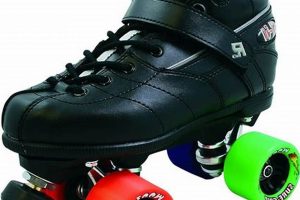

The phrase identifies a specific category of recreational equipment designed for individuals, typically adult males, seeking wheeled mobility for leisure, exercise, or sport. These items consist of boots or shoe-like structures affixed to a frame containing wheels, facilitating movement across smooth surfaces.

The importance of such equipment lies in its provision of a low-impact aerobic activity, contributing to cardiovascular health and muscular strength. Historically, wheeled footwear has evolved from rudimentary designs to sophisticated models incorporating advanced materials and engineering for enhanced performance and safety. This evolution reflects a consistent desire for accessible and enjoyable physical activity.

The following discussion will delve into the diverse styles available, key considerations when selecting appropriate models, maintenance best practices, and the potential impacts of this activity on health and wellness. These elements provide a comprehensive understanding for individuals considering engaging with wheeled footwear as a recreational pursuit.

Essential Considerations for Selecting Wheeled Footwear

Proper selection and maintenance of wheeled footwear are crucial for ensuring a safe and enjoyable experience. Adherence to these guidelines can minimize the risk of injury and prolong the lifespan of the equipment.

Tip 1: Assess Skill Level: Beginner users should prioritize models offering enhanced stability and control. Lower-profile designs and softer wheels can facilitate balance and maneuverability.

Tip 2: Prioritize Fit and Comfort: Ill-fitting footwear can lead to blisters, chafing, and impaired performance. Ensure a snug, yet comfortable fit, allowing adequate room for toe movement.

Tip 3: Evaluate Wheel Durometer: Wheel hardness, measured in durometer, impacts grip and speed. Softer wheels (lower durometer) offer better grip on rough surfaces, while harder wheels (higher durometer) provide greater speed on smooth surfaces. Select based on intended use and terrain.

Tip 4: Inspect Frame Material: The frame, or chassis, provides structural support. Aluminum frames offer superior durability and responsiveness compared to plastic frames, particularly for aggressive or high-impact skating.

Tip 5: Utilize Protective Gear: Helmets, wrist guards, elbow pads, and knee pads are essential for mitigating the risk of injury. Ensure that protective gear fits properly and is in good working condition.

Tip 6: Perform Regular Maintenance: Consistent maintenance is crucial for optimal performance and longevity. Clean bearings, check wheel alignment, and inspect for wear and tear regularly. Replace worn or damaged components promptly.

Tip 7: Consider Braking System: Different models employ various braking systems, including heel brakes and inline brakes. Familiarize yourself with the braking mechanism and practice effective stopping techniques in a controlled environment.

Following these recommendations ensures that the selected wheeled footwear meets the user’s specific needs and promotes a safer, more fulfilling experience.

The subsequent sections will address specific styles and their suitability for various applications, providing further guidance for making informed purchasing decisions.

1. Durability and Support

Durability and support represent fundamental attributes of wheeled footwear designed for men, directly influencing both performance and safety. The physical demands placed on this equipment particularly during aggressive skating or extended use necessitate robust construction capable of withstanding significant stress. Insufficient durability results in premature equipment failure, potentially leading to injury. Adequate support, encompassing ankle stabilization and footbed cushioning, mitigates strain and fatigue, enabling longer periods of comfortable use. For example, wheeled footwear employed in urban environments, where encountering uneven surfaces and obstacles is common, must exhibit higher levels of durability compared to equipment used solely in controlled indoor settings.

The selection of materials significantly impacts both durability and support. High-impact resistant polymers, reinforced stitching, and robust metal alloys are frequently incorporated into quality designs. Furthermore, the structural design, including reinforced ankle cuffs and rigid frame connections, contributes to the overall support provided. A practical example lies in the difference between recreational models, often featuring lighter materials for comfort, and professional models, which prioritize durability and support through the use of advanced composites and precision engineering. This distinction reflects the diverse needs and intensity levels of various users.

In conclusion, durability and support are not merely desirable qualities; they are essential components for wheeled footwear intended for men. The trade-off between weight and robustness necessitates careful consideration based on individual usage patterns and performance expectations. Selecting equipment that adequately addresses these factors mitigates risks, enhances performance, and ultimately contributes to a more fulfilling experience. Neglecting these aspects can compromise safety and reduce the lifespan of the product, leading to potential hazards and increased replacement costs.

