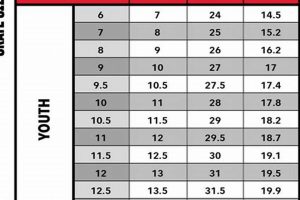

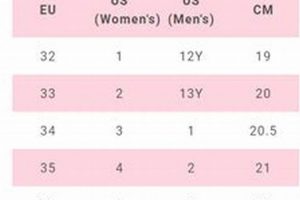

A sizing guide specific to a manufacturer’s ice skates is a table or set of instructions designed to correlate foot measurements (length and sometimes width) with the appropriate skate size. Jackson, a prominent ice skate brand, provides such a guide to assist customers in selecting skates that offer a proper fit. For example, a foot measuring 24.5 centimeters might correspond to a size 6 in their skating boot range, although this can vary depending on the model and skater’s individual preferences.

The relevance of consulting these guides lies in ensuring comfort, performance, and preventing injuries. Ice skates that are too large can lead to instability and poor control, while skates that are too small can cause discomfort and foot problems. Historically, fittings relied solely on in-person assessments by experienced retailers; however, the advent of online shopping has made these standardized charts crucial for remote purchases and informed decision-making. They empower consumers to confidently choose a size that closely matches their foot dimensions, mitigating the risk of ordering incorrectly sized equipment.

The following sections will delve into aspects of accurately measuring one’s foot, interpreting the information found within sizing resources, and understanding the nuances that might necessitate deviating from the initially suggested size. Factors such as skill level, sock thickness, and foot shape will also be considered to provide a holistic view of selecting the optimal size for a positive skating experience.

Guidance on Utilizing Jackson Ice Skate Sizing Resources

Effective application of sizing resources is crucial for selecting appropriately fitting ice skates. The following tips offer guidance on maximizing the utility of these tools to ensure a comfortable and performant skating experience.

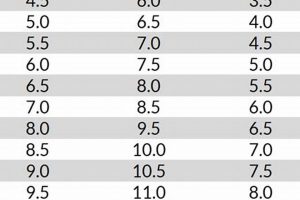

Tip 1: Accurate Foot Measurement is Paramount: Employ a Brannock device or a ruler to measure foot length and width accurately. Measurements should be taken while bearing weight, as the foot expands. Record these measurements in centimeters or inches for cross-referencing with the chart.

Tip 2: Consult the Official Resources: Always refer to the official resources provided by Jackson. Third-party charts may be inaccurate or outdated. Locate the most current chart on the official Jackson website or from authorized retailers.

Tip 3: Account for Sock Thickness: Consider the thickness of the socks typically worn while skating. If thicker socks are preferred, account for the added volume by potentially increasing the skate size by a half-size or a full size.

Tip 4: Consider Skate Model Variations: Recognize that sizing may vary slightly between different Jackson skate models. A specific size might be appropriate in one model but not another. Consult model-specific guides whenever possible.

Tip 5: Prioritize Fit Over Size Number: The numerical size is secondary to the actual fit. Focus on ensuring a snug, comfortable fit around the heel and a secure fit through the arch and ball of the foot, even if it deviates from the expected size.

Tip 6: Evaluate Foot Shape: Consider your foot’s shape. Individuals with wider feet may need to explore models specifically designed for wider fits or consider sizing up to accommodate the width comfortably.

Tip 7: Seek Professional Assistance: If uncertainty persists, consult with a knowledgeable skate fitter at a reputable skate shop. A professional can provide personalized advice and assess the fit of various models and sizes.

Adhering to these guidelines helps to minimize the risk of selecting incorrectly sized ice skates, optimizing comfort, performance, and safety on the ice.

The subsequent section will address frequently asked questions related to fitting, addressing common concerns and clarifying potential points of confusion.

1. Foot measurement accuracy

Foot measurement accuracy serves as the foundational element for effectively utilizing the resources. The chart correlates skate size with foot dimensions. If the foot measurement is inaccurate, the selected skate size will likely be incorrect, negating the purpose of consulting the chart. For instance, if an individual underestimates their foot length by one centimeter, the chart may indicate a skate that is too small, leading to discomfort, blisters, and impaired skating performance.

