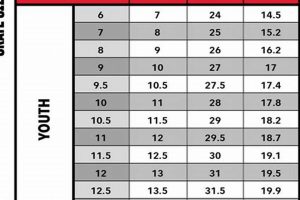

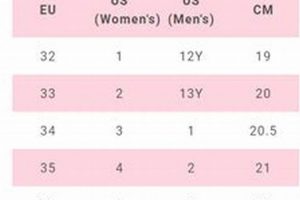

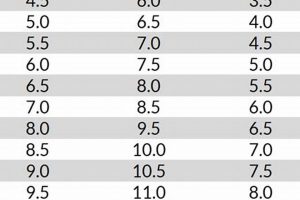

A reference table correlating foot measurements with the appropriate boot size for footwear manufactured by Jackson Ultima Skates, a prominent brand in the figure skating industry, is essential. It provides a standardized guide to ensure proper fit, referencing foot length and width measurements to specific skate sizes. This tool is crucial for individuals selecting their first pair of skates or transitioning to a different model.

The accuracy of skate fit significantly impacts performance, comfort, and injury prevention. Selecting the correct size minimizes the risk of blisters, ankle instability, and other foot-related problems that can hinder a skater’s progress. Historically, selecting skates relied heavily on in-person fittings by experienced professionals. However, this reference table offers a valuable resource for remote purchases or preliminary size estimations. Its effective use contributes to a more comfortable and efficient skating experience.

The following discussion will detail the intricacies of utilizing this reference tool, factors influencing size selection, and common discrepancies encountered when determining the optimal boot dimension for individual needs.

Guidance for Utilizing Jackson Ultima Skate Sizing Information

The following points offer guidance for ensuring appropriate skate fit when using Jackson Ultima’s sizing resources. Careful consideration of these factors will aid in selecting the correct size and optimizing skating performance.

Tip 1: Accurate Measurement is Paramount: Precisely measure foot length and width. Measurements should be taken in socks or tights typically worn while skating. Inconsistent measurements invalidate the reliability of the size table.

Tip 2: Consult the Official Chart: Always refer to the manufacturer’s current size guidelines. Independent or third-party resources may contain outdated or inaccurate information, leading to incorrect size selection.

Tip 3: Consider Foot Shape: Foot volume and width are crucial. Individuals with wider feet may need to consider a wider boot option, if available, or may need to size up to accommodate the width. Ignore the foot shape would give poor performance and uncomfort.

Tip 4: Account for Growth (Youth Skaters): For younger skaters, anticipate foot growth. Select a size that allows for some expansion, but avoid oversizing significantly, as this compromises support and control. In this case, regular measurement is needed to make sure it will fit well.

Tip 5: Understand Model Variations: Sizing can vary slightly between different models within the Jackson Ultima line. Be aware of these nuances and consult reviews or fitting guides specific to the model being considered.

Tip 6: Prioritize Fit Over Existing Shoe Size: Shoe size is not a reliable indicator of skate size. Skate sizes often differ from standard shoe sizes. Use foot measurements in conjunction with the reference table, not general shoe size.

Tip 7: Seek Professional Assistance: When possible, consult with a qualified skate fitter. An experienced professional can provide personalized recommendations based on individual foot characteristics and skating goals. If not, it’s suggested to buy the skates in the physical store.

By adhering to these recommendations, skaters can enhance the accuracy of their size selection, leading to improved comfort, performance, and reduced risk of injury on the ice.

The next section provides information regarding common sizing issues and their potential resolutions.

1. Foot Measurement Accuracy

The precision of foot measurements is foundational to effectively utilizing the Jackson Ultima size chart. Inaccurate measurements render the chart’s guidance unreliable, potentially leading to improper skate fit and subsequent performance issues or discomfort. Thorough and accurate measurements are thus essential for deriving benefit from the sizing information provided.

