a retained value.

The subsequent section will cover common issues and troubleshooting tips associated with roller skates.

1. Material Quality

The material selection is a foundational determinant of performance and longevity. Grades of leather influence the durability, aesthetic qualities, and comfort of the roller skates. Superior full-grain leather resists abrasion and tearing more effectively than split-grain options, directly impacting the skates’ lifespan and ability to withstand rigorous use. Inferior material quality may result in premature wear, color fading, or structural failure, necessitating replacement or costly repairs. For example, cheaper, synthetic imitations may lack the breathable properties of leather, leading to discomfort and potential foot health issues during extended skating sessions.

The processing techniques employed in tanning the leather also significantly affect its characteristics. Vegetable-tanned leather, while more environmentally friendly, may be less water-resistant than chrome-tanned leather. This distinction becomes crucial in environments where exposure to moisture is unavoidable. Furthermore, the uniformity and consistency of the leather’s surface, a direct result of material quality, affect the ease and effectiveness of maintenance procedures. High-quality leather accepts protective treatments more readily, ensuring long-term protection against stains and environmental damage.

In conclusion, the selection of leather is not merely an aesthetic choice but a crucial determinant of the equipment’s overall functionality, longevity, and user experience. Compromising on material quality to reduce costs can lead to long-term expenses and diminished performance. A thorough evaluation of leather grades and processing methods is essential for selecting roller skates that meet the intended use and environmental conditions, ensuring sustained enjoyment and performance.

2. Durability

The resistance to wear and degradation is a paramount attribute of roller skates. The choice of outer material, in this case, napped leather, significantly influences the longevity and performance of the equipment under various conditions. Understanding the specific durability characteristics of this material is essential for informed purchasing decisions and proper maintenance practices.

- Tensile Strength and Tear Resistance

Napped leather’s ability to withstand tensile forces and resist tearing directly impacts its durability. Higher-quality leather exhibits greater tensile strength, reducing the likelihood of ripping or deformation under stress. For example, roller skating maneuvers involving abrupt stops or sharp turns place significant strain on the boot’s exterior. Leather with inadequate tear resistance will degrade rapidly under such conditions, compromising the structural integrity of the skate.

- Abrasion Resistance

Contact with abrasive surfaces, such as pavement or skate park ramps, poses a significant threat to the outer material. Napped leather’s resistance to abrasion determines its ability to withstand this constant friction without excessive wear or scuffing. Materials with superior abrasion resistance maintain their aesthetic appearance and structural integrity for a longer period, extending the skates’ usable lifespan. Lack of abrasion resistance results in rapid degradation, necessitating frequent replacements or repairs.

- Resistance to Environmental Factors

Exposure to environmental elements, including moisture, sunlight, and temperature fluctuations, can accelerate the deterioration of leather. Excessive moisture can lead to stiffness, cracking, and mold growth, while prolonged exposure to sunlight can cause fading and discoloration. The capacity to resist these environmental factors is crucial for maintaining the material’s integrity and preventing premature degradation. Proper maintenance, including the application of protective coatings, can enhance resistance to environmental damage.

- Bonding and Stitching Integrity

The method used to bond the leather to the skate’s sole and the quality of the stitching significantly affect overall durability. Weak bonding or poorly executed stitching can lead to separation between the leather and the sole, compromising the structural integrity of the skate. High-quality adhesives and reinforced stitching are essential for creating a durable bond that can withstand the stresses of roller skating. Regular inspection of the stitching and bonding is recommended to identify and address potential issues before they escalate.

These aspects of durability are intricately linked and collectively determine the lifespan and performance of roller skates. The inherent qualities of the specific type of leather, combined with proper construction techniques and conscientious maintenance, dictate its resistance to wear, environmental factors, and mechanical stress. Prioritizing these aspects ensures long-term use and sustained performance.