2. Wheel Hardness Variation

Wheel hardness variation is a critical factor influencing the performance characteristics of wheeled footwear designed for adult males. This parameter, typically measured using the durometer scale, dictates the rolling efficiency, grip, and wear resistance of the wheels. Softer wheels, characterized by lower durometer values (e.g., 78A-85A), offer enhanced grip and shock absorption, making them suitable for rough or uneven surfaces. Conversely, harder wheels (e.g., 85A-101A) provide reduced rolling resistance and increased speed on smooth surfaces, such as indoor rinks or polished concrete. The selection of appropriate wheel hardness is therefore paramount in optimizing performance for specific skating environments and desired outcomes. For example, a skater prioritizing agility and control on outdoor trails would benefit from softer wheels, whereas a speed skater seeking maximum velocity on a smooth track would favor harder wheels.

The practical significance of understanding wheel hardness variation extends beyond simple performance optimization. It directly impacts safety and comfort. Using excessively hard wheels on rough surfaces compromises grip, increasing the risk of slippage and falls. Conversely, using excessively soft wheels on smooth surfaces can result in premature wear and a reduction in energy transfer, leading to fatigue. Furthermore, the vibration damping properties of softer wheels contribute to a more comfortable skating experience, particularly during extended periods of use. Competitive skaters often maintain multiple sets of wheels with varying hardness to adapt to diverse track conditions, highlighting the strategic importance of this parameter in achieving optimal results. The design of high-performance models includes compatibility with different wheel hardnesses, recognizing the diverse needs and preferences of skaters.

In summary, wheel hardness variation represents a fundamental performance parameter within the design and application of wheeled footwear for men. The correct selection necessitates a careful evaluation of the skating environment, desired performance characteristics, and individual preferences. Neglecting this factor can compromise safety, reduce comfort, and limit the potential for achieving optimal skating performance. Future developments in material science and wheel design will likely focus on further refining the relationship between wheel hardness and performance, providing even greater customization options for users.

3. Boot Comfort Technology

Boot comfort technology within wheeled footwear significantly influences the user experience for adult males. Its relevance stems from the extended periods of use and the repetitive motions involved, necessitating designs that minimize discomfort and prevent injury. These technologies aim to optimize fit, ventilation, and cushioning, addressing common issues such as blisters, chafing, and foot fatigue.

- Anatomically Contoured Liners

Anatomically contoured liners provide a customized fit by conforming to the natural shape of the foot. This reduces pressure points and hot spots, common causes of discomfort during prolonged activity. Examples include heat-moldable liners and liners with integrated arch support. The implementation of such liners within wheeled footwear enhances comfort and improves control by securing the foot properly.

- Moisture-Wicking Materials

Moisture-wicking materials are engineered to draw perspiration away from the skin, promoting a dry and comfortable internal environment. This is particularly crucial during strenuous activity, as excessive moisture can lead to blisters and fungal infections. Fabrics such as synthetic microfiber and breathable mesh are commonly used in boot construction to manage moisture effectively, contributing to enhanced hygiene and comfort.

- Ventilation Systems

Ventilation systems integrated into the boot design facilitate airflow, reducing heat buildup and preventing excessive sweating. These systems often incorporate strategically placed vents and breathable panels to promote air circulation. Adequate ventilation minimizes discomfort caused by overheating and helps to maintain a stable internal temperature, improving overall performance and user satisfaction.

- Impact Absorption Cushioning

Impact absorption cushioning is strategically placed within the boot to mitigate the stress on joints and reduce the risk of injury. This cushioning can consist of gel inserts, foam padding, or air cells, strategically located in areas prone to high impact, such as the heel and forefoot. Effective impact absorption minimizes fatigue and enhances overall comfort, particularly during aggressive skating or use on uneven surfaces.

The incorporation of these comfort technologies directly affects the performance and enjoyment of wheeled footwear for men. Well-designed boots prioritize comfort alongside performance, leading to a more positive user experience. Continuous advancements in materials science and engineering are driving innovations in boot comfort technology, further enhancing the overall functionality and appeal of wheeled sports equipment.

4. Frame Material Options

The selection of frame materials for wheeled footwear designed for men significantly influences performance characteristics, durability, and overall suitability for various skating disciplines. The frame serves as the structural foundation, connecting the boot to the wheels and transmitting forces during movement.

