The subject of this discourse encompasses specialized footwear designed for recreational or athletic activities on paved surfaces and trails. These products integrate a supportive boot structure with a rolling chassis, enabling locomotion via a series of inline or quad wheels. They offer individuals a means of engaging in physical exercise and outdoor leisure pursuits.

Utilizing such equipment presents opportunities for cardiovascular fitness, improved balance and coordination, and exploration of outdoor environments. Historically, the evolution of these wheeled devices has transformed from rudimentary prototypes to sophisticated designs incorporating advanced materials and engineering principles, catering to a diverse range of skill levels and preferences.

The following discussion will address critical aspects related to selecting appropriate models, considering factors such as boot construction, wheel composition, bearing quality, and frame design, with the aim of equipping consumers with the knowledge necessary to make informed purchasing decisions.

Selection and Maintenance Guidance for Wheeled Footwear

The following guidelines are designed to assist in the selection and maintenance of wheeled footwear intended for use on outdoor surfaces, ensuring optimal performance and longevity.

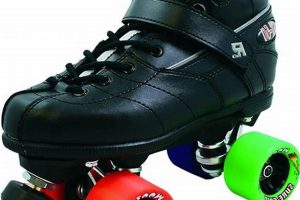

Tip 1: Boot Structure and Support: Prioritize models featuring robust ankle support and a secure lacing system. Adequate support minimizes the risk of injury and enhances control during use. Examine the boot’s material; consider options offering a balance of breathability and durability.

Tip 2: Wheel Durometer and Size: Wheel durometer, measured on the A scale, indicates hardness. Softer wheels (lower durometer) provide enhanced grip and shock absorption on rough surfaces, while harder wheels offer greater speed and durability on smoother terrain. Wheel size also influences performance; larger wheels generally result in higher speeds, while smaller wheels offer improved maneuverability.

Tip 3: Bearing Quality: Bearing quality, typically rated using the ABEC scale, affects the rolling efficiency of the wheels. Higher ABEC ratings indicate tighter tolerances and smoother rotation. Consider bearings constructed from durable materials, such as stainless steel or ceramic, for extended lifespan.

Tip 4: Frame Material and Design: The frame, which connects the boot to the wheels, should be constructed from a rigid material, such as aluminum, to ensure efficient power transfer and stability. Frame length influences maneuverability and stability; shorter frames provide greater agility, while longer frames offer increased straight-line speed and stability.

Tip 5: Protective Gear: Always utilize appropriate protective gear, including a helmet, knee pads, elbow pads, and wrist guards, regardless of skill level. Protective equipment significantly reduces the risk of injury in the event of a fall.

Tip 6: Regular Maintenance: Regular cleaning and lubrication of bearings, as well as inspection of wheels and frame for wear and tear, are crucial for maintaining optimal performance and extending the lifespan of the equipment. Replace worn or damaged components promptly.

Tip 7: Surface Considerations: Be mindful of the surface conditions. Avoid skating on excessively rough, wet, or debris-laden surfaces, as these conditions can compromise control, damage equipment, and increase the risk of accidents.

Adherence to these guidelines will contribute to a safer and more enjoyable experience with wheeled footwear. Proper selection and maintenance are essential for maximizing performance and minimizing the risk of injury.

This information serves as a foundation for further exploration of specific model characteristics and performance attributes.

1. Durability

The attribute of durability represents a critical factor in the evaluation and selection of outdoor wheeled footwear. The operational environment exposes this equipment to abrasive surfaces, varying weather conditions, and repetitive stress, demanding robust construction and material integrity. The direct consequence of inadequate durability is premature wear, component failure, and a diminished service life. For instance, a boot constructed from substandard materials may exhibit tearing or delamination after limited use on asphalt surfaces. Similarly, frames lacking sufficient strength may develop cracks or deform under sustained stress, compromising stability and control.

The selection of durable materials and construction techniques is essential for mitigating these risks. High-density plastics, reinforced stitching, and corrosion-resistant metal alloys contribute to the overall resilience of the footwear. Furthermore, designs incorporating impact-absorbing elements and strategically reinforced stress points can enhance durability by distributing force and minimizing localized wear. Consider a model utilizing a composite frame with reinforced ankle support, designed to withstand the impacts associated with uneven terrain and sustained use.

In summary, durability serves as a primary determinant of value and long-term performance. Its consideration should be prioritized to ensure a safe, efficient, and cost-effective experience. Ignoring this crucial aspect can lead to frequent replacements and increased operational costs, thereby undermining the initial investment.

2. Wheel Composition

Wheel composition is a pivotal determinant of performance characteristics in wheeled footwear intended for outdoor usage. The material formulation directly influences grip, durability, vibration absorption, and rolling efficiency, thereby affecting the user’s overall experience and the equipment’s suitability for diverse terrains.

