Skates designed specifically for roller derby participation are available in smaller sizes to accommodate younger athletes. These specialized skates often feature enhanced ankle support, durable wheels optimized for rink surfaces, and a low profile for increased maneuverability. This equipment caters to children and adolescents whose foot dimensions fall within the range of youth sizes 11 to 2, ensuring a secure and comfortable fit for the demands of the sport.

Providing appropriately sized and performance-oriented equipment is crucial for youth engagement and safety in roller derby. Properly fitted skates contribute to improved performance, reduce the risk of injuries like ankle sprains, and foster a positive experience for young participants. The availability of these skates allows youth to develop skills and confidence within a structured and supportive athletic environment. Historically, access to specialized equipment for youth sports has been a key factor in the growth and development of various athletic disciplines.

The following sections will delve into the specific features and considerations when selecting roller derby skates for young athletes, including aspects such as boot construction, wheel types, bearing quality, and overall skate maintenance. Further discussions will explore the importance of professional fitting services and the impact of skate technology on performance enhancement for youth roller derby participants.

Tips for Selecting Roller Derby Skates (Youth Sizes 11-2)

Proper selection and maintenance of roller derby skates, specifically in youth sizes 11-2, are critical for performance, safety, and longevity of the equipment. The following tips provide guidance for making informed decisions.

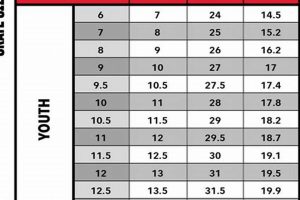

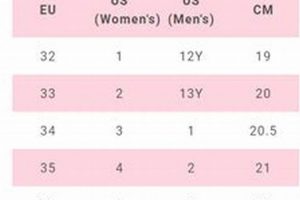

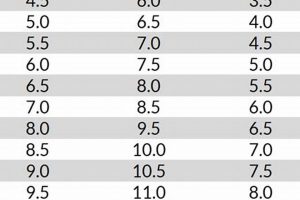

Tip 1: Accurate Foot Measurement: Measure the child’s foot accurately, accounting for sock thickness. Skate sizes often differ from standard shoe sizes; therefore, relying on measurements is essential.

Tip 2: Boot Material Considerations: Leather or synthetic materials offer varying degrees of support and durability. Leather generally molds to the foot over time, while synthetic materials may offer better water resistance.

Tip 3: Ankle Support Evaluation: Ensure adequate ankle support is provided by the boot. Insufficient support can lead to injury, particularly during lateral movements inherent in roller derby.

Tip 4: Wheel Durometer Selection: The durometer (hardness) of the wheels affects grip and roll. Harder wheels are faster on smoother surfaces, while softer wheels offer better grip on slicker surfaces. Consider the typical skating environment.

Tip 5: Bearing Quality Assessment: Higher quality bearings facilitate smoother and faster rolling. ABEC ratings indicate bearing precision; higher ratings generally correlate with improved performance.

Tip 6: Plate Material and Mounting: The plate, which connects the boot to the wheels, should be durable and properly mounted. Aluminum plates are generally more rigid and responsive than nylon plates.

Tip 7: Professional Fitting Consultation: Consultation with a skate professional can provide personalized recommendations and ensure proper fit, maximizing comfort and performance.

Adhering to these tips contributes to optimal performance, reduced risk of injury, and extended lifespan of roller derby skates in youth sizes 11-2.

The subsequent sections will discuss maintenance procedures and advanced considerations for optimizing skate performance.

1. Proper Fit

Proper fit is paramount when selecting roller derby skates in youth sizes 11-2. Ill-fitting skates compromise performance, increase the risk of injury, and diminish the overall experience for young athletes. Accurate sizing and consideration of individual foot characteristics are essential to ensure optimal comfort and functionality.

- Performance Enhancement

Well-fitted skates enable efficient energy transfer during skating maneuvers. Loose skates can lead to wasted energy as the foot moves within the boot, while overly tight skates can restrict circulation and hinder agility. A snug, yet comfortable fit allows for precise control and responsiveness, maximizing the skater’s performance potential.

