These are specialized recreational footwear designed to facilitate movement across ice surfaces for very young children. The designation “size 6” refers to a specific foot measurement within standardized sizing systems used by manufacturers of such equipment. These skates are typically constructed with features to enhance stability and ease of use for beginning skaters.

Providing appropriately sized and supportive skates is crucial for a child’s early experiences with ice skating. Properly fitted skates can contribute to balance, confidence, and enjoyment of the activity, while poorly fitted skates may lead to discomfort, instability, and potentially, injury. The availability of correctly sized equipment allows for participation in a healthy and engaging winter pastime.

The subsequent discussion will address key considerations when selecting appropriate ice skates for toddlers, including safety features, fit guidelines, and maintenance practices. Detailed information will be provided on how to ensure optimal comfort and performance to promote a positive introduction to the sport.

Selection and Use Guidelines

The following guidelines offer important considerations for selecting and using ice skates of this specification to ensure safety and optimize the learning experience.

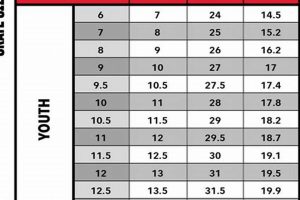

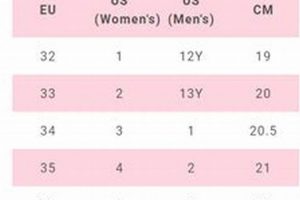

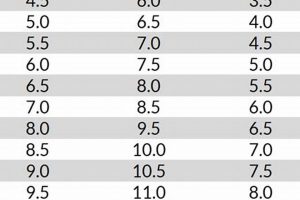

Tip 1: Accurate Measurement: Obtain a precise measurement of the child’s foot. Consult manufacturer sizing charts to correlate foot length with the appropriate skate size, accounting for sock thickness.

Tip 2: Proper Fit: Ensure the skate fits snugly, but not tightly. Toes should have minimal room to move, and the heel should be securely held in place to prevent slippage.

Tip 3: Ankle Support: Select skates with adequate ankle support. Stiff, supportive boots minimize ankle roll and provide stability, which is critical for beginners.

Tip 4: Blade Sharpness: New skates often require sharpening before use. Consult a qualified skate technician to ensure blades are properly sharpened for optimal edge control.

Tip 5: Protective Gear: Always use appropriate protective gear, including a certified helmet, knee pads, and elbow pads, regardless of skill level.

Tip 6: Supervised Use: Constant supervision by a responsible adult is essential, particularly for novice skaters. Provide guidance and assistance as needed.

Tip 7: Gradual Introduction: Begin with short skating sessions and gradually increase duration as the child gains confidence and skill.

Tip 8: Maintenance: After each use, thoroughly dry the blades with a clean cloth to prevent rust. Regularly inspect the skates for wear and tear, and address any issues promptly.

Adhering to these recommendations can significantly improve safety and enhance the overall experience when learning to ice skate, promoting skill development and a lifelong enjoyment of the sport.

The concluding section will summarize the significance of proper skate selection and safe skating practices, emphasizing the benefits of a positive early experience with ice skating.

1. Proper Foot Measurement

Accurate foot measurement is paramount when selecting ice skates for toddlers. Given the rapid growth rate of young children’s feet, precise sizing is crucial for both comfort and safety, directly impacting the fit and performance of size 6 ice skates.

- Minimizing Injury Risk

Inadequate foot measurement can lead to selecting skates that are either too large or too small. Oversized skates may cause the foot to slide within the boot, increasing the risk of ankle sprains or blisters due to friction. Undersized skates can constrict the foot, impairing circulation and causing discomfort, potentially leading to long-term foot problems. Precise measurement reduces these risks.

- Enhancing Stability and Control

Correctly fitted skates allow for optimal contact between the foot and the skate boot. This enhanced contact provides greater stability and control on the ice. Loose-fitting skates compromise balance and coordination, hindering the child’s ability to learn and execute basic skating techniques. Accurate measurements ensure a snug, supportive fit.