- Durometer and Surface Interaction

Durometer, measured on the A scale, quantifies the hardness of the wheel material. Lower durometer values correspond to softer wheels, offering enhanced grip and shock absorption on rough or uneven surfaces. Conversely, higher durometer values signify harder wheels, which provide greater speed and durability on smooth pavements. For example, a user primarily skating on asphalt trails may benefit from wheels with a durometer rating of 82A, balancing grip and wear resistance, while a skater frequenting skate parks may opt for 88A or higher for optimal speed on concrete surfaces.

- Material Type and Performance Traits

Polyurethane (PU) is the prevailing material in the construction of these wheels due to its combination of resilience, abrasion resistance, and energy return. Different PU formulations yield distinct performance traits. Certain blends incorporate additives designed to enhance grip in wet conditions, while others prioritize resistance to heat buildup during prolonged use. The choice of PU compound depends on the intended application and environmental factors. For example, a PU blend specifically formulated for high-speed skating may incorporate a heat-resistant additive to prevent deformation and maintain optimal performance under thermal stress.

- Core Design and Energy Transfer

The wheel’s core, typically constructed from rigid plastic, serves as the structural foundation and influences energy transfer during propulsion. A stiffer core promotes efficient energy transfer, resulting in increased speed and responsiveness. The core design, including the presence of ribs or spokes, affects the wheel’s weight, rigidity, and ability to dissipate heat. Consider a wheel with a lightweight, spoked core designed to minimize rotational inertia and enhance acceleration.

- Wheel Profile and Contact Patch

The wheel profile, or cross-sectional shape, determines the contact patch area and influences maneuverability and stability. A rounded profile offers greater maneuverability and control during turns, while a flatter profile maximizes the contact patch, enhancing grip and stability at higher speeds. A recreational skater may prefer a rounded profile for ease of turning, while a speed skater would benefit from a flatter profile for stability and maximum power transfer.

In conclusion, the wheel composition represents a multifaceted consideration in the selection process. The interplay between durometer, material type, core design, and wheel profile dictates the overall performance and suitability of the footwear for specific applications and environmental conditions. Therefore, a thorough understanding of these factors is essential for informed decision-making and optimal user satisfaction.

3. Ankle Support

Ankle support constitutes a critical design element in wheeled footwear engineered for outdoor use. Its presence, or absence, directly influences stability, control, and the potential for injury. Inadequate ankle support compromises the user’s ability to maintain balance and execute controlled movements, particularly on uneven or unpredictable surfaces. This deficiency leads to an increased susceptibility to ankle sprains, strains, and other lower extremity injuries. As an example, consider a model lacking rigid ankle reinforcement; the wearer may experience difficulty navigating uneven terrain, resulting in instability and a higher risk of falls. Conversely, a design incorporating a high-cut boot and robust lateral support structure promotes stability and reduces the likelihood of ankle inversion or eversion during skating.

The specific type and extent of ankle support incorporated into a design is often dictated by the intended application. Recreational models may feature a moderate level of support, balancing flexibility and stability for general use. Performance-oriented designs, however, frequently prioritize maximum support through the use of rigid cuffs, reinforced exoskeletons, and advanced lacing systems. These features are intended to provide enhanced control and responsiveness during high-speed maneuvers and demanding skating techniques. One can observe this distinction in comparing recreational models with fitness or speed models, where the latter exhibit substantially greater ankle reinforcement to accommodate the increased stresses associated with competitive skating.

In summation, ankle support is not merely an ancillary feature, but rather an integral component directly impacting safety and performance. The appropriate level of support should be carefully considered based on individual skating style, skill level, and intended use environment. Compromising on ankle support to reduce cost or weight can have significant ramifications, increasing the risk of injury and diminishing the overall enjoyment of the activity. Consequently, a thorough evaluation of ankle support features is paramount when selecting suitable models.

4. Bearing Precision

Bearing precision, a critical attribute of wheeled footwear designed for outdoor use, directly influences rolling resistance, speed, and overall efficiency. Its relevance stems from the direct impact on the skater’s effort required to maintain momentum and achieve desired speeds, thereby affecting the enjoyment and performance of the activity.

- ABEC Rating and Manufacturing Tolerances

The Annular Bearing Engineers’ Committee (ABEC) rating system, while not a definitive measure of quality, provides an indication of the manufacturing tolerances associated with bearing production. Higher ABEC ratings, such as ABEC-5, ABEC-7, and ABEC-9, signify tighter tolerances and improved dimensional accuracy. Bearings manufactured to higher ABEC standards tend to exhibit reduced friction and smoother rotation compared to those with lower ratings. These finer tolerances contribute to enhanced speed and efficiency for individuals utilizing outdoor wheeled footwear. A bearing with an ABEC-7 rating, for instance, will generally provide smoother and faster rolling compared to an ABEC-3 rated bearing, assuming other factors such as lubrication and material quality are equivalent.