The practical significance of accurate measurement extends beyond mere comfort. A poorly fitted skate, resulting from inaccurate input into the selection process, can compromise stability and control on the ice. This is particularly critical for skaters performing complex maneuvers or those at higher skill levels. The consequence of an ill-fitting boot, stemming from mismeasurement, can range from diminished athletic achievement to an increased risk of injury, such as ankle sprains or stress fractures. Professional skate fitters routinely emphasize precise foot measurement as the initial and most crucial step in the fitting process. They utilize specialized tools, like Brannock devices, to ensure precise readings, and account for foot width, arch height, and other anatomical factors influencing fit.

In summary, foot measurement accuracy is not merely a preliminary step, but an indispensable component for deriving value from the chart. Failure to obtain accurate measurements undermines the utility of the chart and increases the likelihood of selecting an inappropriately sized skate. The challenge lies in ensuring individuals understand the importance of precision and employ appropriate measuring techniques or seek professional assistance to minimize error.

2. Model-specific variations

Model-specific variations in ice skate construction significantly impact the application of any standardized sizing chart. While a manufacturer, such as Jackson, provides a generalized chart to correlate foot size with skate size, the internal dimensions, last shape, and padding characteristics can differ considerably between models. This necessitates careful consideration beyond simply relying on a single size conversion. For example, a skater measuring a size 7 based on foot length might find that a size 7 in a Jackson Elle boot fits comfortably, while the same size in a higher-end Jackson Premiere boot feels too tight due to its narrower last and thicker internal padding. This discrepancy arises from design choices intended to cater to different skill levels and skating styles.

The practical significance of understanding model-specific variations lies in avoiding mis-sizing and ensuring optimal performance. Skates designed for advanced skaters often feature a closer, more performance-oriented fit, which may require adjusting the size selected based on the chart. Conversely, recreational models may offer a more generous fit, potentially requiring a smaller size. Failure to account for these variations can lead to discomfort, blisters, and impaired skating technique. Retailers who stock multiple Jackson skate models commonly advise customers to try on different sizes within each model to determine the best fit, regardless of the size indicated by the general sizing chart. This emphasizes the chart’s role as a starting point, rather than a definitive solution.

In summary, model-specific variations represent a critical caveat when utilizing resources. While the general chart offers a helpful initial guide, it cannot replace the importance of understanding how individual models differ in their fit characteristics. Skaters are advised to research specific model fit information, read reviews, and, ideally, try on skates in person to ensure optimal size selection. These variations underscore the need for a nuanced approach to fitting, moving beyond reliance on a singular chart to encompass the intricacies of skate design and individual foot anatomy.

3. Width considerations

Width considerations are integral to the proper application of sizing resources. A chart predominantly focuses on foot length, neglecting the dimensional aspect of foot width. This omission can lead to selecting skates that are either too narrow, causing discomfort and potential foot problems like bunions, or too wide, resulting in insufficient support and compromised skating performance. An individual with a foot length corresponding to a size 8 on the Jackson sizing chart, but possessing a wider foot profile, may find the standard width of size 8 skates constricting. This discrepancy necessitates either selecting a wider width option (if available within that model) or sizing up to accommodate the width, potentially compromising the fit in the heel area.

The practical significance of addressing width extends beyond basic comfort. Skates that are too narrow restrict blood flow and can cause numbness or pain during prolonged skating sessions. Conversely, skates that are too wide allow the foot to move excessively within the boot, reducing stability and control, particularly during turns and jumps. Furthermore, improperly fitted skates can accelerate wear and tear, diminishing the lifespan of the equipment. Some skate manufacturers, including Jackson, offer models in multiple widths (e.g., narrow, medium, wide) to better accommodate various foot shapes. Consulting sizing information that specifically addresses width, or seeking professional fitting advice that accounts for this dimension, is essential for mitigating these risks. Ignoring the importance of width effectively renders the length-based sizing chart incomplete, leading to suboptimal skate selection.

