The dimensions of the wooden platform used in skateboarding are a critical factor for riders. These measurements, typically expressed in inches for both length and width, influence a skateboard’s responsiveness, stability, and overall suitability for different skateboarding styles and rider statures. For example, a wider platform generally provides increased stability, while a shorter one can enhance maneuverability.

Proper platform selection is essential for optimizing the skateboarding experience. A well-chosen platform can improve control, reduce the risk of injury, and allow riders to progress more effectively. Historically, these dimensions have evolved alongside the sport, with earlier platforms often being wider and longer than contemporary designs favored for technical street skateboarding. The evolution reflects a shifting emphasis towards greater agility and complexity in skateboarding maneuvers.

The following sections will delve into the specifics of measuring platform dimensions, the impact of different sizes on skateboarding styles, and guidance on selecting an appropriate platform for individual needs and preferences. This will include detailed explanations of width, length, wheelbase, and other relevant measurements, alongside practical recommendations for riders of all skill levels.

Selecting an Appropriate Platform

Choosing the correct platform dimensions is paramount for optimal performance and safety. The following guidelines provide a structured approach to platform selection, taking into account various factors.

Tip 1: Evaluate Riding Style: Different skateboarding disciplines necessitate different platform dimensions. Street skateboarding often benefits from narrower platforms for enhanced flip tricks, while transition skating may require wider platforms for stability in bowls and ramps.

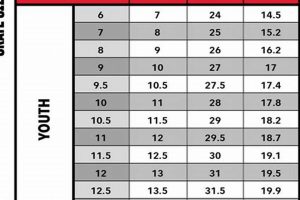

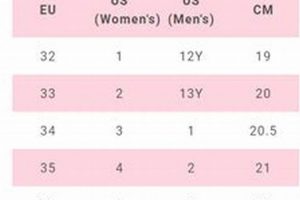

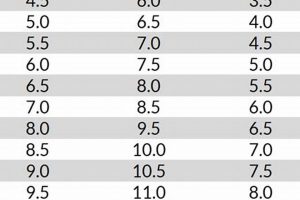

Tip 2: Consider Rider Stature: Height and shoe size are significant determinants. Taller individuals may find greater comfort and control on slightly longer and wider platforms, while smaller riders may prefer smaller dimensions for ease of maneuverability.

Tip 3: Analyze Wheelbase: The wheelbase, the distance between the inner mounting holes, impacts turning radius and stability. A shorter wheelbase results in quicker turning, whereas a longer wheelbase provides increased stability at higher speeds.

Tip 4: Account for Concave: The curvature of the platform’s surface, or concave, affects foot placement and board feel. Steeper concave generally provides greater responsiveness, while mellow concave offers a more relaxed riding experience.

Tip 5: Assess Material Composition: The material used in platform construction influences durability and weight. Maple wood is the industry standard, but alternative materials like carbon fiber offer enhanced strength and reduced weight.

Tip 6: Review Edge Shape: Platform edge shape contributes to grip and foot placement. Rounded edges offer a smoother feel, while sharper edges can provide increased lock-in for certain tricks.

Tip 7: Prioritize Quality Construction: Inspect the platform for defects such as warping, delamination, or inconsistent thickness. A well-constructed platform will ensure longevity and consistent performance.

Following these guidelines should improve the selection process and promote informed decision-making.

The subsequent section will address common misconceptions regarding platform dimensions and provide additional resources for further research.

1. Width (inches)

Platform width, measured in inches, represents a crucial dimension within platform specifications. This measurement directly correlates with rider stability, board control, and suitability for particular skateboarding disciplines. A change in platform width significantly alters the riding experience, impacting everything from executing flip tricks to maintaining balance on ramps. For instance, a platform with a width of 8.5 inches provides a more stable platform for vert skating and bowl riding, while a narrower 8.0-inch platform may be preferred for street skateboarding due to its enhanced flippability. The correct width is often determined by the rider’s stature, shoe size, and preferred skateboarding style, demonstrating its integral role within the overall context of platform dimensions.

The practical significance of understanding platform width extends beyond mere preference. It is also a key factor in reducing the risk of injury. A platform that is too narrow for a rider’s foot size can lead to instability and increased likelihood of falls, particularly during complex maneuvers. Conversely, a platform that is too wide may hinder the rider’s ability to effectively control the board. The interaction between platform width and truck selection further underscores its importance. Matching truck width to platform width ensures optimal leverage and turning capability. Therefore, an informed understanding of platform width is essential for both performance and safety.

