Equipment designed for gliding across ice surfaces, frequently used for recreational skating or ice sports, can be constructed using molded polymers for the boot portion. These implements often offer a cost-effective alternative to traditional leather or composite boot designs. An example would be a child’s beginner skate designed for ease of use and affordability.

The employment of polymer materials in the construction of such footwear can offer advantages in terms of manufacturing efficiency and potential resistance to water damage. Historically, these materials have allowed for wider accessibility to ice skating due to lower production costs. The durability and relative ease of maintenance are further contributing factors to their appeal for casual users.

The subsequent discussion will delve into specific design considerations, performance characteristics, and target user groups relevant to this type of skating equipment. Furthermore, a comparison with alternative materials and construction methods will be presented to offer a complete understanding of its strengths and limitations.

Guidance on Equipment Selection and Use

The following guidance aims to offer useful information regarding the selection, maintenance, and appropriate use of skating equipment employing polymer-based construction. Careful consideration of these points can improve the user experience and prolong the lifespan of the equipment.

Tip 1: Size and Fit Assessment: Prioritize proper sizing and fit. Ill-fitting boots can lead to discomfort, reduced control, and potential injury. Ensure adequate toe room and secure ankle support. Consider wearing skating socks during the fitting process.

Tip 2: Blade Sharpness Inspection: Regularly inspect the blades for sharpness and any signs of damage. Dull blades diminish performance and can increase the risk of falls. Sharpening should be performed by a qualified professional.

Tip 3: Fastener Security Check: Before each use, verify that all buckles, straps, or laces are securely fastened. Loose fasteners can compromise stability and increase the likelihood of accidents. Ensure even pressure distribution across the foot.

Tip 4: Surface Compatibility Awareness: Be mindful of the ice surface conditions. Rough or uneven ice may accelerate wear and tear on the blades. Avoid skating on surfaces contaminated with debris or chemicals.

Tip 5: Storage Considerations: Store the equipment in a dry, well-ventilated area when not in use. Avoid prolonged exposure to direct sunlight or extreme temperatures, as this can degrade the polymer materials. Use blade guards to prevent damage during storage.

Tip 6: Cleaning Protocol: After each use, wipe down the boots and blades with a clean, dry cloth. This will help prevent the buildup of moisture and dirt, which can lead to corrosion or material degradation. Occasional use of a polymer-specific cleaner may be beneficial.

Tip 7: Consider Skill Level: This specific type of skate is generally more suitable for beginner and recreational users. Advanced skaters may prefer equipment with more robust construction and performance-oriented features.

Adherence to these guidelines can improve performance, extend the lifespan of skating equipment employing polymer construction, and enhance user safety. Regular inspection and proper maintenance are crucial for optimal results.

The succeeding sections will explore the performance characteristics and limitations of these implements in greater detail, providing a comprehensive assessment of their suitability for various applications.

1. Cost-effectiveness

The utilization of polymers in manufacturing skating equipment directly contributes to its cost-effectiveness. Polymer-based materials are generally less expensive to acquire and process compared to traditional materials such as leather, steel, or carbon fiber composites. This translates to a lower overall production cost, allowing manufacturers to offer skating equipment at a more accessible price point. The cause is the lower material and processing expenses; the effect is increased affordability for the consumer. Cost-effectiveness is a pivotal component, enabling wider participation in recreational ice skating, especially among budget-conscious individuals and families. A readily available example is the prevalence of plastic-booted ice skates in rental facilities at public skating rinks, where durability and low cost are paramount.

Furthermore, the manufacturing processes associated with polymers often lend themselves to mass production techniques, such as injection molding. This further reduces the per-unit cost of production, allowing manufacturers to achieve economies of scale. The reduced complexity of design and assembly also contributes to lower labor costs. This contrasts sharply with the labor-intensive processes involved in constructing traditional leather ice skates, which often require skilled craftsmanship. The practical significance of understanding this connection lies in recognizing that polymer-based ice skates represent a trade-off: affordability and accessibility are prioritized, potentially at the expense of ultimate performance and durability as compared to higher-end alternatives. For example, adjustable skates for children often feature polymer boots and simplified blade attachments, explicitly designed to minimize cost and maximize usability for growing feet.

