These specialized pieces of equipment are designed for aggressive inline skating. Characterized by a robust construction and unique frame design, they allow skaters to perform complex tricks and maneuvers on various surfaces such as handrails, ledges, and ramps. The design typically includes features that facilitate grinding, sliding, and jumping, allowing for enhanced performance in skate parks and urban environments.

The importance of this type of skate lies in its durability and its ability to withstand the rigors of aggressive skating. They provide the necessary support and protection for skaters executing demanding tricks. Historically, the evolution of these skates reflects the changing needs and styles of aggressive inline skating, with continual advancements in materials, construction, and design to enhance performance and safety.

The subsequent sections will delve into specific aspects such as the technical specifications, the various models available, and maintenance procedures to ensure optimal performance and longevity. This information will aid individuals in selecting the correct equipment for their skill level and intended use, as well as ensuring their continued functionality.

Performance Enhancement Strategies

The following guidelines offer practical strategies for optimizing performance and extending the lifespan of aggressive inline skates. Implementation of these techniques will improve the skating experience and prevent premature equipment failure.

Tip 1: Consistent Bearing Maintenance: Regularly clean and lubricate the bearings. Accumulation of dirt and debris can significantly reduce speed and performance. Clean the bearings every two to four weeks, depending on the skating environment, using a solvent cleaner and applying a light lubricant afterward.

Tip 2: Frame Inspection and Alignment: Frequently inspect the frame for damage or misalignment. Misalignment can cause uneven wear on the wheels and affect stability. Ensure the frame is properly aligned with the boot and replace any damaged parts promptly.

Tip 3: Wheel Rotation and Replacement: Rotate the wheels regularly to ensure even wear. This prolongs the life of the wheels and maintains consistent grip. Replace wheels as needed to maintain optimal performance, particularly when the wheel profile becomes excessively worn.

Tip 4: Hardware Tightening: Periodically tighten all bolts and screws, especially those securing the frame to the boot. Loose hardware can compromise the structural integrity of the skate and increase the risk of accidents. Use the appropriate tools and torque specifications to avoid over-tightening.

Tip 5: Liner Care and Hygiene: Maintain the liner’s cleanliness to prevent odor and bacterial growth. Regularly remove the liner and allow it to air dry. Consider using antibacterial sprays to maintain hygiene and prolong liner lifespan.

Tip 6: Grind Plate Maintenance: Inspect grind plates for excessive wear and replace them when necessary. Worn grind plates can reduce slideability and increase the risk of catching on surfaces. Ensure replacement plates are compatible with the skate model.

Adhering to these guidelines will significantly improve the skating experience, prolong the lifespan of the equipment, and enhance overall safety during aggressive inline skating.

The subsequent section will address specific considerations regarding selection criteria for specific skate components, including frames, wheels, and bearings, providing comprehensive guidelines for informed purchasing decisions.

1. Durability

Durability is a cornerstone attribute of aggressive inline skates. Given the demanding nature of aggressive skating, encompassing high-impact landings and consistent abrasion against diverse surfaces, the structural integrity of the skate is paramount. Failure to maintain sufficient durability results in premature wear, compromised performance, and increased risk of injury. For example, the stress imposed during grinding maneuvers necessitates robust materials and construction to prevent frame fractures or boot delamination. Absent sufficient durability, skaters face equipment failure during critical moments, negating performance and potentially causing dangerous situations.

The selection of materials directly influences the overall durability. High-density plastics, reinforced composites, and hardened metals contribute to increased resistance to impact and abrasion. Seams and joints are also areas of vulnerability, requiring meticulous construction techniques and robust adhesives to prevent separation. Specific design elements, such as reinforced cuffs and impact-resistant soles, further enhance the skate’s ability to withstand the rigors of aggressive skating. Furthermore, regular maintenance practices, including hardware tightening and component replacement, are crucial in preserving structural integrity and extending the usable lifespan. The skate’s durability, maintained through proper design and upkeep, directly impacts its ability to perform consistently and safely.

In conclusion, durability is not merely a desirable feature but a fundamental requirement for aggressive inline skates. It ensures reliable performance under extreme conditions, reduces the risk of equipment failure and injury, and ultimately enhances the skater’s confidence and ability to progress. Understanding the factors that contribute to durability, along with implementing proactive maintenance strategies, is essential for maximizing the investment in high-performance equipment. Future discussions will address frame design and its importance to the performance of the skate.