In summary, width is a critical, yet often overlooked, component of ice skate sizing. The resource provides a length-based starting point, but its utility is contingent on addressing width considerations. Failure to do so can lead to discomfort, impaired performance, and potential foot problems. The challenge lies in ensuring that individuals are aware of the importance of width and take appropriate steps, such as measuring foot width, exploring width-specific sizing options, or consulting with a professional fitter, to ensure a comprehensively accurate skate fit.

4. Skill level influence

Skill level significantly impacts skate selection, necessitating a nuanced interpretation of resources. A skater’s proficiency and intended use directly correlate with the type of boot required, thereby influencing the optimal size and fit, even when foot measurements align with chart recommendations.

- Beginner Support Needs

Novice skaters require more ankle support than experienced individuals. This translates to stiffer boots, which often feature thicker padding. The additional padding within a beginner skate can affect the internal volume, potentially necessitating a half-size larger than indicated on the chart to accommodate the foot comfortably without excessive pressure. For example, a beginner measuring a size 6 on the chart might find a size 6.5 to be a better fit in a beginner-level Jackson skate due to the increased internal padding.

- Advanced Performance Fit

Advanced skaters prioritize responsiveness and control. Their skates tend to have a closer, more form-fitting design to maximize energy transfer and minimize foot slippage. This “performance fit” often requires a more precise size selection, potentially deviating from the size suggested by the chart based on foot length alone. An advanced skater requiring a snug fit might opt for the exact size indicated by the resource or even a half-size smaller to achieve optimal feel and control within the skate.

- Boot Stiffness Impact

Boot stiffness is directly related to skill level. Stiffer boots offer greater support but reduced flexibility, while softer boots allow for more ankle movement but less overall support. A less experienced skater needing a stiffer boot may find that the added structure affects the fit, requiring size adjustments. Conversely, a more experienced skater comfortable in a softer boot may prioritize a tighter, more responsive fit, leading to a different size selection than suggested by the standard chart.

- Break-In Period Considerations

The break-in period also varies depending on the skill level and boot construction. Stiffer, higher-level boots typically require a longer break-in period, during which the skater may experience some discomfort. This can influence size selection, as skaters may initially choose a slightly larger size to accommodate potential swelling or discomfort during the break-in phase. However, this approach carries the risk of the skate becoming too large once fully broken in, highlighting the importance of considering long-term fit alongside initial comfort.

These skill-dependent factors demonstrate that the tool serves as a valuable starting point, but should not be the sole determinant in size selection. A skater’s abilities, preferences for boot stiffness, and tolerance for a tighter fit all contribute to finding the optimal size. Consulting with a knowledgeable skate fitter who can assess these individual needs is crucial for ensuring a comfortable and performant skating experience.

5. Sock thickness allowance

The consideration of sock thickness represents a critical adjustment when utilizing a Jackson ice skate sizing resource. A chart provides a correlation between foot dimensions and skate size, but it does not inherently account for the volume occupied by socks worn during skating. Ignoring this allowance can lead to selecting an incorrectly sized skate, impacting comfort, performance, and potentially causing injury.

- Impact on Internal Volume

Sock thickness directly influences the internal volume of the skate boot. Thicker socks compress the foot, effectively shortening its length and increasing its width within the boot. If the chart is used without factoring in this compression, the selected skate may feel too small, leading to discomfort, restricted circulation, and blisters. Conversely, thinner socks may result in a skate that feels too loose, reducing stability and control. For example, a skater measuring a size 7 with bare feet might find a size 7.5 to be more comfortable when wearing thick skating socks.

- Material Composition Influence

The material composition of socks also plays a role. Wool or synthetic blends offer different levels of insulation and compression compared to cotton. Thicker wool socks can significantly reduce the available space within the skate, requiring a larger size allowance than thinner synthetic options. The compressibility of the sock material also affects the overall fit, as some materials compress more readily than others under pressure. An individual who typically wears thick wool socks for warmth may need to account for a larger size adjustment than someone who prefers thinner, less compressive synthetic socks.