3. Aesthetic Appeal

The aesthetic dimension of roller skates constructed with napped leather holds significant value for many consumers. The material’s visual and tactile properties contribute directly to the overall perceived quality and desirability of the product. The soft, velvety texture provides a tactile experience distinct from synthetic materials or smooth leather alternatives. This texture often evokes feelings of luxury and craftsmanship, which can be a key factor in purchasing decisions. Furthermore, the material often accepts dyes and finishes readily, allowing for a wide range of color options and customization possibilities. This versatility empowers manufacturers to cater to diverse stylistic preferences and market segments. For instance, retro-inspired skates often utilize vibrant color palettes and contrasting stitching to enhance their visual impact, while more contemporary designs may opt for muted tones and minimalist detailing to convey a sense of understated elegance.

The specific nap and finish of the leather also influence its aesthetic properties. A longer nap can create a more pronounced texture and a more casual, bohemian look. Conversely, a shorter, more tightly compressed nap offers a smoother, more refined appearance. These subtle variations allow manufacturers to tailor the visual appeal of their skates to specific target audiences. In addition, the ability to emboss or perforate leather provides further opportunities for customization and branding. Logos, patterns, and decorative elements can be permanently etched into the material’s surface, enhancing its visual identity and differentiating it from competitors. This customization can be particularly valuable for brands seeking to establish a strong and recognizable presence in the roller skating market. The visual qualities of this leather can also influence the perceived value of the roller skates, potentially allowing for premium pricing.

In summary, aesthetic appeal is a crucial component of roller skates constructed with napped leather. The material’s unique visual and tactile characteristics, combined with its versatility in terms of color, finish, and customization, contribute significantly to the overall perceived quality and desirability of the product. Understanding the nuances of the material’s aesthetic properties is essential for manufacturers seeking to create roller skates that resonate with their target audiences and command a competitive position in the market. However, it is crucial to balance aesthetic considerations with performance and durability, ensuring that the roller skates not only look appealing but also provide a safe and enjoyable skating experience.

4. Comfort

Comfort, in the context of roller skates constructed with napped leather, is a multifaceted attribute encompassing fit, breathability, cushioning, and flexibility. These factors collectively determine the user’s experience, influencing enjoyment, performance, and the potential for injury.

- Conformability and Fit

The inherent flexibility of napped leather allows it to conform more readily to the unique contours of the foot compared to rigid synthetic materials. This characteristic is crucial for achieving a snug, yet comfortable fit, minimizing pressure points and preventing chafing. A well-fitting skate reduces the risk of blisters and ensures efficient power transfer during skating. Improper fit, often caused by stiff materials, can lead to discomfort and impaired performance.

- Breathability and Moisture Management

Leather, in general, possesses inherent breathability properties, allowing for the circulation of air and the dissipation of moisture. Napped leather further enhances this breathability due to its open structure, facilitating the evaporation of sweat and reducing the build-up of heat within the boot. Effective moisture management is essential for maintaining a comfortable internal environment, preventing the development of odor, and minimizing the risk of fungal infections.

- Cushioning and Impact Absorption

While napped leather itself does not provide significant cushioning, its pliability allows for the incorporation of padding materials without compromising the overall fit and feel of the skate. The combination of supple leather and strategically placed cushioning enhances impact absorption, reducing stress on joints and muscles during skating. Adequate cushioning is particularly important for absorbing vibrations and mitigating the effects of uneven surfaces.

- Flexibility and Range of Motion

The flexibility of leather enables a greater range of motion compared to rigid alternatives. This flexibility is essential for performing various skating maneuvers, such as turns, crossovers, and jumps. Restricted movement can lead to discomfort, impaired balance, and an increased risk of injury. Leather allows for natural foot articulation, promoting agility and control while maintaining a secure and supportive fit.

The interplay of conformability, breathability, cushioning, and flexibility directly impacts the comfort experienced by the roller skater. Napped leather, with its inherent properties and ability to integrate with comfort-enhancing features, contributes to a more enjoyable and less fatiguing skating experience. Prioritizing these aspects when selecting skates promotes long-term comfort and well-being.

5. Maintenance Needs

The necessity for consistent and appropriate upkeep is inextricably linked to roller skates constructed with napped leather. The material’s inherent properties, while contributing to aesthetic appeal and comfort, necessitate specific maintenance protocols to preserve its integrity and extend its lifespan.