2. Frame Design

Frame design is a critical determinant of performance characteristics in aggressive inline skates. The frame serves as the structural foundation connecting the boot, wheels, and grinding surfaces, directly influencing stability, maneuverability, and the skaters ability to execute tricks. A well-designed frame optimizes energy transfer, providing a responsive feel and precise control, while a poorly designed frame can compromise performance, increase fatigue, and elevate the risk of injury. In aggressive skating, where intricate maneuvers and demanding landings are commonplace, the frame’s geometry, material composition, and mounting system significantly impact the skater’s confidence and execution. For example, a frame with a low center of gravity enhances stability during grinds, while a frame with strategically placed grind blocks facilitates smoother transitions across various surfaces.

Real-world examples illustrate the impact of frame design. Some frames incorporate recessed wheel wells to minimize wheel bite during deep carves and grinds. Others employ a symmetrical design, allowing for quick transitions between forward and backward skating. The choice of material, such as aircraft-grade aluminum or reinforced composites, dictates the frame’s stiffness and weight, influencing responsiveness and impact resistance. Moreover, adjustable frame positioning systems offer customization, enabling skaters to fine-tune their setup for optimal balance and control. The development of “anti-rocker” wheel configurations, where smaller inner wheels provide grinding clearance, exemplifies the ongoing innovation in frame design driven by the evolving demands of aggressive skating. The specific type of frame used in skates drastically changes the feel of the skate itself.

In summary, the frame design constitutes a fundamental element in aggressive inline skates, influencing virtually every aspect of performance and safety. A comprehensive understanding of frame geometry, material properties, and mounting systems is essential for skaters seeking to maximize their potential and minimize the risk of injury. This knowledge allows for informed equipment selection and customization, aligning the skate’s performance characteristics with the skater’s specific style and preferences. Future discussions will explore the impact of wheel hardness and its interaction with frame design, offering further insight into optimizing aggressive inline skate performance.

3. Wheel Hardness

Wheel hardness is a significant factor affecting the performance and suitability of aggressive inline skates. Measured on the durometer scale, wheel hardness influences grip, speed, and durability. The selection of an appropriate durometer rating is crucial for optimizing the skate’s performance characteristics and ensuring rider satisfaction.

- Grip and Control

Softer wheels (e.g., 86A-88A) offer enhanced grip, allowing for greater control and maneuverability, particularly on smooth surfaces. This increased grip, however, often comes at the cost of reduced speed and increased wear. The additional friction generated by softer wheels may be advantageous for skaters prioritizing precise control and stability in tight spaces or intricate maneuvers.

- Speed and Roll

Harder wheels (e.g., 90A-92A) provide increased speed and roll, making them suitable for skaters prioritizing momentum and distance. These harder compounds reduce friction, allowing for quicker acceleration and sustained speeds. However, the trade-off is a reduction in grip, potentially compromising control on slick or uneven surfaces. Aggressive skaters seeking to maximize speed and maintain momentum on larger ramps or during long grinds may find harder wheels beneficial.

- Durability and Wear

Wheel hardness directly affects the durability and wear rate. Softer wheels tend to wear down more quickly due to increased friction and deformation under load. Harder wheels, while offering greater resistance to wear, may exhibit a higher propensity for cracking or chipping under extreme conditions. The choice between longevity and performance is therefore a key consideration, influencing the frequency of wheel replacements and the overall cost of ownership.

- Surface Compatibility

Different wheel hardness ratings are better suited for various surfaces. Softer wheels provide superior grip on smooth, polished surfaces, while harder wheels perform optimally on rougher, more abrasive surfaces. Understanding the specific skating environment is essential for selecting wheels that provide the appropriate balance of grip, speed, and durability. Skating in a skate park with smooth concrete may benefit from softer wheels, while navigating rough urban terrain might necessitate the use of harder, more durable compounds.

In essence, wheel hardness dictates a compromise between grip, speed, durability, and surface compatibility. A thorough understanding of these trade-offs is imperative for skaters to select wheels that align with their specific skating style, environmental conditions, and performance objectives. Selecting the incorrect wheel durometer can significantly impact the experience and progression of an aggressive inline skater. This knowledge provides a foundational basis for subsequent optimization of aggressive inline skate setups.

4. Bearing Precision

Bearing precision significantly impacts the performance characteristics of aggressive inline skates. As these skates are subjected to substantial forces and rapid changes in direction, the quality and precision of the bearings directly influence speed, smoothness of roll, and energy efficiency.

- ABEC Rating and Tolerance

The Annular Bearing Engineers’ Committee (ABEC) rating system defines the manufacturing tolerances of bearings. Higher ABEC ratings (e.g., ABEC 5, ABEC 7) indicate tighter tolerances and increased precision, resulting in smoother and faster rotation. In aggressive skating, where instant acceleration and consistent roll are crucial, higher ABEC-rated bearings offer a performance advantage. However, it is essential to note that ABEC ratings primarily address dimensional accuracy and do not fully represent the bearing’s suitability for impact resistance and load-bearing capacity under aggressive skating conditions.