- Material Selection and Durability

Bearing construction material directly affects its durability and resistance to corrosion and wear. Stainless steel bearings, for example, offer superior resistance to rust and corrosion compared to carbon steel bearings, making them more suitable for outdoor environments where exposure to moisture and contaminants is inevitable. Ceramic bearings, while more expensive, provide exceptional hardness and reduced friction, contributing to increased speed and longevity. A stainless steel bearing is more likely to withstand exposure to rain or road salt without degradation compared to a standard carbon steel bearing, thereby prolonging its operational lifespan.

- Lubrication and Maintenance

Proper lubrication is essential for maintaining bearing precision and performance. The type of lubricant used influences friction, heat dissipation, and resistance to contamination. Synthetic lubricants often outperform petroleum-based lubricants in terms of thermal stability and resistance to oxidation. Regular cleaning and re-lubrication are necessary to remove dirt, grit, and debris that can compromise bearing performance. A bearing that is regularly cleaned and lubricated with a high-quality synthetic lubricant will maintain its precision and efficiency for a longer period compared to one that is neglected.

- Bearing Size and Compatibility

Standard bearing size (608) for inline skate is the most common bearing used on outdoor inline skates. Ensuring compatibility with the wheel hub and axle is critical for proper function. Using an incompatible bearing can result in misalignment, increased friction, and premature failure. The wheel should spin smoothly and freely without any noticeable wobble or play. This proper fitting ensures safety and optimal performance for the skater.

The interplay between ABEC rating, material selection, lubrication, and compatibility underscores the importance of bearing precision in wheeled footwear. These factors collectively determine the equipment’s ability to efficiently translate user effort into motion, thereby impacting speed, endurance, and overall satisfaction. Investing in high-quality, well-maintained bearings directly correlates with improved performance and a more enjoyable outdoor skating experience.

5. Frame Rigidity

Frame rigidity, an essential characteristic of the chassis in outdoor wheeled footwear, dictates the efficiency of power transfer and the stability of the skate. It influences the responsiveness and control experienced by the user, impacting both performance and safety.

- Material Composition and Stiffness

The material employed in frame construction directly affects its rigidity. Aluminum alloys, commonly used in higher-performance skates, offer superior stiffness compared to composite materials or plastics. This increased stiffness minimizes energy loss during propulsion, allowing for more efficient power transfer from the skater’s leg to the wheels. For example, a frame constructed from 7000-series aluminum will exhibit less flex under load than a frame made of a lower-grade alloy, resulting in a more responsive skating experience.

- Frame Design and Structural Integrity

Frame design contributes significantly to overall rigidity. Designs incorporating bridges, reinforced sections, or specific geometric shapes enhance structural integrity, reducing flex and deformation. A frame with a well-designed bridge connecting the wheel axles will maintain its shape under stress, providing a more stable platform for skating. Frames lacking these structural enhancements may exhibit undesirable flex, leading to reduced control and increased effort for the user.

- Wheelbase Length and Stability

The distance between the front and rear wheels, known as the wheelbase, also impacts stability and maneuverability. A longer wheelbase generally provides greater stability at higher speeds, while a shorter wheelbase enhances maneuverability and agility. However, excessive length can compromise responsiveness, while insufficient length may reduce stability. A skater seeking stability for long-distance skating might opt for a longer wheelbase, whereas a skater prioritizing agility for urban environments might prefer a shorter wheelbase.

- Mounting System and Boot Interface

The method by which the frame is attached to the boot influences the overall rigidity and responsiveness of the skate. A secure and rigid mounting system minimizes play and ensures efficient power transfer. Frames with integrated mounting systems or those utilizing multiple mounting points provide a more direct connection between the boot and the frame, resulting in improved control and responsiveness. A poorly designed mounting system can introduce unwanted flex and reduce the efficiency of the skating motion.

In summary, frame rigidity represents a critical factor in the selection of outdoor wheeled footwear. The interplay between material composition, frame design, wheelbase length, and mounting system collectively determines the skate’s responsiveness, stability, and overall performance. Careful consideration of these factors ensures a safe, efficient, and enjoyable skating experience.