- Promoting Positive Experience

Comfortable feet are essential for a positive skating experience. If the skates are ill-fitting, the child may become distracted by discomfort or pain, diminishing their enjoyment of the activity. Properly sized skates contribute to a more pleasurable and engaging experience, fostering a positive association with ice skating and encouraging continued participation.

- Facilitating Skill Development

Proper foot measurement directly supports the child’s ability to develop skating skills. Ill-fitting skates can impede natural foot movement and hinder the learning process. Appropriately sized skates allow for better foot articulation, enabling the child to practice and master fundamental skating skills with greater ease and efficiency.

In summary, proper foot measurement is a prerequisite for selecting the correct size of ice skates for toddlers. Addressing safety, enhancing stability, promoting positive experiences, and facilitating skill development are all interconnected benefits that emphasize the need for precise foot measurement before choosing size 6 ice skates.

2. Adequate Ankle Support

For “toddler ice skates size 6,” adequate ankle support serves as a critical safety and performance feature. The undeveloped musculature and skeletal structure of toddlers necessitate external support to maintain stability on the ice. The skate’s boot must extend sufficiently up the ankle and provide firm lateral restraint to prevent excessive pronation or supination. Insufficient ankle support leads to instability, increasing the risk of falls and ankle injuries, such as sprains. A well-designed size 6 skate incorporates rigid materials and reinforced construction around the ankle area to mitigate these risks.

The effectiveness of ankle support directly impacts the learning curve for young skaters. With stable ankles, toddlers can focus on mastering fundamental skating techniques, such as balance and forward motion, rather than struggling to maintain an upright position. This enhanced stability translates to increased confidence and a more positive initial experience with ice skating. Conversely, inadequate ankle support can lead to frustration and discouragement, potentially deterring the child from further participation. An example is a toddler attempting to skate with a soft-sided boot; the ankle collapses inward with each stride, hindering forward progress and increasing fall potential.

The integration of adequate ankle support into “toddler ice skates size 6” represents a compromise between stability and mobility. While robust support is essential, excessive rigidity can restrict ankle movement and impede skill development. The ideal design strikes a balance, offering sufficient support to prevent injury while allowing for a degree of flexibility to facilitate proper skating form. Parents and caregivers should prioritize skates with a firm, supportive boot construction, ensuring the ankle is securely held in place, yet not excessively constricted, to promote a safe and enjoyable introduction to ice skating. Neglecting this aspect can substantially increase the risk of injury and hinder the child’s progress.

3. Blade Material Quality

The material composition of the blade in toddler ice skates of size 6 directly influences the performance, safety, and longevity of the product. The selection of appropriate materials requires a balance between durability, edge retention, and cost-effectiveness.

- Steel Hardness and Tempering

The hardness of the steel used in the blade determines its resistance to wear and its ability to maintain a sharp edge. Higher hardness values, often achieved through tempering processes, result in blades that require less frequent sharpening. However, excessively hard steel can become brittle and prone to chipping, particularly when subjected to impacts. In the context of toddler ice skates, where impacts are common, a balance between hardness and ductility is crucial. For instance, a blade made from high-carbon steel that has not been properly tempered may lose its edge quickly or even fracture, posing a safety hazard.

- Corrosion Resistance

Ice skate blades are exposed to moisture, which can lead to corrosion if the material is not adequately resistant. Rust can compromise the blade’s edge and weaken its structure, ultimately reducing its performance and lifespan. Stainless steel alloys, often containing chromium, are frequently employed to enhance corrosion resistance. Protective coatings, such as chrome plating, are sometimes applied to further safeguard against rust. The climate and storage conditions can expedite corrosion without corrosion-resistant materials. For example, skates stored in damp environments without proper drying are more susceptible to rust.

- Edge Retention and Glide Efficiency

The ability of a blade to retain its sharp edge directly affects its glide efficiency on the ice. A dull edge increases friction and requires more effort to maintain momentum. High-quality blade materials, combined with proper sharpening techniques, contribute to longer edge retention and smoother gliding. The grind of the steel can dramatically change glide efficiency. For example, a novice skater using skates with poorly sharpened blades may struggle to maintain balance and forward motion, hindering skill development.

