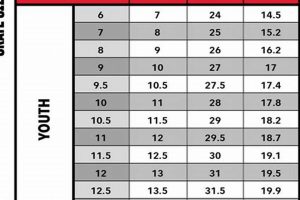

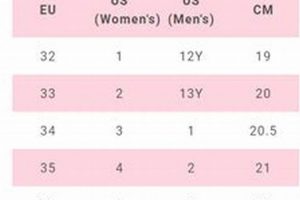

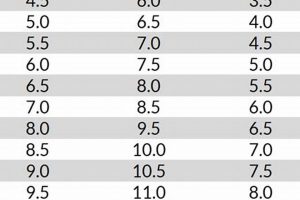

A standardized table correlating foot dimensions with appropriate footwear measurements for gliding on ice surfaces is an essential tool for selecting the correct equipment. For instance, an individual with a foot length of 270mm might consult the table to find a corresponding size recommendation.

The utility of such a resource lies in its ability to mitigate discomfort and performance limitations resulting from improperly fitted skates. Historically, finding the right fit relied heavily on trial and error, leading to potential injuries and diminished enjoyment. Standardized measurements offer a more precise and efficient method.

Understanding the nuances of measurement systems, including variations across brands and models, is critical for accurate selection. The subsequent sections will explore these aspects in detail, providing a guide to navigating the complexities of ice equipment sizing.

Guidance for Accurate Skate Selection

The following points offer essential advice for utilizing a measurement table effectively, ensuring proper fit and optimal performance on the ice.

Tip 1: Measure Foot Dimensions Accurately: Precise foot length and width measurements are paramount. Use a Brannock device, or a ruler and piece of paper against a wall, to determine accurate values in millimeters or inches.

Tip 2: Consult Specific Brand Tables: Different manufacturers employ varying grading systems. Always refer to the table provided by the skate brand being considered, as a size 8 in one brand may not equate to a size 8 in another.

Tip 3: Consider Foot Shape and Volume: Tables primarily address length. Individuals with wide feet, high arches, or other unique foot characteristics may need to adjust sizes or explore models designed for specific foot types.

Tip 4: Account for Sock Thickness: When measuring feet, wear the type of socks that will be worn during skating. Thick socks can significantly alter fit, so this step is crucial for accurate sizing.

Tip 5: Prioritize Comfort and Performance: While the table offers a starting point, the ultimate determinant of correct fit is comfort and the ability to execute skating maneuvers effectively. A professional fitting is highly recommended.

Tip 6: Professional Fitting Advised: When possible, seek the assistance of a qualified skate technician or retailer. Their expertise can assist in selecting the appropriate skate model and size based on foot characteristics and skating ability.

Adhering to these guidelines will maximize the probability of selecting equipment that promotes comfort, performance, and safety on the ice.

The next segment of this discussion will focus on troubleshooting common sizing challenges and addressing frequently asked questions.

1. Accuracy in Measurement

Precise foot dimension determination forms the foundational element for effective utilization of standardized sizing resources. Deviation from accurate measurement introduces potential for incorrect equipment selection, compromising comfort and performance.

- Impact on Fit

Inaccurate foot measurements can lead to the selection of skates that are either too small or too large. Undersized skates can cause discomfort, blisters, and restricted circulation, while oversized skates result in poor control, instability, and increased risk of injury. The degree of accuracy directly correlates with the likelihood of achieving a proper, performance-enhancing fit.

- Importance of Standardized Tools

Employing standardized measuring instruments, such as a Brannock device or a calibrated ruler, is critical for obtaining reliable foot dimensions. Using non-standard or improvised measuring methods increases the risk of error, diminishing the value of consulting standardized tables.

- Consistency in Measurement Technique

Adherence to a consistent measurement technique is essential for minimizing variability. This includes ensuring the individual is standing with their full weight distributed evenly on both feet and measuring both feet, as foot sizes can differ slightly. Consistent methodology ensures measurements accurately reflect foot dimensions and enables reliable size comparisons.

- Influence on Performance

Correctly measured foot dimensions, when used in conjunction with standardized skate measurements, directly impact skating performance. Proper fit allows for better energy transfer, improved control, and enhanced agility on the ice. Conversely, inaccurate measurements and subsequent improper fit can hinder performance, compromise technique, and increase fatigue.

The relationship between accurate measurement and the effective use of skate dimensions is undeniable. By prioritizing precision in determining foot dimensions, individuals can significantly improve the likelihood of selecting equipment that enhances comfort, performance, and safety on the ice.