- Injury Prevention

Inadequate fit contributes to various injuries, including blisters, chafing, and ankle instability. Loose skates increase the likelihood of ankle sprains due to reduced support. Conversely, skates that are too tight can cause foot pain, numbness, and potentially long-term foot problems. A proper fit minimizes these risks, ensuring a safer skating experience.

- Comfort and Enjoyment

Comfort directly impacts a young athlete’s enjoyment of roller derby. Ill-fitting skates can cause discomfort, distraction, and fatigue, leading to a negative experience. Properly fitted skates provide a comfortable and supportive environment for the foot, allowing skaters to focus on their skills and enjoy the sport.

- Growth Considerations

When selecting skates for youth, it’s tempting to choose a slightly larger size to accommodate growth. However, excessive space within the boot compromises performance and safety. Regular foot measurements and professional fitting advice are recommended to balance growth considerations with the need for a secure and supportive fit. Avoid upsizing excessively. Opt for a snug fit now, rather than planning for prolonged use that compromises safety.

In summary, the significance of proper fit in roller derby skates for youth sizes 11-2 extends beyond mere comfort. It encompasses performance enhancement, injury prevention, and overall enjoyment of the sport. Consistent monitoring of foot size and professional consultation are recommended to ensure a safe and effective skating experience for young athletes. A properly fitted skate is an investment in the skater’s well-being and athletic development.

2. Ankle Support

Ankle support constitutes a critical element in roller derby skates designed for youth sizes 11-2. The aggressive maneuvers, rapid directional changes, and potential for impact inherent in roller derby place substantial stress on the ankle joint. Inadequate ankle support can directly correlate with an elevated risk of ankle sprains, fractures, and other lower extremity injuries among young skaters. Skates offering robust ankle support aim to mitigate these risks by providing stabilization and restricting excessive lateral movement. For example, skates featuring reinforced ankle padding and high-cut boot designs contribute to a more secure and controlled skating experience, particularly during intense gameplay.

The type and extent of ankle support incorporated into roller derby skates vary depending on the specific model and intended use. Some skates prioritize flexibility to allow for a greater range of motion, while others emphasize rigidity for maximum support. The optimal balance between flexibility and support is often determined by the skater’s skill level, playing style, and individual biomechanics. Skates intended for beginner or younger skaters frequently incorporate greater ankle support to compensate for developing muscle strength and coordination. Consider a scenario where a young skater executes a crossover maneuver. If the skate lacks sufficient ankle support, the skater’s ankle may buckle inward, potentially leading to a sprain. Conversely, a skate with adequate support helps maintain ankle stability throughout the maneuver, reducing the risk of injury.

In conclusion, ankle support represents a fundamental design consideration in roller derby skates for youth sizes 11-2. Its presence directly affects skater safety and performance by mitigating the risk of ankle injuries. While individual needs and preferences may influence the specific type of ankle support desired, ensuring adequate stabilization remains paramount. Challenges exist in balancing ankle support with the need for mobility, highlighting the importance of selecting skates that align with the skater’s skill level and anticipated use. Prioritizing ankle support is essential for fostering a safe and positive roller derby experience for young participants.

3. Wheel Durometer

Wheel durometer, a measurement of wheel hardness, directly impacts the performance characteristics of roller derby skates, particularly those in youth sizes 11-2. Softer wheels (lower durometer values) offer increased grip and control, crucial for younger skaters still developing their skills and agility. This enhanced grip allows for more confident maneuvering and reduces the likelihood of slips or falls on various rink surfaces. Conversely, harder wheels (higher durometer values) prioritize speed and roll, often favored by more experienced skaters on smoother, well-maintained surfaces. The selection of an inappropriate wheel durometer can negatively impact a young skater’s progress. For example, equipping a novice skater with extremely hard wheels could lead to instability and difficulty maintaining control, thus hindering skill development and potentially increasing the risk of injury.

The optimal wheel durometer for roller derby skates in youth sizes 11-2 is therefore contingent upon several factors: the skater’s skill level, the typical skating surface, and the desired balance between grip and speed. A common starting point for younger skaters is a wheel in the range of 88A to 92A durometer. These wheels provide a suitable combination of grip and roll, allowing for confident skating and skill progression. As the skater gains experience and the surfaces they skate on become more consistent, harder wheels can be considered. The selection process should also account for rink conditions. Indoor rinks often have smoother surfaces, allowing for harder wheels. Outdoor surfaces tend to be rougher, necessitating softer wheels for enhanced grip and vibration absorption. Regular evaluation of wheel performance and adjustments as needed are recommended.

