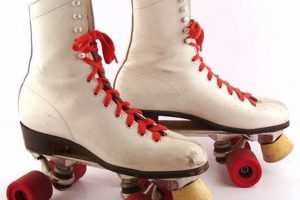

The acquisition of pre-owned recreational footwear, specifically those designed with wheels for gliding movement across surfaces, represents a transaction where ownership is transferred from a previous user to a new one. An example of this is the purchase of previously owned quad or inline models through online marketplaces or consignment shops.

This type of acquisition offers several advantages, including potential cost savings compared to purchasing new equipment. Furthermore, it contributes to sustainability efforts by extending the lifespan of existing products and reducing the demand for new manufacturing. Historically, the exchange of goods in this manner has been a common practice, reflecting both economic considerations and resourcefulness.

The subsequent sections will delve into factors influencing the purchase decision, evaluating the condition of pre-owned equipment, and highlighting platforms that facilitate the exchange of such recreational items.

Guidance on Acquiring Pre-Owned Wheeled Footwear

This section provides essential guidance for individuals considering the purchase of previously owned recreational footwear. Careful consideration of these points will aid in making informed decisions.

Tip 1: Assess Wear and Tear: Closely examine the wheels, bearings, and boot for signs of excessive use. Significant wear may indicate reduced performance or the need for immediate repairs.

Tip 2: Inspect the Frame and Fasteners: Verify the structural integrity of the frame. Check for cracks, bends, or corrosion. Ensure all screws, bolts, and straps are present and in good working order.

Tip 3: Evaluate Wheel Condition: Observe the wheels for even wear patterns. Uneven wear can affect balance and maneuverability. Consider the wheel durometer (hardness) to ensure it matches the intended skating style.

Tip 4: Check Bearing Performance: Spin each wheel individually to assess bearing smoothness. Noisy or slow-spinning bearings may require cleaning, lubrication, or replacement.

Tip 5: Determine Proper Fit: Ensure the boots fit snugly and comfortably. Ill-fitting boots can lead to discomfort, blisters, and impaired performance. Try on the equipment with appropriate socks before purchase.

Tip 6: Inquire About Usage History: Gather information about the equipment’s past use, including frequency, skating environment (indoor/outdoor), and any modifications made. This information can provide insights into its overall condition.

Tip 7: Sanitize Thoroughly: Prior to use, clean and disinfect all components, particularly the boot interior, to remove dirt, bacteria, and odors. This promotes hygiene and prolongs the equipment’s lifespan.

These guidelines are designed to facilitate a more informed and satisfactory purchase. Paying close attention to these details will mitigate the risks associated with acquiring pre-owned equipment.

The following section will explore avenues for locating and purchasing these items.

1. Price Point

The price point is a primary consideration when evaluating previously owned wheeled footwear. It reflects a complex interplay of factors beyond mere monetary value, influencing accessibility and perceived worth.

- Depreciation and Condition

Depreciation represents the decline in value from the original retail price due to use and time. Condition directly impacts the asking price. Items with significant wear, damaged components, or outdated designs will command lower prices. For example, a model from a past year with scuffed boots and worn wheels will be priced considerably less than a similar model in excellent condition.

- Market Demand and Scarcity

Current demand for particular models or styles affects the resale value. If a specific vintage quad style is highly sought after, its price may remain elevated despite its age or condition. Limited availability or discontinued models can further drive up the price point, creating a collectors’ market.

- Seller Motivation and Negotiation

A seller’s willingness to negotiate influences the final transaction price. Factors such as the seller’s urgency to sell, awareness of market value, or openness to offers can impact the buyer’s ability to secure a favorable price. An individual simply trying to clear space may accept a lower offer than a reseller aiming to maximize profit.

- Maintenance and Replacement Costs

The potential for future maintenance and component replacement affects the initial price point. While the initial acquisition cost might be low, worn bearings, damaged wheels, or broken straps may require immediate investment, ultimately increasing the overall cost of ownership. A seemingly inexpensive purchase could become more expensive in the long run.

These factors demonstrate that the price point is not an isolated attribute but rather a confluence of considerations. Buyers should evaluate depreciation, market demand, seller motivation, and future costs to determine the true value proposition when acquiring this type of equipment.

2. Condition Assessment

When considering the acquisition of previously owned recreational footwear, condition assessment assumes paramount importance. It functions as a critical determinant of value, safety, and potential longevity. The state of these items directly influences their performance characteristics and suitability for intended use.