- Regular Cleaning and Debris Removal

The napped surface of the leather is susceptible to accumulating dirt, dust, and debris. If left unattended, these particles can become embedded within the nap, leading to abrasion and premature wear. Regular brushing with a specialized suede brush is essential to remove loose particles and prevent them from causing damage. For example, skating on dusty surfaces can quickly degrade the appearance and structural integrity of the leather if not addressed promptly.

- Protection Against Moisture and Stains

Napped leather is particularly vulnerable to damage from moisture and staining agents. Water can cause the leather to stiffen and discolor, while oil-based stains can be difficult to remove. Applying a protective spray specifically designed for napped leather creates a barrier against moisture and stains. Promptly addressing spills and avoiding exposure to wet conditions are crucial for preserving the material’s appearance and preventing irreversible damage. Failing to protect against moisture can lead to cracking and peeling, significantly shortening the lifespan of the skates.

- Proper Storage and Environmental Control

The manner in which roller skates are stored when not in use directly impacts their longevity. Exposure to direct sunlight can cause fading and discoloration, while excessive humidity can promote the growth of mold and mildew. Storing the skates in a cool, dry place away from direct sunlight is essential for preventing environmental damage. Using a breathable storage bag can further protect the leather from dust and scratches. Leaving skates exposed to the elements can lead to accelerated degradation and compromised performance.

- Professional Cleaning and Restoration

For deep cleaning or restoration of damaged leather, professional services may be required. Standard cleaning methods can damage the delicate nap of the leather, necessitating specialized techniques and equipment. Professional leather cleaners possess the expertise to address stubborn stains, restore faded colors, and repair minor damages without compromising the material’s integrity. Attempting to clean or repair damaged leather without professional assistance can result in further damage and irreversible alteration of the material’s characteristics.

These maintenance considerations underscore the importance of proactive care for roller skates constructed with napped leather. Neglecting these needs can result in premature wear, compromised performance, and diminished aesthetic appeal. Adhering to a consistent maintenance schedule and utilizing appropriate cleaning and protection methods is essential for maximizing the lifespan and enjoyment of these skates. The inherent properties of this material dictate a higher level of care compared to synthetic alternatives.

6. Flexibility

The capacity of roller skates to conform and adapt to the movements of the user is critical for performance and safety. When napped leather is incorporated into the boot construction, it introduces a degree of flexibility not readily achievable with more rigid materials. This inherent flexibility directly influences the skater’s ability to execute precise maneuvers, maintain balance, and experience a natural range of motion. A stiff, unyielding boot restricts ankle movement, increasing the risk of strain and hindering the skater’s capacity to react swiftly to changing conditions. For example, during a crossover turn, the boot needs to flex inward to accommodate the ankle’s angle. A boot constructed with leather allows for this movement, promoting control and minimizing the risk of ankle roll.

Consider the practical implications of flexibility in different skating disciplines. In roller derby, skaters require agility and responsiveness to navigate the track effectively. Leather boots allow for quick pivots, acceleration, and deceleration, providing a competitive edge. Similarly, in artistic skating, fluid movements and graceful transitions demand a boot that can move in harmony with the skater’s body. Napped leather facilitates the intricate footwork and expressive movements essential to the discipline. The material properties provide support while not hindering maneuverability. A lack of flexibility can result in restricted technique and a higher likelihood of falls. This characteristic contributes directly to the comfort level and fatigue, affecting performance during prolonged use.

In summary, the flexibility afforded by leather represents a significant advantage in roller skate design. It directly impacts maneuverability, safety, and comfort, making it a critical factor for skaters across various disciplines. Understanding this relationship enables informed decision-making when selecting roller skates. While the maintenance requirements of leather are greater than synthetic alternatives, the performance benefits derived from its flexibility often outweigh these considerations. The material improves the connection between the skater and the skates.