- Aluminum Alloys

Aluminum alloys are widely used in high-performance wheeled footwear due to their favorable strength-to-weight ratio and rigidity. Frames constructed from aluminum alloys exhibit excellent responsiveness and energy transfer, enhancing maneuverability and speed. Extruded aluminum frames, commonly found in fitness and aggressive skating models, offer a balance of performance and durability. Die-cast aluminum frames, often utilized in speed skating boots, provide increased stiffness for optimal power transfer. The specific alloy composition and manufacturing process influence the frame’s properties, necessitating careful consideration based on intended use. A skater engaging in demanding maneuvers, such as jumps or grinds, would benefit from the increased rigidity offered by an aluminum frame, minimizing energy loss and maximizing control.

- Carbon Fiber Composites

Carbon fiber composites represent a premium material option, offering exceptional stiffness and lightweight properties. These frames are typically found in high-end speed skating and racing models, where minimizing weight is paramount. Carbon fiber frames provide unparalleled energy transfer and responsiveness, enabling rapid acceleration and precise handling. However, carbon fiber composites are more brittle than aluminum alloys and may be susceptible to damage from impacts or abrasion. The increased cost associated with carbon fiber frames reflects their superior performance characteristics and specialized manufacturing requirements. A speed skater competing at an elite level would likely opt for a carbon fiber frame to gain a competitive advantage through reduced weight and enhanced power transfer.

- Reinforced Polymers

Reinforced polymers, such as glass-filled nylon, offer a cost-effective alternative for recreational and entry-level wheeled footwear. These materials provide adequate support and durability for casual skating, while remaining lightweight and comfortable. Reinforced polymer frames are more flexible than aluminum or carbon fiber frames, providing increased shock absorption and a smoother ride on uneven surfaces. However, they lack the rigidity and responsiveness of higher-end materials, limiting their suitability for more demanding skating styles. A beginner skater seeking comfortable and affordable equipment for recreational use would find reinforced polymer frames a practical choice.

- Magnesium Alloys

Magnesium alloys, while less common than aluminum or carbon fiber, offer a unique combination of lightweight properties and vibration damping characteristics. These frames are often utilized in fitness and recreational models to enhance comfort and reduce fatigue during extended skating sessions. Magnesium alloys exhibit excellent shock absorption, minimizing stress on joints and providing a smoother ride on rough surfaces. However, they are more susceptible to corrosion than aluminum alloys and may require specialized coatings to protect against environmental degradation. A fitness skater seeking comfortable and lightweight equipment for long-distance skating would benefit from the vibration damping properties of a magnesium alloy frame.

In summary, the selection of frame material directly impacts the performance, durability, and overall suitability of wheeled footwear for men. Aluminum alloys offer a balance of strength and weight for various skating disciplines, while carbon fiber composites prioritize lightweight performance for competitive applications. Reinforced polymers provide a cost-effective option for recreational use, and magnesium alloys enhance comfort through vibration damping. The ideal frame material depends on the skater’s skill level, intended use, and budget, requiring careful consideration to optimize performance and enjoyment.

5. Bearing Precision Ratings

Bearing precision ratings, frequently denoted using the Annular Bearing Engineers’ Committee (ABEC) scale or similar standards, directly influence the performance of wheeled footwear designed for men. The rating assigned to a bearing quantifies its manufacturing tolerances, influencing its rolling efficiency, smoothness, and operational lifespan within the context of wheeled sports.

- ABEC Scale and its Significance

The ABEC scale, ranging from ABEC-1 to ABEC-9 with higher numbers indicating tighter tolerances, provides a standardized method for evaluating bearing precision. Tighter tolerances result in reduced friction and improved rolling efficiency. For example, a skater utilizing equipment with ABEC-7 bearings experiences a smoother and faster glide compared to one using ABEC-1 bearings, assuming other factors remain constant. However, higher ABEC ratings do not necessarily equate to increased durability or load-bearing capacity. The ABEC rating solely addresses dimensional accuracy.

- Impact on Rolling Efficiency

Higher precision bearings, as indicated by elevated ABEC ratings, minimize energy loss due to friction. This translates to improved rolling efficiency, allowing skaters to maintain speed with less effort. This becomes particularly relevant in disciplines such as distance skating or speed skating, where minimizing energy expenditure is crucial for optimal performance. Conversely, lower precision bearings generate more friction, requiring increased effort to maintain a given speed. This difference in rolling efficiency is discernible even in casual recreational skating.