- Material Fatigue Resistance

Repeated use can induce fatigue in the blade material, potentially leading to cracks or fractures. The selection of materials with high fatigue resistance ensures the blade’s structural integrity over time. Factors such as the thickness of the blade and the presence of any manufacturing defects can influence its fatigue life. The blades, if made out of cheap, injection-molded materials might not hold up after several uses. For instance, blades subjected to frequent use on rough or uneven ice surfaces are more likely to experience fatigue-related failures.

- Manufacturing Process

How a blade is produced has a direct impact on its longevity and its ability to perform well. Improper manufacturing techniques can lead to structural weaknesses in the blade, making it more prone to breaking or failing to keep an edge. For instance, a blade that is improperly forged, stamped, or molded may have internal cracks or flaws that make it dangerous.

In summary, the selection of blade materials for toddler ice skates of size 6 must prioritize safety, durability, and performance. The steel composition, heat treatment, and corrosion resistance are crucial factors that determine the blade’s edge retention, glide efficiency, and overall lifespan. Regular inspection and maintenance are essential to ensure the continued safe and effective use of these skates.

4. Secure Fastening System

The secure fastening system of toddler ice skates of size 6 is an essential component that directly impacts safety, stability, and overall performance. A properly designed system ensures that the skate remains firmly attached to the child’s foot, preventing slippage and minimizing the risk of injury.

- Ankle Stability Enhancement

A robust fastening system that effectively secures the ankle is crucial for providing adequate support and preventing lateral movement. Systems employing a combination of laces, buckles, and Velcro straps offer enhanced adjustability and a more secure fit. Insufficient ankle support can compromise balance, increasing the risk of falls and ankle sprains. For example, a lace-only system may not provide sufficient tightening around the ankle area, particularly for children with narrow feet. This can lead to instability and difficulty in maintaining proper skating posture.

- Foot Confinement and Control

The fastening system should effectively confine the foot within the boot, preventing excessive movement and allowing for optimal control. A loose-fitting skate can hinder the child’s ability to execute basic skating maneuvers and increase the risk of blisters or chafing. Systems that incorporate a power strap across the instep can improve foot confinement and enhance responsiveness. However, systems with insufficient confinement will not achieve a great performance and can cause a lot of physical problems.

- Ease of Use for Caregivers

The fastening system should be relatively easy for caregivers to operate, allowing for quick and efficient securing of the skates. Complex or cumbersome systems can be frustrating and time-consuming, potentially delaying the start of skating sessions. Systems with large buckles or simplified lacing mechanisms are often preferred for their ease of use. Systems lacking a straightforward securing method may deter caregivers from properly tightening the skates, compromising safety.

- Durability and Longevity

The materials and construction of the fastening system should be durable and able to withstand repeated use and exposure to cold and damp conditions. Fragile buckles, worn-out Velcro straps, or frayed laces can compromise the system’s effectiveness and require frequent replacement. Fastening systems constructed from high-quality materials, such as reinforced nylon or corrosion-resistant metal, offer greater longevity. Inferior systems will fail more quickly and the blades risk falling apart.

In summary, a secure fastening system is an indispensable feature of toddler ice skates size 6, contributing to safety, stability, and ease of use. Careful consideration of the system’s design, materials, and functionality is essential when selecting skates for young children, ensuring a positive and injury-free introduction to ice skating.

5. Protective Gear Compatibility

The compatibility of protective gear with toddler ice skates size 6 is a critical consideration for ensuring the safety and well-being of young skaters. The interaction between skates and protective equipment directly influences the effectiveness of the gear in mitigating potential injuries. Therefore, attention to compatibility is paramount.

- Helmet Integration

The design of the skate boot and its lacing system should not impede the proper fit and use of a helmet. A helmet must sit level on the head and its straps must not be obstructed by the skate’s upper portion. Interference between the skate and helmet can compromise the helmet’s ability to absorb impact forces during a fall. For example, high-backed skate boots might push the helmet forward, exposing the forehead and increasing the risk of head injury.

- Knee Pad Articulation

The length and design of toddler ice skates size 6 should allow for unrestricted movement of the knee joint when wearing knee pads. The top of the skate boot should not dig into the back of the knee, as this can cause discomfort and limit mobility. Furthermore, restrictive skate designs can displace knee pads during falls, reducing their effectiveness. The pads should overlap the skate at the upper part, without gaps that could allow the knee to hit the ice.