In summary, platform width is a fundamental aspect of platform dimensions, influencing stability, control, and the overall skateboarding experience. Its careful consideration, alongside other dimensions, is paramount for selecting a platform that is both appropriate and safe. An understanding of how this dimension interacts with riding style, rider stature, and equipment selection is critical for optimizing performance and minimizing the risk of injury within the sport.

2. Length (inches)

Platform length, measured in inches, is a defining component of the skateboard platform’s overall dimensions. It exerts a direct influence on maneuverability and stability, interacting closely with other parameters, such as wheelbase and width, to determine the platform’s suitability for various skateboarding styles. A longer platform generally offers increased stability, particularly at higher speeds, while a shorter platform facilitates quicker rotations and enhanced responsiveness in tight spaces. For example, longboard platforms designed for downhill racing typically exceed 36 inches in length, providing a stable platform for maintaining control at high velocities. Conversely, street platforms often range from 29 to 32 inches, enabling riders to execute rapid flip tricks and navigate urban obstacles with greater agility. The practical consequence of selecting an inappropriate length is reduced control and potential for injury.

The relationship between platform length and wheelbase further underscores its significance. Wheelbase, the distance between the inner truck mounting holes, is directly influenced by the platform’s overall length. A longer platform typically accommodates a longer wheelbase, which contributes to enhanced stability but reduces turning responsiveness. A shorter wheelbase, achievable with a shorter platform, promotes quicker turning but may compromise stability at high speeds. These trade-offs necessitate careful consideration based on the rider’s individual preferences and intended skateboarding style. The material composition of the platform can also interact with the length, affecting its flex and overall performance. The length influences how and where the board will flex. Therefore, the interplay of length, wheelbase, and material properties shapes the riding experience.

In conclusion, platform length is not an isolated dimension but an integral element that influences platform performance and handling characteristics. Its relationship with wheelbase, width, and material composition creates a multifaceted system that must be carefully considered when selecting a platform. Understanding the trade-offs between stability and maneuverability associated with different lengths empowers riders to make informed decisions, optimizing their skateboarding experience and mitigating potential risks. Choosing an appropriate platform length is a fundamental step towards achieving both performance and safety.

3. Wheelbase (inches)

Wheelbase, measured in inches, represents a critical dimension within platform specifications, directly impacting a skateboard’s turning radius, stability, and overall responsiveness. Its relationship to platform dimensions is paramount for determining the suitability of a given platform for specific skateboarding styles and rider preferences.

- Turning Radius and Maneuverability

The wheelbase dictates the tightness of turns achievable on a skateboard. A shorter wheelbase reduces the distance between the front and rear trucks, enabling tighter turns and increased maneuverability, which is advantageous for street skateboarding and navigating obstacles. Conversely, a longer wheelbase increases the turning radius, providing greater stability at higher speeds, making it suitable for downhill skateboarding and transportation.

- Stability and Control

A longer wheelbase enhances stability, especially at higher speeds, as it increases the distance between the points of contact with the ground. This reduces the likelihood of wobbles and improves overall control. Shorter wheelbases, while offering increased maneuverability, can be less stable at high speeds and may require more rider input to maintain control.

- Influence on Pop and Ollie Height

The wheelbase affects the distribution of weight and leverage when performing ollies and other aerial maneuvers. A shorter wheelbase can make it easier to pop the board, requiring less effort to lift the front end. A longer wheelbase may require more force to initiate the ollie but can provide a more stable landing platform.

- Adaptation to Riding Style

Different skateboarding disciplines require different wheelbase lengths. Technical street skaters often prefer shorter wheelbases for quick maneuvering and executing flip tricks, while transition skaters who frequent bowls and ramps may opt for longer wheelbases for stability and control. Cruisers and longboarders typically utilize even longer wheelbases for comfortable riding and high-speed stability.

In summary, wheelbase is an integral component of platform dimensions, influencing turning radius, stability, and the board’s responsiveness. Matching the wheelbase to the rider’s skill level, intended skateboarding style, and personal preferences is crucial for optimizing performance and ensuring a safe and enjoyable riding experience. The relationship between wheelbase and other platform dimensions underscores the interconnected nature of skateboard design.

4. Nose Length

Nose length, an integral aspect of platform design, directly influences skateboarding performance. Its measurement, typically in inches, impacts board control, pop, and overall maneuverability. Understanding the relationship between nose length and overall platform dimensions is essential for platform selection.

- Impact on Pop and Ollie Height

Nose length influences the leverage available for generating pop during ollies and other aerial maneuvers. A longer nose, relative to the tail, can provide increased leverage, potentially leading to higher ollies. However, excessive nose length can reduce responsiveness, making it more difficult to initiate tricks quickly.