In summary, understanding the connection between wheel durometer and the performance of roller derby skates in youth sizes 11-2 is essential for optimizing the skating experience. Choosing the appropriate wheel durometer can enhance grip, control, and speed, ultimately contributing to improved skill development and skater safety. The ongoing challenge lies in balancing these factors to meet the specific needs of each young skater and the unique conditions of their skating environment. Prioritizing grip and control for beginners, and gradually transitioning to harder wheels as skill develops is the standard approach.

4. Bearing Quality

Bearing quality directly influences the performance and longevity of roller derby skates, particularly in youth sizes 11-2. Low-quality bearings exhibit increased friction, hindering roll speed and requiring greater effort from the skater. This is especially detrimental for younger athletes who may lack the strength and stamina to compensate for inefficient equipment. High-quality bearings, conversely, reduce friction, allowing for smoother and faster rolling. This translates to improved acceleration, enhanced maneuverability, and reduced fatigue. For instance, ABEC-rated bearings, with higher numbers indicating greater precision, typically offer superior performance compared to unrated or lower-rated options. Skates equipped with high-quality bearings are more responsive and efficient, enabling young skaters to focus on skill development rather than struggling with equipment limitations. The consistent roll provided by quality bearings also promotes safer skating by reducing the risk of sudden stops or uneven movements.

Practical applications of understanding bearing quality extend beyond immediate performance benefits. Regular maintenance, including cleaning and lubrication, is crucial for preserving the performance of quality bearings. Contaminants such as dirt and debris can accumulate within the bearing, increasing friction and accelerating wear. Proper maintenance protocols extend the lifespan of the bearings, minimizing the need for frequent replacements and reducing overall equipment costs. Furthermore, the choice of bearing lubricant significantly impacts performance. Synthetic lubricants often outperform petroleum-based lubricants in terms of friction reduction and temperature resistance, particularly under the demanding conditions of roller derby. Selecting appropriate lubricants and adhering to a consistent maintenance schedule optimizes the performance and extends the useful life of the skates. A skate with low-quality bearings might be cheaper initially but will likely need replacement sooner. It might also lead to reduced performance and increased risk of injury.

In summary, bearing quality represents a critical factor in the overall performance and durability of roller derby skates in youth sizes 11-2. High-quality bearings enhance roll speed, reduce fatigue, and promote safer skating. Implementing proper maintenance procedures, including regular cleaning and lubrication with appropriate lubricants, preserves bearing performance and extends equipment lifespan. The challenge lies in balancing cost considerations with the long-term benefits of investing in quality bearings. Investing in higher quality components yields long-term dividends in performance, safety, and reduced equipment expenses. As such, an increased understanding of bearing quality is crucial for informed purchasing and maintenance decisions.

5. Plate Material

The plate material of roller derby skates in youth sizes 11-2 directly influences skate performance, durability, and maneuverability. The plate, connecting the boot to the wheels, absorbs impact and transfers energy during skating. Materials such as aluminum, nylon, or composite blends are employed, each possessing distinct characteristics affecting a skater’s ability to execute swift turns, stops, and other dynamic maneuvers. Aluminum plates, for instance, generally exhibit greater rigidity and responsiveness than nylon alternatives. This translates to more efficient energy transfer and enhanced control, especially crucial for competitive play. However, aluminum plates may also transmit more vibration to the skater’s feet, potentially causing fatigue over extended periods. The selection of plate material, therefore, necessitates consideration of the skater’s weight, skill level, and preferred skating style. An illustrative example would involve a young, lightweight skater benefiting from a lighter, more flexible nylon plate, while a heavier, more advanced skater might require the stability and responsiveness of an aluminum plate.