In summary, the cost-effectiveness of skating equipment utilizing polymer construction is a direct consequence of lower material costs, efficient manufacturing processes, and reduced labor requirements. This affordability makes ice skating more accessible to a broader segment of the population. While acknowledging the limitations in performance and durability compared to higher-priced options, polymer-based skates represent a practical and widely adopted solution for recreational ice skating. The challenge lies in balancing cost considerations with desired performance characteristics when selecting skating equipment.

2. Molded construction

Molded construction is intrinsically linked to polymer-based ice skating equipment, serving as a defining characteristic of their design and manufacturing process. The implementation of molding techniques, primarily injection molding, facilitates the creation of the boot component in a single, unified piece. This contrasts with traditional methods involving the assembly of multiple leather or composite parts. The cause is the inherent moldability of polymers; the effect is simplified manufacturing and reduced production costs. The resulting one-piece construction contributes to the structural integrity and water resistance of the skate boot. As a component, molded construction is paramount to the cost-effectiveness and accessibility of polymer-based ice skates. A real-life example is the consistent design of recreational ice skates found in rental inventories; their uniform shape and size gradations are direct outcomes of molding techniques. Understanding this connection is of practical significance, as it clarifies the design principles that enable widespread adoption of this type of skating equipment.

The design freedom afforded by molding processes allows for intricate geometries and integrated features. Reinforcements, hinge points for buckles, and textured surfaces can be incorporated directly into the mold, eliminating the need for separate components or assembly steps. This streamlining of the manufacturing process translates to lower labor costs and increased production efficiency. Furthermore, molding enables the creation of complex shapes optimized for comfort and support. Ergonomic contours and integrated ankle supports can be achieved with precision, enhancing the overall user experience. An example is the incorporation of ventilation holes directly into the molded boot, improving breathability and moisture management. This design flexibility differentiates molded skates from traditional designs, where such features would require additional manufacturing steps. The practical application is a more comfortable and user-friendly ice skate, particularly beneficial for beginners and recreational skaters.

In summary, molded construction is a fundamental aspect of skating equipment utilizing polymers, enabling efficient manufacturing, intricate design integration, and cost-effective production. The resulting benefits of improved water resistance, structural integrity, and enhanced user comfort contribute to the widespread adoption of these skates for recreational purposes. While acknowledging potential limitations in performance compared to specialized equipment, molded construction represents a pragmatic and versatile approach to ice skate design. The ongoing challenge lies in optimizing molding techniques and polymer formulations to further improve the performance and durability of this type of skating equipment.

3. Water resistance

Water resistance is a notable characteristic directly correlated with the utilization of polymeric materials in the construction of ice skating equipment. The inherent properties of many polymers render them impervious to water absorption and penetration, providing a significant advantage in the context of ice skating, where exposure to moisture is inevitable.

- Material Impermeability

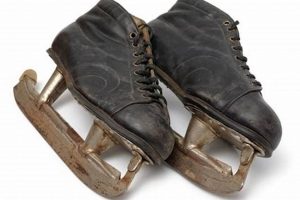

The core component of water resistance lies in the inherent impermeability of the polymers used in the skate boot. Unlike traditional materials such as leather, which are porous and susceptible to water absorption, polymers like polyethylene and polypropylene do not readily absorb water. This property prevents the boots from becoming waterlogged and heavy during use, maintaining comfort and performance. For example, consider the stark contrast between older leather skates that require extensive waterproofing treatments and modern polymeric skates that offer inherent protection.

- Molded Construction Benefit

The molded construction method, commonly employed in the production of skates utilizing polymeric materials, further enhances water resistance. The seamless, one-piece construction minimizes potential entry points for water, eliminating seams and stitching that could otherwise allow moisture to seep in. A practical example is the absence of visible stitching on the outer shell of a typical recreational ice skate, a design choice that directly contributes to its water-resistant properties.