- Influence on Foot Placement and Board Control

The nose length affects foot placement and the rider’s ability to control the board during various maneuvers. A longer nose provides a larger surface area for foot placement, which can be advantageous for certain tricks, such as nose manuals and nollies. However, a shorter nose may offer greater agility and responsiveness in tight spaces.

- Relationship with Tail Length and Overall Balance

Nose length is intrinsically linked to tail length. The ratio between nose and tail length contributes to the overall balance and feel of the platform. Platforms with similar nose and tail lengths may offer a more balanced and symmetrical feel, while those with significantly different lengths can provide distinct performance characteristics. This balance affects how the board responds to weight distribution.

- Considerations for Riding Style and Terrain

The optimal nose length depends on the rider’s style and the terrain being skated. Street skaters who perform technical tricks often prefer platforms with shorter noses for increased agility, while transition skaters may opt for longer noses for stability in bowls and ramps. Cruisers may prefer less aggressive angles with longer noses as well.

Nose length should be considered in conjunction with other platform measurements. By understanding how nose length interacts with tail length, wheelbase, and overall platform dimensions, skateboarders can select platforms that are best suited to their individual needs and preferences. The correct nose length enhances the skateboarding experience, improving performance and control.

5. Tail Length

Tail length, a component of “skate deck sizes”, fundamentally influences a skateboard’s functionality. Its dimension, typically measured in inches, directly affects a rider’s capacity to generate pop, control stability, and execute various maneuvers. Shorter tails generally enhance responsiveness, facilitating quicker pop for technical tricks. Conversely, longer tails can provide increased stability, particularly at higher speeds or during landings. The influence of tail length becomes evident when comparing street and vert platforms. Street platforms often feature shorter tails to enable rapid ollies and flip tricks, while vert platforms might utilize longer tails for enhanced stability on ramps and in bowls. Consequently, understanding tail length and its relationship to other dimensions is crucial for platform selection.

The interaction between tail length and wheelbase further emphasizes its significance. A shorter tail combined with a shorter wheelbase creates a highly maneuverable platform suitable for tight spaces and quick turns. However, this configuration may sacrifice stability. Conversely, a longer tail paired with a longer wheelbase provides increased stability but can reduce responsiveness. Consider the example of a cruiser platform designed for comfortable transportation. These platforms often feature a longer tail to provide a more stable platform for foot braking and navigating varied terrain. Selecting a tail length that complements the wheelbase and intended riding style optimizes performance. A properly chosen tail length reduces the risk of misexecuting tricks and improves overall control.

In summary, tail length is an indispensable element of “skate deck sizes”. It influences pop, stability, and maneuverability. Recognizing how tail length interacts with other platform dimensions, such as wheelbase and nose length, enables informed decision-making. The appropriate tail length enhances the skateboarding experience, improving both performance and safety. As such, considering tail length is a key component in choosing the right platform.

6. Concave Depth

Concave depth, a critical aspect of platform design, significantly influences a skateboard’s handling and responsiveness. Measured as the degree of curvature across the width of the platform, concave depth directly affects a rider’s foot placement, board feel, and ability to execute various skateboarding maneuvers. Different degrees of concave cater to diverse riding styles and preferences, thereby impacting the overall “skate deck sizes” equation.

- Influence on Foot Lock-In and Control

Concave depth dictates the security of foot placement on the platform. Deeper concave provides a more pronounced pocket for the feet, enhancing grip and control during technical tricks and high-speed maneuvers. Shallower concave offers a more relaxed foot position and a greater sense of board feel, preferred by some for cruising or flat ground skating. As an example, street skaters may opt for deeper concave for more secure footing during flip tricks, while cruisers might choose a mellow concave for increased comfort.

- Impact on Board Responsiveness

The degree of concave affects the board’s responsiveness to rider input. Steeper concave can amplify the leverage exerted by the feet, resulting in quicker and more precise turns. Mellow concave, conversely, provides a more gradual and predictable response. For instance, a platform with a radial concave (consistent curve) will offer a predictable response across the width of the board, whereas a progressive concave (varying curve) might offer enhanced edge control for specific maneuvers.

- Relationship with Platform Width and Rider Stance

Concave depth should be considered in conjunction with platform width and the rider’s stance. A wider platform may require deeper concave to provide adequate foot lock-in, while a narrower platform might perform optimally with shallower concave. Additionally, a rider’s stance (regular or goofy) and foot size can influence their preferred concave depth. For instance, a rider with a wider stance might benefit from a deeper concave to maximize control, especially on larger platforms.