6. Surface Compatibility

Surface compatibility represents a fundamental consideration in the selection and utilization of outdoor wheeled footwear. The interaction between the skate wheels and the terrain directly impacts performance, safety, and equipment longevity. The type of surface encountered ranging from smooth asphalt to rough concrete or unpaved paths dictates the optimal wheel durometer, frame design, and bearing characteristics. For example, utilizing skates designed for smooth surfaces on a rough trail will result in increased vibration, reduced speed, and accelerated wear on the wheels and bearings. Conversely, using skates designed for rough surfaces on smooth pavement may lead to reduced efficiency and unnecessary energy expenditure.

The selection of appropriate equipment must therefore align with the intended skating environment. Skates designed for urban environments often incorporate features such as softer wheels with higher rebound characteristics to absorb shocks and maintain grip on uneven surfaces. Models intended for paved trails may prioritize harder wheels for increased speed and efficiency. Furthermore, frame designs optimized for surface compatibility can enhance stability and control. Long wheelbase frames, for instance, provide greater stability on uneven surfaces, while shorter frames offer increased maneuverability in congested urban areas. Considerations for surface compatibility should extend to bearing selection, where sealed or shielded bearings provide protection against dirt and debris encountered in outdoor environments.

The understanding of surface compatibility principles is essential for maximizing the performance and extending the lifespan of outdoor wheeled footwear. Failure to account for surface characteristics can lead to compromised safety, reduced efficiency, and premature equipment failure. Therefore, a thorough assessment of intended skating environments and a corresponding selection of appropriate equipment are crucial for a safe and enjoyable skating experience. This understanding promotes informed purchasing decisions, contributing to optimal performance and enhanced user satisfaction in diverse outdoor settings.

Frequently Asked Questions Regarding Outdoor Wheeled Footwear for Men

The following section addresses commonly encountered inquiries concerning wheeled footwear designed for outdoor use. These questions aim to provide clarity and inform purchasing decisions.

Question 1: What constitutes the primary difference between indoor and outdoor wheeled footwear?

Outdoor models are typically designed with features that enhance durability and performance on varied terrain. This often includes more robust wheel compositions, enhanced ankle support, and frames constructed to withstand rougher surfaces. Indoor models, conversely, prioritize maneuverability and speed on smooth, predictable surfaces.

Question 2: How does wheel durometer impact the performance of wheeled footwear on different outdoor surfaces?

Wheel durometer, measured on the A scale, indicates hardness. Softer wheels (lower durometer) offer improved grip and shock absorption on rough surfaces. Harder wheels (higher durometer) provide greater speed and efficiency on smooth surfaces. Selecting the appropriate durometer is crucial for optimizing performance and control.

Question 3: What role does bearing precision play in the functionality of wheeled footwear?

Bearing precision, often indicated by the ABEC rating, affects the rolling efficiency of the wheels. Higher ABEC ratings generally signify tighter tolerances and smoother rotation, resulting in reduced friction and increased speed. Bearing material and construction also contribute to overall performance and durability.

Question 4: How should the frame material and design be considered when purchasing wheeled footwear for outdoor use?

The frame provides the structural foundation of the skate. A rigid frame, typically constructed from aluminum, ensures efficient power transfer and stability. Frame design influences maneuverability and control. Longer frames offer greater stability at higher speeds, while shorter frames enhance agility.

Question 5: What types of protective gear are essential when utilizing wheeled footwear outdoors?

The utilization of appropriate protective gear is paramount for safety. A helmet is essential to protect against head injuries. Knee pads, elbow pads, and wrist guards mitigate the risk of abrasions and fractures. Proper fitting and consistent use of protective gear are crucial.

Question 6: How frequently should maintenance be performed on wheeled footwear intended for outdoor use?

Regular maintenance is essential for preserving performance and extending the lifespan of the equipment. Bearings should be cleaned and lubricated periodically. Wheels and frames should be inspected for wear and damage. Component replacement should occur promptly when necessary.

These responses highlight critical considerations when selecting and maintaining wheeled footwear for outdoor activities. Adherence to these principles promotes safety, enhances performance, and maximizes the longevity of the equipment.

The subsequent segment will explore potential upgrades and customization options for wheeled footwear.

Conclusion

The preceding exploration has illuminated critical aspects of mens outdoor skates, underscoring the significance of considering design elements, material composition, and intended use environments. These considerations are paramount for ensuring user safety, optimizing performance, and maximizing the longevity of the equipment. A thorough understanding of boot structure, wheel characteristics, bearing precision, and frame rigidity provides a framework for making informed purchasing decisions.

Ultimately, the selection of appropriate mens outdoor skates requires a commitment to informed decision-making and a dedication to prioritizing safety. By carefully evaluating individual needs and aligning those needs with the characteristics of available equipment, consumers can ensure a positive and enduring skating experience. The continued advancement of materials and engineering promises ongoing improvements in performance and durability, further enhancing the potential for outdoor skating endeavors.