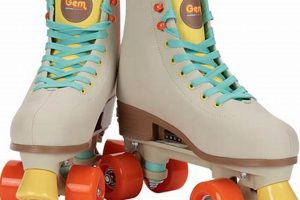

Specialized footwear designed for a specific style of skating characterized by rhythmic movements and dance-like sequences constitute a distinct category within the roller skating world. These skates, often featuring a low-cut boot for enhanced ankle mobility and a smaller wheel diameter for increased maneuverability, facilitate the execution of intricate footwork and expressive routines. As an example, individuals participating in artistic or jam skating typically utilize this type of equipment.

The utilization of this equipment allows for heightened control and responsiveness, enabling skaters to perform complex steps and maintain balance during dynamic movements. Historically, this equipment has played a significant role in the evolution of various skating disciplines, fostering creativity and innovation in skating techniques. The unique design and construction of this specific footwear contribute to the fluidity and artistry associated with certain roller skating styles.

The subsequent sections will delve into the components, maintenance, and selection criteria relevant to this particular type of skating equipment. Further details regarding suitable surfaces, optimal techniques, and the diverse community surrounding this activity will also be presented.

Guidance for Optimal Use

The following recommendations are designed to enhance performance and longevity when utilizing equipment designed for rhythmic skating applications.

Tip 1: Boot Fit Assessment: Ensure the boot provides a snug, yet comfortable fit, allowing for maximum ankle articulation. Excessive tightness can impede movement, while looseness compromises stability.

Tip 2: Wheel Durometer Selection: Consider surface conditions when choosing wheel durometer. Softer wheels offer greater grip on slick surfaces, whereas harder wheels provide increased speed on smoother terrains.

Tip 3: Bearing Maintenance: Regular cleaning and lubrication of bearings are crucial. Debris accumulation can significantly reduce rotational efficiency, hindering performance.

Tip 4: Plate Alignment Verification: Periodically inspect plate alignment. Misalignment can cause uneven wear and negatively affect balance and maneuverability.

Tip 5: Toe Stop Adjustment: Adjust toe stop height according to individual skating style and skill level. Proper adjustment is paramount for executing controlled stops and transitions.

Tip 6: Protective Gear Integration: Always incorporate appropriate protective gear, including wrist guards, knee pads, and elbow pads. Safety is paramount, especially when practicing complex maneuvers.

Tip 7: Controlled Practice Progression: Focus on mastering fundamental skills before attempting advanced techniques. Gradual progression minimizes the risk of injury and promotes long-term development.

Adherence to these guidelines will contribute to a more enjoyable and effective skating experience, extending the lifespan of the skating equipment and minimizing the potential for adverse events.

The concluding section will offer insights into selecting the appropriate equipment and identifying resources for further skill development.

1. Ankle Mobility

Ankle mobility constitutes a critical biomechanical factor influencing performance in roller skating, particularly in disciplines emphasizing rhythmic expression. The degree of dorsiflexion, plantarflexion, inversion, and eversion achievable at the ankle joint directly affects the skater’s ability to execute complex footwork and maintain balance during dynamic movements.

- Range of Motion and Maneuverability

Ankle mobility directly correlates with the range of motion available for executing intricate skating maneuvers. Increased dorsiflexion allows for deeper knee bends and lower stances, essential for certain dance steps. Conversely, plantarflexion facilitates pushing off and maintaining forward momentum. Limited ankle mobility restricts the repertoire of achievable movements and compromises fluidity.

- Balance and Stability

The ankle joint plays a pivotal role in maintaining balance and stability, particularly when shifting weight during transitions and turns. Adequate ankle mobility enables subtle adjustments that compensate for imbalances, preventing falls and maintaining control. Restricted ankle mobility necessitates reliance on other joints, potentially leading to fatigue and increased risk of injury.

- Impact on Skating Style

Ankle mobility significantly influences skating style. Skaters with greater ankle mobility tend to exhibit a more fluid, expressive, and dynamic skating style. They can execute intricate footwork with greater ease and precision, contributing to an enhanced aesthetic appeal. Limited ankle mobility may result in a stiffer, more restricted skating style.

- Equipment Selection and Modification

The design of equipment significantly impacts ankle mobility. Low-cut boot designs, common in equipment designed for rhythmic styles, prioritize ankle freedom. However, proper fit remains crucial to prevent instability. Skaters with limited natural ankle mobility may require specific boot modifications or orthotics to achieve optimal range of motion and support.

