The confluence of footwear designed for skateboarding, a promotional pricing strategy, and a specific foot dimension presents a unique opportunity for consumers. This intersection allows individuals to acquire specialized athletic footwear at a reduced cost, provided the size corresponds to their needs. As an example, a retailer might offer a discount on a particular style of skateboarding footwear that is available only in the specified dimension.

The significance lies in the potential cost savings for the consumer and the reduction of inventory for the retailer. Such sales can clear out-of-season merchandise, discontinued lines, or excess stock. Historically, this type of promotional event has driven consumer demand and influenced purchasing decisions, particularly among budget-conscious individuals seeking quality athletic footwear.

The following discussion will delve into the features, selection criteria, and considerations when seeking out such opportunities. Understanding these aspects will aid individuals in making informed choices and maximizing the benefits available during these promotional periods.

This section provides practical guidelines for consumers seeking reduced-price skateboarding footwear in a specific size. These tips aim to ensure informed purchasing decisions and maximize the value obtained.

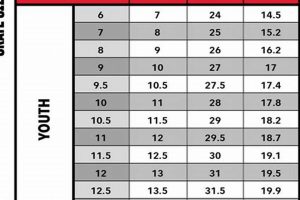

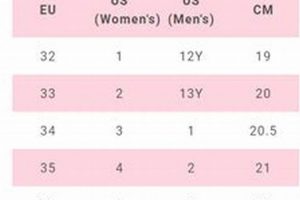

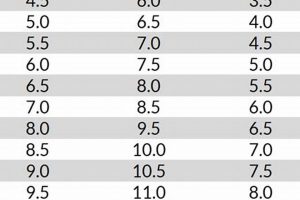

Tip 1: Verify Sizing Charts. Footwear dimensions can vary significantly between manufacturers. Consult the specific brand’s sizing chart before making a purchase to ensure accurate fit.

Tip 2: Inspect for Defects. Discounted merchandise may sometimes have minor cosmetic or structural flaws. Thoroughly examine the footwear for any signs of damage before completing the transaction.

Tip 3: Confirm Return Policies. Clarify the seller’s return policy regarding discounted items. Determine if returns or exchanges are permitted in case of sizing issues or defects.

Tip 4: Research Reputable Brands. Prioritize well-established skateboarding footwear brands known for durability and performance, even when purchasing at a reduced price. This will help ensure quality and longevity.

Tip 5: Evaluate Sole Construction. Scrutinize the sole’s material and construction. Look for durable rubber compounds and reinforced stitching, which are essential for withstanding the rigors of skateboarding.

Tip 6: Consider Material Composition. Examine the upper material, opting for durable options such as suede, leather, or reinforced canvas. These materials offer superior abrasion resistance and support.

Tip 7: Compare Prices Across Retailers. Conduct comparative price analysis across multiple retailers offering discounted skateboarding footwear in the required size. This will ensure the best possible deal.

These guidelines enable consumers to make well-informed decisions when seeking skateboarding footwear at reduced prices in the defined dimension, balancing cost savings with considerations of fit, quality, and performance.

The subsequent sections will address long-term care and maintenance practices to extend the lifespan of the acquired skateboarding footwear.

1. Inventory Availability

Inventory availability directly dictates the feasibility of acquiring skateboarding footwear at a reduced price in a dimension of 10. The existence of a “skate shoes sale size 10” is entirely contingent upon the retailer possessing stock matching these criteria. Without sufficient inventory in this specific size, the promotional offer becomes theoretical and inaccessible to potential customers. A retailer, for instance, might advertise a “skate shoes sale,” but if the dimension 10 selection is depleted, only consumers with differing foot sizes can benefit.

The effect of limited inventory is amplified during peak shopping periods. High demand coupled with low stock levels often results in rapid depletion of popular styles and sizes. This necessitates prompt action from consumers seeking to capitalize on the reduced prices. Retailers may employ strategies such as limiting the quantity each customer can purchase or implementing “first-come, first-served” policies. The practical significance lies in the understanding that the advertised “skate shoes sale size 10” might be a fleeting opportunity rather than a guarantee of availability.

In summary, the interplay between inventory and sales is paramount. Low stock nullifies the sale’s accessibility, emphasizing the need for timely action and realistic expectations. Monitoring retailer stock levels, subscribing to alerts, and understanding seasonal demand patterns can mitigate the risk of missing out on desired skateboarding footwear dimension 10 discounts. The challenge lies in balancing the allure of reduced prices with the inherent uncertainty of product availability.