The choice of plate material also affects the overall durability and maintenance requirements of roller derby skates. Aluminum plates are generally more resistant to bending and breakage under stress compared to nylon or composite plates. This enhanced durability translates to a longer lifespan for the skate, reducing the frequency of replacements. However, aluminum plates may be susceptible to corrosion, particularly in humid environments. Regular cleaning and lubrication are necessary to mitigate this risk. Conversely, nylon plates are less prone to corrosion but may be more susceptible to cracking or deformation under extreme stress. Composite plates, offering a blend of materials, aim to balance durability, weight, and responsiveness. For instance, youth-sized skates intended for recreational use may prioritize durability and affordability, opting for nylon or composite plates. Skates designed for competitive youth roller derby, where performance is paramount, will likely feature aluminum plates despite their increased cost.

In summary, the selection of plate material represents a critical decision in the configuration of roller derby skates for youth sizes 11-2. The chosen material influences skate performance, durability, and maintenance requirements. While aluminum offers enhanced responsiveness and durability, nylon and composite materials provide cost-effective alternatives suitable for recreational use. The challenge lies in balancing these factors to align with the skater’s individual needs, skill level, and budget constraints. Thorough evaluation of plate material characteristics is essential for ensuring optimal skate performance and longevity. Ultimately, an understanding of the properties of different plate materials informs purchasing decisions and contributes to a safer, more enjoyable skating experience.

6. Boot Durability

Boot durability is a primary consideration in the selection of roller derby skates for youth sizes 11-2. The rigors of roller derby demand a robust boot construction capable of withstanding impacts, abrasions, and repetitive stress. The lifespan, safety, and performance of the skates are directly linked to the materials and construction techniques employed in the boot.

- Material Composition and Abrasion Resistance

The boot material, whether leather, synthetic polymers, or a combination thereof, dictates its resistance to abrasion. Repeated contact with the rink surface, other skaters, and potential falls subject the boot to significant wear. Higher-quality materials, such as reinforced leather or abrasion-resistant synthetics, extend the boot’s lifespan and maintain its structural integrity. Choosing materials with inherently high abrasion resistance minimizes cosmetic damage and prevents premature wear that can compromise support and protection.

- Seam Strength and Construction Integrity

The seams and stitching securing the boot components are critical points of potential failure. Weak or poorly constructed seams can unravel under stress, leading to boot deformation and reduced support. Reinforced stitching techniques and durable thread materials enhance seam strength and prevent premature failure. Examining the quality of stitching and the presence of reinforcements in high-stress areas is paramount in assessing boot durability.

- Ankle Support Structure and Reinforcement

The ankle support system within the boot must withstand lateral forces and provide adequate stability. Boots with reinforced ankle padding and rigid support structures minimize ankle flex and prevent injuries. The integrity of this support system is directly linked to the materials used and the construction methods employed. Inadequate ankle support stemming from material degradation leads to instability and increased risk of sprains or fractures.

- Sole Attachment and Impact Resistance

The attachment of the sole to the boot must endure repeated impacts and stresses. A secure and durable bond between the sole and boot prevents separation, which can compromise stability and render the skates unusable. Impact-resistant soles, often constructed from dense polymers or reinforced materials, absorb shock and protect the foot from jarring forces. The method of attachment, whether stitching, bonding, or a combination, influences the strength and longevity of the connection.

The long-term viability of roller derby skates in youth sizes 11-2 is fundamentally dependent on boot durability. Choosing skates constructed from high-quality materials, featuring robust construction techniques, and incorporating reinforced support structures is essential for ensuring skater safety, performance, and equipment longevity. Careful assessment of these aspects is crucial for making informed purchasing decisions and maximizing the value of the investment.

7. Safety Features

Safety features incorporated into roller derby skates for youth sizes 11-2 directly mitigate risks associated with the sport’s inherent physical demands. The inclusion of toe guards, for example, protects the front of the boot and the skater’s toes from impacts during falls or collisions. Similarly, reinforced ankle support structures reduce the likelihood of ankle sprains by limiting excessive lateral movement. High-quality closure systems, such as secure laces combined with power straps or buckles, ensure a snug and stable fit, preventing the foot from shifting within the boot during aggressive maneuvers. These safety features collectively contribute to a reduction in injury rates among young roller derby participants. A real-life example involves a youth skater falling forward; the presence of toe guards prevents direct impact to the toes, averting potential fractures or contusions. Without these features, the risk of injury escalates significantly.