In summary, ankle mobility represents a fundamental biomechanical determinant in equipment designed for rhythmic roller skating. It directly influences maneuverability, balance, skating style, and equipment selection. Optimizing ankle mobility through targeted training and appropriate equipment configuration enhances performance, reduces injury risk, and contributes to a more aesthetically pleasing skating experience.

2. Wheel Hardness

Wheel hardness, measured on the durometer scale, is a critical parameter influencing performance in rhythmic roller skating. The durometer value, typically ranging from 74A to 103A, dictates the wheel’s resilience and grip characteristics. Appropriate selection is paramount for optimal control and maneuverability.

- Grip and Slip Dynamics

Softer wheels (lower durometer values) offer enhanced grip, particularly on smooth indoor surfaces. This increased traction facilitates precise footwork and controlled turns, crucial for executing intricate routines. Conversely, harder wheels (higher durometer values) promote greater slip, enabling slides and spins. The choice depends on the skater’s style and the performance surface characteristics. Insufficient grip can hinder precise movements, while excessive grip may impede fluid transitions.

- Speed and Roll Efficiency

Harder wheels generally exhibit lower rolling resistance, translating to increased speed and improved roll efficiency. This is advantageous for maintaining momentum during extended routines and navigating larger performance areas. Softer wheels, while providing superior grip, tend to absorb more energy, reducing speed and increasing fatigue. Therefore, skaters must balance the need for grip and speed based on the demands of their skating style and performance environment. Surface conditions, such as polished concrete versus wood, should also be considered when selecting wheel hardness.

- Surface Compatibility and Wear Resistance

The chosen wheel hardness must align with the characteristics of the skating surface. Soft wheels are more prone to wear and tear on rough or abrasive surfaces, while hard wheels may provide insufficient grip on slick surfaces. Indoor rhythmic skating typically favors softer wheels due to the smooth, controlled environment. Outdoor skating often necessitates harder wheels to withstand the challenges posed by uneven terrain and abrasive asphalt. Regular inspection and rotation of wheels are essential to ensure even wear and maintain consistent performance characteristics.

- Vibration Absorption and Comfort

Softer wheels offer superior vibration absorption, contributing to a more comfortable skating experience, particularly on less-than-ideal surfaces. This can be beneficial for skaters performing long routines or practicing for extended periods. Harder wheels transmit more vibrations, potentially leading to fatigue and discomfort. The impact of vibration also affects joint health. Skaters with pre-existing joint conditions should prioritize wheel hardness that maximizes vibration absorption. The trade-off between comfort and performance must be carefully considered.

In conclusion, wheel hardness represents a critical variable influencing performance in rhythmic roller skating. The selection process requires careful consideration of grip requirements, speed preferences, surface conditions, and skater comfort. Optimizing wheel hardness based on these factors is crucial for maximizing control, efficiency, and overall skating experience. The dynamic interplay between these factors underscores the importance of informed decision-making when selecting equipment for this specialized skating discipline.

3. Plate Material

The plate, a foundational component of roller skates, establishes the connection between the boot and the wheels, significantly influencing the performance characteristics of rhythm roller skates. The material composition of the plate directly affects attributes such as weight, strength, responsiveness, and vibration dampening, each impacting the skater’s ability to execute precise movements and maintain control during rhythmic routines. Aluminum alloys and composite materials are frequently employed, each presenting a distinct set of advantages and disadvantages. The selection of plate material, therefore, constitutes a critical decision in the customization and optimization of rhythm roller skates.

Aluminum plates, renowned for their high strength-to-weight ratio, offer exceptional responsiveness, allowing for quick and precise directional changes. This characteristic is particularly beneficial in disciplines emphasizing intricate footwork and rapid transitions. However, aluminum plates may transmit more vibration than their composite counterparts, potentially leading to fatigue over extended periods. Composite plates, conversely, often provide superior vibration dampening, enhancing comfort and reducing stress on the skater’s joints. They may, however, exhibit slightly reduced responsiveness compared to aluminum, potentially affecting the precision of subtle movements. Real-world examples demonstrate professional skaters often selecting aluminum for competitive performance demanding peak responsiveness, while recreational skaters prioritize composite plates for enhanced comfort during longer sessions.