2. Brand Reputation

The standing of a manufacturer significantly influences the perceived value and consumer confidence when acquiring skateboarding footwear, even at a reduced price point such as within a “skate shoes sale size 10.” A brand’s history, product quality, and customer service record collectively shape its reputation, directly impacting purchasing decisions.

- Materials and Construction Quality

Established brands frequently invest in superior materials and construction techniques, leading to enhanced durability and performance. While a “skate shoes sale size 10” might offer a lower price, the brand’s commitment to quality assures the consumer of a product capable of withstanding the rigors of skateboarding. Conversely, less reputable brands may cut corners, resulting in premature wear and reduced protection.

- Technological Innovation

Reputable brands often pioneer innovations in skateboarding footwear technology, such as improved cushioning systems, enhanced grip patterns, and reinforced stress points. Consumers searching for a “skate shoes sale size 10” from these brands benefit from accessing cutting-edge features at a discounted rate, potentially improving their skateboarding experience and reducing the risk of injuries. Lesser-known brands may lack the resources for such innovation, offering only basic features.

- Warranty and Customer Support

Brands with strong reputations typically offer comprehensive warranties and readily accessible customer support channels. If a “skate shoes sale size 10” item proves defective or exhibits premature wear, consumers can rely on the brand’s support system for assistance, including repairs or replacements. This peace of mind is less assured with brands lacking a proven track record.

- Resale Value and Brand Loyalty

Skateboarding footwear from well-regarded brands often retains a higher resale value, even after use. Moreover, consumers tend to develop brand loyalty to companies that consistently deliver quality products and positive experiences. A “skate shoes sale size 10” purchase from a trusted brand can solidify this loyalty and potentially lead to future purchases at full price. Conversely, a negative experience with a less reputable brand can deter future patronage.

In conclusion, brand reputation serves as a crucial indicator of product quality, durability, and overall value, even when considering a “skate shoes sale size 10.” While price is a significant factor, the long-term benefits of investing in a reputable brand often outweigh the short-term savings of choosing a less established alternative. The inherent quality and support associated with strong brands contribute to a more satisfying and reliable skateboarding experience.

3. Sole Durability

The longevity of skateboarding footwear is intrinsically linked to the construction and composition of the sole. Sole durability is a critical factor when evaluating the value proposition presented by a “skate shoes sale size 10.” While a reduced price may be attractive, insufficient sole durability negates potential cost savings due to accelerated wear and the consequent need for frequent replacement. For example, a heavily discounted shoe with a poorly constructed sole might only withstand a few weeks of regular skateboarding, whereas a more durable option, even at a slightly higher initial price, could last for several months. The reduced price is therefore a misleading indicator of value.

Several elements contribute to the robustness of a skateboarding shoe sole. Vulcanized rubber, known for its strength and flexibility, is a common material choice. The thickness and tread pattern of the sole also play significant roles; thicker soles provide greater resistance to abrasion, while aggressive tread patterns enhance grip and board feel. Furthermore, reinforcement in high-wear areas, such as the toe and heel, extends the lifespan of the sole. Independent skateboarders or smaller brands may use innovative techniques to extend sole life. In contrast, a “skate shoes sale size 10” lacking these characteristics might be unsuitable for demanding skateboarding activities, regardless of its low price. An example of this is a street skater who prefers flat, minimalist soles might sacrifice durability. However, if the sole is a weak spot it may not last as long.

In summary, although the “skate shoes sale size 10” offers the enticement of affordability, it is imperative to prioritize sole durability. Inadequate sole construction undermines the economic benefit of a reduced price, leading to premature wear and a need for more frequent replacement. Careful inspection of sole materials, construction techniques, and reinforcement details is essential to ensure that the discounted skateboarding footwear provides long-term value and meets the performance requirements of the user. The ultimate goal is to balance cost considerations with the necessity for durable and reliable equipment.

4. Material Quality

The perceived value of “skate shoes sale size 10” is directly correlated with the quality of materials utilized in their construction. While a reduced price point might initially attract consumers, the long-term economic benefit hinges on the durability and performance characteristics conferred by the constituent materials. Inferior materials, despite the initial cost savings, often lead to accelerated wear, diminished protection, and ultimately, more frequent replacement purchases. For example, a discount skateboarding shoe constructed with low-grade canvas and unreinforced stitching may quickly succumb to abrasion from griptape and impact forces, rendering it unusable within a short timeframe. Inversely, a discounted shoe featuring high-quality suede or reinforced leather, coupled with robust stitching, can provide significantly greater longevity and performance, making it a more economically sound investment, irrespective of the sale context.