Deficiencies in condition, such as worn wheels, compromised bearings, or structural damage to the boot or frame, can directly impact performance and safety. For example, significantly worn wheels reduce grip and maneuverability, increasing the risk of falls. Similarly, malfunctioning bearings impede smooth rolling, requiring greater exertion from the user and potentially leading to fatigue. In extreme cases, structural damage renders the equipment unsafe for use. Consequently, a thorough examination of all components is crucial before finalizing a purchase.

Comprehensive condition assessment extends beyond merely identifying visible defects. It encompasses evaluating the residual lifespan of key components, such as the wheels and bearings, and identifying potential maintenance requirements. Understanding the correlation between condition assessment and the overall value proposition of used items enables prospective buyers to make informed decisions, mitigating the risks associated with acquiring equipment that may require immediate repairs or have a limited remaining lifespan.

3. Size Availability

Size availability constitutes a critical factor in the acquisition of pre-owned wheeled footwear. The availability of a suitable size directly impacts usability, comfort, and safety, rendering this aspect of paramount importance in the purchase process.

- Impact on Fit and Performance

The correct size directly influences the fit of the boot. An ill-fitting boot can cause discomfort, blisters, and impaired control. A boot that is too large may lead to slippage, reducing stability and increasing the risk of ankle injuries. A boot that is too small restricts movement and causes pressure points. Consequently, size availability directly affects both performance and the potential for injury.

- Inventory Limitations in the Secondary Market

The secondary market for these items is characterized by variability in inventory. Unlike retail environments that offer a full range of sizes, the pre-owned market is subject to the availability of specific sizes from previous owners. This inherent limitation can restrict options and require prospective buyers to compromise on preferred models or features to secure a suitable size.

- Influence of Footwear Sizing Standards

Variations in sizing standards across different manufacturers necessitate careful attention to size charts and measurements. A size 9 from one brand may not equate to a size 9 from another. Furthermore, sizing may differ between inline and quad models. Prospective buyers must account for these variations to ensure a proper fit, further complicating the acquisition process.

- Adaptation Strategies and Modifications

In some instances, buyers may consider adaptations to achieve a better fit. This can include using thicker or thinner socks, adding insoles, or adjusting straps and buckles. However, these modifications are not always sufficient to compensate for a significantly incorrect size, highlighting the importance of prioritizing size availability from the outset.

The aforementioned factors underscore the importance of size availability in the context of acquiring used recreational footwear. The inherent limitations of the secondary market, variations in sizing standards, and the impact of fit on performance and safety necessitate careful consideration of this factor. Prioritizing size appropriateness is essential for ensuring a positive and safe experience.

4. Model type

The model type represents a primary differentiating factor within the context of previously owned wheeled footwear. The distinction between quad and inline models directly impacts the user’s skating experience, performance characteristics, and intended application. Consequently, understanding the model type forms a crucial element in the decision-making process when acquiring used recreational equipment.

Quad models, characterized by two pairs of wheels arranged in a rectangular configuration, generally offer greater stability, particularly for beginners. They are commonly employed in rink skating, roller derby, and artistic disciplines. Conversely, inline models, featuring wheels aligned in a single row, provide increased speed and maneuverability, making them suitable for outdoor skating, hockey, and fitness activities. Therefore, the selection of a particular model type should align with the user’s skill level, intended skating environment, and desired performance attributes. For example, an individual seeking stable and controlled movement for recreational rink skating would likely find a quad model more suitable. Conversely, a skater aiming for speed and agility on outdoor surfaces would likely prefer an inline model.

The availability of specific model types within the used market is subject to fluctuations in supply and demand. Vintage or specialized models may command higher prices due to their rarity or collector appeal. Furthermore, the condition of the model type, including the integrity of the frame, boot, and wheel mounts, directly affects its value and safety. The recognition of model type as a key attribute facilitates a more informed assessment of used equipment, ensuring alignment with the user’s requirements and mitigating the risks associated with acquiring unsuitable or compromised items.