Ultimately, the choice of plate material necessitates a careful evaluation of individual skating style, skill level, and performance objectives. The optimal selection represents a compromise between responsiveness, vibration dampening, and weight considerations. Understanding the inherent properties of various plate materials empowers skaters to make informed decisions, maximizing performance and minimizing potential discomfort. The ongoing development of novel materials and manufacturing techniques continues to refine the performance characteristics of roller skate plates, driving innovation and enhancing the overall skating experience. Further research into material science promises to yield even more advanced plates optimized for the specific demands of rhythmic roller skating.

4. Bearing Precision

Bearing precision exerts a direct influence on the performance characteristics of equipment designed for rhythmic roller skating. Higher precision bearings, manufactured to tighter tolerances, minimize friction and maximize rotational efficiency. This reduction in friction translates to smoother, faster, and more consistent wheel rotation, enabling skaters to execute intricate footwork and maintain momentum with greater ease. The ABEC (Annular Bearing Engineers’ Committee) rating system, commonly used to classify bearing precision, provides a standardized metric for evaluating manufacturing tolerances. Higher ABEC ratings indicate tighter tolerances and, consequently, improved performance. For example, skaters performing complex spins and transitions often benefit from ABEC 7 or ABEC 9 bearings, which offer superior rotational characteristics compared to lower-rated bearings.

The practical significance of understanding bearing precision extends to maintenance and longevity. High-precision bearings, while offering enhanced performance, may be more susceptible to damage from contaminants and improper lubrication. Regular cleaning and lubrication are crucial for preserving the performance and extending the lifespan of these components. Furthermore, selecting appropriate bearing lubricant tailored to the specific operating conditions of rhythmic roller skating is essential. For instance, lightweight synthetic lubricants can minimize friction without attracting excessive dirt and debris. Conversely, neglecting maintenance can lead to bearing degradation, resulting in reduced rotational efficiency, increased friction, and ultimately, compromised skating performance. Real-world scenarios demonstrate that consistent bearing maintenance can significantly extend the lifespan of high-precision bearings, providing a tangible return on investment.

In summary, bearing precision represents a critical factor influencing the performance of equipment designed for rhythmic roller skating. Higher precision bearings offer improved rotational efficiency, enabling smoother and faster skating. However, maintaining these bearings requires diligence to prevent contamination and ensure proper lubrication. The ABEC rating system provides a valuable metric for evaluating bearing precision, guiding skaters in selecting components appropriate for their skill level and performance objectives. The inherent challenge lies in balancing the performance benefits of high-precision bearings with the increased maintenance demands. Recognizing the interplay between bearing precision, maintenance practices, and skating performance contributes to a more informed and effective approach to equipment selection and utilization.

5. Toe Stop Design

The toe stop, a seemingly small but critical component of rhythm roller skates, significantly influences a skater’s ability to execute a range of essential maneuvers. Its design directly impacts braking efficiency, stability during transitions, and the capacity to perform specialized rhythmic techniques. Variations in material, shape, and adjustability cater to diverse skating styles and skill levels. Understanding the nuances of toe stop design is essential for optimizing performance and safety within the realm of rhythm roller skating.

- Material Composition and Grip

Toe stops are commonly manufactured from natural or synthetic rubber compounds, each offering varying degrees of grip and durability. Softer compounds provide enhanced traction on smooth surfaces, facilitating controlled stops and pivots. Harder compounds, while sacrificing some grip, exhibit greater wear resistance, making them suitable for abrasive surfaces. The selection of material composition should align with the skater’s preferred environment and skating style. For instance, indoor rhythmic skating often favors softer compounds for optimal grip, while outdoor skating may necessitate harder compounds to withstand wear.

- Shape and Contact Area

Toe stops are available in a variety of shapes, including round, cylindrical, and asymmetrical designs. The shape influences the contact area between the toe stop and the skating surface, directly affecting braking power and stability. Larger contact areas provide greater braking force, while smaller contact areas allow for more precise control during specialized maneuvers, such as toe spins. Asymmetrical designs may offer a combination of both, catering to skaters who require versatility. The choice of shape should reflect the skater’s emphasis on braking versus intricate footwork.