- Material Composition and Hardness

Bearing material influences durability and resistance to deformation under stress. Chrome steel is a common material due to its balance of hardness and corrosion resistance. Ceramic bearings, while offering superior hardness and reduced friction, may be more susceptible to shattering under high impact. The choice of bearing material must consider the demanding nature of aggressive skating, prioritizing materials that can withstand repeated shocks and loads without compromising performance.

- Lubrication and Maintenance

Proper lubrication is critical for maintaining bearing precision and prolonging lifespan. Lubricants reduce friction, dissipate heat, and prevent corrosion. Selecting the appropriate lubricant for aggressive skating requires consideration of viscosity, temperature stability, and resistance to contaminants. Regular cleaning and re-lubrication are necessary to remove dirt, debris, and degraded lubricant, ensuring consistent performance. Neglecting bearing maintenance can lead to increased friction, reduced speed, and premature bearing failure.

- Seals and Shields

Bearing seals and shields protect internal components from contamination. Seals provide a tighter barrier against dirt and moisture but generate more friction than shields. Shields offer less protection but allow for freer rotation. The choice between seals and shields depends on the skating environment and the skater’s preference. In aggressive skating, where exposure to dirt and debris is common, sealed bearings may offer better protection, while skaters prioritizing minimal friction might opt for shielded bearings with more frequent maintenance.

These facets ABEC rating, material composition, lubrication, and seals collectively define the operational characteristics and longevity of bearings in aggressive inline skates. Optimizing these attributes is essential for skaters seeking peak performance and reliability. Careful consideration of these parameters, coupled with diligent maintenance practices, ensures that the bearings function optimally under the demanding conditions inherent to aggressive inline skating.

5. Liner Comfort

Liner comfort is a critical, yet often underestimated, component of aggressive inline skates. Liners directly interface with the skater’s foot, affecting comfort, performance, and overall skating experience. Ill-fitting or poorly designed liners can cause discomfort, blisters, and reduced control, whereas well-designed liners provide enhanced support, shock absorption, and a secure fit. The connection between liner comfort and performance is evident in the ability to skate for extended periods without fatigue or discomfort, facilitating improved trick execution and skill progression. For instance, a liner that adequately cushions impacts reduces stress on the joints, preventing injury and allowing for more aggressive skating. A snug and supportive liner enhances energy transfer, improving responsiveness and control during complex maneuvers.

The significance of liner comfort extends beyond mere physical well-being. The mental aspect of skating is intrinsically linked to comfort. A skater who is constantly distracted by discomfort or pain is less likely to focus on improving their skills or pushing their limits. Comfortable liners enable a skater to remain fully present and engaged, maximizing learning and enjoyment. In the context of aggressive skating, where split-second decisions and precise movements are paramount, any source of distraction can negatively impact performance. Real-world examples illustrate the importance of liner comfort. Skaters often invest in aftermarket liners to replace stock liners that do not meet their specific needs, seeking enhanced padding, improved breathability, or a more customized fit. This practice underscores the recognition that liner comfort is a critical factor in optimizing the overall skating experience.

In summary, liner comfort is an essential element in the overall design and functionality of aggressive inline skates. It affects not only physical comfort but also performance, control, and mental focus. Skaters who prioritize liner comfort are more likely to experience improved performance, reduced risk of injury, and a more enjoyable skating experience. As such, manufacturers and skaters alike should give careful consideration to liner design, materials, and fit to ensure optimal comfort and performance. Further research into innovative liner technologies and customization options holds the potential to further enhance the skating experience for all levels of skaters.

6. Grind Plates

Grind plates are integral components of aggressive inline skates, functioning as the primary interface for sliding and grinding on various surfaces. Their design and material composition directly influence a skater’s ability to execute tricks smoothly and efficiently. In the context of “gawds skates,” these plates are engineered to withstand the considerable abrasion and impact inherent in aggressive skating styles. A well-designed grind plate minimizes friction, facilitating smooth transitions across obstacles, while a poorly designed plate can hinder performance, increase the risk of catching edges, and accelerate wear on both the skate and the grinding surface. For example, a “gawds skate” model might feature a replaceable grind plate made from a high-density polyethylene (HDPE) material, known for its durability and low coefficient of friction. This design allows skaters to replace worn-out plates without needing to replace the entire frame, thereby extending the lifespan of the skate.