2. Brand Specific Variations

Brand-specific variations represent a critical factor in the application of ice skate dimensions charts. Discrepancies in sizing conventions between manufacturers necessitate that individuals consult the specific chart provided by the brand under consideration. Failure to account for these variations can lead to incorrect equipment selection, resulting in discomfort, reduced performance, and potential injury. For instance, a size 7 in Brand A may correspond to a size 7.5 in Brand B. This difference arises from variations in internal skate construction, last shapes, and measurement methodologies employed by each manufacturer. Ignoring this variable renders a generic dimensions chart largely ineffective.

The significance of brand-specific charts is further amplified by the specialized nature of equipment, categorized by discipline (e.g., hockey, figure skating, recreational skating). Within each discipline, manufacturers may tailor their grading to suit the specific demands of the activity. A hockey skate dimensions chart, for example, might prioritize a snug, performance-oriented fit, whereas a recreational skate might offer a more generous fit for enhanced comfort. Consulting the appropriate chart, specific to both brand and skate type, is therefore crucial for informed decision-making.

In summary, the presence of brand-specific variations underscores the limitations of relying on generalized measurement resources. Correct application necessitates meticulous attention to the manufacturer’s dimensions chart and awareness of the intended use of the equipment. Overlooking this crucial aspect undermines the utility of any standardized measurement system and increases the likelihood of an unsuitable fit.

3. Foot Shape Considerations

Variations in foot morphology significantly impact the selection process when utilizing a dimensional table for ice equipment. Standardized tables primarily address length; however, neglecting foot shape characteristics compromises optimal fit.

- Foot Width

Foot width, measured at the broadest point of the forefoot, is a critical factor. Individuals with wide feet may require models designed with a wider last or selecting a larger size to accommodate the increased girth. Conversely, narrow feet may experience excessive movement within standard-width equipment, necessitating specialized models or fitting adjustments.

- Arch Height

Arch height influences the support and stability provided by the skate. High arches may require specialized insoles or models with increased arch support to prevent excessive pronation or supination. Low arches or flat feet may benefit from flatter footbeds or orthotics to promote proper alignment and reduce discomfort.

- Ankle Prominence

The prominence of the medial or lateral malleoli (ankle bones) can affect equipment fit. Individuals with prominent ankle bones may experience pressure points or discomfort from the boot’s shell. Specialized padding, heat molding, or custom boot modifications may be necessary to alleviate pressure and ensure a comfortable fit.

- Volume and Instep Height

Foot volume and instep height influence the overall fit and closure of the equipment. High-volume feet or individuals with a high instep may struggle to achieve a secure closure with standard lacing systems or buckle configurations. Alternative lacing techniques, power straps, or boot models designed for higher insteps may be required.

Consideration of foot shape is indispensable for proper selection. While standardized dimensional tables provide a baseline, foot shape considerations enable a more individualized and precise approach, maximizing comfort, performance, and minimizing the risk of injury.

4. Sock Thickness Inclusion

The determination of ice equipment dimensions is significantly influenced by sock thickness. A direct correlation exists between the thickness of the sock worn during measurement and the appropriate equipment size. Failure to account for sock thickness can lead to equipment that is either too tight, restricting circulation and causing discomfort, or too loose, resulting in inadequate support and control. For instance, if foot dimensions are measured without socks, and then thick winter socks are used while skating, the equipment will likely be too small, impeding performance and potentially causing injury. Conversely, if measurements are taken with excessively thick socks, the resulting equipment may be too large when thinner performance socks are worn.

The practical application of this understanding is crucial in several scenarios. Skaters who use custom orthotics or specialized insoles, in addition to socks, must consider the combined thickness when determining equipment dimensions. Similarly, individuals who switch between different types of socks depending on weather conditions or skating intensity should adjust equipment dimensions accordingly. Retailers and skate technicians often advise customers to bring the socks they intend to wear while skating when being fitted for new equipment. This ensures that the equipment is properly sized to accommodate the sock’s thickness, optimizing comfort and performance. A specific example involves hockey players, who typically wear thin, moisture-wicking socks to maximize sensitivity and control. If a hockey player were to select equipment based on measurements taken with thick, woolen socks, the resulting fit would be far too loose, compromising their ability to maneuver effectively on the ice.

