The items under discussion are a specific line of recreational footwear designed for smooth, gliding movement across surfaces. These products, typically constructed with a boot or shoe attached to a chassis with wheels, allow individuals to propel themselves forward using a combination of balance and leg muscle power. They are often used for leisure, exercise, and sporting activities.

These wheeled boots hold significance in the realm of personal transportation and recreation. Their development represents an evolution in mobility, providing a convenient and enjoyable means of covering short distances. Historically, they have contributed to the growth of roller rinks and various related sports, fostering communities and providing opportunities for physical activity and social interaction. They continue to be enjoyed by individuals of all ages.

The following sections will delve into the attributes and characteristics of this equipment, including materials used in construction, design variations, and considerations for optimal usage and maintenance. Further examination will also cover the target demographic, pricing, and availability of this product line within the market.

Guidance for Optimal Utilization

The following recommendations are designed to enhance the user experience and prolong the lifespan of the equipment. Adherence to these guidelines will contribute to both safety and performance.

Tip 1: Prioritize appropriate protective gear. Helmet use is paramount to mitigate head injuries. Wrist guards, elbow pads, and knee pads are strongly advised to minimize potential abrasions and fractures resulting from falls.

Tip 2: Conduct pre-use inspections. Verify the secure attachment of wheels and the functionality of brakes prior to each use. Loose components can compromise stability and control.

Tip 3: Maintain clean bearing surfaces. Accumulated dirt and debris can impede wheel rotation and diminish speed. Regular cleaning with appropriate solvents is recommended.

Tip 4: Ensure proper fit. The equipment should conform snugly to the foot and ankle, providing adequate support without causing constriction or discomfort. Incorrect sizing can lead to instability and potential injury.

Tip 5: Practice in controlled environments. New users should initially familiarize themselves with the equipment in designated skating areas or smooth, level surfaces free from obstacles.

Tip 6: Avoid use on wet or uneven surfaces. These conditions can significantly reduce traction and increase the risk of falls. Adherence to dry, smooth surfaces is crucial for maintaining control.

Tip 7: Periodically adjust wheel tightness. Overly tight wheels can restrict movement, while excessively loose wheels can introduce instability. Optimal tightness allows for smooth rotation without lateral play.

Tip 8: Store equipment in a dry, cool environment. Prolonged exposure to moisture or extreme temperatures can degrade materials and shorten the lifespan of the equipment.

Following these recommendations promotes a safer and more enjoyable experience. Regular maintenance and attentive use contribute significantly to the long-term performance and durability of the equipment.

The subsequent section will provide information on troubleshooting common issues and identifying potential warning signs of equipment failure.

1. Brand Recognition

Brand recognition, in the context of wheeled footwear, is a critical factor influencing consumer choice and market dominance. The name associated with these products acts as a shorthand for perceived quality, durability, and performance. Positive recognition reduces purchase risk for consumers, who often rely on established brands with a proven track record. For example, a well-known brand might command a premium price due to its perceived reliability and longevity, affecting market segmentation.

The effect of brand recognition extends beyond initial purchase decisions. Strong brands often foster customer loyalty, leading to repeat business and positive word-of-mouth referrals. Conversely, a lack of brand recognition or a negative reputation can severely hinder sales and market penetration, regardless of the actual product quality. Marketing efforts, sponsorships, and endorsements directly contribute to shaping and maintaining brand image and influence.

Therefore, understanding the importance of brand recognition is practically significant for manufacturers and consumers. Manufacturers can leverage brand equity to increase sales and establish a competitive advantage, while consumers can use brand reputation as a heuristic for making informed purchasing decisions. Successful brands cultivate trust and association with positive attributes, securing their position in the marketplace, while less recognized brands face the challenge of overcoming skepticism and building credibility.

2. Construction Materials

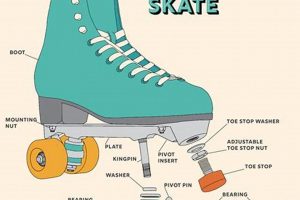

The selection of construction materials directly and profoundly influences the performance, durability, and safety of this line of wheeled footwear. Material choices affect weight, flexibility, impact resistance, and overall comfort, impacting the user experience. For example, the boots composition dictates ankle support and susceptibility to wear and tear. A robust, supportive boot crafted from high-quality leather or reinforced polymers provides greater stability and protection against injury compared to a flimsy, less durable material.