7. Breathability

The capacity for air circulation within roller skates is influenced significantly by the materials used in their construction. Napped leather, owing to its porous structure, exhibits a degree of breathability that impacts user comfort and foot health. The interconnected fibers create microscopic channels that facilitate the passage of air and the evaporation of moisture. This characteristic is particularly relevant in roller skating, where sustained physical exertion can generate significant perspiration within the enclosed environment of the boot. Insufficient breathability can lead to the accumulation of moisture, resulting in discomfort, odor, and an increased susceptibility to fungal infections. The use of napped leather, therefore, serves as a mitigation strategy against these adverse effects by promoting ventilation and facilitating the removal of perspiration. For instance, a skater using boots constructed from impermeable synthetic materials may experience excessive sweating and discomfort, potentially impacting performance and increasing the risk of skin irritation. Conversely, napped leather allows for a more temperate internal environment, reducing these risks.

The specific tanning and finishing processes applied to napped leather also influence its breathability characteristics. Certain treatments can compromise the material’s porosity, thereby diminishing its ability to facilitate air circulation. Therefore, the selection of leather tanned and finished with breathability in mind is crucial. Additionally, the integration of breathable linings and ventilation systems within the boot can further enhance the overall airflow. The effect of these measures is to provide a controlled microclimate around the foot, contributing to improved comfort and reduced moisture build-up. This approach has practical implications for extended skating sessions or in warmer climates, where maintaining a comfortable and hygienic environment within the boot is essential.

In conclusion, breathability constitutes a significant component of roller skates incorporating leather. The material’s natural porosity promotes ventilation and moisture evaporation, mitigating discomfort and potential health risks associated with prolonged use. The selection of appropriately tanned and finished leather, combined with the integration of breathable linings, enhances the overall effectiveness of the ventilation system. Understanding the interplay between material properties and environmental factors is critical for designing and selecting roller skates that prioritize user comfort and well-being. However, it’s important to acknowledge that other factors, such as sock selection and activity level, also influence breathability and should be considered accordingly.

Frequently Asked Questions

The following addresses common inquiries regarding roller skates incorporating napped leather construction. Accurate information promotes informed purchasing decisions and appropriate maintenance practices.

Question 1: How does the durability of leather compare to synthetic materials in roller skate construction?

Napped leather, when properly maintained, exhibits comparable durability to many synthetic materials. High-grade leather resists abrasion and tearing, provided it receives appropriate care. Lower-quality leather or neglected maintenance, however, can compromise its lifespan relative to certain synthetics.

Question 2: What specific maintenance procedures are crucial for leather roller skates?

Essential maintenance includes regular brushing with a suede brush to remove debris, application of a protective spray to guard against moisture and stains, and proper storage in a cool, dry environment. Prompt stain removal is also critical.

Question 3: Is napped leather suitable for all roller skating disciplines?

Napped leather is adaptable to various disciplines, but its suitability depends on the specific demands. While suitable for recreational skating and artistic roller skating, it may be less ideal for aggressive styles where abrasion resistance is paramount.

Question 4: How does napped leather contribute to the comfort of roller skates?

Napped leather provides comfort through its flexibility, which allows the boot to conform to the foot’s shape, and its inherent breathability, which aids in moisture management and temperature regulation within the boot.

Question 5: Can napped leather be repaired if damaged?

Minor damage, such as scuffs and stains, may be repairable with specialized cleaning products and techniques. However, significant damage, such as tears or excessive wear, may necessitate professional repair or replacement.

Question 6: What are the key considerations when selecting roller skates constructed with leather?

Key considerations include the quality of the leather, the overall construction of the skate, the intended skating discipline, the fit and comfort, and the commitment to performing appropriate maintenance procedures.

These answers offer guidance on key aspects of roller skates. Understanding them is essential for making well-informed decisions and ensuring longevity of roller skates.

The subsequent sections will cover common issues and troubleshooting tips associated with roller skates.

Conclusion

The preceding exploration has illuminated critical facets of roller skates suede. Material composition impacts durability, aesthetic considerations influence purchasing decisions, and maintenance directly determines product longevity. These factors coalesce to define the overall value proposition for consumers considering this specific type of roller skate.

A comprehensive understanding of these variables empowers informed choices. Recognizing the balance between material properties, maintenance demands, and intended use is paramount. Continued diligence in product care and informed decision-making will contribute to sustained performance and user satisfaction.