The selection of materials directly impacts specific performance attributes crucial for skateboarding. Suede, known for its abrasion resistance and board feel, is a common choice for the upper construction. Leather offers comparable durability with enhanced support. Reinforced canvas provides a lighter-weight alternative, often treated for increased resistance to tearing and water damage. The sole composition, typically vulcanized rubber or a similar high-traction compound, determines grip and board control. A “skate shoes sale size 10” featuring a premium rubber compound will provide superior traction and shock absorption compared to a shoe with a generic or low-grade rubber sole. Similarly, the quality of the cushioning system, whether it be foam-based or gel-based, contributes to impact protection and overall comfort. A shoe with inadequate cushioning can lead to foot fatigue and increased risk of injury, despite the discounted price.

In conclusion, the allure of “skate shoes sale size 10” necessitates careful consideration of material quality. While price is a significant factor, overlooking the inherent properties and durability of the materials can lead to short-sighted purchasing decisions. Prioritizing shoes constructed with durable uppers, robust stitching, high-quality soles, and adequate cushioning systems ensures long-term value and performance, mitigating the potential drawbacks of a superficially attractive discount. The challenge lies in discerning the true value proposition, balancing cost savings with the fundamental requirements of skateboarding footwear.

5. Discount Percentage

The “Discount Percentage” is the primary quantitative factor determining the attractiveness of any “skate shoes sale size 10.” It represents the proportional reduction from the original retail price, directly influencing the perceived value and affordability of the footwear. A higher discount percentage typically translates to greater cost savings for the consumer, assuming all other factors, such as brand reputation and material quality, are equal. For instance, a skateboarding shoe originally priced at $80, offered at a 50% discount, results in a final price of $40. In contrast, a 20% discount on the same shoe would yield a price of $64. This variance demonstrates the substantial impact of the discount percentage on the overall purchase decision. Discount Percentage also affects the velocity of sales. Skate shoes, especially older models, need to be cleared out of inventory, and a steeper discount can lead to a quicker turnover.

The practical significance of understanding the discount percentage extends beyond mere cost comparison. It enables consumers to evaluate the true value proposition relative to their individual needs and budget constraints. A consumer seeking high-performance skateboarding footwear might be willing to invest in a higher-priced option, even with a modest discount, if it offers superior durability and functionality. Conversely, a casual skateboarder might prioritize the “Discount Percentage” above all other factors, opting for the most affordable option available, regardless of brand or specific features. For example, closeout sales from retailers needing to liquidate large amounts of skate shoes might offer exceedingly high discount rates such as 70-80%.

The challenge lies in discerning whether the “Discount Percentage” is genuinely reflective of a value proposition or simply a marketing tactic employed to offload inferior or outdated merchandise. Consumers must therefore critically assess the interplay between the discount, the brand, the quality, and their personal needs to make informed purchasing decisions. The most successful approach involves a balanced consideration of these factors, rather than solely fixating on the most prominent “Discount Percentage.” Ultimately, a well-informed evaluation ensures that a “skate shoes sale size 10” results in both immediate cost savings and long-term satisfaction.

6. Return Eligibility

The capacity to return purchased merchandise is a crucial element of consumer confidence, particularly when acquiring discounted items. Within the context of “skate shoes sale size 10,” return eligibility serves as a risk mitigation strategy, protecting buyers from potential discrepancies in sizing, product defects, or dissatisfaction with the footwear’s performance.

- Sizing Discrepancies

Footwear sizing can vary significantly between manufacturers and even within the same brand across different models. A “skate shoes sale size 10” may not conform precisely to the buyer’s expected fit, necessitating a return. Clear return policies address this issue by permitting exchanges for a different size or providing a refund if a suitable alternative is unavailable. For instance, if an online retailer inaccurately represents a particular brand’s sizing chart, return eligibility becomes essential for rectifying the situation.

- Product Defects

Discounted items are sometimes end-of-line or slightly imperfect products. While retailers typically conduct quality checks, minor defects can be overlooked. Return eligibility ensures that consumers are not burdened with substandard merchandise. Examples include sole separation, stitching irregularities, or cosmetic blemishes that compromise the footwear’s functionality or aesthetics. Without a clear return policy, the consumer bears the financial burden of a defective product.