- Standardized Measurement Protocols

Consistently employing standardized measurement protocols is crucial. This involves using a calibrated measuring device, such as a Brannock device or a ruler, and adhering to a defined methodology for determining foot length and width. Failure to follow a uniform protocol introduces variability, jeopardizing accuracy. For example, measuring the foot while standing versus sitting can yield different results due to foot expansion under weight.

- Impact of Sock Thickness

The thickness of socks worn during measurement must be consistent with the socks typically worn while skating. A significant discrepancy between measurement conditions and actual skating conditions introduces error. For instance, measuring the foot with thin socks and then skating with thick socks will likely result in skates that feel too small.

- Accounting for Foot Shape and Deformities

Standard measurements may not fully capture the nuances of individual foot shapes or the presence of deformities such as bunions or hammertoes. These anatomical variations can influence the fit of the skate regardless of chart-indicated size. Compensating for these factors may necessitate consulting a professional fitter or considering custom skate options.

- Regular Re-Measurement, Especially for Children

Feet, particularly in children and adolescents, undergo rapid growth. Regular re-measurement is necessary to ensure the continued accuracy of the skate size relative to the foot. Infrequent measurements can lead to wearing skates that are too small, potentially causing discomfort and impeding proper skating technique.

The preceding facets illustrate the crucial role of meticulous foot measurement in achieving a proper skate fit via the Jackson Ultima size chart. Neglecting any of these aspects compromises the chart’s effectiveness and increases the risk of selecting an inappropriate skate size. This underscores the importance of combining the chart’s guidelines with careful individual assessment and, when feasible, professional fitting advice. The ultimate goal is a skate that provides adequate support and allows for optimal performance on the ice.

2. Model-Specific Variation

Within the Jackson Ultima skate line, dimensional discrepancies exist between different models, necessitating nuanced application of the standard sizing information. These variations stem from differences in boot construction, materials, and intended performance characteristics. A skater selecting a specific boot size based solely on the generic sizing information may find that a different model, despite theoretically being the same size, exhibits a tighter or looser fit. For instance, a skater who wears a size 6 in the Elle model might require a size 6.5 in the Premiere model to achieve a comparable fit, due to differences in internal padding and last shape.

Such model-specific differences highlight the importance of consulting model-specific size guides, where available, or seeking advice from experienced skate fitters who possess familiarity with the nuances of each Jackson Ultima model. Ignoring these variations can lead to discomfort, reduced performance, and potentially increased risk of injury. Retailers often provide supplementary sizing information tailored to specific models, acknowledging that the general size chart is merely a starting point. Moreover, reviews and user feedback frequently highlight these discrepancies, enabling skaters to make more informed decisions. The practical consequence of acknowledging model-specific variation is a more accurate initial size selection, reducing the likelihood of returns or exchanges and minimizing the time spent breaking in improperly fitting skates.

In summary, the “jackson ice skates size chart” provides a foundational framework, but the discerning skater must recognize that model-specific variations act as a critical modifying factor. Relying solely on the generalized chart without considering these nuances undermines the objective of achieving a precise and comfortable skate fit. A comprehensive understanding, supplemented by model-specific data and expert guidance, remains paramount for successful skate selection.

3. Width Consideration

Accurate utilization of the “jackson ice skates size chart” necessitates careful consideration of foot width. While the chart primarily focuses on length, neglecting width can lead to improper skate fit, compromised performance, and potential discomfort or injury. Matching foot width to the appropriate boot width is as critical as matching foot length to boot size.

- Significance of Proper Width Fit

A properly fitted skate boot accommodates the foot’s width without undue constriction or excessive space. Constriction can cause numbness, blisters, and impaired circulation, while excessive space allows the foot to move excessively within the boot, reducing control and increasing the risk of ankle instability. The chart serves as a reference, but real-world conditions of a person’s foot should be considered, even a custom fit.