- Influence on Smoothness and Vibration

Bearing precision influences the smoothness of the rolling motion and the level of vibration experienced by the skater. Higher precision bearings, with their tighter tolerances, reduce vibration and provide a smoother, more comfortable ride. This is especially important on uneven surfaces or during aggressive maneuvers, where excessive vibration can compromise control and lead to fatigue. Lower precision bearings, with their looser tolerances, tend to generate more vibration, resulting in a less comfortable and less stable skating experience.

- Durability and Maintenance Considerations

While ABEC ratings primarily address precision, they indirectly impact durability and maintenance requirements. Higher precision bearings, manufactured to tighter tolerances, are often more sensitive to contaminants and require more frequent cleaning and lubrication. Conversely, lower precision bearings, with their looser tolerances, are typically more tolerant of dirt and debris but may exhibit reduced rolling efficiency over time. The selection of appropriate bearings must therefore consider the balance between performance requirements and maintenance capabilities. Skaters operating in environments with high levels of dirt and debris may opt for lower precision bearings to minimize maintenance demands.

The selection of appropriate bearing precision ratings for wheeled footwear requires a careful consideration of the intended use, skating environment, and maintenance capabilities. While higher ABEC ratings offer improved rolling efficiency and smoothness, they also necessitate increased maintenance and may not be suitable for all skating conditions. The optimal choice represents a balance between performance, durability, and practicality, aligning with the specific needs and preferences of the individual skater.

6. Braking System Effectiveness

Braking system effectiveness is a critical safety component of wheeled footwear designed for men. The capacity to rapidly and reliably decelerate or halt motion directly influences the user’s ability to avoid collisions, navigate obstacles, and maintain control in varied environments. The lack of an effective braking mechanism can lead to severe injuries, particularly in urban settings with unpredictable traffic or pedestrian movement. The design and implementation of braking systems are therefore paramount considerations in the manufacture and selection of this recreational equipment. For example, a poorly designed or malfunctioning braking system might fail to engage promptly, extending stopping distances and increasing the risk of impact.

The performance of a braking system is influenced by several factors, including the braking mechanism type (e.g., heel brake, toe stop, inline brake), the materials used in its construction, and the user’s skill in its operation. Heel brakes, commonly found on recreational models, offer a relatively simple and intuitive method of deceleration. Toe stops, prevalent in artistic and roller derby applications, provide precise control for quick stops and pivots. Inline braking systems, often integrated into the frame, offer a streamlined design and consistent performance. Real-world examples include instances where experienced skaters successfully avoid accidents due to well-maintained and responsive braking systems, underscoring the direct correlation between braking effectiveness and safety.

In summary, braking system effectiveness is not merely a desirable feature, but a fundamental requirement for wheeled footwear intended for adult males. Its contribution to safety, control, and maneuverability cannot be overstated. The informed selection and consistent maintenance of braking systems are essential for mitigating risks and promoting a positive skating experience. Ignoring this critical aspect can have severe consequences, highlighting the practical significance of understanding and prioritizing braking effectiveness in wheeled footwear applications. Continuous advancements in braking system technology aim to improve performance and reliability, further enhancing user safety.

7. Protective Gear Integration

Protective gear integration represents a critical aspect of wheeled footwear designed for adult males, addressing the inherent risks associated with the activity. The design and utilization of protective elements directly influence the potential for injury mitigation, emphasizing the importance of understanding and implementing effective safety measures.

- Helmet Compatibility

Helmet compatibility involves ensuring that the wheeled footwear user consistently and correctly wears a properly fitted helmet conforming to relevant safety standards (e.g., CPSC, ASTM). The helmet must provide adequate coverage of the head, and the chinstrap must be securely fastened. Failure to wear a helmet significantly increases the risk of head trauma in the event of a fall or collision. For example, studies have shown that helmet use can reduce the risk of head injury by up to 85%.

- Wrist Guard Design and Functionality

Wrist guards are designed to protect the wrist joint from fractures and sprains, common injuries in wheeled sports. Effective wrist guard design incorporates rigid splints that distribute impact forces and prevent hyperextension. The guards should fit snugly and securely, allowing for a full range of motion while providing adequate protection. Many injuries result from ill-fitting or poorly designed wrist guards that fail to provide sufficient support during a fall.