5. Wheel quality

Wheel quality, in the context of used wheeled footwear, directly influences performance, safety, and longevity. The materials, durometer (hardness), and size of the wheels affect grip, speed, and the ability to absorb vibrations. Inferior wheel quality can lead to reduced control, increased risk of falls, and accelerated wear on other components. For instance, wheels made of low-grade polyurethane may exhibit poor grip on smooth surfaces, leading to instability. Conversely, wheels with improper hardness ratings for the intended surface can result in either excessive slippage or rapid degradation. Therefore, the integrity of the wheels represents a critical element in determining the value and usability of used equipment.

Assessing wheel quality in used items necessitates careful examination. Uneven wear patterns, cracks, or chunks missing from the wheel indicate potential issues. The durometer rating, typically indicated numerically, reveals the wheel’s hardness. Softer wheels (lower durometer) offer greater grip but wear more quickly, while harder wheels (higher durometer) are faster but provide less grip. A buyer must consider the intended use and surface conditions when evaluating the appropriate wheel durometer. An example would be a skater planning to use the equipment primarily outdoors, who may opt for wheels with a higher durometer rating to withstand the abrasive nature of asphalt. The condition of the wheels also affects the performance of the bearings, as worn or damaged wheels can impart uneven forces on the bearings, accelerating their wear.

In summary, wheel quality is paramount when acquiring used wheeled footwear. Deficiencies in wheel quality can compromise safety, reduce performance, and increase maintenance costs. A thorough assessment of the wheel material, durometer, and overall condition is essential for making informed purchasing decisions and ensuring a safe and enjoyable skating experience.

6. Bearing Function

Bearing function is a critical determinant of performance in wheeled recreational footwear. These components facilitate smooth wheel rotation around the axle. The condition of the bearings directly affects the skater’s speed, efficiency, and overall skating experience. In the context of used equipment, evaluating bearing function is paramount due to its susceptibility to wear and degradation.

Compromised bearing function stems from factors such as dirt ingress, lubricant breakdown, and physical damage. Deteriorated bearings manifest through increased friction, resulting in reduced speed, increased exertion, and potentially unsafe instability. For example, if the wheels on a pre-owned pair are difficult to spin freely by hand, or if they emit a grinding noise during rotation, it indicates that the bearings require cleaning, lubrication, or replacement. The practical consequence of neglecting bearing function is not only a diminished skating experience but also the potential for premature wear on the wheels and axles, escalating maintenance costs.

The evaluation of bearing function in used wheeled footwear necessitates a hands-on assessment. The wheels should be spun individually to gauge their freedom of movement. Excessive noise or resistance signifies compromised bearings. While cleaning and lubrication may restore function in some cases, severely damaged or corroded bearings require replacement. Given the impact of bearing function on performance and safety, meticulous evaluation is indispensable when considering the acquisition of previously owned equipment. Ignoring bearing function can lead to unexpected expenses and a potentially hazardous skating experience.

7. Seller Reputation

Seller reputation constitutes a critical element in transactions involving previously owned recreational equipment. It serves as a proxy for trust and reliability, mitigating information asymmetry inherent in the secondary market. A seller’s established reputation functions as a signal of past behavior, informing potential buyers about the likelihood of a satisfactory transaction.

- Feedback Metrics and Ratings

Online marketplaces often employ feedback systems, wherein buyers rate and comment on their experiences with sellers. Positive feedback, high ratings, and a substantial transaction history indicate a reliable seller. Conversely, negative feedback, low ratings, or a limited transaction history raise concerns. For instance, a seller with consistently positive feedback regarding accurate product descriptions and prompt shipping is more likely to provide a satisfactory transaction than a seller with numerous complaints about misrepresented items or delayed deliveries. Such metrics inform risk assessment.

- Transparency and Communication

A reputable seller typically provides detailed product descriptions, including accurate information regarding condition, usage history, and any known defects. They respond promptly and professionally to inquiries, demonstrating a willingness to address concerns. A seller who withholds information or avoids communication signals potential dishonesty. For instance, a seller willing to provide close-up images of wear points inspires more confidence than one providing only generic, stock photos.

- Return Policies and Guarantees

Reputable sellers often offer return policies or guarantees, providing recourse for buyers who receive misrepresented or defective items. The presence of a clear and fair return policy demonstrates a commitment to customer satisfaction. A seller unwilling to offer any form of return or guarantee raises significant red flags. The presence of a stated return window offers security to a potential buyer.