- Width Measurement and Chart Interpretation

Foot width should be measured at its widest point, typically across the ball of the foot. The chart may offer width designations, such as “Narrow,” “Medium,” or “Wide.” Comparing the measured width to these designations is crucial for selecting the correct boot. Some charts provide specific width measurements (e.g., in inches or centimeters) corresponding to each width designation.

- Impact of Foot Shape on Width Selection

Foot shape, including arch height and instep volume, influences width selection. Individuals with high arches or high insteps may require a wider boot to accommodate the increased volume, even if their measured width falls within the “Medium” range. Similarly, individuals with flatter feet may find that a narrower boot provides a more secure and supportive fit.

- Addressing Width Discrepancies

When foot width falls between width designations on the chart, or when one foot is significantly wider than the other, adjustments may be necessary. Options include selecting a wider boot and using padding or inserts to fine-tune the fit in the narrower foot, or consulting a professional skate fitter for personalized recommendations. Some models have options for heat molding to customize the fit further.

Effective width consideration elevates the practical utility of the “jackson ice skates size chart.” While the chart provides a length-based framework, neglecting width dimensions introduces a significant source of potential error. By integrating precise width measurements and accounting for individual foot shape characteristics, skaters can optimize their skate selection for enhanced comfort, performance, and injury prevention.

4. Growth Allowance (Youth)

The practical application of the “jackson ice skates size chart” for youth skaters necessitates the incorporation of a growth allowance. The rapid and often unpredictable rate of foot development in children introduces a dynamic element not present in adult skate selection. Ignoring potential growth results in skates that quickly become too small, compromising comfort, performance, and potentially leading to foot problems. The “jackson ice skates size chart,” while providing a size reference based on current foot measurements, requires a proactive adjustment to accommodate future growth spurts. Failure to account for this directly negates the intended benefits of the chart, as the selected size becomes obsolete within a compressed timeframe. A figure skater, for example, accurately measured at a size 3 on the chart, may require a size 3.5 or 4 to allow for projected growth over a six-month period, thus prolonging the usable lifespan of the skates.

Continued foot growth necessitates regular re-evaluation of the skate fit, even when a growth allowance is initially factored in. The selected allowance represents an estimation, and actual growth rates can deviate significantly. Consequently, periodic assessment is crucial to identify when the skates become too constrictive. This involves physically examining the skater’s foot within the boot, noting any signs of pressure or restricted movement. Furthermore, observing the skater’s performance can provide indirect indicators of inadequate fit, such as a decline in technique or expressions of discomfort during practice. A child who initially fits comfortably into skates with a growth allowance may, within a few months, begin experiencing toe crowding, indicating the need to either resize the existing skates or transition to a larger pair.

In summary, the “jackson ice skates size chart” serves as a static reference point, while growth allowance represents a necessary dynamic adjustment for youth skaters. Regular monitoring and reassessment are essential to ensure that the selected skate size continues to accommodate evolving foot dimensions. This proactive approach maximizes the utility of the chart and promotes both the skater’s comfort and long-term development. Ignoring the growth factor undermines the chart’s value and can have detrimental consequences.

5. Professional Fitting Advice

Professional fitting advice constitutes a critical augmentation to the “jackson ice skates size chart,” addressing inherent limitations in standardized sizing approaches. The chart provides a general guideline based on foot length and width, but it cannot account for individual foot anomalies, biomechanical factors, or skating skill level, all of which directly influence optimal skate fit. Consequently, relying solely on the chart without professional guidance increases the probability of selecting an unsuitable skate size. For example, an individual with pronated ankles may require specific boot modifications or orthotics not addressed by a generic size recommendation, necessitating expert intervention to prevent injury and enhance performance.