The placement and shape of grind plates on “gawds skates” are strategically determined to optimize performance across a range of tricks. Larger plates provide a more stable platform for grinds, while contoured shapes facilitate smoother transitions on uneven surfaces. Furthermore, the mounting system securing the plate to the frame is crucial. A robust and reliable mounting system prevents the plate from shifting or detaching during use, maintaining consistent performance and minimizing the risk of injury. For example, a “gawds skate” frame might utilize countersunk bolts and reinforced mounting points to ensure a secure and flush connection between the grind plate and the frame, even under extreme stress. The integration of the grind plate with the overall skate design reflects a holistic approach to performance and durability. This thoughtful engineering allows skaters to execute complex maneuvers confidently, knowing that their equipment is designed to withstand the demands of aggressive skating.

In summary, grind plates are indispensable components of “gawds skates,” directly influencing performance, durability, and safety. Their design, material composition, and mounting system are carefully considered to optimize the skating experience. Recognizing the importance of these elements allows skaters to make informed decisions when selecting and maintaining their equipment, ensuring that their “gawds skates” perform optimally under the demanding conditions of aggressive inline skating. This focus on detail enhances both the longevity and the functional effectiveness of the skates, supporting the user’s technical skill and creative expression.

Frequently Asked Questions Regarding “gawds skates”

The following section addresses common inquiries concerning the characteristics, maintenance, and selection of “gawds skates”. These responses are intended to provide clear and concise information to assist in informed decision-making.

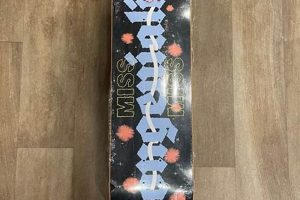

Question 1: What distinguishes “gawds skates” from other aggressive inline skate brands?

“gawds skates” are characterized by a focus on durability and performance, often featuring proprietary frame designs and high-quality materials specifically chosen for aggressive skating. Distinguishing features include robust construction, replaceable components, and designs catered to the specific needs of professional and advanced skaters.

Question 2: How often should “gawds skates” be maintained?

Maintenance frequency depends on the intensity and frequency of use. As a general guideline, bearings should be cleaned and lubricated every 2-4 weeks. Hardware should be checked and tightened before each skating session. Liners should be aired out after each use, and wheels should be rotated regularly to ensure even wear.

Question 3: What wheel hardness is recommended for “gawds skates”?

Wheel hardness recommendations vary based on skating style and surface conditions. Softer wheels (86A-88A) provide increased grip on smooth surfaces, while harder wheels (90A+) offer greater speed and durability on rougher terrain. Experimentation is encouraged to determine the optimal hardness for individual preferences.

Question 4: Can components of “gawds skates” be replaced individually?

Yes, a key feature of “gawds skates” is the ability to replace individual components, such as wheels, bearings, frames, grind plates, and liners. This modular design extends the lifespan of the skate and allows for customization to meet specific needs and preferences.

Question 5: What safety precautions should be observed when using “gawds skates”?

Adherence to safety protocols is paramount. It is imperative to wear appropriate protective gear, including a helmet, knee pads, elbow pads, and wrist guards. Skating should occur in designated areas free from vehicular traffic. A pre-skating inspection of the equipment is also recommended to identify any potential issues.

Question 6: Are “gawds skates” suitable for beginner skaters?

While “gawds skates” are primarily designed for intermediate to advanced skaters due to their performance-oriented features, beginner skaters with a strong commitment to aggressive skating can use them. However, beginners should prioritize proper instruction and protective gear to minimize the risk of injury. Stiffer boots and advanced frame designs can hinder the learning process.

These FAQs provide a foundational understanding of “gawds skates”. As individual needs and preferences vary, further research and consultation with experienced skaters or retailers are recommended for making informed decisions.

The next section will delve into the historical context and evolution of aggressive inline skates, providing a broader perspective on the development of “gawds skates” within the industry.

Concluding Remarks on “gawds skates”

This exploration has provided a comprehensive overview of “gawds skates”, detailing their construction, functionality, and significance within the aggressive inline skating community. From frame design and wheel hardness to bearing precision and liner comfort, each element contributes to the overall performance and durability of the equipment. The importance of regular maintenance, adherence to safety protocols, and informed component selection has been emphasized throughout, highlighting the necessity of responsible equipment stewardship.

As the sport of aggressive inline skating continues to evolve, “gawds skates” remain at the forefront of innovation, pushing the boundaries of performance and enabling skaters to reach new levels of technical skill and creative expression. Continued advancements in materials and design will undoubtedly further refine these skates, reinforcing their position as a benchmark for quality and performance within the industry. The future of aggressive inline skating hinges on a commitment to excellence in both equipment design and skater proficiency.