Wheel materials are similarly critical. Polyurethane (PU) wheels, known for their abrasion resistance and grip, are commonplace. Softer PU wheels offer improved shock absorption and traction on rough surfaces, while harder wheels provide greater speed and durability on smooth surfaces. Bearing construction, often steel or ceramic, influences rolling efficiency and the effort required for propulsion. Frame materials, such as aluminum or reinforced nylon, determine the overall rigidity and responsiveness of the equipment. Lighter frames can enhance maneuverability, while stronger frames withstand greater stress and impact.

The understanding of material properties is essential for both manufacturers and consumers. Manufacturers must strategically select materials to meet performance targets, balance cost considerations, and comply with safety regulations. Consumers, in turn, can make informed purchasing decisions based on their individual needs and preferences, considering factors such as intended use, skating style, and budget. Selecting the proper construction materials ultimately provides an enhanced experience.

3. Wheel Configuration

Wheel configuration, regarding this specific brand of recreational footwear, significantly influences performance characteristics. The arrangement of wheels on the chassis affects stability, maneuverability, and speed, directly impacting the user’s skating experience. Different arrangements cater to diverse skating styles and skill levels. For instance, inline configurations, featuring wheels arranged in a single line, generally prioritize speed and agility, facilitating efficient forward motion. Quad configurations, with two pairs of wheels positioned at the front and rear, offer enhanced stability and are often preferred by beginners or those engaging in artistic skating.

Real-world examples illustrate the practical implications of wheel configuration choices. A skater using inline wheels on a smooth, flat surface might achieve higher speeds and execute tighter turns compared to someone using quad wheels. Conversely, a skater using quad wheels on an uneven or textured surface might experience greater stability and control, reducing the risk of falls. Furthermore, wheel size and hardness also play crucial roles. Larger wheels generally provide higher speeds and smoother rides, while harder wheels offer improved durability and reduced rolling resistance. Soft wheels provide better grip and shock absorption.

In conclusion, wheel configuration is a critical determinant of the skating experience. Its influence on stability, maneuverability, and speed necessitates careful consideration when selecting this specific type of recreational footwear. Understanding the strengths and weaknesses of different wheel configurations, coupled with awareness of wheel size and hardness, allows users to optimize their skating performance and enjoyment. Correctly matching wheel configuration to the intended skating environment can also minimize potential injuries, contributing to the safety and longevity of use.

4. Intended use

The specific purpose for which these wheeled boots are designed and manufactured dictates numerous product characteristics, influencing construction, features, and performance capabilities. Aligning product selection with the intended activity optimizes user experience and safety.

- Recreational Skating

Models designed for recreational skating prioritize comfort and ease of use. These products often feature softer boots, wider wheelbases for stability, and moderate wheel hardness suitable for various surfaces. Intended for leisurely skating on paved trails or in rinks, they offer a balance between maneuverability and control, providing a safe and enjoyable experience for casual users.

- Artistic/Figure Skating

Products engineered for artistic or figure skating require precision and responsiveness. These models typically incorporate stiffer boots for enhanced ankle support, specialized toe stops for executing spins and jumps, and carefully selected wheel durometers for optimal grip and glide. The design allows for intricate movements and routines, prioritizing control and agility over raw speed.

- Speed Skating

Wheel configurations intended for speed skating are built for maximum velocity and efficiency. Inline models with larger diameter wheels and low-cut boots for greater ankle flexion are common. Stiffer frames provide improved energy transfer, allowing for powerful strides and sustained high speeds. These products are optimized for competitive racing on smooth, dedicated surfaces.

- Aggressive Skating

Equipment designed for aggressive skating must withstand significant impact and abrasion. Reinforced boots, durable frames, and smaller, harder wheels are crucial for performing tricks and grinds on ramps, rails, and other obstacles. These models prioritize durability and protection, enabling skaters to execute challenging maneuvers in demanding environments.

Therefore, the proposed and actual use of this footwear represents a primary determinant of its suitability and performance. The consequences of mismatched equipment and usage include increased risk of injury, diminished performance, and accelerated product wear. Careful alignment of product selection with the demands of the intended activity leads to a more positive, safer, and prolonged user experience.

5. Price Point

The cost associated with acquiring this specific line of wheeled boots serves as a critical determinant influencing accessibility, market positioning, and perceived value. Price points reflect production costs, branding, feature sets, and target demographics, effectively segmenting the market.

- Material Quality and Construction

Higher price points often correlate with the utilization of premium materials such as high-grade leather, reinforced polymers, and precision-engineered bearings. Advanced construction techniques, including heat-molding and custom fitting, also contribute to increased costs. Conversely, lower-priced models typically employ more economical materials and standardized manufacturing processes, impacting durability and performance.