- Material and Construction Considerations

The materials and construction methods employed in manufacturing can influence the effectiveness of a particular concave profile. Certain materials may be more conducive to maintaining a specific concave shape over time, while others may be prone to flattening or warping. Similarly, pressing techniques can affect the consistency and accuracy of the concave across multiple platforms. Quality construction is crucial for ensuring that the intended concave depth translates into tangible performance benefits for the rider.

The interplay between concave depth and other platform dimensions contributes to a holistic understanding of “skate deck sizes.” Selecting an appropriate concave depth, in conjunction with other specifications, is crucial for optimizing performance and enhancing the overall skateboarding experience. Furthermore, this is only to illustrate skateboard specifications.

7. Mounting Holes

Mounting holes, a seemingly minor but critical element of platform construction, directly correlate with overall platform dimensions and compatibility within skateboarding equipment. These precisely drilled apertures dictate the attachment point for trucks, thereby influencing wheelbase, turning radius, and the distribution of weight across the platform. Deviation from established standards or inaccuracies in placement compromises the functionality of the entire setup. Therefore, mounting holes are an essential consideration when determining the overall specifications.

The industry-standard pattern, often referred to as “old school” or “new school,” provides interchangeability between different truck and platform manufacturers. However, variations exist, particularly in vintage platforms or those from niche manufacturers. Mismatched mounting patterns necessitate the use of adapter plates or drilling new holes, both of which can weaken the platform structure and alter its intended performance characteristics. The positioning of these holes, relative to the platform’s nose and tail, defines the effective wheelbase, which, as previously discussed, significantly impacts handling. Real-world implications include instability at high speeds or an inability to properly execute certain tricks if the wheelbase is unintentionally altered due to improper mounting.

In summation, mounting holes are not merely perforations; they are integral to the structural integrity and performance capabilities of a skateboard. Their precise placement, adherence to industry standards, and compatibility with chosen trucks are crucial for ensuring a safe and functional skateboarding experience. Ignoring these aspects of platform dimension can lead to compromised performance, equipment damage, and potential injury. Understanding the relationship between mounting holes and overall platform dimensions is fundamental for informed platform selection and equipment compatibility.

Frequently Asked Questions About Platform Dimensions

This section addresses common inquiries regarding platform specifications, providing concise and informative answers based on established skateboarding knowledge.

Question 1: How does platform width impact stability?

Increased platform width generally enhances stability, providing a larger surface area for foot placement and improved balance, particularly beneficial for vert skating and navigating ramps.

Question 2: What is the significance of wheelbase in relation to turning radius?

Wheelbase dictates the tightness of turns. Shorter wheelbases enable tighter turns, advantageous for street skateboarding, while longer wheelbases increase the turning radius, enhancing stability at higher speeds, suitable for downhill skating.

Question 3: How does nose length influence ollie height?

Nose length affects leverage during ollies. A longer nose, relative to the tail, can provide increased leverage, potentially leading to higher ollies, although excessive length may reduce responsiveness.

Question 4: What role does tail length play in generating pop?

Tail length directly impacts the ability to generate pop. Shorter tails generally enhance responsiveness and facilitate quicker pop for technical tricks, while longer tails can provide increased stability during landings.

Question 5: How does concave depth affect foot lock-in?

Concave depth influences foot security on the platform. Deeper concave provides a more pronounced pocket for the feet, enhancing grip and control during technical tricks and high-speed maneuvers.

Question 6: Why is mounting hole placement critical?

Mounting hole placement dictates truck attachment, influencing wheelbase, turning radius, and weight distribution. Deviation from industry standards or inaccuracies in placement compromise functionality.

A comprehensive understanding of platform dimensions ensures informed decision-making, optimizing both performance and safety within skateboarding.

The subsequent section will explore advanced topics in platform design and construction.

Skate Deck Sizes

This exploration has detailed the fundamental dimensions governing skateboard platforms, including width, length, wheelbase, nose length, tail length, concave depth, and mounting hole placement. Each element contributes uniquely to a platform’s handling characteristics, impacting stability, maneuverability, pop, and overall rider control. Understanding these dimensions and their interplay is essential for selecting a platform suited to individual needs and skateboarding style.

Given the demonstrated importance of skateboard platform dimensions in influencing both performance and safety, thorough consideration during equipment selection is paramount. Continued research and adherence to industry standards will further enhance the skateboarding experience, promoting both progression and injury prevention within the sport. The future of skateboarding relies on the application of informed choices, driven by a comprehensive understanding of the “skate deck sizes” and their profound impact.