- Maintenance Reduction

The water-resistant nature of polymer-based ice skates translates to a reduction in maintenance requirements. Unlike leather skates, which require regular application of waterproofing agents to maintain their integrity, polymer skates generally require minimal upkeep to remain resistant to water damage. This ease of maintenance contributes to the overall appeal of skates employing polymer construction, particularly for casual users. An illustration of this is the simplified cleaning process, often requiring only a wipe-down with a damp cloth.

- Performance Consistency

Water resistance contributes to performance consistency by preventing changes in the weight and rigidity of the skate boot during use. Water absorption can significantly alter the flex and feel of traditional materials, impacting the skater’s control and stability. Polymer skates, on the other hand, maintain their structural integrity and responsiveness, even when exposed to moisture. A real-world scenario is the consistent performance of rental skates at ice rinks, where skates are subjected to frequent and prolonged exposure to wet conditions.

In summary, the water-resistant properties associated with polymer-based ice skates stem from the inherent impermeability of the materials, the benefits of molded construction, reduced maintenance demands, and the resulting performance consistency. These attributes contribute to the widespread adoption of this type of skating equipment, especially for recreational use and beginner skaters. By preventing water absorption and maintaining structural integrity, polymer skates offer a practical and reliable solution for navigating icy conditions.

4. Beginner Suitability

The design and material characteristics of skating equipment utilizing polymers often align favorably with the needs of novice ice skaters. This suitability stems from a combination of factors that prioritize ease of use, stability, and affordability, characteristics that are particularly beneficial for those new to the sport.

- Enhanced Ankle Support

Polymer boots frequently incorporate a higher degree of ankle support compared to traditional designs. The stiffer material provides greater stability, reducing the likelihood of ankle roll and promoting confidence for beginners who may lack the muscle strength and balance required for more flexible skates. Examples include the extended cuff found on many recreational models, which serves to restrict lateral movement and assist in maintaining an upright posture.

- Simplified Fastening Systems

Skates employing polymers often feature simplified fastening systems, such as buckles or Velcro straps, that are easier to use than traditional laces. This allows beginners to quickly and securely fasten their skates without the need for specialized knowledge or assistance. Consider the self-tightening mechanisms on some children’s models, designed for independent use and adjustment.

- Forgiving Blade Geometry

The blades on many polymer-booted skates designed for beginners exhibit a less aggressive curvature and a flatter profile. This design promotes stability and reduces the tendency for the skate to unexpectedly catch an edge, making it easier for novices to maintain balance and control. An illustrative example is the more gradual rocker on entry-level blades, allowing for smoother glides and turns.

- Lower Center of Gravity

The overall design of these skates often results in a lower center of gravity, further enhancing stability and reducing the risk of falls. This is achieved through a combination of boot design and blade placement. Imagine a novice skater taking their first strides; the lowered center of gravity assists them in maintaining balance and control.

These factors collectively contribute to the “Beginner Suitability” of skating equipment utilizing polymers. The design choices prioritize stability, ease of use, and confidence-building features, making them a practical choice for individuals new to ice skating. While experienced skaters may prefer equipment offering greater performance and responsiveness, polymer-booted skates provide an accessible and supportive introduction to the sport.

5. Limited performance

The relationship between polymer-constructed ice skates and restricted performance capabilities is significant. The inherent properties of polymers, while advantageous in terms of cost and manufacturing, impose limitations on the performance envelope of the equipment. The primary cause is the reduced stiffness and resilience of polymers compared to materials like carbon steel or composite materials. This directly affects blade responsiveness, energy transfer, and overall control. “Limited performance” is a vital element to consider when selecting skating equipment employing polymer boots, especially for individuals seeking advanced capabilities. Recreational ice skates in rental facilities offer a practical example, prioritizing affordability and durability over performance characteristics sought by competitive skaters. Understanding this limitation clarifies the intended use-case and target audience for this type of equipment.