- Single vs. Multiple Layers

The decision to wear a single layer of thick socks or multiple layers of thinner socks also affects the fit. Multiple thin layers can create pressure points and reduce circulation more than a single layer of equivalent thickness. While some skaters prefer layering for warmth or customization, this approach necessitates careful consideration of the overall volume and potential impact on skate fit. In such cases, professional fitting advice is particularly valuable to ensure that the skate is appropriately sized to accommodate the chosen sock configuration.

- Compromise with Performance

Selecting too large a size to accommodate thick socks can compromise performance. A skate that is too large, even with thick socks, can result in heel slippage and reduced control, particularly during complex maneuvers. The ideal scenario involves finding a balance between sock thickness and skate size to achieve both comfort and optimal performance. This often requires experimentation with different sock thicknesses and skate sizes to determine the most effective combination.

The interplay between sock thickness and sizing highlights the limitations of relying solely on resources for selecting ice skates. While such charts provide a useful starting point, they must be supplemented by a thorough understanding of how sock thickness influences fit and comfort. Skaters are encouraged to consider their typical sock choices and, if possible, try on skates with their preferred socks to ensure an accurate and comfortable fit. Consulting with a professional fitter can further assist in navigating this nuanced aspect of skate selection.

6. Professional fitting advice

Professional fitting advice significantly enhances the effective utilization of resources. While the chart offers a standardized correlation between foot measurements and skate sizes, it inherently lacks the capacity to account for individual foot characteristics, skating style, and personal preferences. A skilled skate fitter possesses the expertise to assess these nuanced factors, providing tailored guidance that transcends the limitations of the chart alone. For instance, an individual measuring a size 8 on the chart may require a different size or model based on foot width, arch height, or ankle flexibility, assessments that a professional fitter can accurately perform. The fitter’s role is to bridge the gap between standardized sizing and personalized fit, ensuring optimal comfort and performance.

The practical significance of professional advice extends to injury prevention and enhanced skating technique. A properly fitted skate, guided by professional assessment, minimizes the risk of blisters, pressure points, and other foot-related discomforts that can arise from an ill-fitting boot. Furthermore, a skilled fitter can evaluate the skater’s technique and recommend a skate model that complements their skating style, promoting proper alignment and maximizing performance. For example, a figure skater requiring precise ankle support for jumps and spins will benefit from a fitter’s expertise in selecting a boot with the appropriate stiffness and support characteristics, a determination that goes beyond simply matching foot length to a number on a chart. Professional fitting also entails proper lacing techniques and customization options, such as heat molding, to further refine the fit and address individual foot anomalies.

In summary, professional fitting advice acts as a critical complement to the utilization of resources. While the chart provides a foundational reference point, it cannot replace the individualized assessment and tailored recommendations offered by a qualified skate fitter. The benefits of professional fitting extend beyond mere comfort, encompassing injury prevention, performance enhancement, and optimized equipment selection. The challenge lies in promoting awareness of the value of professional fitting and ensuring access to qualified fitters who possess the knowledge and experience to guide skaters towards the best possible skate fit. Ultimately, combining standardized resources with expert guidance yields the most effective approach to ice skate selection.

7. Chart updates frequency

The frequency with which sizing charts are updated directly influences the accuracy and reliability of a Jackson ice skate size chart. Shoe and skate manufacturing, including lasts and sizing conventions, is not static. If the manufacturer alters its lasts or internal padding, the corresponding sizing chart must reflect these modifications to provide users with accurate fitting information. A failure to regularly update a chart in response to product changes renders it obsolete, potentially leading to mis-sizing and customer dissatisfaction. The longer the period between chart updates, the greater the likelihood of discrepancies arising between the charted measurements and the actual fit of current skate models. For instance, a chart that has not been revised in five years may not accurately represent the sizing of newly released skate models or even models with subtle manufacturing adjustments implemented during that time.