The expertise of a qualified skate fitter extends beyond basic foot measurements to encompass an evaluation of gait, posture, and skating technique. This holistic assessment informs the selection of a skate model and size that supports the skater’s specific needs and minimizes the risk of developing biomechanical imbalances. In the case of a novice skater, a fitter might prioritize a boot with enhanced ankle support, regardless of the skater’s foot dimensions according to the chart, to promote proper alignment and prevent injury during initial skill acquisition. Conversely, an elite skater may require a tighter, more responsive boot to maximize power transfer, even if it deviates from the chart’s recommended size based on simple measurements. The fitter can also assess the alignment of the blade relative to the skater’s body, making adjustments to optimize balance and edge control.

In summary, while the “jackson ice skates size chart” offers a convenient starting point for skate selection, professional fitting advice serves as an indispensable complement, mitigating the inherent shortcomings of a purely measurement-based approach. Expert assessment considers individual biomechanics, skating skill, and anatomical variations, ensuring a skate fit that promotes comfort, performance, and injury prevention. Ignoring professional guidance in favor of sole reliance on the chart represents a considerable risk, potentially leading to sub-optimal skate performance and increased susceptibility to injury.

Frequently Asked Questions Regarding Jackson Ultima Skate Sizing

This section addresses common inquiries and clarifies misunderstandings concerning the application of the Jackson Ultima “jackson ice skates size chart.” The information provided is intended to ensure accurate size selection and optimal skate performance.

Question 1: Is the “jackson ice skates size chart” a definitive indicator of skate size?

No, the “jackson ice skates size chart” should be regarded as a general guideline, not an absolute determinant of skate size. Model variations, foot shape, and individual preferences necessitate consideration beyond the chart’s parameters.

Question 2: How frequently should foot measurements be taken when selecting skates for children?

Foot measurements should be taken every 2-3 months for children undergoing periods of rapid growth. Consistent monitoring ensures that the skate size remains appropriate and prevents discomfort or injury resulting from ill-fitting skates.

Question 3: Does the “jackson ice skates size chart” account for sock thickness?

The “jackson ice skates size chart” assumes a standard sock thickness typical for skating. Measurements should be taken while wearing the type of socks intended for use with the skates. Deviations in sock thickness can influence the accuracy of the chart’s recommendations.

Question 4: What recourse exists if foot width falls between two sizes indicated on the “jackson ice skates size chart?”

When foot width falls between sizes, it is generally advisable to select the larger width to avoid constriction. Padding or inserts can be used to fine-tune the fit if necessary. Professional fitting assistance is recommended in such instances.

Question 5: Are sizing conventions consistent across all Jackson Ultima skate models?

No, sizing conventions can vary slightly between different Jackson Ultima skate models. Always consult model-specific size guides or seek advice from experienced skate fitters to account for these discrepancies.

Question 6: Can prior shoe size be used as a reliable indicator for selecting ice skate size using the “jackson ice skates size chart?”

No, prior shoe size is not a reliable indicator of ice skate size. Skate sizes often differ significantly from standard shoe sizes. Rely on accurate foot measurements and the “jackson ice skates size chart” for a more precise determination.

In summary, the “jackson ice skates size chart” functions as a helpful tool, but its effectiveness relies on accurate measurement practices, awareness of model-specific variations, and consideration of individual foot characteristics. Professional fitting advice is strongly encouraged for optimal results.

The following section provides information regarding common fitting challenges and potential resolutions.

Conclusion

The preceding exploration of the “jackson ice skates size chart” underscores its value as a foundational resource for determining appropriate skate size. However, its effective application demands meticulous attention to detail, encompassing accurate foot measurements, consideration of model-specific variations, and an understanding of individual foot characteristics. The limitations of the chart necessitate supplementary professional guidance to ensure optimal skate fit.

Recognizing the inherent complexities of skate sizing promotes informed decision-making and ultimately contributes to enhanced skating performance and reduced risk of injury. Further research and ongoing refinement of sizing methodologies remain essential to improving the accuracy and usability of resources such as the “jackson ice skates size chart,” thereby benefiting skaters of all levels.