In summary, “Sock Thickness Inclusion” forms an integral component of accurate equipment sizing. The thickness of the sock worn during the measurement process directly impacts the suitability of the equipment. Overlooking this variable introduces a significant source of error, leading to compromised comfort, performance, and safety. Therefore, consideration of sock thickness is paramount for anyone seeking correctly sized ice equipment, and failing to do so negates the utility of measurement guides.

5. Comfort Level Evaluation

Comfort level evaluation functions as a critical, albeit subjective, component in the application of ice equipment dimensions charts. While dimensions charts provide a quantitative starting point for equipment selection, they cannot fully account for individual anatomical variations, pressure sensitivities, or personal preferences. Consequently, a comprehensive assessment of comfort is essential to refine the fitting process and ensure optimal performance and safety. The dimensions chart offers a size suggestion, but the individual’s perception of how that size feels during simulated skating motions determines the ultimate suitability. This involves assessing for pressure points, heel slippage, and overall stability. For instance, an individual whose foot measurements align with a specific size on the chart may still experience discomfort due to a wider forefoot or a more prominent ankle bone, necessitating an adjustment in size or model.

The importance of comfort level evaluation extends beyond mere subjective preference. Persistent discomfort can lead to alterations in skating technique to compensate, potentially increasing the risk of injury. Furthermore, discomfort can significantly impair performance, reducing agility, responsiveness, and overall endurance. The iterative process of trying on equipment, simulating skating movements, and carefully assessing for pressure points and areas of instability is therefore crucial. This assessment should be performed while wearing the type of socks that will be used during skating, as sock thickness can significantly affect the fit. Retailers and experienced skate technicians often utilize heat molding to customize the fit and alleviate pressure points, further emphasizing the importance of tailoring the fit based on individual comfort assessments. Real-world examples abound where skaters, initially selecting equipment based solely on dimensional recommendations, later experienced discomfort and performance limitations, ultimately requiring a refitting that prioritized their subjective comfort feedback.

In summary, comfort level evaluation serves as an indispensable complement to ice equipment dimensions charts. While charts provide a quantitative foundation, they must be augmented by a thorough assessment of individual comfort and fit. Failing to prioritize comfort can lead to compromised performance, increased risk of injury, and ultimately, a diminished skating experience. The challenge lies in striking a balance between objective measurements and subjective feedback to achieve a fit that is both precise and comfortable, ensuring optimal performance and long-term enjoyment of the sport.

6. Skate Type Relevance

The relevance of skate type constitutes a critical factor in the application and interpretation of dimensions charts. Different skate types (e.g., hockey, figure, recreational) exhibit distinct construction characteristics and intended uses, which directly influence the grading conventions employed by manufacturers. Consequently, a single chart cannot accurately represent sizing across all skate types; instead, specific charts tailored to each discipline are necessary. For example, a hockey skate prioritizes a snug, responsive fit to maximize agility and control, whereas a figure skate demands a more precise fit in the toe box to facilitate intricate footwork. Recreational skates, designed for comfort and general use, often feature a more forgiving fit. Selecting a skate dimensions chart intended for hockey skates while purchasing figure skates would predictably result in an incorrect size selection and a compromised skating experience.

Practical application underscores the imperative of considering skate type. A competitive hockey player, seeking maximum performance, will consult a hockey skate chart and prioritize a snug, performance-oriented fit, potentially opting for a smaller size than indicated by a generic foot measurement. Conversely, a recreational skater, focused on comfort and extended use, would consult a recreational skate chart, likely selecting a slightly larger size to accommodate thicker socks and reduce pressure points. The intended use of the skate directly dictates the appropriate fit, and therefore, the appropriate dimensions chart. Professional skate fitters invariably inquire about the skater’s discipline and skill level to ensure the selection of the correct dimensions chart and to provide tailored sizing recommendations.

In conclusion, the relevance of skate type constitutes a fundamental aspect of accurate equipment sizing. The construction differences and intended uses of various skate types necessitate the use of discipline-specific measurement resources. Failure to account for skate type will inevitably lead to an incorrect size selection and a compromised skating experience. Accurate application of sizing charts demands meticulous attention to the skate type in question. Only by aligning the dimensions chart with the intended use of the equipment can an individual ensure an optimal fit that promotes performance, comfort, and safety.

7. Skill Level Adaptation

The influence of skill level adaptation on appropriate equipment selection necessitates a nuanced understanding of measurement resources. While a dimensions chart provides a foundational reference point, the skater’s proficiency directly informs the desired fit characteristics and, consequently, the optimal size range.