- Elbow Pad Clearance

While less frequently considered, the design of the skate and the childs skating posture should not interfere with elbow pads. Specifically, arm movement shouldn’t be restricted by the skate, nor should falls cause the elbow pad to shift or be pushed off. The fit of elbow pads with respect to the skates primarily concerns the range of motion permitted and whether the skate design contributes to the pad’s dislodgement upon impact. Elbow pads and gloves need to be taken to try it out.

- Ankle Support and Padding Alignment

If the skates lack sufficient integrated ankle support or padding, this absence can impact the effectiveness of separate ankle supports or guards worn in conjunction. The added external supports or pads should fit comfortably within the skate without causing pressure points or restricting circulation. The goal is a synergistic effect, where external gear complements the skates, not compromises them. Alignment ensures appropriate ankle stabilization with the skates.

The interplay between toddler ice skates size 6 and various forms of protective gear is multifaceted. Ensuring compatibility among all components allows for comprehensive protection against potential injuries, promoting a safer and more positive skating experience for young children.

6. Weight and Balance

The distribution of weight and overall balance within toddler ice skates size 6 significantly influences a child’s ability to learn and execute fundamental skating skills. A skate that is disproportionately heavy or exhibits poor balance characteristics can impede a toddler’s natural movements and increase the risk of falls. The positioning of the blade relative to the boot, the weight of the materials used in construction, and the overall design all contribute to the skate’s center of gravity. Ideally, the skate should be designed to promote a stable and balanced stance, allowing the child to maintain equilibrium with minimal effort. An example of poor balance is a skate with a blade mounted too far forward, causing the child to lean backwards excessively to compensate, ultimately hindering forward progress.

The weight of the skate itself is another crucial factor. Overly heavy skates can fatigue a toddler’s leg muscles quickly, making it difficult to sustain practice sessions and potentially leading to improper form. Lightweight materials, such as certain plastics and alloys, are often preferred to minimize the overall weight of the skate. A heavier skate may also reduce balance and increases instability. Consideration should be given to the relative weight of the blade versus the boot, aiming for a balanced distribution that doesn’t disproportionately load the front or rear of the foot. The proper design enhances a positive initial skating experience.

In summary, achieving optimal weight distribution and balance is essential in toddler ice skates size 6. These features directly impact stability, maneuverability, and the overall comfort of the skater. Skates designed with careful consideration of weight and balance enable young children to develop confidence and skill on the ice, promoting a positive introduction to the sport. Ignoring weight or balance characteristics during selection may reduce confidence and result in safety concerns.

7. Overall Skate Condition

The overall condition of ice skates directly impacts the safety, performance, and longevity of toddler ice skates size 6. Regular inspection and maintenance are imperative to ensure that the skates function as intended and to minimize the risk of injury. A compromised skate can lead to falls, hinder skill development, and potentially cause physical harm.

- Blade Integrity and Sharpness

The blade is the critical component for gliding and maneuvering on the ice. Regular inspection should reveal any signs of rust, nicks, or dullness. Rust can compromise the blade’s structural integrity, while nicks can impede smooth gliding. Dull blades reduce control and increase the effort required to skate. For instance, a rusted blade may break unexpectedly, while a dull blade can cause a toddler to struggle with balance, increasing the likelihood of a fall.

- Boot Support and Fastening

The boot provides essential ankle support and stability. Examine the boot for any signs of wear and tear, such as cracks, tears, or loose stitching. Ensure that the fastening mechanisms (laces, buckles, or straps) are in good working order and provide a secure fit. A compromised boot can lead to ankle instability, increasing the risk of sprains or other injuries. Loose or broken fasteners can cause the skate to come off during use.

- Internal Padding and Comfort

The internal padding contributes to comfort and helps secure the foot within the boot. Check for any signs of compression, wear, or moisture accumulation. Compressed padding can reduce support and comfort, while moisture can promote bacterial growth and odors. For example, a toddler may refuse to wear skates with matted or damp padding. A toddler using skates with overly worn padding may experience blisters.