- Adjustability and Positioning

Toe stop adjustability is a crucial feature, allowing skaters to fine-tune the height and angle of the toe stop to match their individual preferences and skating technique. Lowering the toe stop increases braking power, while raising it enhances maneuverability. Adjusting the angle can also optimize the contact area for specific maneuvers. Proper positioning of the toe stop is essential for maintaining balance and preventing unintended contact with the skating surface. Experienced skaters often experiment with different toe stop positions to identify the optimal configuration for their unique style.

- Thread Type and Compatibility

Toe stops attach to the skate plate via a threaded stem. Various thread types exist, and compatibility with the skate plate is paramount. Selecting the correct thread type ensures a secure and stable connection, preventing the toe stop from loosening or detaching during use. Incompatibility can lead to damage to the plate or toe stop, compromising safety and performance. Skaters should consult manufacturer specifications to verify compatibility before purchasing replacement toe stops.

In conclusion, toe stop design encompasses a multifaceted array of considerations that directly impact performance and safety in rhythm roller skating. From material composition and shape to adjustability and compatibility, each element contributes to the skater’s ability to control movement and execute complex routines. A thorough understanding of these design nuances empowers skaters to make informed decisions, optimizing their equipment for peak performance and enjoyment. The ongoing evolution of toe stop design reflects a continued commitment to enhancing the capabilities and safety of rhythm roller skating.

Frequently Asked Questions

The following section addresses common inquiries regarding rhythm roller skates, providing concise and informative answers to enhance understanding.

Question 1: What distinguishes rhythm roller skates from other types of roller skates?

Rhythm roller skates are specifically designed for the execution of rhythmic movements and dance-oriented skating styles. They typically feature a lower boot cut for increased ankle mobility, smaller wheel diameters for enhanced maneuverability, and a toe stop for controlled stops and pivots, differentiating them from recreational or speed skates.

Question 2: What role does ankle mobility play in rhythm roller skating?

Ankle mobility is paramount. It enables skaters to execute intricate footwork, maintain balance during dynamic movements, and achieve the range of motion necessary for expressive skating styles. Rhythm roller skates are often designed to facilitate maximal ankle articulation.

Question 3: How does wheel hardness affect performance in rhythm roller skating?

Wheel hardness dictates the level of grip and slip. Softer wheels provide enhanced grip on smooth surfaces, facilitating controlled turns and precise footwork. Harder wheels offer greater slip, enabling slides and spins. The optimal wheel hardness depends on skating style and surface conditions.

Question 4: What is the significance of plate material in rhythm roller skate construction?

The plate connects the boot to the wheels and influences responsiveness, weight, and vibration dampening. Aluminum plates offer high responsiveness, while composite plates provide superior vibration dampening. The ideal plate material is determined by the skater’s skill level and performance objectives.

Question 5: How does bearing precision impact the performance of rhythm roller skates?

Bearing precision minimizes friction and maximizes rotational efficiency. Higher precision bearings facilitate smoother, faster, and more consistent wheel rotation, enhancing performance, particularly in intricate maneuvers. Regular cleaning and lubrication are crucial for maintaining bearing performance.

Question 6: What factors should be considered when selecting toe stops for rhythm roller skates?

Toe stop material, shape, adjustability, and thread type should be considered. Softer materials offer greater grip, while harder materials provide enhanced durability. The shape and adjustability influence braking power and maneuverability. Correct thread type ensures compatibility with the skate plate.

These FAQs provide a foundational understanding of the key characteristics and considerations associated with rhythm roller skates.

The subsequent section will provide guidelines for selecting appropriate rhythm roller skate equipment.

Conclusion

The preceding sections have explored the multifaceted characteristics of rhythm roller skates, encompassing design elements, performance attributes, and maintenance considerations. The analysis has underscored the critical interplay between components such as boot design, wheel hardness, plate material, bearing precision, and toe stop configuration in shaping the skater’s experience and enabling the execution of complex rhythmic routines. A comprehensive understanding of these factors is essential for informed equipment selection and optimized skating performance.

As the discipline of rhythm roller skating continues to evolve, ongoing research and technological advancements will undoubtedly lead to further refinements in equipment design and manufacturing. Continued exploration of material science and biomechanical principles holds the potential to unlock new levels of performance and safety for skaters of all skill levels. The pursuit of innovation and the dedication to advancing the art of rhythmic movement remain central to the future trajectory of this dynamic and expressive activity. Further engagement with resources, instruction, and community interaction will contribute to a deeper appreciation of rhythm roller skates and their significance within the broader context of roller sports.