- Beginner Support and Comfort

Novice skaters often benefit from a more forgiving fit that prioritizes comfort and stability. A slightly larger size may accommodate thicker socks for added cushioning and ankle support. The dimensions chart serves as a starting point, but experienced fitters may recommend a slightly larger size to promote confidence and reduce the risk of discomfort during initial learning stages.

- Intermediate Performance Fit

As skill progresses, the skater’s need for responsiveness and control increases. An intermediate skater may opt for a snugger fit, aligning more closely with the dimensions chart recommendations, to enhance energy transfer and improve maneuverability. Support remains crucial, but a balance between comfort and performance becomes paramount.

- Advanced Precision and Control

Advanced skaters demand the highest level of precision and control. The dimensions chart provides a critical baseline, but meticulous attention to detail, including custom modifications and heat molding, becomes essential. A highly customized, performance-oriented fit is often achieved, prioritizing responsiveness and minimizing energy loss, even if it means sacrificing some degree of initial comfort.

- Discipline-Specific Requirements

Skill level adaptation intersects with discipline-specific requirements. A novice figure skater requires different equipment characteristics than a novice hockey player. Advanced skaters in both disciplines, however, demand highly specialized fits tailored to the unique demands of their respective techniques. Dimensions charts must be interpreted within the context of both skill level and the specific discipline being pursued.

In summary, skill level adaptation influences the interpretation and application of measurement resources. While the dimensions chart remains a valuable tool, the skater’s proficiency dictates the desired fit characteristics, ultimately shaping the final size selection. The relationship between skill level, skate type, and dimensions chart application underscores the importance of seeking expert guidance to ensure an optimal fit that promotes safety, comfort, and performance.

Frequently Asked Questions

The subsequent section addresses prevalent inquiries concerning equipment measurement resources and their application in securing a proper fit.

Question 1: Why do sizes vary across different manufacturers?

Equipment manufacturers utilize disparate grading methodologies and internal construction standards. Consequently, a seemingly equivalent dimension may manifest differently across brands. Consulting the specific dimensions resource provided by each manufacturer is critical.

Question 2: How should foot measurements be performed for maximum accuracy?

Measurements should be conducted while bearing weight, ideally using a calibrated Brannock device. If unavailable, a ruler and a vertical surface can be employed. Both feet should be measured, as discrepancies in size are common.

Question 3: How does sock thickness impact size determination?

Sock thickness directly influences the internal volume occupied within the equipment. Foot measurements should be taken while wearing the type of socks intended for use during skating. Significant variations in sock thickness necessitate corresponding adjustments in size selection.

Question 4: Are standardized measurement resources sufficient for all individuals?

Standardized resources provide a foundational reference but cannot account for individual anatomical variations. Foot width, arch height, and ankle prominence require additional consideration. Specialized models or custom modifications may be necessary to achieve an optimal fit.

Question 5: What are the potential consequences of improperly sized equipment?

Improperly sized equipment can lead to discomfort, blisters, impaired performance, and an elevated risk of injury. Equipment that is too small restricts circulation, while equipment that is too large compromises control and stability.

Question 6: Is professional fitting advisable, even with standardized resources?

Professional fitting is highly recommended, particularly for individuals seeking performance-oriented equipment or those with unique foot characteristics. Qualified technicians possess the expertise to assess individual needs and recommend appropriate sizing and modifications.

Accurate measurement, consideration of individual characteristics, and adherence to manufacturer specifications are crucial for maximizing the utility of sizing charts. Professional consultation further enhances the likelihood of securing a proper and comfortable fit.

The following section will explore advanced fitting techniques, including heat molding and custom modifications.

The Importance of Accurate Sizing with Ice Skate Sizes Chart

This exploration has underscored the multi-faceted nature of effectively utilizing resources for equipment selection. Accurate foot measurement, consideration of brand-specific variations, foot shape, sock thickness, skill level and skate type, and comfort level evaluation are all indispensable components of the fitting process. Dimensions resources serve as a valuable starting point, but they must be complemented by careful assessment and, ideally, professional guidance.

Selecting the correct equipment is paramount not only for enhancing performance and comfort but also for ensuring safety and preventing injury. Continued advancements in fitting technology and techniques hold the promise of even more personalized and precise equipment solutions, further emphasizing the importance of staying informed and seeking expert advice.