The practical significance of monitoring chart update frequency lies in ensuring that consumers are making informed purchasing decisions. An outdated chart can lead to individuals selecting the wrong size skates, resulting in discomfort, impaired performance, and even potential injuries. To mitigate this risk, skaters should prioritize accessing resources directly from the manufacturer’s official website or authorized retailers, as these sources are more likely to provide the most up-to-date information. Retailers also bear a responsibility to prominently display the date of the sizing chart to inform customers of its currency. Checking for a revision date or a statement confirming the chart’s validity is a crucial step in the skate selection process. Moreover, a high update frequency signals a commitment to quality and customer satisfaction on the part of the manufacturer.

In conclusion, chart update frequency is an indispensable component of a functional and trustworthy Jackson ice skate size chart. The accuracy of the chart diminishes over time unless regularly revised to reflect manufacturing changes and evolving sizing standards. While individuals can mitigate the risk of using outdated information by consulting official sources and verifying the chart’s revision date, the responsibility ultimately rests with the manufacturer to maintain and communicate accurate sizing data. Regular chart updates are not merely a technicality but a critical factor in ensuring customer satisfaction and the integrity of the sizing process.

Frequently Asked Questions About Ice Skate Resources

This section addresses common inquiries regarding the application of sizing charts to facilitate informed ice skate selection. The following questions clarify prevalent points of confusion.

Question 1: How often should foot measurements be taken when determining ice skate size?

Foot measurements should be taken at least annually, or whenever significant changes in foot size are suspected, such as after pregnancy or substantial weight fluctuations. Additionally, measurements are advisable before purchasing a new skate model, as sizing may vary.

Question 2: Are the charts universal across all ice skate brands, or are they brand-specific?

Sizing resources are brand-specific. The dimensions and shapes of ice skates differ between manufacturers. Utilizing the chart from Jackson is essential when selecting Jackson skates, and should not be interchanged with other brands.

Question 3: What action should be taken if foot measurements fall between two sizes on the chart?

In instances where foot measurements fall between two sizes, selecting the larger size is generally recommended, particularly for younger skaters whose feet are still growing. However, considering factors such as foot width and skating experience is also crucial. Consulting a professional fitter is advisable in such cases.

Question 4: Can using a chart alone guarantee a proper fit without trying on the skates?

While charts provide a helpful starting point, they cannot guarantee a perfect fit. Individual foot variations and skate model nuances necessitate trying on skates whenever possible to assess comfort and ensure adequate support.

Question 5: How do different skate boot stiffness levels affect sizing?

Stiffer skate boots may require a slightly larger size to accommodate the increased rigidity and reduced flexibility of the boot. Conversely, softer boots may allow for a more snug fit, potentially necessitating a smaller size. Considering the intended skating discipline and skill level is essential when evaluating boot stiffness and sizing.

Question 6: What recourse is available if skates purchased online, based on a chart, do not fit properly?

Most reputable online retailers offer return or exchange policies for skates that do not fit properly. Carefully reviewing the retailer’s policies before making a purchase is essential. Consulting with a customer service representative to discuss sizing concerns is also advisable.

The utilization of resources requires careful attention to detail, consideration of individual factors, and, whenever possible, professional guidance. Reliance solely on a chart may not guarantee a perfect fit, emphasizing the importance of thorough assessment and informed decision-making.

The subsequent section will summarize the key insights discussed throughout this exploration.

Conclusion

The preceding analysis has comprehensively explored the nature, application, and limitations of the “jackson ice skate size chart”. Its role as a foundational tool for determining appropriate skate size based on foot measurements was established, alongside critical considerations such as foot width, skill level, sock thickness, model-specific variations, and the importance of professional fitting advice. The significance of regularly updated charts to reflect manufacturing changes was also underscored.

While this resource provides a valuable starting point, its inherent limitations necessitate a holistic approach to skate selection. Individuals are encouraged to integrate this standardized guide with personalized assessments and expert counsel to ensure optimal comfort, performance, and safety on the ice. Ultimately, informed decision-making remains paramount in achieving a properly fitted skate that supports athletic endeavors and minimizes the risk of injury.