- Feature Sets and Technology

Advanced features, such as adjustable frames, enhanced braking systems, and specialized wheel compounds, command higher price points. Models incorporating innovative technologies, such as integrated lighting or digital performance tracking, further contribute to increased costs. Basic models, lacking these enhancements, generally occupy the lower end of the price spectrum.

- Brand Prestige and Marketing

Established brands with a strong reputation for quality and performance often command premium prices. Marketing investments, sponsorships, and celebrity endorsements contribute to brand perception and perceived value, allowing manufacturers to justify higher price points. Lesser-known brands typically offer more competitive pricing to gain market share.

- Target Market and Distribution Channels

Models targeted towards competitive athletes or serious enthusiasts typically carry higher price tags due to specialized features and performance capabilities. Distribution channels, such as specialty sporting goods stores or online retailers, also impact pricing. Products sold through premium channels may command higher prices due to associated costs and perceived exclusivity. Discount retailers typically offer lower-priced options, often sacrificing quality or features.

In summary, the price of wheeled boots represents a complex interplay of material quality, features, branding, and distribution strategies. Consumers must carefully weigh their individual needs and budget constraints when selecting a product, recognizing that price often serves as an indicator of quality, performance, and overall value.

Frequently Asked Questions About “Douglas Snyder Roller Skates”

The following addresses commonly encountered inquiries regarding “Douglas Snyder Roller Skates.” The content aims to provide clear and concise information.

Question 1: What distinguishes Douglas Snyder Roller Skates from other brands?

Douglas Snyder Roller Skates possess a reputation for precision engineering and durable construction. Specific models often feature proprietary wheel compounds and frame designs not found in competing brands. Historical company records indicate a commitment to quality control and customer satisfaction.

Question 2: Are replacement parts readily available for Douglas Snyder Roller Skates?

Availability of replacement parts varies depending on the specific model and its age. Common components, such as wheels and bearings, are typically stocked by authorized dealers and online retailers. However, parts for discontinued models may prove difficult to source, potentially requiring aftermarket alternatives or specialized repair services.

Question 3: What is the recommended maintenance schedule for Douglas Snyder Roller Skates?

Regular maintenance is essential for optimal performance and longevity. It is advisable to clean bearings every 20-30 hours of use and inspect wheel alignment periodically. Furthermore, routine checks for loose hardware and frame integrity are crucial for safety. Consult the product manual for specific recommendations related to the model in question.

Question 4: Are Douglas Snyder Roller Skates suitable for all skating disciplines?

Suitability depends on the specific model and its intended use. Certain models are designed for recreational skating, while others cater to artistic, speed, or aggressive disciplines. Utilizing a model outside its intended purpose can compromise performance and increase the risk of injury. Refer to the product specifications for application guidelines.

Question 5: What factors influence the sizing of Douglas Snyder Roller Skates?

Sizing considerations include foot length, width, and arch height. Douglas Snyder Roller Skates often employ a specific sizing chart that may differ from standard shoe sizes. It is recommended to consult the manufacturer’s sizing guide and, if possible, try on the product before purchase. A proper fit ensures comfort, stability, and control.

Question 6: Where can Douglas Snyder Roller Skates be purchased?

Distribution channels include authorized dealers, sporting goods stores, and online retailers. Availability may vary depending on geographic location and model. Purchasing from reputable sources ensures product authenticity and access to warranty services. Discounted prices from unauthorized vendors may indicate counterfeit or damaged products.

In summary, careful consideration of maintenance, model selection, and sizing is crucial for the safe and effective utilization of Douglas Snyder Roller Skates. Consulting official resources and authorized vendors provides the most accurate and reliable information.

The next section will delve into consumer reviews and testimonials regarding Douglas Snyder Roller Skates.

Conclusion

The preceding examination of Douglas Snyder roller skates has elucidated key aspects ranging from construction materials and wheel configurations to intended use and pricing. The brand recognition associated with these products, coupled with considerations for optimal utilization and maintenance, underscore the importance of informed consumer choices. A thorough understanding of these elements is essential for maximizing performance, safety, and longevity.

Ongoing advancements in materials science and engineering suggest continued evolution in roller skate technology. Potential future developments may include enhanced energy efficiency, improved shock absorption, and increased customization options. Continued research and adherence to established best practices are crucial for ensuring the continued safe and effective use of wheeled footwear across various recreational and competitive disciplines.

![Best Roller Skate Brands in [Year] - Glide in Style! How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Roller Skate Brands in [Year] - Glide in Style! | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/01/th-478-300x200.jpg)