The practical application of understanding the importance of safety features extends to informed purchasing decisions. When selecting roller derby skates for youth, prioritizing models that incorporate comprehensive safety measures is paramount. This necessitates careful examination of materials, construction techniques, and the presence of specific safety components. Regular inspection and maintenance of safety features are also crucial. Worn or damaged toe guards should be replaced promptly, and closure systems should be checked for proper functionality. Moreover, parents and coaches play a vital role in educating young skaters about the importance of utilizing these safety features and adhering to safe skating practices. This includes emphasizing the correct lacing technique to ensure adequate ankle support and the proper use of protective gear, such as helmets, elbow pads, and knee pads, to complement the safety features of the skates themselves. Example- ensuring laces are tightly tied can provide more support to skaters ankle.

In summary, the integration of safety features into roller derby skates designed for youth sizes 11-2 is not merely an optional add-on but an essential component for injury prevention and skater well-being. The combination of robust safety features, informed equipment selection, and consistent safety education fosters a safer and more positive experience for young athletes participating in roller derby. Challenges remain in ensuring all skaters have access to adequately equipped skates and in maintaining a consistent emphasis on safety protocols. Continued advocacy for enhanced safety standards within youth roller derby programs is therefore crucial.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, maintenance, and performance of roller derby skates specifically designed for youth participants with foot sizes ranging from 11 to 2.

Question 1: How does one accurately determine the correct size of roller derby skates for a youth skater?

Precise foot measurement is crucial. It is recommended to measure the child’s foot in socks, preferably those intended for skating. Compare the measurement to the specific manufacturer’s sizing chart, as skate sizes may vary. Professional fitting assistance is strongly advised.

Question 2: What level of ankle support is appropriate for youth roller derby skates?

Adequate ankle support is essential for stability and injury prevention. The boot should provide firm support without restricting movement excessively. Beginners may benefit from higher ankle support, while more experienced skaters may prefer a balance of support and flexibility.

Question 3: How often should the bearings in youth roller derby skates be cleaned and lubricated?

Bearing maintenance frequency depends on usage and environmental conditions. Regular cleaning and lubrication are recommended every 1-3 months for skaters who participate frequently. Skaters should inspect bearings regularly and clean them whenever performance declines.

Question 4: What is the significance of wheel durometer in roller derby skates for youth?

Wheel durometer influences grip and roll. Softer wheels (lower durometer) offer greater grip, which is beneficial for beginners. Harder wheels (higher durometer) provide faster roll speeds, preferred by experienced skaters on smooth surfaces. The selection must match skater skill level and rink conditions.

Question 5: What are the key indicators that roller derby skates need to be replaced?

Signs of wear include boot deformation, sole separation, worn bearings, damaged wheels, and compromised ankle support. Skates showing these deficiencies compromise safety and performance, requiring replacement.

Question 6: Are there specific safety certifications that roller derby skates should meet?

While specific certifications may vary, ensuring that skates meet general safety standards and that all components, such as wheels and bearings, are in good working order is crucial. Prioritizing reputable brands known for quality and safety is advisable.

Proper equipment selection and diligent maintenance are paramount for ensuring the safety and performance of youth roller derby participants. Consultation with experienced skate professionals is strongly recommended.

The subsequent sections will explore advanced techniques for optimizing skate performance and prolonging equipment lifespan.

Concluding Remarks on Roller Derby Skates Youth Sizes 11-2

This exploration has emphasized the crucial elements to consider when selecting roller derby skates youth sizes 11-2. Accurate fitting, adequate ankle support, appropriate wheel durometer, quality bearings, durable plate material, robust boot construction, and integrated safety features are paramount for ensuring skater well-being and performance. These aspects are inextricably linked to a young athlete’s development within the sport and must be carefully evaluated during the purchasing process.

The informed selection and diligent maintenance of roller derby skates youth sizes 11-2 represents a fundamental commitment to fostering a safe and productive athletic environment. Prioritizing these considerations will contribute to the continued growth and positive experiences of young roller derby participants, while minimizing the risk of injury and maximizing their potential within this demanding sport. Continued research and development in skate technology are vital for enhancing safety and performance within youth roller derby programs.