Further analysis reveals that the reduced torsional rigidity of polymer boots impacts edge control and precision during complex maneuvers. The boot’s tendency to flex under load diminishes the skater’s ability to efficiently transfer energy to the blade, resulting in reduced speed and agility. The blade’s capacity to maintain a sharp edge over extended use might also be compromised. In practical application, a figure skater attempting intricate jumps and spins would likely find polymer-booted skates inadequate for their performance requirements. A hockey player requiring rapid acceleration and precise turns would similarly encounter significant limitations. This emphasizes that polymeric construction serves as an appropriate design choice for beginner and recreational users but may restrict advanced skill development and performance at higher levels.

In summary, the correlation between polymer-constructed ice skates and “Limited performance” stems from inherent material properties and design choices. This limitation is a critical consideration for informed equipment selection. While polymer skates offer compelling advantages in cost-effectiveness and ease of use, their restricted performance envelope makes them less suitable for advanced skating disciplines. The challenge lies in balancing cost constraints with performance requirements to ensure the chosen equipment aligns appropriately with the skater’s skill level and intended application.

Frequently Asked Questions About Plastic Ice Skates

The following addresses common inquiries regarding the characteristics, suitability, and limitations of skating equipment employing polymer construction.

Question 1: What distinguishes polymer ice skates from traditional leather or composite models?

Skating implements constructed with molded polymers differ significantly in material composition and manufacturing techniques. Leather and composite models typically employ multiple components assembled through stitching or bonding, whereas polymer skates utilize a single, molded boot. This construction impacts cost, durability, and performance characteristics.

Question 2: For whom are polymer ice skates best suited?

Equipment featuring molded polymer boots is primarily designed for beginner and recreational ice skaters. The design often prioritizes stability, ease of use, and affordability, making them suitable for individuals new to the sport or those engaging in casual skating activities.

Question 3: How does the performance of polymer ice skates compare to that of higher-end models?

Polymer ice skates typically exhibit a reduced performance envelope compared to high-end models constructed from leather or composite materials. The inherent flexibility of polymers can limit responsiveness and control, particularly during advanced maneuvers or high-speed skating.

Question 4: What are the primary advantages of selecting polymer ice skates?

The principal advantages include affordability, water resistance, and ease of maintenance. The lower production costs associated with polymer materials translate to a more accessible price point. The non-porous nature of polymers also provides enhanced resistance to water damage, reducing the need for specialized care.

Question 5: What limitations should be considered when using skates featuring polymeric construction?

Limitations include reduced stiffness, which can compromise ankle support and energy transfer. Furthermore, the durability of polymers may be lower compared to traditional materials, particularly when subjected to rigorous use or extreme environmental conditions.

Question 6: How should polymer ice skates be properly maintained?

Maintenance primarily involves cleaning the boots and blades with a dry cloth after each use. Avoid prolonged exposure to direct sunlight or extreme temperatures. Blade sharpening should be performed by a qualified professional as needed. Inspect fasteners regularly and ensure they are securely fastened before each use.

Understanding the nuances of polymer-constructed skating equipment enables informed decision-making, aligning equipment selection with individual skill levels and intended applications.

Further sections will delve into the long-term implications of polymer use in skating equipment and potential future developments.

Conclusion

This exploration has elucidated the characteristics of ice skates employing polymer construction. The examination of cost-effectiveness, molded construction, water resistance, beginner suitability, and limited performance has highlighted the trade-offs inherent in selecting this type of equipment. The cost advantages and manufacturing efficiencies are undeniable, rendering ice skating more accessible. However, the material properties impose constraints on advanced performance, indicating a specific target user group.

The implications of widespread polymer use in skating extend beyond individual performance, impacting accessibility and democratization within the sport. As material science advances, future iterations may address current limitations, potentially broadening the applicability of polymer-based designs. Therefore, a discerning approach to equipment selection, balancing cost with performance needs, remains paramount.