- Elbow and Knee Pad Coverage and Fit

Elbow and knee pads serve to protect the respective joints from abrasions, contusions, and fractures. Adequate coverage is essential, ensuring that the entire joint is shielded from impact. The pads should fit snugly and remain in place during activity, preventing them from slipping or shifting during a fall. Loose-fitting or improperly positioned pads offer minimal protection, increasing the risk of injury.

- Reflective Element Incorporation

Reflective element incorporation enhances visibility, particularly during low-light conditions. Retroreflective materials strategically placed on the wheeled footwear and protective gear increase the user’s conspicuity to motorists and other pedestrians. This is especially crucial for urban skating or use on roadways. Examples include reflective strips, patches, and piping integrated into the boot and protective gear designs. Increased visibility significantly reduces the risk of collisions with vehicles or other objects.

These facets of protective gear integration are interconnected and contribute to the overall safety profile of wheeled footwear use. Adherence to these guidelines is essential for mitigating risks and promoting a safer and more enjoyable experience. The selection and consistent use of appropriately fitted and functioning protective gear remains a paramount responsibility for all users of wheeled footwear, supplementing the inherent design features of the equipment.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding wheeled footwear designed for adult males, providing clear and concise information to facilitate informed decision-making.

Question 1: What constitutes the primary distinction between wheeled footwear intended for recreational use versus that designed for aggressive skating?

Recreational models typically prioritize comfort, affordability, and ease of use, featuring softer wheels and less rigid frames. Aggressive skating models emphasize durability, support, and responsiveness, incorporating reinforced frames and harder wheels to withstand high-impact maneuvers.

Question 2: Is there a standardized method for determining the appropriate size of wheeled footwear?

While sizing may vary slightly between manufacturers, measuring the foot’s length in millimeters and consulting the manufacturer’s size chart is the most reliable method. Ensure adequate toe room to prevent discomfort and potential injury.

Question 3: What is the recommended frequency for cleaning and lubricating wheel bearings?

The frequency depends on usage and environmental conditions. Generally, cleaning and lubricating bearings every 20-40 hours of use, or more frequently if exposed to dirt and moisture, is advisable.

Question 4: Are replacement parts readily available for most models of wheeled footwear?

The availability of replacement parts varies depending on the brand and model. Major manufacturers typically offer replacement wheels, bearings, brakes, and other components. However, discontinued models may present challenges in sourcing replacement parts.

Question 5: What are the potential health benefits associated with engaging in wheeled sports activities?

Wheeled sports activities can provide cardiovascular benefits, improve muscular strength and endurance, enhance balance and coordination, and promote overall physical fitness.

Question 6: What safety precautions should be observed when utilizing wheeled footwear in urban environments?

Always wear appropriate protective gear, including a helmet, wrist guards, elbow pads, and knee pads. Be aware of surroundings, obey traffic laws, and avoid skating in areas with heavy traffic or hazardous conditions.

These frequently asked questions serve to clarify essential aspects of wheeled footwear for men, facilitating informed choices and promoting safe and enjoyable participation.

The following section will explore maintenance practices to maximize equipment lifespan and performance.

Conclusion

This exploration of “roller skates men” has illuminated the multifaceted aspects of this recreational equipment category. From material selection and design considerations to safety protocols and maintenance procedures, the preceding information emphasizes the importance of informed decision-making. The selection and proper utilization of these skates directly impacts user safety, performance, and overall satisfaction.

Responsible engagement with wheeled sports necessitates a commitment to safety and ongoing maintenance. Adherence to recommended practices ensures equipment longevity and minimizes potential risks. The continuous evolution of designs and materials promises future advancements, further enhancing the capabilities and safety features available to users of roller skates. Continued vigilance regarding safety and technological advancements remains paramount for all participants.

![Best Riedell Mens Roller Skates for [Year]: Top Picks + Guide How to Skateboard: A Beginner's Guide to Your First Board & Tricks Best Riedell Mens Roller Skates for [Year]: Top Picks + Guide | How to Skateboard: A Beginner's Guide to Your First Board & Tricks](https://cruzskateshop.com/wp-content/uploads/2026/01/th-121-300x200.jpg)