- Platform Policies and Dispute Resolution

Online marketplaces typically have policies in place to protect buyers and sellers. These policies may include dispute resolution mechanisms and fraud protection. A seller who adheres to platform policies and demonstrates a willingness to resolve disputes fairly is more likely to be reputable. A seller who attempts to circumvent platform policies raises concerns. Dispute history, if available, should be reviewed.

The facets outlined above highlight the multifaceted nature of seller reputation. In the context of “roller skates for sale used,” assessing seller reputation is essential for mitigating the risks associated with acquiring pre-owned equipment. A thorough evaluation of feedback metrics, transparency, return policies, and adherence to platform policies contributes to a more informed and secure transaction.

Frequently Asked Questions

The following addresses common inquiries pertaining to the acquisition of pre-owned recreational footwear designed for gliding movement across surfaces. These answers provide clarity on key considerations.

Question 1: What constitutes a fair price range for pre-owned recreational footwear?

The valuation of used recreational footwear is contingent upon several factors, including the model’s original retail price, the extent of wear and tear, current market demand, and the presence of any specialized features or modifications. Comparative analysis of similar items available through online marketplaces or consignment shops provides a benchmark for determining a reasonable price range. A difference of 20-50% less than retail price is acceptable.

Question 2: How does one assess the remaining lifespan of wheels on used recreational footwear?

Evaluation of wheel lifespan involves a comprehensive assessment of their condition. Uneven wear patterns, significant reductions in wheel diameter, and the presence of cracks or chunks indicate substantial wear. The durometer, or hardness, of the wheel also influences its lifespan. Softer wheels generally exhibit shorter lifespans compared to harder wheels. Measurements using digital calipers can give precise readings of wheel width and diameter.

Question 3: What are the potential risks associated with purchasing recreational footwear without a trial fitting?

Acquiring footwear without a trial fitting introduces the risk of improper fit, leading to discomfort, blisters, and impaired control. Inaccurate sizing information from the seller or variations in sizing standards across manufacturers exacerbate this risk. Foot measurements, while helpful, do not guarantee an optimal fit due to variations in foot shape and boot design. Consulting sizing charts is recommended.

Question 4: What steps should be taken to sanitize recreational footwear prior to use?

Prior to using previously owned footwear, thorough sanitation is recommended to mitigate the risk of bacterial or fungal contamination. The interior of the boot should be cleaned with a disinfectant solution, such as isopropyl alcohol or a commercially available disinfectant spray. Removable components, such as insoles, should be washed separately with soap and water. Thorough drying is essential to prevent moisture buildup and odor development. A combination of both rubbing alcohol and sunlight is an optimal choice.

Question 5: How does one verify the authenticity of high-end or collectible recreational footwear?

Verifying the authenticity of high-end or collectible recreational footwear requires careful scrutiny. Comparison with authenticated models, examination of serial numbers and manufacturing details, and consultation with expert appraisers can aid in detecting counterfeit items. Discrepancies in stitching, materials, or branding raise suspicion. A professional opinion is valuable.

Question 6: What recourse is available if the purchased recreational footwear is misrepresented by the seller?

Recourse for misrepresented items depends on the platform used for the transaction. Online marketplaces typically offer dispute resolution mechanisms, allowing buyers to file claims for misrepresented items. Photographic evidence documenting the discrepancies is essential for supporting the claim. Legal action may be pursued in cases of deliberate fraud. Contacting legal expert is recommended.

These answers should provide a clearer understanding of the key considerations involved in purchasing pre-owned recreational footwear.

The next section will delve into maintenance and care.

Considerations Regarding Acquisition of Previously Owned Wheeled Footwear

The preceding discussion has illuminated critical factors associated with acquiring “roller skates for sale used.” It has emphasized the importance of condition assessment, size appropriateness, model type selection, wheel quality evaluation, bearing function verification, and seller reputation analysis. Each element contributes to a comprehensive understanding of the risks and rewards inherent in this market segment.

Potential purchasers are encouraged to apply diligence and scrutiny throughout the acquisition process. By exercising informed judgment, individuals can maximize the likelihood of a satisfactory transaction while mitigating potential pitfalls. The responsible acquisition and utilization of previously owned equipment promotes sustainability and resourcefulness. It would be wise for stakeholders to share this information to improve the experience for themselves and others.

![Best Roller Skate Helmet [Safe & Stylish] Guide How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Roller Skate Helmet [Safe & Stylish] Guide | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/02/th-108-300x200.jpg)