- Size Appropriateness

Verify that the skates still fit the toddler properly. Children’s feet grow quickly, so regular checks are necessary. Too-small skates can cause discomfort and restrict circulation, while too-large skates can compromise stability and control. A skate of “size 6” as manufactured and a skate of “size 6” that is worn and stretched beyond its normal fit are meaningfully different items.

These four points combine to demonstrate how a high quality skate can turn into a safety risk. Careful attention to the overall condition of toddler ice skates size 6 is an investment in a child’s safety and enjoyment of the sport.

Frequently Asked Questions

The subsequent section addresses common inquiries regarding selecting, fitting, and maintaining ice skates for toddlers, focusing on specific considerations for size 6 skates.

Question 1: What is the appropriate age range for a size 6 toddler ice skate?

The age range associated with a size 6 toddler ice skate varies depending on individual foot size and growth patterns. It is imperative to measure the child’s foot accurately and consult the manufacturer’s sizing chart. Generally, a size 6 may fit children between the ages of approximately two to three years. However, foot measurements should always supersede age as the primary determinant.

Question 2: How tight should size 6 ice skates fit on a toddler’s foot?

The skates should fit snugly, without being overly restrictive. The toes should have minimal room to move forward and back, but should not be cramped. The heel should be firmly seated in the heel cup to prevent slippage. Overly tight skates can impede circulation, while loose skates can compromise stability. One finger should be able to fit between the back of the heel and the back of the boot with very little pressure.

Question 3: What safety features are most important to consider when purchasing size 6 ice skates?

Key safety features include robust ankle support, a secure fastening system (laces, buckles, or straps), and durable blade construction. Ankle support prevents excessive lateral movement, reducing the risk of sprains. The fastening system ensures a snug fit, preventing the skate from coming loose during use. Durable blades maintain their edge and resist corrosion.

Question 4: How frequently should toddler ice skates be sharpened?

The frequency of sharpening depends on the usage and the type of ice. Under normal circumstances, size 6 ice skates should be sharpened after every 10 to 20 hours of use. If the blades exhibit visible dullness or nicks, sharpening is necessary regardless of usage time. Sharp edges provide better control and glide efficiency.

Question 5: What is the best method for cleaning and storing ice skates to prevent rust?

After each use, thoroughly dry the blades with a clean, absorbent cloth. Allow the skates to air dry completely before storing them in a well-ventilated area. Consider using blade covers made from a moisture-wicking material to protect the blades from rust. Avoid storing skates in damp or humid environments.

Question 6: Are rental ice skates a suitable option for toddlers, or is it better to purchase their own?

While rental skates may be a convenient option for occasional use, purchasing skates ensures a proper fit and promotes better hygiene. Rental skates may not always be available in the appropriate size or may exhibit wear and tear. If a toddler intends to skate regularly, purchasing size 6 ice skates that are specifically fitted to their feet is generally the preferred choice.

These FAQs highlight the need for careful evaluation when selecting appropriate ice skates, emphasizing safety, comfort, and proper maintenance for an optimal skating experience.

The succeeding section will provide resources and recommendations for further information on selecting appropriate ice skates and developing fundamental skating skills.

Conclusion

The preceding analysis has explored the multifaceted considerations surrounding “toddler ice skates size 6.” Key aspects, including proper fit, ankle support, blade material quality, secure fastening systems, protective gear compatibility, weight and balance, and overall skate condition, have been examined. The information presented underscores the importance of careful selection and maintenance to ensure both the safety and enjoyment of young children engaging in ice skating. Proper foot measurement, combined with an understanding of essential safety features, is crucial for mitigating risks and maximizing skill development.

The long-term benefits of a positive initial experience with ice skating extend beyond mere recreation. Fostering confidence, coordination, and a love for physical activity from a young age contributes to overall well-being. It is therefore imperative that parents and caregivers prioritize the acquisition of appropriately sized and well-maintained equipment, recognizing that “toddler ice skates size 6” are not merely footwear, but a foundational element in a child’s introduction to a potentially lifelong pursuit. Continued diligence in monitoring fit and condition will ensure that these skates continue to provide a safe and enjoyable platform for learning and growth.