- Performance Dissatisfaction

Skateboarding footwear is designed for specific performance characteristics, such as board feel, impact absorption, and grip. A “skate shoes sale size 10” may not meet the buyer’s expectations once tested in actual skateboarding conditions. Return eligibility allows for recourse if the footwear fails to perform adequately, providing an opportunity to select a more suitable alternative. This is particularly relevant for experienced skateboarders with specific preferences.

- Conditional Restrictions

Return eligibility is frequently subject to certain conditions, such as time limits, original packaging requirements, and proof of purchase. Consumers considering a “skate shoes sale size 10” must carefully review these restrictions to ensure compliance. Failure to adhere to the stipulated conditions may invalidate the return, leaving the buyer with unusable or ill-fitting footwear. Examples of common restrictions include a 30-day return window, a requirement to return the shoes in their original box with all tags attached, and the presentation of a valid sales receipt.

The presence of favorable return eligibility terms significantly enhances the attractiveness of a “skate shoes sale size 10.” It provides consumers with a degree of security against potential sizing issues, product defects, and performance inadequacies, fostering a greater willingness to purchase discounted items. Conversely, restrictive or absent return policies can deter potential buyers, even if the discount is substantial.

Frequently Asked Questions

This section addresses common inquiries regarding discounted skateboarding footwear in a specific dimension. The information provided aims to clarify key considerations and guide informed purchasing decisions.

Question 1: What factors contribute to the occurrence of skateboarding shoe sales in dimension 10?

Several factors influence the availability of discounted skateboarding shoes in size 10, including seasonal clearance, overstock situations, discontinuation of specific models, and promotional events designed to attract customers and stimulate sales. These sales offer opportunities to acquire skateboarding footwear at reduced prices.

Question 2: How can one verify the authenticity of a “skate shoes sale size 10” advertisement?

To verify the legitimacy of a sale advertisement, examine the retailer’s reputation, scrutinize the listed discounts against the original prices, compare prices across multiple retailers, and carefully review the terms and conditions of the sale, including return policies and warranty information. Exercise caution with unfamiliar or unverifiable sources.

Question 3: What are the potential drawbacks of purchasing skateboarding footwear from a sale?

Potential drawbacks include limited selection, the possibility of discontinued models, the risk of minor cosmetic or structural imperfections, and potentially restricted return policies compared to regularly priced merchandise. Inspect the footwear thoroughly before purchase.

Question 4: Does a lower price necessarily indicate lower quality in discounted skateboarding shoes?

A lower price does not automatically equate to lower quality. Sale items may be from previous seasons or overstock, but the fundamental quality of the materials and construction should remain consistent with the brand’s standards. Thorough inspection is always advised.

Question 5: What are the key considerations when evaluating the fit of discounted skateboarding footwear?

Key considerations include measuring foot length accurately, consulting brand-specific sizing charts, accounting for sock thickness, and assessing the internal shape and volume of the shoe. Allow for adequate toe room and heel support. If possible, try on the footwear before purchase to ensure a proper fit.

Question 6: Are return policies typically the same for sale items as for regularly priced merchandise?

Return policies may differ for sale items. It is crucial to carefully review the specific return policy applicable to the “skate shoes sale size 10” before purchase. Some retailers may offer limited or no returns on discounted items, while others may provide standard return options.

In summary, navigating a “skate shoes sale size 10” requires diligent research, careful inspection, and a thorough understanding of the retailer’s policies. Balancing cost considerations with quality expectations is essential for a satisfactory outcome.

The subsequent section explores methods for preserving the condition and extending the lifespan of newly acquired skateboarding footwear.

Skate Shoes Sale Size 10

The preceding analysis has explored the multifaceted considerations surrounding discounted skateboarding footwear in the specified dimension. Key points include the significance of brand reputation, material quality, and sole durability in relation to the offered discount percentage. The presence and stipulations of return eligibility policies further influence the value proposition, mitigating potential risks associated with sizing discrepancies or product defects. Furthermore, awareness of inventory limitations and authentication methods is crucial for successful acquisition.

Ultimately, informed engagement with “skate shoes sale size 10” opportunities necessitates a balanced evaluation of cost savings and inherent product attributes. A thorough understanding of the interplay between these factors empowers consumers to make discerning choices, maximizing both economic benefits and skateboarding performance. Continued vigilance regarding product quality and retailer trustworthiness remains paramount in ensuring satisfactory outcomes and avoiding potentially detrimental purchasing decisions.